The photo above shows General Jacob Devers posing with the T6 (Sherman) pilot on "Presentation Day" 3 September 1941. A month earlier Devers had been promoted to Chief of the Armored Force. He was responsible for organizing and training the Army's new Armored Divisions and independent Tank Battalions and was a strong advocate for his men. On 2 December 1941, Devers sent a note to General Gladeon Barnes, Chief of the Research and Engineering Office of the Ordnance Department. "As a result of viewing the performance of medium tanks on all of the recent maneuvers and conversations with officers and men in tank units, I am convinced that our M3 Medium Tank does not have sufficient floatation. This same conclusion will apply to the new M4 Medium Tank. Plans should be made at once to correct this defect in future M3's and all M4 Medium Tanks." Devers was right, of course, but using a word like "defect" did not endear him to the Army bureaucracy as it struggled to mass produce a workable Medium Tank for his Armored Force.

Numerous attempts were made to "reduce ground pressure and improve floatation" of Shermans outfitted with the original Vertical Volute Spring Suspension with its 16 9/16-inch track width. The most practical was the development of extended end connectors which could be retrofitted, without a great deal of labor, to the outside edge of the tracks. EEC production commenced in the Summer of 1944, and 100,000 connectors, enough for 630 tanks, had arrived in the European Theater by early October. By April 1945, over 1.3 million had been supplied to ETOUSA, and the British had received 600,000 as Lend Lease. The "ultimate" solution to the Sherman's floatation problem was the development of the "E8" or Horizontal Volute Spring Suspension. HVSS increased the track width to 23 inches, and entered Sherman production at Chrysler in August 1944, and completely replaced VVSS on the assembly line the following month. HVSS replaced VVSS at Pressed Steel Car and Fisher Body at the beginning of January 1945. The E9 modification was a "too late for WW II” attempt to further increase the floatation of VVSS Shermans by the addition of spacers that extended the suspension away from the hull by 4.5 inches. This permitted extended end connectors to be installed on the inside as well as on the outside of the tracks. Essentially, this increased the track width to 23 11/16 inches, slightly more than the 23-inch track on the "E8." On October 26, 1944, production of 1000 E9 modification kits was authorized for installation "on the last 1000 vehicles...remanufactured by Chrysler at Evansville and International Harvester at Bettendorf." Above shows a rare small hatch M4 Composite on display at a National Guard Post in Trenton, Tennessee. On 3 August 1944, the Ordnance Department directed that Shermans installed with the spaced suspension have "E9" added to their designations. Although we can't say that we have ever seen that in an official document, we will use "E9" in this piece for convenience. In any case, we suspect that this "M4E9" was remanufactured by Chrysler-Evansville in the Spring of 1945. Photo courtesy of Jim Goetz.

The production of the spacers and other components of the E9 assembly took some time, and it is thought that the modification did not become available to the remanufacturers until January, 1945. An additional "1000 sets for field service" were procured, and a Modification Work Order was published on March 3, 1945. The MWO states that the modification would require an enormous 240 man hours to complete. As a consequence, it was considered impractical for field installation, and it would appear that most of the kits were "utilized in further remanufacture of medium tanks," with perhaps a few mods being performed during tank overhauls at Base Shops. E9 was applicable to any "vehicle using medium tank type vertical volute suspension," and, other than Shermans, appears on M36 and M36B2 Tank Destroyers, M32B1 Tank Recovery Vehicles and M7 Howitzer Motor Carriages. Manufacturers charged about $2000 more for HVSS installation, and we assume there would have been an additional charge for E9. However, we have not come across any invoices which might provide a clue about production figures. Companies known to have installed E9 include Chrysler-Evansville, International Harvester, Montreal Locomotive, ALCO, Baldwin Locomotive and Federal Machine and Welder. Above shows a large hatch M4 Composite remanufactured by International Harvester in Bettendorf, Iowa. This tank has another "too late for WW II" modification - the M34 gun mount with "wing piece" retrofitted to the rotor shield.

Above is Serial Number 3714, a Pacific Car and Foundry M4A1 currently displayed in front of the Oorlogsmuseum in Overloon, The Netherlands "as a remembrance of the actions of the American 7th Armored Division in 1944." It was restored by Iwan Van Dijk, Niek Hendrix, Hans van Toer, Piet Peters and Herman Dinnissen, with the aid of a number of local firms. The left side photo shows the tank just before it was recovered from a target range. At that time, it had the E9 suspension modification, which would indicate that it was remanufactured in the US in 1945. The E9 was removed during the restoration to give the tank more of the appearance of a 7th AD Sherman in the Fall of 1944. Nothing is known of its WW II history, but 3714 was most likely sent to The Netherlands as military aid in the early 1950s. Left side photo courtesy of http://www.shermantankoverloon.nl/ and right side photo courtesy of Massimo Foti.

The restorers of 3714 documented the removal of the E9 components, which provides us with the opportunity to examine them in detail. The topmost photos show the "final drive extension" which was attached to the final drive shaft, and spaced the drive sprocket further out from the hull. The "final drive extension" created a "hole" in the hub of the drive sprocket. This gives us a recognition feature that we informally refer to as the "E9 recess." The recess is shown in the bottom left photo, and can be compared to the original "flat" drive sprocket configuration as seen on the bottom right.

The suspension bracket assemblies were removed, and 6 "suspension bracket spacers" were welded to the hull. It was reported that the tank was elevated by 1 inch, because the spacers were “put on 1” lower than normal.” Kurt Laughlin measured one of the spacers on a surviving Sherman and reported, "The E9 spacers, much like the brackets themselves, had a flange on the underside. It was 1-1/2 inches thick...so mounting the suspension bracket on the spacer placed it 4-1/2 inches outboard and 1-1/2 inches lower than its previous position."

The VVSS bogie assemblies were then attached to the the suspension bracket spacers. The E9 kit provided all new bolts, lock washers and locking wire for the procedure.

The "rear idler bracket spacers" were both bolted on and welded to the hull.

Above shows the rear idler assemblies bolted on to the spacers. Note that the spacer is in the original, upward orientation (1) on the side of the hull. The original idler assembly was mounted to the spacer with a more horizontal orientation (2). One additional track shoe was required “owing to the fact that the idler is moved back 2.75 ” [inches].” 330 Extended End Connectors were provided with the Modification kit. We would note that the M4A4 was listed in the MWO as applicable for the E9 mod. This appears to have been an oversight. The vertical orientation of the M4A4's lower rear hull plate would have required rear idler bracket spacers different from the ones provided, or at the least, some special purpose shims. In any case, there are no additional instructions in the MWO regarding the M4A4.

The E9 Modification Kit provided fenders and 36 "fender braces" as shown above. Note that the fender braces illustrated were simple flat affairs, as opposed to the adjustable, tubular turnbuckle braces typically seen on M4A1(76)s with HVSS. However, a number of surviving M4s and M4A1s with E9 have the tubular type (inset). We believe that these units were remanufactured by Chrysler-Evansville and International Harvester.

The

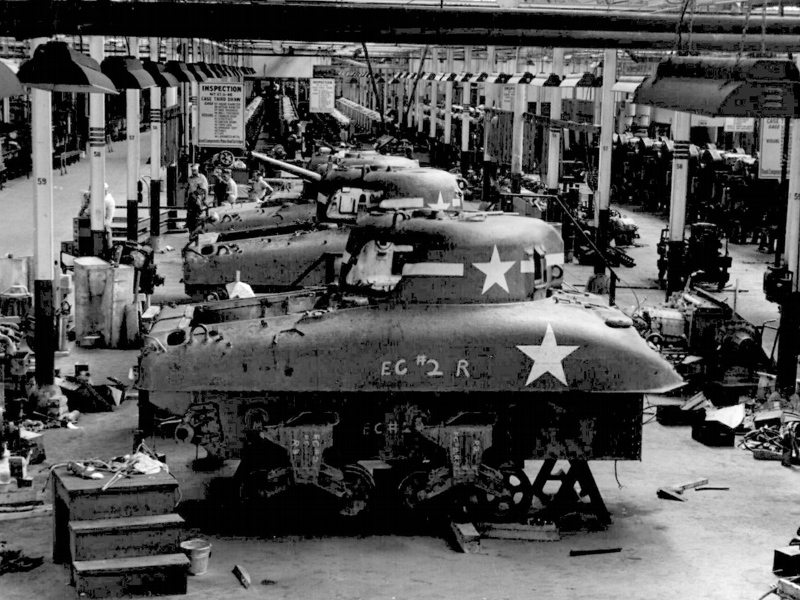

undated photo above shows some M4A1s at Chrysler-Evansville in

Indiana. C-E remanufactured the largest number of Shermans during WW II.

From September 1944 through May 1945, the company completed 446 M4s and

1216 M4A1s. For future reference, we would observe that all of the

Shermans remanufactured during WW II are listed as 75mm in the Summary

Report of Acceptances. Ordnance documents note that tanks were ideally

suited to the process, since, unlike wheeled vehicles, their frames were

rarely bent, and the basic shells could be stripped out, and updated

with new or refurbished components. A fine collection of Chrysler-Evansville photos

held by the University of Southern Indiana leads us to conclude

that the company painted the remanufacturer's serial number on their

tanks with the prefix "EC." Thus, we interpret that the

"EC #2" painted on the upper and lower hull of the M4A1 in the

foreground stands for "Evansville Chrysler, Serial Number 2." This

would have been only the second tank in the program, and another photo

from the USI page, which shows that EC #2 was also painted on the turret,

is dated 7 July 1944. Note that the bogie assemblies have been labeled

with paint, "EC #2 R2" (second bogie on the right side) and "EC #2 R3."

This seems to suggest that C-E made an attempt to keep the original

components in their original positions. The "R1" bogie has either been

removed or was missing, but re-uniting the hull with its original

turret, differential, and suspension strikes us as a formidable task. We

can't help but think that it would have been impossible in many cases

during a remanufacture program due to missing or unsalvageable parts. We

have examined a small number of surviving M4A1E9s that still have

readable Chrysler-Evansville Remanufacture dataplates. Their serial

numbers and date stamps hint that the E9 mod was introduced into the

program starting in January 1945. For the purpose of "counting heads,"

we hope to be able to examine some more survivors in the future.

While 75mm Shermans were no longer "required" by the US Army in 1945, a few remanufactured units were shipped to the European Theater to make up for the losses suffered during the Battle of the Bulge. Only a handful with E9 are seen in period photos, all of which show them in possession of the French Army. Oddly, none are seen with the extended end connectors installed. At the end of the war in Europe, the priority for EECs shifted to the "active theater" - the Pacific. In Europe, the US Army directed that EECs be removed and collected up so that they could be passed on to the PTO. The photo above shows an M4A1 of the 501ème Régiment de Chars de Combat in a village in Germany, around April 27, 1945. Although the EECs are not installed, the noticeable distance between the tracks and the differential housing indicates that this unit is installed with the E9 spacers. Other hints of late remanufacture are the commander’s vision cupola, and the M34 gun mount with "wing piece" retrofitted to the rotor shield. It is thought that some remanufactured Shermans, including a few with E9, were taken from US Army reserve pools, and supplied to the French as replacements shortly before VE-Day, May 8, 1945. In any case, this is one of only two WW II “combat shots” we have encountered. With thanks to Claude Gillono. Photo courtesy of Musée de la libération-Jean Moulin-Ville de Paris.

Flamethrower Shermans had proven to be potent weapons in several of the Island Campaigns against the Japanese. More were wanted for the proposed invasion of Japan scheduled for late 1945. In the Summer of 1945, "Initial issue and maintenance requirements for next six months estimated at 333 flame throwers and 91 service units...the assignment of 10 such tanks to each of 23 tank battalions and 54 flame throwers to the 713 Tank Battalion." The numbers required included reserve formations and took "into consideration 36 serviceable POA model flame throwers on hand in 713th Tank Battalion" [which were left of the original 54 the unit had on Okinawa]. Over 600 M42 series Flamethrowers were ordered, and by the end of October 1945, 151 remanufactured M4A1s had been converted to M42B1 Flamethrowers in the US. The project was terminated due to the Japanese surrender, and the M42B1s along with 49 M42B3s (M4A3 conversions) served post war as training tanks with various flamethrower units in the US. Above shows an M42B1 during a demonstration at Ft. McClellan, Alabama on June 8, 1954. This tank can be seen to be USA 3015884, indicating that it was originally accepted at Pressed Steel Car in December 1942. For the most part, tanks fought "buttoned up" in the fierce campaigns against the Japanese. During the battles of Iwo Jima and Okinawa, the commander's all round vision cupola (1) had shown to be greatly superior to the original split hatch and was wanted for all tanks slated for the invasion of Japan. An item that became available to the remanufacturers at about the same time as the E9 was the armored first aid box (2).

Quite a few M42B1s from the Chemical Warfare School at Ft. McClellan have survived in the US. Above shows a unit with E9 suspension on display at Camp Shelby, Mississippi. Years ago, the Museum curator responded to our inquiry with a letter in which he reported that he found "11382" stamped on an identification plate, which we interpreted to mean the dataplate with the tank's original Ordnance Serial Number. In this case, SN 11382 would signify that this M4A1 had been accepted at Pressed Steel Car in February 1943. He reported that another plate indicated that it had been "reconditioned by Chrysler Ordnance in April 1945" and that "1594" was stamped into that plate. We assumed that must have been the Chrysler-Evansville Remanufacturer's Serial Number, and that these numbers would have run from 1 through 1662. Some time later, we finally got to see one of these plates which was mounted just below the main dataplate. As seen in the inset, it reads: "THIS VEHICLE HAS BEEN RECONDITIONED BY CHRYSLER EVANSVILLE ORDNANCE PLANT EVANSVILLE, IND. E.O.P. SER.NO. 469 (stamped) DATE 11-44 (stamped)." "E.O.P." no doubt stands for "EVANSVILLE ORDNANCE PLANT." This particular M4A1, reconditioned in November 1944, did not have E9. We have recorded the numbers from a few more Chrysler Evansville Recondition plates since then, including one from an M4A1E9 with a date stamp of "1-45" and an E.O.P. SN of "947." Although our sample is admittedly too small for an effective head count, we would speculate that Chrysler Evansville began to install E9 on the M4s and M4A1s it reconditioned starting in January 1945. Photo courtesy of Joe Daneri.

As best we can determine, in 1945, the only new production Sherman based vehicles built with VVSS were 176 M7 Priests and 162 M7B1s. This was intentional according to Ordnance Committee Memorandum 24984, "105MM Howitzer Motor Carriage M7 and M7B1 - Delay in Conversion to Horizontal Volute Spring Suspension and 23" Wide Track" dated 31 August 1944. "Due to the estimated lack of availability of sufficient quantities of the new suspensions and tracks to equip all vehicles at the same time, it is intended to delay this application in the case of the 105mm Howitzer Motor Carriage M7 and M7B1 until the third quarter of 1945." The Priests were excepted due to their relatively light weight. It was noted that with standard 16 9/16-inch VVSS tracks, the M7 series had a ground pressure of 11 pounds per square inch, and this could be reduced to 9 PSI "when duckbill end connectors are used." In any case, all of the M7s were produced by Federal Machine and Welder from March through July 1945. Not much is known about them, but the few period photos available suggest that at least some were made with E9 factory installed. Above are views of the 7th unit, Serial Number 4917, USA 40190389, photographed at the General Motors Proving Ground, May 2, 1945. Note that this M7 features the "flat" fender braces such as provided in the E9 Modification kit. We don't find evidence on any surviving units that would suggest that the 162 M7B1s produced by Pressed Steel Car in January and February 1945 had E9 factory installed. With thanks to Kurt Laughlin for providing a copy of OCM 24984.

Due to their late date of production, it seems unlikely that any of the Federal M7s were shipped overseas, east or west, before the end of WW II. The photo above is dated September 29, 1954 and was taken at the Tokorozawa Ordnance Sub Depot in Japan. The unit on the left can be seen to be USA 40190456, indicating that it was accepted at FMW in June, 1945. Another M7 with the flat fender braces and "E9 recess" in the drive sprocket drum can be seen on the far right. Note that units 1 and 2 have "shallow pulpits" typical of M7s produced from April through December, 1942. The sign just behind 40190456 includes the nomenclature "M7J1." The "J1" indicates that these Priests had been modified by the Tokyo Ordnance Depot to increase the elevation of the gun, as had been requested during the Korean War, due to the mountainous terrain. The armistice ending the Korean War was signed on July 27, 1953, and these Priests may have been provided to the Japanese and/or South Koreans as part of the Military Defense Assistance Program.

During the Korean War, the Army of the Republic of Korea was supplied with some 216 M36 series Tank Destroyers. Above shows a unit of the 51st Tank Company, attached to the ROK Capital Division, and photographed while training on October 23, 1951. This is an M36E9, converted from an M10A1 with Ford V8 engine. Note the open engine deck doors with the debris catching "chutes" on the undersides, typical of M4A3 Shermans. Also visible is "USA 4046826." This is the original Registration Number, indicating that it was accepted as an M10A1 at Ford Motor Company in March, 1943. 200 M36 conversions were completed at Montreal Locomotive Works from May through September, 1945. It is thought that most or all of these would have been the only M36s to have the E9 factory installed. Based on this and a small number of other photos, we would theorize that Montreal Locomotive did not assign new Registration Numbers to their M36 and M36B2 conversions. Instead, the original M10A1 or M10 Reg. Numbers were retained. The E9 Modification Work Order directed that, on Tank Destroyers, the 1/4 inch sloping armor below the sponson line be cut away, and this can be seen to good effect in the photo.

The 90mm gun power of the M36 series was wanted for the planned Invasion of Japan. The Ford V8 was the US Army's preferred tank engine, but when the supply of available M10A1s was exhausted, M10s with GM twin diesel power plants were rounded up for conversion to M36B2. According to Ordnance Committee Memorandum 26685 dated 15 February 1945, "a continuing demand for this type of vehicle in 1945 cannot be met with the M36 and M36B1 due to a shortage of 3" Gun Motor Carriages M10A1 and Medium Tanks M4A3 available for conversion. This shortage can be overcome by the conversion of 3" Gun Motor Carriages M10 to produce the equivalent vehicle." Above shows front and rear views of an M36B2 with E9 from the Technical Manual. Again, not much is known, but all of the 724 M36B2 conversions (52 by Montreal and 672 by ALCO) were done from May through September 1945. It would appear that all of them were equipped with E9 during the conversion. Indeed, OCM 26685 includes "Track width - 23-11/16" including extended end connectors on both inside and outside of track" as part of the military characteristics of the M36B2. Furthermore, in the "Suspension" chapter of the Tech Manual, it is mentioned that the M36B2 is installed with 4.5-inch spacers. Another addition described as standard equipment in both the OCM and the TM is the folding, armored "turret top." Thus, by definition, it seems, an "M36B2" would have included these features. The differences between an M36 and M36B2 are not readily apparent in most photos. The engine deck doors of M36B2s were smaller than the doors of the M36. The armored gas caps were located in different positions as well. With thanks to Kurt Laughlin for providing a copy of OCM 26685.

Hundreds of surplus M36 series TDs were provided to US Allies as Military Assistance in the early 1950s, and some were outfitted with E9. Turkey is reported to have received 36 units up to January 31, 1954. M36s, M36B1s (converted from new M4A3(75)Ws) and M36B2s were sent, but the MDAP documents we have seen only list the figures generically as "Carriage, Motor, 90mm Gun, M36 Series." Above shows a military review in Ankara in 1953. Not enough can be seen to determine if these are M36s or M36B2s. The front and rear units have the Ford type drive sprockets, which may be a hint that they were originally built by Ford as M10A1s, and thus are M36s.

France is reported to have received 80, and Indochina 82 "M36 series" as MDAP. The French deployed the Régiment Blindé Colonial d'Extrême-Orient equipped with Shermans to Indochina in January 1951. A few sources state that by November 1953, the RBCEO had replaced its Shermans with 65 Tank Destroyers which are specifically listed as "TD M36 B2." It is thought that these were part of the 82 "M36 series" that had been allocated to Indochina though MDAP. Field reports note that the M36B2s had cross-country performance that was superior to the Shermans they replaced. We must assume that this was due to the E9 suspension. The reports also note that the TD's 90mm gun would be superior to the Sherman's 75mm if there was "an armored threat from the outside" (meaning we take it in the event that the Chinese chose to provide the Vietminh guerillas with armor support). The photos above show three units of the RBCEO. It is obvious that the TDs on the left are equipped with E9, while the one on the right can be identified as a diesel powered M36B2 by the smaller engine deck doors and the locations of the armored gas caps.

There are over 100 surviving Ford built M4A3s on display in the US. About a dozen of them can be seen with the E9 Modification, although none that we know of still have the extended end connectors installed. The example shown above is on display at the National Museum of WW II in New Orleans. All of the M4A3E9s we have seen have the extended fenders with the "flat" fender braces, such as shown here on Serial Number 12050. Montreal Locomotive was the only company that remanufactured M4A3s in 1945, and we suspect that the last 45 units done in March and April may have received the E9 mod. Most of the surviving M4A3s in the US were remanufactured once during WW II, and again in the early 1950s. However, the 1950s era rebuilds did not include the installation of modifications such as the Quick Fix or E9, for the simple reason that these kits would have long since been used up. In general, the 1950s programs involved the reconditioning of mechanical components so that the tanks were made "Ready for Issue." A 1950s era modification that is present on many surviving Ford M4A3s in the US can be seen here - the torsion bar helper hinges on the engine deck doors (arrow). Photo courtesy of Paul and Lorén Hannah.

After

the M26, the post war US Army wanted the M4A3(76)HVSS for use by its

troops. Some M4A3(76)VVSS Shermans were converted to HVSS by

cannibalization of suspension components from less desirable types such

as the M4A1(76)HVSS and M4A2(76)HVSS. Most likely, this procedure was

not much more labor intensive than the E9 modification. USA 3099991

would have been accepted at Chrysler in April, 1944. Some other early

production M4A3(76)s, such as 3099989 and 3099994 were test

installations of the HVSS suspension system, that were provided to the

Armored Board and the various Proving Grounds. We suspect 3099991 may

have been a testbed for the E9. "Blatz" was photographed at Ft. Irwin

California, date unknown. There are no extended end connectors on the

tracks, so the photo probably dates to the early 1950s. The infantry

phone seen on the right rear was wanted for the invasion of Japan, and

became available in July, 1945.

There are a few other period photos of 76mm Shermans with E9. A surviving example of an M4A1(76)VVSS is on display at Grafenwöhr, Germany. This tank has all the hallmarks of an M4A1(76) remanufactured by Bowen-McLaughlin-York in the early 1950s, and supplied to European Allies as MDAP. However, we would interpolate that the E9 modification and the armored first aid box were retrofitted a few years before that at Rock Island Arsenal or a Base Shop. The Serial Number, 52582, is stamped on the differential housing in a "European font" suggesting perhaps that this unit was supplied to the French. By the SN, the tank would have been accepted at Pressed Steel Car in November 1944.

We have seen WW II era photos of exactly 2 Tank Retrievers with E9 installed. Both were cast hull conversions done by Baldwin. The Aberdeen Proving Ground photo above is dated 22 June 1945, and lists the vehicle as Serial Number 2143, the highest Tank Retriever serial number we have recorded. USA 3060795 is the original tank Registration Number, indicating that this unit was accepted in December 1942 at Pacific Car & Foundry. The other photo was in the September 1945 issue of Baldwin's company produced magazine and was dated July 1945 and captioned something like "The last Tank Recovery Vehicle produced by Baldwin." Unfortunately, we were not permitted to reproduce the photo, but the vehicle looked exactly like "Miss Tex", complete with a late production retriever addition - the "automatic tow hook" (1). Over the years, a certain confusion has attended the issue of 1945 production TRVs. Note that while the vehicle has "M32B1" stenciled on, the APG information panel identifies "Miss Tex" as an "M32A1B1." Baldwin Locomotive is stated to have done 180 M32B1 (converted from M4A1s) and 37 M32A1B1 conversions. According to Ordnance Committee Memorandum 27196 dated 4 April 1945, the designator "A1" was assigned to the retrievers being built with a package of changes/modifications to the earlier M32 series design. These included E9 suspension, raised boom, remote control recovery hook, elimination of 81mm mortar and miscellaneous changes to stowage. TRVs with these features were to be standardized as M32A1, M32A1B1, M32A1B2 and M32A1B3. The use of HVSS was not considered at this time because it was not "available in sufficient quantities to permit application to tank recovery vehicles without jeopardizing the medium tank program." Going by the definition in OCM 27196, only 37 Tank Recovery Vehicles with the designation "A1" were actually produced during WW II - specifically 37 M32A1B1s according to the Summary Report of Acceptances. So, the "A1" inserted in the nomenclature indicates a retriever built with E9 suspension along with the other changes listed in the OCM. This goes against the commonly held notion that the "A1" designator applied to M32 series TRVs installed with HVSS. We would interpolate that "Miss Tex" was the first of the 37 M32A1B1s, and that they would have been assigned Serial Numbers 2143 through 2179. With thanks to Kurt Laughlin for providing a copy of OCM 27196.

Baldwin was contracted to do some more "A1s", but production was terminated due to the end of the war. On 21 August 1945, Ordnance Officers at Baldwin requested direction regarding the disposition of incomplete TRVs "in various stages of "tear down"" including 215 M32A1B1s, 90 M32A1s and 8 M32A1B3s. At present, the final disposition of these is unknown. The options appear to have been: reassemble as unserviceable vehicles and transfer to Stock Control or dispose of (scrap?) in accordance with regulations. In any case, the photo above provides a right-side view of "Miss Tex." The item that stands out in this photo is the "boom raising sheave" (top right). The standard tank retriever had a lifting drum attached to the right drive sprocket (bottom right) to raise and lower the boom. M32 series conversions had been approved only for VVSS Shermans whose track width was 16 9/16 inches. The addition of the E9 modification with extended end connectors on both sides of the track increased the width to 23 11/16 inches. At the time, it was not known if the standard sprocket lifting drum configuration would work with 23-inch tracks, so the drum was replaced with the boom raising sheave on the M32A1 series design. The 81mm mortar previously mounted between the hatches (red arrow) was eliminated, no doubt due to interference issues with the boom raising sheave. OCM 27196 only refers to "miscellaneous changes to stowage" and does not make mention of the inclusion of oxygen (1) and acetylene (2) cylinders very neatly mounted on the vehicle with purpose made fittings.

The photos above show what may have been the only surviving example of an M32A1B1. It was photographed at Keep Them Rolling Association events in The Netherlands in 2009. This retriever can be seen with fittings for the boom raising sheave along with the automatic tow hook. It is thought that The Netherlands received 10 of the Baldwin built M32A1B1s as Military Assistance. This "Miss Tex" can be seen to have a riveted lower hull, indicating that it was originally produced as an M4A1 by Pressed Steel Car, whereas the real "Miss Tex" shown previously was based on an M4A1 made by Pacific Car and had a welded lower hull. Note the oxygen and acetylene cylinders installed with purpose made fittings such as seen on the real "Miss Tex." We were curious to know if this unit still had its dataplate and, if so, did it have the nomenclature "M32A1B1"? However, it was reported that it did not have a dataplate installed, and that the retriever has since been converted to M4A1(75) gun tank. Photos courtesy of Keep Them Rolling Association.

The E9 Modification Work Order featured an additional or "Group II" modification - "Installation of a 37-inch extended grouser on vehicles equipped with spaced suspension and extended end connectors on both sides of the track." The grousers had been tested on the mud courses at both the Tank Arsenal and Aberdeen Proving Grounds in late 1944. In one report, their performance was described as "amazing." As a result, 1000 sets of these grousers were approved for production in February, 1945. Ground pressure was stated to be 7.3 pounds per square inch, better than the 11 psi provided by the T80 HVSS track.The main drawbacks were that the E9 and grouser mods added 12500 pounds to the weight of the tank, and there was a tendency towards thrown tracks. Due to the limited number of photos of Shermans with the 37-inch grousers, we suspect that the order for 1000 may have been cut back or terminated as the end of the war approached. Above shows a remanufactured Sherman with the grousers at APG on July 31, 1945. Note that this tank has been misidentified as an M4A1, when, in fact, it is a small hatch M4 Composite like the one shown at the beginning of this piece.

In closing this piece, we thought readers might like to see a "Suggested Design to Increase Floatation" submitted to Tank Automotive Command on January 1, 1944. As can be seen, the idea was to install a second set of bogies, idlers and tracks (but not drive sprockets) to the Sherman. An officer wrote on the back of this drawing "What the hell are we supposed to do with this?" As it turned out, this concept was used on the T95 105mm Gun Motor Carriage.

HOME