Above

we see the T6 after a mishap at APG on 11 July 1942. At this point the

pepper pot exhausts have been replaced with externally mounted air

cleaners (1) and the "high" exhaust pipes (2) typical of the R-975-C1

engine installation. The pepper pot holes have been blanked off (3).

Note that no door stops were retrofitted when the configuration was

changed.

This

photo shows an early M4A1 under construction at the Lima Locomotive

Works in Ohio. The M3's cast transition piece has been replaced with a

formed quarter round section (1) that joins to the belly plate. The

quarter round is welded to the side plates (2) and these are welded to

a cast top section (3). It would appear that the engine access door

opening was framed out using 3 slightly protruding strips welded to the

sides and the bottom. (4). Note that the idler wheel holder assemblies

were still riveted on some early Lima M4A1s while the bogies were

bolted on from the start.

This view of what we

think was the

16th Lima M4A1 shows that the top cast piece (1) of the lower rear hull

had a raised section in its shape. Note that, unlike

the M3's

cast transition piece where the towing lugs were part of the casting,

the lugs were welded on to the quarter round piece. As can be seen

here, some early Limas were assembled with the M3 style "pepper pot"

exhaust typical of the R-975-EC2 engine installation. An Ordnance

Department document has it that it was “the first 56 tanks

produced.” Field reports from users of the M3 Medium noted

that

the original exhaust system created a dangerous heat buildup on the

engine deck. Lima documents mention that all M4A1s not built with the

standard M4/M4A1 exhaust and external air cleaner configuration would

have it retrofitted. We think that, in fact, except for 4 evaluation

units sent to the British, any Lima M4A1s produced with the original 90

octane R-975-EC2 Radial engines with the internal air cleaners and

pepper pot exhausts had them removed and replaced with the 80 octane

R-975-C1 with the standard M4/M4A1 exhaust and external air cleaner set

up before issue to troops.

This view of what we

think was the

16th Lima M4A1 shows that the top cast piece (1) of the lower rear hull

had a raised section in its shape. Note that, unlike

the M3's

cast transition piece where the towing lugs were part of the casting,

the lugs were welded on to the quarter round piece. As can be seen

here, some early Limas were assembled with the M3 style "pepper pot"

exhaust typical of the R-975-EC2 engine installation. An Ordnance

Department document has it that it was “the first 56 tanks

produced.” Field reports from users of the M3 Medium noted

that

the original exhaust system created a dangerous heat buildup on the

engine deck. Lima documents mention that all M4A1s not built with the

standard M4/M4A1 exhaust and external air cleaner configuration would

have it retrofitted. We think that, in fact, except for 4 evaluation

units sent to the British, any Lima M4A1s produced with the original 90

octane R-975-EC2 Radial engines with the internal air cleaners and

pepper pot exhausts had them removed and replaced with the 80 octane

R-975-C1 with the standard M4/M4A1 exhaust and external air cleaner set

up before issue to troops.

This

photo

shows the lower rear hull of the M4A1 "Michael" the oldest

known

surviving Sherman in the world which is on display at the Tank Museum

at Bovington. Michael was accepted at Lima in March 1942 and

shipped to the British for evaluation shortly thereafter. In

can

be seen that the door hinges used on the M3 Medium have been replaced

by what we would consider the "standard" ones used on M4 and M4A1

Shermans. It is obvious that the hinges are welded on to both the doors

and the rear hull plate. The flange is also welded on to the right

door, and here it is a continuous weld which seems to be typical of

Lima M4A1s, whereas some of the other manufacturers attached the flange

using a series of tack welds. Note the raised section (1) of

the

casting which made up the top of the lower rear hull plate. The pepper

pot exhausts would suggest that "Michael" never had its original

R-975-EC2 engine replaced.

The

M4A1 shown here is on display in Dompaire, France. The inset shows

Lima's diamond logo with the number "1022" stamped below. This has been

observed on the right front of most of the handful of surviving Lima

built M4A1s. From that small counting heads sample, we believe that

"1022" is a build sequence number with 1000 added to it. Thus, it is

our theory that the hull was the 22nd M4A1 produced by LLW and would

have been accepted in April 1942. We stipulated "the hull" because the

turret and bogie units are retrofitted parts made in 1943. It is almost

certain that this M4A1 was built with the R-975-EC2 engine and the

pepper pot exhausts. The tank has obviously been rebuilt, and

Pierre-Olivier photographed a French rebuild plate on the inside that

was too indistinct to read. It is likely that it has had more than one

engine change during its service life. The air cleaners are missing

their bottom sections which affords us a view of the method used on

this example to blank off the pepper pot holes (1). We suspect that

this tank was not originally built with door stops so those seen here

(2) would have been retrofits. Also retrofitted are the fittings (3)

for the Barber-Colman exhaust deflector, a modification that was

introduced on the M4/M4A1 series at the end of 1943. Earlier we

mentioned that the idler wheel holder assemblies were "still" secured

by rivets on some of Lima's first Shermans. The rivets can be seen on

the assembly on the right. The one on the left has had the rivets

replaced with bolts, the standard configuration for VVSS equipped

Shermans.

After the fall of Tobruk

on 21 June 1942, President Roosevelt ordered an "Emergency Shipment" of

pretty much all of the available Shermans to the British in North

Africa. The convoy sailed on July 15, 1942 with 302 Shermans and 100

Priests. The Shermans break down to 212 M4A1s and 90 M4A2s. Few if any

Pacific Car M4A1s would have been available by mid July, 1942, so the

200 odd M4A1s the British received would have been a mix of Limas and

Pressed Steel Cars. It is thought that most of the Alamein M4A1s would

have had plates covering the holes of the original "pepperpot" exhaust.

The example shown above was featured in a Military Intelligence Report

sent to the US in December, 1942 showing "battle damage encurred (sic)

by American tanks during the recent Alamein Offensive." Photographed at

the "Rahman Collecting Point" this M4A1 can be seen to have an

octagonal blank off plate bolted on (1). The tank has several features

typical of Lima Locomotive. Note the rounded transition piece (2) and

the Lima type tail light guards (3). Lima appears to have been the only

builder to mount the engine access door bumpers on the doors themselves

(4). The right side air scoop (5) can be seen to be one of the

fabricated types. In this case, it appears to be quarter round shaped.

After the fall of Tobruk

on 21 June 1942, President Roosevelt ordered an "Emergency Shipment" of

pretty much all of the available Shermans to the British in North

Africa. The convoy sailed on July 15, 1942 with 302 Shermans and 100

Priests. The Shermans break down to 212 M4A1s and 90 M4A2s. Few if any

Pacific Car M4A1s would have been available by mid July, 1942, so the

200 odd M4A1s the British received would have been a mix of Limas and

Pressed Steel Cars. It is thought that most of the Alamein M4A1s would

have had plates covering the holes of the original "pepperpot" exhaust.

The example shown above was featured in a Military Intelligence Report

sent to the US in December, 1942 showing "battle damage encurred (sic)

by American tanks during the recent Alamein Offensive." Photographed at

the "Rahman Collecting Point" this M4A1 can be seen to have an

octagonal blank off plate bolted on (1). The tank has several features

typical of Lima Locomotive. Note the rounded transition piece (2) and

the Lima type tail light guards (3). Lima appears to have been the only

builder to mount the engine access door bumpers on the doors themselves

(4). The right side air scoop (5) can be seen to be one of the

fabricated types. In this case, it appears to be quarter round shaped.

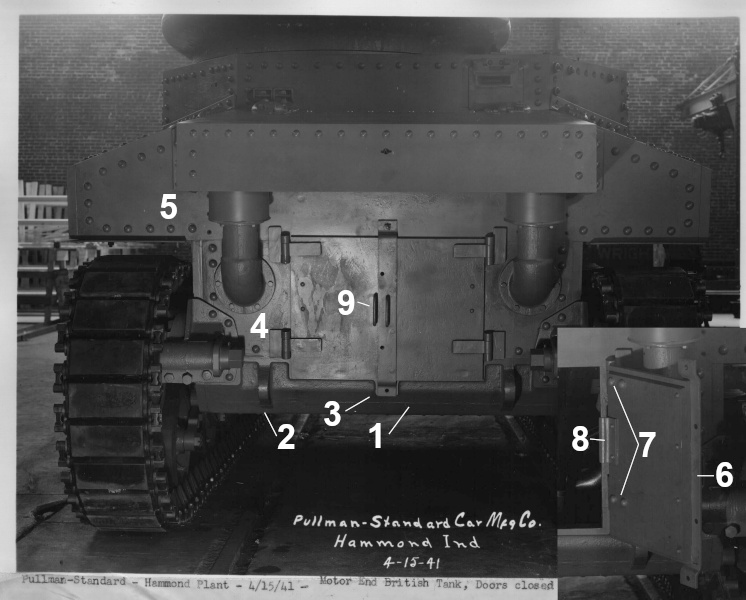

M4A1 SN 7320/USA 3058832

was on display for many years at the Ordnance Museum at Aberdeen

Proving Ground. The unit represented an example of a Sherman tank

installed with the Multiple Rocket Launcher T34, nicknamed "Calliope."

The tank itself would have been accepted at Lima Locomotive in January

1943. It has what we think of as the standard LLW lower rear hull and

engine access door configuration. The 80 octane R-975-C1 radial engine

with external air cleaners (1) and centrally mounted, "high" exhaust

pipes (2) was the standard engine of the M4/M4A1 Sherman. The air

cleaners could have been damaged by the heavy engine access doors, so

door stops were installed to protect them. The evidence suggests that

Lima was the only manufacturer that welded the door stops (3) to the

doors themselves as seen here. The other M4/M4A1 producers affixed the

stops to the lower rear hull plate on either side of the doors. Some

very early production Shermans had the idler wheel holder assemblies

riveted on, but it is obvious that the standard method of attachment

was with bolts as seen here.

M4A1 SN 7320/USA 3058832

was on display for many years at the Ordnance Museum at Aberdeen

Proving Ground. The unit represented an example of a Sherman tank

installed with the Multiple Rocket Launcher T34, nicknamed "Calliope."

The tank itself would have been accepted at Lima Locomotive in January

1943. It has what we think of as the standard LLW lower rear hull and

engine access door configuration. The 80 octane R-975-C1 radial engine

with external air cleaners (1) and centrally mounted, "high" exhaust

pipes (2) was the standard engine of the M4/M4A1 Sherman. The air

cleaners could have been damaged by the heavy engine access doors, so

door stops were installed to protect them. The evidence suggests that

Lima was the only manufacturer that welded the door stops (3) to the

doors themselves as seen here. The other M4/M4A1 producers affixed the

stops to the lower rear hull plate on either side of the doors. Some

very early production Shermans had the idler wheel holder assemblies

riveted on, but it is obvious that the standard method of attachment

was with bolts as seen here.

Lima Locomotive Works and Pacific Car & Foundry assembled all

of their lower hulls by welding as directed by the Ordnance Department.

The photos above show the PCF pilot model, Serial Number 3005, USA

3060572, the first and only unit accepted in May 1942. It arrived at

Aberdeen Proving Ground in early June. It is thought that about the

first 50 units were made with direct vision and the M3 type suspension.

Unlike Lima and Pressed Steel Car, PCF did not produce any M4A1s with

the pepper pot exhaust. Note, however, that the lower rear hull plate

of 3005 was built for the early exhaust, but the holes (1) were blanked

off. PCF lower hulls are pretty much identical to those used by Lima

with the "quarter round" transition piece (2) and welded on towing

lugs. Note that the idler wheel holder assemblies are riveted on this

example. SN 3005 appears to have been built without the door stops, and

there is some small evidence that this may have been the case with

other PCF M4A1s, possibly up to as late as early 1943.

Here we have one of the

few available rear view period photos of a PCF M4A1. This tank was

photographed in early 1943 on the PCF test track in Renton, Washington.

Note that no door stop is evident. The square type of Vortox Air

Cleaner (1) is most commonly seen on PCF built Shermans.

Here we have one of the

few available rear view period photos of a PCF M4A1. This tank was

photographed in early 1943 on the PCF test track in Renton, Washington.

Note that no door stop is evident. The square type of Vortox Air

Cleaner (1) is most commonly seen on PCF built Shermans.

The M4A1 above is

identified as SN 3658/USA 3061255, indicating PCF June 1943 production.

This unit can be seen to be installed with a fairly thick, possibly 1

inch, door stop (1). The method by which the flange was welded to the

right door is not entirely clear in this photo. We would point out that

the appearance of the taillight guard (2) shown here is typical of PCF

M4A1s. The first type of trailer towing pintle, described as

the "long" pintle (3), is stated to have been factory installed at PCF

starting on 30 April 1943 with SN 3555.

The M4A1 above is

identified as SN 3658/USA 3061255, indicating PCF June 1943 production.

This unit can be seen to be installed with a fairly thick, possibly 1

inch, door stop (1). The method by which the flange was welded to the

right door is not entirely clear in this photo. We would point out that

the appearance of the taillight guard (2) shown here is typical of PCF

M4A1s. The first type of trailer towing pintle, described as

the "long" pintle (3), is stated to have been factory installed at PCF

starting on 30 April 1943 with SN 3555.

The

photo above is of a surviving PCF M4A1in a private collection.

Unfortunately, the Serial Number could not be found. This tank was

obviously rebuilt, but it has features which suggest that it was

produced before February 1943. We examined it closely and there is no

weld scar evidence that door stops were ever installed. We were

somewhat surprised by this, thinking that, for the sake of protecting

the air cleaners, they would have been mandated during a rebuild. What

is evident is that the flange was tack welded (1) to the right door.

The Barber-Colman exhaust deflector would have been added during a

rebuild and the fittings (2) that held it are seen welded to the doors.

When the trailer towing pintle was introduced, the bottom part of the

door flange (3) was cut off to avoid interference issues. The inset

provides a side view of the "quarter round" transition piece

configuration typical of PCF and Lima M4A1s.

We are limited by the

lack of photos and surviving examples, but it would appear that some of

the first M4A1s built by Pressed Steel Car used M3 Medium type engine

access door hinges. On the left we have a close up of their first M4A1,

Serial Number 5 on the factory floor in February 1942. One of the

hinges is just visible (circled). On the right is Serial Number 7, USA

3014763 photographed at the General Motors Proving Ground on December

31, 1942. Both of these tanks would have been accepted during PSC's

first month of Sherman production, March 1942. On SN 7, again we have a

case where the original pepper pot exhaust was replaced with what

became the standard M4/M4A1 exhaust and air cleaner configuration.

Triangular shaped door stops (circled) were retrofitted in order to

protect the air cleaners from being damaged by the heavy doors swinging

open. On this example, the flange appears to be riveted to the right

door in the manner of the M3 Medium. We suspect that the door hinges

were affixed with slotted screws as on the M3, but it is not possible

to tell for certain. An anomaly seen exclusively on PSC M4s and M4A1s

is the riveted lower hull. The military characteristics of the M4

series only authorized "fabrication by welding" of the lower hull. Our

"head count" suggests that Pressed Steel Car began production with, and

continued to use riveted lower hulls until around May 1943. We have

found no explanation for this exception, but it may be that PSC was

tasked with using up the remaining supply of M3 Medium riveted lower

hulls once production was terminated.

We are limited by the

lack of photos and surviving examples, but it would appear that some of

the first M4A1s built by Pressed Steel Car used M3 Medium type engine

access door hinges. On the left we have a close up of their first M4A1,

Serial Number 5 on the factory floor in February 1942. One of the

hinges is just visible (circled). On the right is Serial Number 7, USA

3014763 photographed at the General Motors Proving Ground on December

31, 1942. Both of these tanks would have been accepted during PSC's

first month of Sherman production, March 1942. On SN 7, again we have a

case where the original pepper pot exhaust was replaced with what

became the standard M4/M4A1 exhaust and air cleaner configuration.

Triangular shaped door stops (circled) were retrofitted in order to

protect the air cleaners from being damaged by the heavy doors swinging

open. On this example, the flange appears to be riveted to the right

door in the manner of the M3 Medium. We suspect that the door hinges

were affixed with slotted screws as on the M3, but it is not possible

to tell for certain. An anomaly seen exclusively on PSC M4s and M4A1s

is the riveted lower hull. The military characteristics of the M4

series only authorized "fabrication by welding" of the lower hull. Our

"head count" suggests that Pressed Steel Car began production with, and

continued to use riveted lower hulls until around May 1943. We have

found no explanation for this exception, but it may be that PSC was

tasked with using up the remaining supply of M3 Medium riveted lower

hulls once production was terminated.

The Canadians received 4

M4A1s as direct Lend Lease. The first, Serial Number 192, was shipped

to Canada in December 1942. With the exception of the 188 M4A1

Grizzlies built by Montreal Locomotive, all of the other Shermans used

by Canada were allocated from British Lend Lease stocks. The photo

above shows SN 192 in mid 1943, when it was used as a stowage model for

the Grizzly. SN 192 would have been accepted in July 1942. On PSC M4s

and M4A1s with riveted lower hulls, rivets are present not only on the

side plates, but on the lower rear hull. Note how the idler wheel

holder assemblies are secured with rivets (circled). Right up until the

transition to the use of welded lower hulls around May 1943, PSC M4s

and M4A1s are noted to have had their idler wheel assemblies riveted,

not bolted on as was the case with the other Sherman producers. The

engine access doors seen here have what we would characterize as the

"standard" M4/M4A1 hinges (1), but not quite, since the standard hinge

had a small square plate that was welded to the rear hull's armor. In

this case, the middle section of the hinge barrel was welded directly

to the armor, possibly because of the rivet (2) next to where the hinge

plate would have been installed. As with most M4s and M4A1s, the door

stops (3) are welded on next to, not on, the doors. The stops appear to

have been about 1 inch thick up to around the end of 1942. In the

postwar years, the Canadians sold most of their remaining Grizzlies to

the Portuguese, and Serial Number 192, retrofitted with M4 type bogies

and Canadian Dry Pin tracks, was thrown in as well. When the Portuguese

disposed of these WW II relics in the late 1970's, they were bought up

by collectors.

The Canadians received 4

M4A1s as direct Lend Lease. The first, Serial Number 192, was shipped

to Canada in December 1942. With the exception of the 188 M4A1

Grizzlies built by Montreal Locomotive, all of the other Shermans used

by Canada were allocated from British Lend Lease stocks. The photo

above shows SN 192 in mid 1943, when it was used as a stowage model for

the Grizzly. SN 192 would have been accepted in July 1942. On PSC M4s

and M4A1s with riveted lower hulls, rivets are present not only on the

side plates, but on the lower rear hull. Note how the idler wheel

holder assemblies are secured with rivets (circled). Right up until the

transition to the use of welded lower hulls around May 1943, PSC M4s

and M4A1s are noted to have had their idler wheel assemblies riveted,

not bolted on as was the case with the other Sherman producers. The

engine access doors seen here have what we would characterize as the

"standard" M4/M4A1 hinges (1), but not quite, since the standard hinge

had a small square plate that was welded to the rear hull's armor. In

this case, the middle section of the hinge barrel was welded directly

to the armor, possibly because of the rivet (2) next to where the hinge

plate would have been installed. As with most M4s and M4A1s, the door

stops (3) are welded on next to, not on, the doors. The stops appear to

have been about 1 inch thick up to around the end of 1942. In the

postwar years, the Canadians sold most of their remaining Grizzlies to

the Portuguese, and Serial Number 192, retrofitted with M4 type bogies

and Canadian Dry Pin tracks, was thrown in as well. When the Portuguese

disposed of these WW II relics in the late 1970's, they were bought up

by collectors.

We

have a rare opportunity to compare a period photo with the real thing,

since SN 192 has survived and is a popular attraction at the annual

show put on by the Americans in Wartime Museum in Virginia. In the view

above, one of the "offending" rivets (1) is shown. Note how the middle

section of the hinge barrel is welded directly to the lower rear hull

plate (arrow). Also evident is that the flange is riveted (2) to the

right-side door in the manner of the M3 Medium.

A rear-view showing SN

415, USA 3015171 a PSC M4A1 accepted in August 1942. This tank was

rebuilt by Chrysler-Evansville in the Spring of 1945 at which point it

received many upgrades including the E9 suspension (1). E9 increased

the original 16 9/16 track width to 23 11/16 inches by the addition of

extended end connectors on both the inside and outside of the tracks.

Shortly thereafter, SN 415 was converted to M42B1 flamethrower in

anticipation of the planned invasion of Japan. Despite all of the added

"bells and whistles," what we might consider to be the "second"

configuration of the engine access doors, such as on SN 192, is

evident. Again, the flange can be seen to have been riveted to the

right-side door. The bottom section of the flange was removed so as not

to interfere with the trailer towing pintle fitting (2) that was most

likely retrofitted during remanufacture. In the realm of 'counting

heads," we can observe that SN 415 is the first instance we have

recorded of a PSC M4A1 where the upper hull casting features the

elongated drivers' hoods that replaced the direct vision hoods of the

original design.

A rear-view showing SN

415, USA 3015171 a PSC M4A1 accepted in August 1942. This tank was

rebuilt by Chrysler-Evansville in the Spring of 1945 at which point it

received many upgrades including the E9 suspension (1). E9 increased

the original 16 9/16 track width to 23 11/16 inches by the addition of

extended end connectors on both the inside and outside of the tracks.

Shortly thereafter, SN 415 was converted to M42B1 flamethrower in

anticipation of the planned invasion of Japan. Despite all of the added

"bells and whistles," what we might consider to be the "second"

configuration of the engine access doors, such as on SN 192, is

evident. Again, the flange can be seen to have been riveted to the

right-side door. The bottom section of the flange was removed so as not

to interfere with the trailer towing pintle fitting (2) that was most

likely retrofitted during remanufacture. In the realm of 'counting

heads," we can observe that SN 415 is the first instance we have

recorded of a PSC M4A1 where the upper hull casting features the

elongated drivers' hoods that replaced the direct vision hoods of the

original design.

Pressed Steel Car began to produce M4 Shermans alongside M4A1s starting

in July 1942 and the example shown above is on display at the USS

Alabama Battleship Memorial Park in Mobile. Unfortunately, we haven't

been able to discover the serial number of this one. Like the M4A1 of

the previous caption, it shows evidence of having been remanufactured,

and we would note that the remanufacturing firms often stamped the

serial number behind where the dataplate was mounted, so we hold out a

hope that the tank's SN may become known at some point. Based on a

period photo of M4 USA 3015102 which we think may be our subject, and

some clues seen on the vehicle itself, our best guess is that it was

accepted in August 1942. The few surviving examples of PSC built M4s

show that the top section differed from the casting used on their M4A1s.

As seen here, the top piece consisted of an armored plate (1), with an

additional 1/2 inch (?) plate (2) welded on above the door opening. Note

that the door hinges are in the "second" configuration where the middle

section of the hinge barrel was welded directly to the rear hull plate.

This M4 was reportedly "rescued" from a target range at nearby Eglin

Air Force Base, where it sustained quite a bit of damage. The door

flange appears to have been shot off, but there are traces of the rivets

(circled) that once held it.

Here we have a rear view of Serial Number 453 in storage at Ft. Moore,

(formerly Ft. Benning) Georgia. At the time this photo was taken, the

USA Registration Number, 3015209, was still faintly visible, painted on

in the original PSC "railroad" font. This M4A1 would have been accepted

in August 1942, about 38 units after SN 415 shown in a previous caption.

Like SN 415 and the M4 in Mobile it has a number of modifications

typical of the late 1944/early 1945 US remanufacture program. On this

example, the hinges of the engine access doors have transitioned to what

we might characterize as the "third" configuration. Note the small

square hinge plates (1) welded to the armor. The bottom plates can be

seen to be riveted on as well. It would appear that the "interfering"

rivets were removed and replaced with longer rivets driven through the

bottom hinge plates (inset). The flange is "still" riveted on to the

right door. Counting heads suggests that the "third" configuration was

used by Pressed Steel Car up until riveted lower hulls were completely

replaced with welded lower hulls around May 1943.

Here we have a rear view of Serial Number 453 in storage at Ft. Moore,

(formerly Ft. Benning) Georgia. At the time this photo was taken, the

USA Registration Number, 3015209, was still faintly visible, painted on

in the original PSC "railroad" font. This M4A1 would have been accepted

in August 1942, about 38 units after SN 415 shown in a previous caption.

Like SN 415 and the M4 in Mobile it has a number of modifications

typical of the late 1944/early 1945 US remanufacture program. On this

example, the hinges of the engine access doors have transitioned to what

we might characterize as the "third" configuration. Note the small

square hinge plates (1) welded to the armor. The bottom plates can be

seen to be riveted on as well. It would appear that the "interfering"

rivets were removed and replaced with longer rivets driven through the

bottom hinge plates (inset). The flange is "still" riveted on to the

right door. Counting heads suggests that the "third" configuration was

used by Pressed Steel Car up until riveted lower hulls were completely

replaced with welded lower hulls around May 1943.

Above shows a PSC M4 (SN unknown) with hinges in the "third"

configuration (bottom hinges riveted). Again, we see that the top plate

(1) was riveted to the side plates, with an additional plate (2) welded

on above the door opening. It is thought that the raised plate framed

the top of the door opening and served as an attachment point for the

upper flange bolt. The inset taken from inside the engine bay, shows the

method used to rivet the top plate to the side plate. Note that there

was some welding used as well on this example.

Above shows a PSC M4 (SN unknown) with hinges in the "third"

configuration (bottom hinges riveted). Again, we see that the top plate

(1) was riveted to the side plates, with an additional plate (2) welded

on above the door opening. It is thought that the raised plate framed

the top of the door opening and served as an attachment point for the

upper flange bolt. The inset taken from inside the engine bay, shows the

method used to rivet the top plate to the side plate. Note that there

was some welding used as well on this example.

M4A1 USA 3015334 (September 1942) was photographed in January 1943 when

it was used by the Barber-Colman Company to demonstrate its "Air Flow

Corrective Devices." The Barber-Colman system was adopted for use on PSC

M4A1s starting on December 1, 1943, and Chrysler M4s starting on

January 1, 1944. Generally speaking, however, it was a Second Generation

modification mandated for use on M4(105) and M4A1(76) Shermans. It

featured "Pyramid Turning Vanes" on the engine air intake and a "Hinged

Air Exit Vane" (1) in place of the original exhaust deflector. Since the

fittings (2) that held the deflector are seen retrofitted on many

surviving M4s and M4A1s, we thought we might show their purpose. This

unit can be seen with the hinges in the "third" configuration.

Here we have the running M4A1 on display at the Planes of Fame Air

Museum in Chino California. As best we have been able to determine,

Pressed Steel Car did not stamp the Serial Number anywhere on the

exterior of its Shermans. This makes studying them more difficult

than those built by most of the other companies. As with the Mobile M4,

the serial number has not been found on the Chino. However, it is our

theory that PSC M4A1s have a loose build sequence number stamped into

the armor on one or the other sides in the rear. This example has been

recorded as "786." We characterize the number as "loose" but for what it

is worth, the 786th M4A1 produced by PSC would have been accepted in

January 1943. In any case, using this tank as an example, we would

observe as a matter of Sherman minutia, that, at some point in late

1942/early 1943, the thickness of the door stops appears to have been

reduced by more than half (circled). "Eyeballing" it we would guess that

the door stops were downsized to maybe 3/8 of an inch from then on.

Photos courtesy of Chris Hughes

Here we have the running M4A1 on display at the Planes of Fame Air

Museum in Chino California. As best we have been able to determine,

Pressed Steel Car did not stamp the Serial Number anywhere on the

exterior of its Shermans. This makes studying them more difficult

than those built by most of the other companies. As with the Mobile M4,

the serial number has not been found on the Chino. However, it is our

theory that PSC M4A1s have a loose build sequence number stamped into

the armor on one or the other sides in the rear. This example has been

recorded as "786." We characterize the number as "loose" but for what it

is worth, the 786th M4A1 produced by PSC would have been accepted in

January 1943. In any case, using this tank as an example, we would

observe as a matter of Sherman minutia, that, at some point in late

1942/early 1943, the thickness of the door stops appears to have been

reduced by more than half (circled). "Eyeballing" it we would guess that

the door stops were downsized to maybe 3/8 of an inch from then on.

Photos courtesy of Chris Hughes

There aren't many period photos that clearly show the Sherman's

lower rear hull and the doors and such. Most are in heavy shadow. The

example above was used in "Service Test of Medium Tank, M4A1, with 76mm

Gun" dated June 1943. This was an experimental installation of a 76mm

gun in a "small" turret casting made with a slightly larger bustle.

Known as the M4A1(76M1), only 12 units were produced before the project

was terminated in May 1943. In any case, the report from the Desert

Warfare Board at Camp Young, California included a few photos and listed

the tank's Registration Number as USA 3016680, indicating that it would

have been accepted at PSC in March 1943 and would have been Serial

Number 13679. This unit can be seen in the "third" configuration with

rivets through the lower hinge plates. We are somewhat surprised that

the idler wheel holder assemblies were still secured with rivets at this

late date. It seems like that would have made it harder to remove and

replace them in the event they were damaged. The bogie assemblies were

bolted on, so why not the idlers? Note the "thin" door stops. Some new

items can be seen on this tank, such as the "Original Design" exhaust

deflector (1) reported to have been introduced at PSC on 10 March 1943

at Serial Number 13610. The deflector was notched to accommodate the

exhaust pipe (2) for the auxiliary generator. The "long" trailer towing

pintle was reportedly introduced at PSC on 29 April 1943 at Serial

Number 28205, so its appearance on SN 13679 seems a little early. It may

have been intended to be standard equipment on the M4A1(76M1)s. The

bottom section of the door flange can be seen to have been cut off so as

not to interfere with the pintle. In some instances, the long pintle

got bent up in service, which created an interference issue with the

engine access doors. A shorter pintle was designed and became available

by the end of 1943. It was used on "Second Generation" and

remanufactured Shermans.

The M4A1 shown above is

on display in Square Patton in Ettelbruck, Luxembourg. We have chosen

this tank to represent the rear access door configuration after PSC

joined the rest of the builders in producing Shermans with welded lower

hulls. AFVs in service with the post war French Army are often seen with a "serial

number in a box" stamping on the glacis (inset). This has been a great

help to our research, particularly in cases where the manufacturer (PSC,

Pullman and Federal Machine & Welder) did not stamp the serial

number anywhere on the exterior of their tanks. Serial Number 29178

would have been accepted at PSC in July 1943. It can be

seen that the flange was no longer riveted but was attached to the

right-side doors by a series of welds (1). As mentioned previously, the

towing pintle (2) was reportedly introduced at PSC on 29 April 1943, at

Serial Number 28205. Again, it is evident that the bottom section of the

door flange was cut off so as not to interfere with the pintle. The

offset attachment point at the top (3) remained the same, but a new bolt

hole (4) was added at the bottom of the flange to secure the door. Note

that the idler wheel holder assemblies are now affixed with bolts (5).

The missing air cleaners permit us to see that the top casting (6) is

attached to the middle plates (7) by welding (8).

The M4A1 shown above is

on display in Square Patton in Ettelbruck, Luxembourg. We have chosen

this tank to represent the rear access door configuration after PSC

joined the rest of the builders in producing Shermans with welded lower

hulls. AFVs in service with the post war French Army are often seen with a "serial

number in a box" stamping on the glacis (inset). This has been a great

help to our research, particularly in cases where the manufacturer (PSC,

Pullman and Federal Machine & Welder) did not stamp the serial

number anywhere on the exterior of their tanks. Serial Number 29178

would have been accepted at PSC in July 1943. It can be

seen that the flange was no longer riveted but was attached to the

right-side doors by a series of welds (1). As mentioned previously, the

towing pintle (2) was reportedly introduced at PSC on 29 April 1943, at

Serial Number 28205. Again, it is evident that the bottom section of the

door flange was cut off so as not to interfere with the pintle. The

offset attachment point at the top (3) remained the same, but a new bolt

hole (4) was added at the bottom of the flange to secure the door. Note

that the idler wheel holder assemblies are now affixed with bolts (5).

The missing air cleaners permit us to see that the top casting (6) is

attached to the middle plates (7) by welding (8).

Pressed Steel Car produced a total of 1000 M4s from July 1942 through

August 1943. Surviving examples are very rare; we know of 8 at present.

Pierre-Olivier once photographed a PSC M4 on a target range in Oberhoffen, France.

This tank strikes us as being in WW II configuration, so may possibly be

a combat veteran Sherman. Part of the painted-on Registration Number

was still visible on the left rear side as USA 30366XX. This is enough

information to determine that it would have been accepted in April 1943.

It has a welded lower hull, and we would judge that it was one of the

first PSC Shermans built as such. It can be seen that the lower rear

hull sections were welded together at the points indicated by

arrows. The top plate can "still" be seen with some rivets (circled)

perhaps hinting at the transitional nature of the introduction of

changes. That is to say that this piece may have been intended for a

riveted lower hull but was adapted for a welded. Note how the idler

wheel holder assemblies are now affixed with bolts. We would observe in

passing that on this example, there is an additional piece of armor

laminated to the upper rear hull plate (1), suggesting that the

underlying plate may not have been 1.5 inches thick as required by the

design. We haven't seen this on any other surviving PSC M4s to date but

have noted it on a few surviving ALCO M4s.

Montreal Locomotive produced 188

M4A1s from October through December 1943. The Canadians referred to

them as "Grizzlies." There are about 50 surviving examples, and as best

we can tell from our examinations, the lower rear hull was configured

as seen above on Shop Number 18 on display in Groesbeek in the

Netherlands. The top section (1) is the familiar casting with the

raised areas. Aside from armor plates (2) on either side of the doors,

there appears to be a small bottom plate (3). The transition piece (4)

is angled like PSC M4A1s. However, it is not a casting, but rather

another armor plate. The towing lugs (5) can be seen to be welded on.

The weld scars (6) are from a towing pintle fitting. Towing pintles

appear to have been installed as standard equipment on the Grizzlies

but are noted to have been removed on most surviving examples.

Again, the bottom section of the door flange can be seen to have been

cut off so as not to interfere with the pintle. The offset attachment

point at the top (7) remained the same, but a new bolt hole (8) was

drilled at the bottom of the flange to secure the door. As shown

in the inset, a new attachment point (9) was added to the lower lip of

the engine access door opening.

Montreal Locomotive produced 188

M4A1s from October through December 1943. The Canadians referred to

them as "Grizzlies." There are about 50 surviving examples, and as best

we can tell from our examinations, the lower rear hull was configured

as seen above on Shop Number 18 on display in Groesbeek in the

Netherlands. The top section (1) is the familiar casting with the

raised areas. Aside from armor plates (2) on either side of the doors,

there appears to be a small bottom plate (3). The transition piece (4)

is angled like PSC M4A1s. However, it is not a casting, but rather

another armor plate. The towing lugs (5) can be seen to be welded on.

The weld scars (6) are from a towing pintle fitting. Towing pintles

appear to have been installed as standard equipment on the Grizzlies

but are noted to have been removed on most surviving examples.

Again, the bottom section of the door flange can be seen to have been

cut off so as not to interfere with the pintle. The offset attachment

point at the top (7) remained the same, but a new bolt hole (8) was

drilled at the bottom of the flange to secure the door. As shown

in the inset, a new attachment point (9) was added to the lower lip of

the engine access door opening.

American Locomotive (ALCO) switched from production of M4A2s to M4s in

February 1943, and made 2150 M4s up to December 1943 at which point the

company left the Sherman program. The lower rear hulls of ALCO M4s

appear to have been assembled entirely of armor plates. We don't know of

any informative period photos, so will try to make do with what can be

seen on the few surviving ALCO M4s, starting with SN 3949 which would

have been produced in April 1943. This tank is in storage at Ft. Moore

(formerly Ft. Benning) Georgia. There is an angled plate (1) at the

bottom, which is attached to a single plate (2) in the middle that was

cut out for part of the engine access door opening. This plate is welded

to a single top plate (3) which was also cut out for the upper part of

the engine access door opening. On the other M4s and M4A1s we have

examined, the top and middle sections are seen riveted or welded

together at about the level of the upper edge of the engine access

doors. Here the join line is several inches lower. The door flange (4)

is a straight piece. That is, it does not curve inward at the top and

bottom as was commonly the case. A pair of rectangular shims (5) were

welded to the top and bottom to provide bolt on points for the flange.

The flange is attached to the right-side door by a continuous weld in

this case. The door stops (6) appear to be a little less than 1 inch

thick. The fitting and a section of the original "long" trailer towing

pintle (7) can be seen attached low enough on the transition piece so as

to provide clearance for the bottom of the door flange. The towing lugs

(8) were, of course welded on. We would observe that we know of 5 ALCO

M4s where the lower rear hulls are made up of 3 sections.

Next is SN 24871/USA 3033401 which would have been produced by ALCO in

July 1943. SN 24871 is on display at the War Museum at Overloon in The

Netherlands. The evidence indicates that it was a combat casualty named

"Cookie" of the 31st Tank Battalion, 7th Armored Division, put out of

action during the Battle of Overloon in October 1944. The air cleaners

are missing which permits us to see the simplified lower rear hull,

comprised of an angled transition piece (1) and only a single plate (2),

cut out for the engine access doors. Weld joints were a weakness in the

armor protection, and as production continued, the manufacturers tried

to incorporate fewer armor plates and thereby lower the number of weld

joints needed in the assembly of the Sherman. A complete long trailer

towing pintle (3) is installed on this unit. There is no welding visible

to show that the flange was attached to the right-side door. The inset

is a blow up of a photo taken circa 1946, that shows that indeed the

flange was not attached to the right-hand door but was simply bolted on

to the left. This would be sufficient to hold the flange to the door,

but if all the bolts were removed, the flange would be likely to fall

off and perhaps become misplaced.

Next is SN 24871/USA 3033401 which would have been produced by ALCO in

July 1943. SN 24871 is on display at the War Museum at Overloon in The

Netherlands. The evidence indicates that it was a combat casualty named

"Cookie" of the 31st Tank Battalion, 7th Armored Division, put out of

action during the Battle of Overloon in October 1944. The air cleaners

are missing which permits us to see the simplified lower rear hull,

comprised of an angled transition piece (1) and only a single plate (2),

cut out for the engine access doors. Weld joints were a weakness in the

armor protection, and as production continued, the manufacturers tried

to incorporate fewer armor plates and thereby lower the number of weld

joints needed in the assembly of the Sherman. A complete long trailer

towing pintle (3) is installed on this unit. There is no welding visible

to show that the flange was attached to the right-side door. The inset

is a blow up of a photo taken circa 1946, that shows that indeed the

flange was not attached to the right-hand door but was simply bolted on

to the left. This would be sufficient to hold the flange to the door,

but if all the bolts were removed, the flange would be likely to fall

off and perhaps become misplaced.

In the realm of Sherman minutia, we would note that there are a few

surviving ALCO M4s that are without flanges and show no evidence of

having had the flange welded on to the right-side door. This is seen on

SN 25054 on display at the National Infantry Museum at Ft. Moore,

Georgia. The missing flange provides us with good views of the

rectangular shims (circled) that are welded to the top and bottom to

provide bolt-on points for the flange.

There are 3 ALCO M4 Composite hull Fireflies in South Africa that are

also without flanges. Here we don't see the flange on SN 40381 on

display in Bethlehem. This tank (inset) would have been part of ALCO's

final Sherman Production Order and would have been accepted in November

1943. Other surviving ALCO M4s of the same vintage are noted with the

flange tack welded on to the right door, but in this and 2 other cases,

there is no weld scar evidence that this was done. Could the failure to

weld the flange to the right door have been an oversight that was missed

by the Army inspector who accepted these tanks? Of note is that SN

40381 has double towing lugs (1), as do the other 6 known surviving

ALCO M4 Composites. From that we would guess that the addition of the

"Quick Release" towing shackles to the rear took place at ALCO in

October 1943. The fittings labeled "2" were added by the British and

held a trailer towing pintle mounted on an automobile type leaf spring.

The British preferred that design over the standard US pintle and made

an unsuccessful request to have it provided and installed by the US as

part of Lend Lease. It is thought that item 3 was a component of a tail

smoke emitter retrofitted by the British.

There are 3 ALCO M4 Composite hull Fireflies in South Africa that are

also without flanges. Here we don't see the flange on SN 40381 on

display in Bethlehem. This tank (inset) would have been part of ALCO's

final Sherman Production Order and would have been accepted in November

1943. Other surviving ALCO M4s of the same vintage are noted with the

flange tack welded on to the right door, but in this and 2 other cases,

there is no weld scar evidence that this was done. Could the failure to

weld the flange to the right door have been an oversight that was missed

by the Army inspector who accepted these tanks? Of note is that SN

40381 has double towing lugs (1), as do the other 6 known surviving

ALCO M4 Composites. From that we would guess that the addition of the

"Quick Release" towing shackles to the rear took place at ALCO in

October 1943. The fittings labeled "2" were added by the British and

held a trailer towing pintle mounted on an automobile type leaf spring.

The British preferred that design over the standard US pintle and made

an unsuccessful request to have it provided and installed by the US as

part of Lend Lease. It is thought that item 3 was a component of a tail

smoke emitter retrofitted by the British.

Pullman Standard manufactured 689 M4s from May through September 1943 at

which point the company's contract to produce Shermans was terminated.

The photo shows the lower rear hull configuration of "Blood and Guts,"

an M4 that served with B Company (B9) of the 707th Tank Battalion. On 19

December 1944, this tank was reported to have been abandoned in the

village of Erpeldange when the 707th TB was overrun by the Germans

during the Battle of the Bulge. It has been on display in the Place des

Martyrs in Wiltz, Luxembourg for more than 70 years, and was refurbished

and rededicated in 2016. Pullman is another of the builders that did

not stamp the Serial Number anywhere on the exterior of its Shermans,

but a period photo shows that "Blood and Guts" was USA 3038800,

indicating it was accepted at Pullman in May 1943. The lower rear hull

can be seen in the "simplified" configuration made up of an angled

transition piece (1) and only a single plate (2), which was cut out for

the engine access opening. The flange (3) is a straight piece, tack

welded to the right-side door. Again, a pair of rectangular shims (4)

were welded to the top and bottom to provide bolt-on points for the

flange. There are 2 "suspected" Pullman M4s on display in Florida which

have the same configuration. In the case of the one at Eglin Air Force

Base, the doors stops (5) are thinner than what is shown here.

The

Chrysler Corporation manufactured 1676 M4 Composite hull Shermans from

August 1943 through January 1944. Serial Number 59162 is on display at

the Fort Douglas Military Museum in Salt Lake City. We

would judge that the lower rear hull seen here is representative of the

configuration used by Chrysler on its M4 Composites. The missing air

cleaners permit us to see the "simplified" assembly made up of an

angled transition

piece (1) and only a single plate (2), which was cut out for the engine

access opening. The flange (3) is welded to the right-side door and,

unlike some other examples we have featured, it is no more than the same

height as the doors. The inset shows the attachment points (4) for the

upper and lower bolts on the door opening. "Counting heads" evidence

suggests that Chrysler did not factory install door stops or towing

pintles on its M4 Composites. Note the single towing lugs (5) welded on.

This Signal Corps photo is dated 14

April 1945 and captioned as being "along road to Baguio" [Luzon]. The

caption does not identify the tank's unit, but the "triangle inside a

circle" symbol (circled) appears in some other SC photos where the unit

is identified as the 775th Tank Battalion. An item of interest seen

here is the "quick release towing shackle with handle" (1). These had

been installed on the front from the outset, while the rear continued

in the original Sherman configuration. The quick release required

double towing lugs, and the doubles show up on the rear of only a small

number of period photos of Chrysler Composites. We can observe that

double rear towing lugs have been noted on 2 surviving examples, SNs

59644 and 59646, both of which would have been accepted in January

1944, the final month of M4 Composite production at Chrysler. This tank

can be seen with a fitting (2) on the engine access door that held the

Barber-Colman type exhaust deflector. The "Freeze Date" [that is,

"No tank without this item accepted after..."] at Chrysler is listed as

1/1/44. However, as in our photo, the deflector itself is seldom

seen installed, possibly because it would have created interference

issues when wading trunks were retrofitted. Blanket roll racks (3) were

standard equipment on the "ultimate design" Shermans. As yet, it can't

be confirmed if the racks were ever factory installed on any M4

Composites. They are seen in a few period photos like this one, but we

would judge that they were retrofitted at a Depot or in the field.

This Signal Corps photo is dated 14

April 1945 and captioned as being "along road to Baguio" [Luzon]. The

caption does not identify the tank's unit, but the "triangle inside a

circle" symbol (circled) appears in some other SC photos where the unit

is identified as the 775th Tank Battalion. An item of interest seen

here is the "quick release towing shackle with handle" (1). These had

been installed on the front from the outset, while the rear continued

in the original Sherman configuration. The quick release required

double towing lugs, and the doubles show up on the rear of only a small

number of period photos of Chrysler Composites. We can observe that

double rear towing lugs have been noted on 2 surviving examples, SNs

59644 and 59646, both of which would have been accepted in January

1944, the final month of M4 Composite production at Chrysler. This tank

can be seen with a fitting (2) on the engine access door that held the

Barber-Colman type exhaust deflector. The "Freeze Date" [that is,

"No tank without this item accepted after..."] at Chrysler is listed as

1/1/44. However, as in our photo, the deflector itself is seldom

seen installed, possibly because it would have created interference

issues when wading trunks were retrofitted. Blanket roll racks (3) were

standard equipment on the "ultimate design" Shermans. As yet, it can't

be confirmed if the racks were ever factory installed on any M4

Composites. They are seen in a few period photos like this one, but we

would judge that they were retrofitted at a Depot or in the field.

It is somewhat difficult to "count heads" on the factory introduction of

the Barber-Colman type exhaust deflector, since this item appears to

have been a requirement of the M4/M4A1 remanufacturing programs and so

the fittings are present on quite a few survivors. If we go by the 1

January Freeze Date, 149 units were manufactured during the final month

of M4 Composite production. However, SN 59427 at the Royal Australian

Armoured Corps Museum in Puckapunyal has the fittings (top photo). This

tank was altered slightly during its service with the Australians, but

we would judge that it is 90% "as built." There is even a period photo

of the tank with the Barber-Colman exhaust deflector installed. In any

case, SN 59427 would have been accepted in December 1943, a little ahead

of the 1 Jan. 1944 "Freeze Date." Another mostly "as built" December

1943 example with the Barber-Colman deflector fittings is SN 59440 on

display at the Philipine Military Academy in Baguio (bottom photo). This

tank can be seen with the remnants of wading trunk fittings which

suggests to us that it is probably a combat veteran Sherman of the Luzon

Campaign.

Baldwin Locomotive manufactured 1233 M4s from January 1943 through

January 1944. Oddly, all of them appear to have been built with direct

vision drivers' hoods. As for the lower rear hull, we shall examine some

of the surviving examples starting with SN 1940 on display at the

Normandy Victory Museum in Catz, France. This tank would have been

accepted in February 1943 and is, at present, the earliest known

surviving Baldwin M4. Note the Lima/PCF style of rounded transition

piece (1) that joined the lower rear hull plate to the belly plate. This

is welded to a pair of side armor plates (2) which are then welded to

an upper plate (3). Shims (4) were added to the transition piece to

support the idler wheel holder assemblies. This M4, and most but not all

other surviving Baldwins, can be seen with M3 Medium type of engine

access door hinges. We suspect these may have been leftover parts from

when Baldwin was directed to change from production of Radial to Diesel

powered M3 Mediums. The hinges appear to be welded on, but also fixed

with some "blobs." This may be a very crude example of flush riveting.

The flange is tack welded (5) to the right door. The door stops on

Baldwin M4s seem to have been mounted a little below the center. In this

case, the right doorstop is thicker than the left, which we would guess

is a replacement. This tank shows evidence of having been

remanufactured, hence the presence of the fittings for the Barber-Colman

type exhaust deflector.

Here we have a Baldwin M4 on display at the War Museum in Overloon, The

Netherlands. This tank is Serial Number 15499, indicating that it was

accepted in May 1943. Shortly after the end of WW II, this tank and a

previously featured ALCO M4 were recovered from the fields around

Overloon. It is almost certain that SN 15499 served with the US 7th

Armored Division and is said to have been put out of action in

Hattertweg Vierlingsbeek, Netherlands on 4 October 1944. The lower rear

hull is very much like that shown in the prior caption, however the

welded on M3 type hinges are smooth although some dimpling is observed

on the faces of the ones on the right (1). The original "long" trailer

towing pintle (2) is stated to have been introduced in production at

Baldwin on 30 April 1943 at SN 2150. As mentioned, there were some

reports of instances where the pintle got bent up in service resulting

in interference issues with the engine access doors. The clamp (3) could

be pivoted out of the way, but to our eyes, the pintle seen here

appears to be mounted at a slight upward angle which might cause a

problem with the doors. We

would point out that the upper rear hull plate (4) on Baldwin and

Pressed Steel Car M4s was vertical, whereas it was installed on an

outward angle on ALCO, Pullman and Chrysler M4s.

As best we can tell, only Baldwin built M4s with the M3 type hinges. A

few surviving Baldwins are noted with the regular type of M4 hinges.

From the small sample we have to work with, we would judge that there

was no chronology regarding the hinge type. It appears to have been

random. Occasionally, modelers ask if it is possible to determine the

appearance of the front of a Sherman if all one has as reference is a

photo of the rear. In the case of the two 755th Tank Battalion M4s shown

above and based on the M3 style hinges that can be seen, we would

suggest that these tanks would have had the unmodified Baldwin direct

vision glacis pattern. The round air cleaners seen on both of these

Shermans, appear on most, but not all surviving Baldwin M4s.

As best we can tell, only Baldwin built M4s with the M3 type hinges. A

few surviving Baldwins are noted with the regular type of M4 hinges.

From the small sample we have to work with, we would judge that there

was no chronology regarding the hinge type. It appears to have been

random. Occasionally, modelers ask if it is possible to determine the

appearance of the front of a Sherman if all one has as reference is a

photo of the rear. In the case of the two 755th Tank Battalion M4s shown

above and based on the M3 style hinges that can be seen, we would

suggest that these tanks would have had the unmodified Baldwin direct

vision glacis pattern. The round air cleaners seen on both of these

Shermans, appear on most, but not all surviving Baldwin M4s.

The Ordnance Department decided to

terminate M4(75) production, and the last units rolled off the

lines at Baldwin and Chrysler in January 1944. The only radial powered

M4 built after that was the Second Generation M4(105). The Chrysler

Corporation began manufacturing them in February 1944 and produced a

total of 1641 units through March 1945. We like to try to find

surviving examples that are close to "as built" and Pierre-Olivier

photographed a few M4(105)s in South Africa that fit the bill. The

photo on the left shows the lower rear hull of Serial Number 57397

(Bloemfontein) which would have been accepted in July 1944. The

M4(105)s were installed with double towing lugs (1) from the outset.

The Barber-Colman exhaust deflector was also standard from the

beginning, and most of the fittings (2) are still in place. Fitting 3

was used to hold the deflector in the up position during servicing.

Second Generation Shermans were equipped with the later "short" trailer

towing pintle although just the fitting (4) is present here. This

example does not show evidence of having had door stops installed, an

omission also noted on Chrysler's M4 Composites. The photo on the right

is of SN 57568 on display in Johannesburg. This tank would have been

accepted in August 1944. The evidence suggests that Chrysler began to

incorporate the "thin" type of door stops (5) seen here in July. Here

we have the opportunity to see the quick release towing shackles (6)

complete with retaining chains, and one can see why they required

double towing lugs. It is thought that the British or South Africans

added fitting 7, possibly as a sort of quick release for the

engine access doors. A similar Y-shaped pin (8) was also added to

the pintle fixture. The reinforcing gussets (9) are consistently

seen to be in a triangular configuration, which leads us to posit that

they were factory installed by Chrysler starting in July 1944.

The Ordnance Department decided to

terminate M4(75) production, and the last units rolled off the

lines at Baldwin and Chrysler in January 1944. The only radial powered

M4 built after that was the Second Generation M4(105). The Chrysler

Corporation began manufacturing them in February 1944 and produced a

total of 1641 units through March 1945. We like to try to find

surviving examples that are close to "as built" and Pierre-Olivier

photographed a few M4(105)s in South Africa that fit the bill. The

photo on the left shows the lower rear hull of Serial Number 57397

(Bloemfontein) which would have been accepted in July 1944. The

M4(105)s were installed with double towing lugs (1) from the outset.

The Barber-Colman exhaust deflector was also standard from the

beginning, and most of the fittings (2) are still in place. Fitting 3

was used to hold the deflector in the up position during servicing.

Second Generation Shermans were equipped with the later "short" trailer

towing pintle although just the fitting (4) is present here. This

example does not show evidence of having had door stops installed, an

omission also noted on Chrysler's M4 Composites. The photo on the right

is of SN 57568 on display in Johannesburg. This tank would have been

accepted in August 1944. The evidence suggests that Chrysler began to

incorporate the "thin" type of door stops (5) seen here in July. Here

we have the opportunity to see the quick release towing shackles (6)

complete with retaining chains, and one can see why they required

double towing lugs. It is thought that the British or South Africans

added fitting 7, possibly as a sort of quick release for the

engine access doors. A similar Y-shaped pin (8) was also added to

the pintle fixture. The reinforcing gussets (9) are consistently

seen to be in a triangular configuration, which leads us to posit that

they were factory installed by Chrysler starting in July 1944.

Here we see the lower rear hull of M4(105)HVSS Serial Number 58486

(October 1944) on display at the Tank Museum at Bovington. Chrysler

switched over to the use of HVSS in September 1944 at SN 58308,

according to our math. Ultimately, 800 M4(105) Shermans with VVSS and

841 with HVSS were produced. Note the HVSS type idler wheel holder

assembly (1). Again, the triangular reinforcing plates (2) are present.

These were intended to stiffen the "grouser compartment plate(s)" (3)

which were "very often bent in when the track is thrown, resulting in

damage to the air cleaner." The Technical Bulletin (inset) has it that

these could be field installed using "scrap steel 1/2 in. to 3/4 in.

thick." However, due to their consistent appearance, we believe that

these were armor plates factory installed by Chrysler.

Pressed Steel Car was the sole manufacturer of the M4A1(76) and began

production in January 1944. Evidence suggests that the company

discontinued use of the cast transition piece and adopted the

simplified lower rear hull, comprised of an angled transition plate (1)

and a single armor plate (2), cut out for the engine access doors.

"Thin" doors stops and double tow lugs appear to have been installed

from the start. The M4A1(76) shown here is on display in La

Roche-en-Ardenne, Belgium. It appears to be nearly as built. Certain

features suggests that this Sherman was produced in February 1944 and

was very likely a combat casualty of either the 2nd or 3rd Armored

Division. The familiar Barber-Colman fittings can be seen, but we would

note that the fitting for holding the deflector in the up position was

not included at first. Also not installed from the beginning were

the reinforcing plates for stiffening the "grouser compartment

plate(s)." These items appear to have been incorporated in production

in the Summer of 1944.

In early 1944, a special task force of 156 of the first M4A1(76)s was

sent to the UK for familiarization. They evoked little interest from US

armored commanders whose troopers had been training for the Invasion for

many months with M4 & M4A1(75)s. Confrontations with heavy German

armor in Normandy aroused interest in the "orphan" M4A1(76)s sitting

idle in England, and General Bradley ordered that they be shipped to

France to take part in First Army's upcoming Operation Cobra. 120 were

evenly distributed to the 2nd and 3rd Armored Divisions, and they made

their combat debut in late July 1944. The "look" of these early ones

is of some interest to modelers and restorers since the US Army did not

use any M4A1(76)s in the other war theaters, and only received a few

later production units in early 1945. The photo above shows "Duke," USA

3070582 of the 66th Armored Regiment, 2nd AD, one of the last M4A1(76)s

accepted in January 1944. It was photographed in Coutances, France

during Operation Cobra. The lower rear hull is identical to the M4A1(76)

in La Roche-en-Ardenne, but it provides an opportunity to see the early

"unframed" exhaust deflector.

Pressed

Steel Car changed over to production of the M4A1(76) with HVSS at the

beginning of January 1945. The example shown above is on display in

Toulon, France. It is SN 68975 one of the last units accepted in May

1945. During the month of April 1945, 169 "M4A1 (76mm gun) 23" track"

are reported to have been allocated to units of the US 12th Army Group

in the ETO. However, it seems unlikely that many of these could have

been processed and delivered to front line units in time to have

"fought" before V-E Day, May 8th. In any case, at present we don't have

any definitive evidence of the use of the M4A1(76)HVSS in combat during

WW II. SN 68975 has all the hallmarks of having been distributed to the

French as Military Defense Assistance in the early 1950s. Regarding the

lower rear hull, it can be seen that the exhaust deflector was

strengthened a bit by the addition of frame pieces (1) on its sides. The

original quick release towing fixtures were replaced at PSC with "even

quicker" release T-shaped shackles (2) around October 1944. A tow cable

could be hooked on to the new shackles without removing them. This saved

crews a few seconds when attempting to retrieve a tank while under

fire. It was no longer necessary to have two tow lugs per side on the

rear with the new shackles. The examination of surviving M4A1(76)s

suggests that the transition to single lugs was completed in December

1944. Thus, we have seen the singles on a few of the final VVSS units

made in December 1944, and all of the M4A1(76)s produced with HVSS. From

the beginning, it was obvious that the externally mounted air cleaners

on the M4 and M4A1 were vulnerable to combat damage. Some units in the

field attempted to protect the air cleaners by simply welding steel

plates in front of them. A "protector assembly" was designed in late

1944. The protectors (3) are observed only on some surviving

M4A1(76)HVSS's. Supplies of these appear to have become available to PSC

in May 1945, and we would judge that not more than 250 of the last

M4A1(76)s produced had them factory installed. As best we can tell, the

M4A1(76)HVSS was the only radial engine AFV that had the protectors

factory installed. There doesn't seem to have been any excess or later

production of these items, so they don't show up on 1950s era rebuilds.

That is to say, they are only present on the last 250 or so M4A1(76)s

and none of the rebuilds, nor are they seen on any surviving M7 Priests,

M4A1E6s or M32B1 retrievers.

Pressed

Steel Car changed over to production of the M4A1(76) with HVSS at the

beginning of January 1945. The example shown above is on display in

Toulon, France. It is SN 68975 one of the last units accepted in May

1945. During the month of April 1945, 169 "M4A1 (76mm gun) 23" track"

are reported to have been allocated to units of the US 12th Army Group

in the ETO. However, it seems unlikely that many of these could have

been processed and delivered to front line units in time to have

"fought" before V-E Day, May 8th. In any case, at present we don't have

any definitive evidence of the use of the M4A1(76)HVSS in combat during

WW II. SN 68975 has all the hallmarks of having been distributed to the

French as Military Defense Assistance in the early 1950s. Regarding the

lower rear hull, it can be seen that the exhaust deflector was

strengthened a bit by the addition of frame pieces (1) on its sides. The

original quick release towing fixtures were replaced at PSC with "even

quicker" release T-shaped shackles (2) around October 1944. A tow cable

could be hooked on to the new shackles without removing them. This saved

crews a few seconds when attempting to retrieve a tank while under

fire. It was no longer necessary to have two tow lugs per side on the

rear with the new shackles. The examination of surviving M4A1(76)s

suggests that the transition to single lugs was completed in December

1944. Thus, we have seen the singles on a few of the final VVSS units

made in December 1944, and all of the M4A1(76)s produced with HVSS. From

the beginning, it was obvious that the externally mounted air cleaners

on the M4 and M4A1 were vulnerable to combat damage. Some units in the

field attempted to protect the air cleaners by simply welding steel

plates in front of them. A "protector assembly" was designed in late

1944. The protectors (3) are observed only on some surviving

M4A1(76)HVSS's. Supplies of these appear to have become available to PSC

in May 1945, and we would judge that not more than 250 of the last

M4A1(76)s produced had them factory installed. As best we can tell, the

M4A1(76)HVSS was the only radial engine AFV that had the protectors

factory installed. There doesn't seem to have been any excess or later

production of these items, so they don't show up on 1950s era rebuilds.

That is to say, they are only present on the last 250 or so M4A1(76)s

and none of the rebuilds, nor are they seen on any surviving M7 Priests,

M4A1E6s or M32B1 retrievers.

HOME