"Early" Driver's Hoods with Direct Vision (DV)

The earliest Sherman tanks were designed with "direct vision" ports installed at the front of the driver's and assistant driver's hoods. The drivers could look directly through small slits, and when necessary, could close off the slits by means of hinged armored blocks. However, it was noted that, when closed, a small gap the size of a pencil permitted the entry of bullet splash. Ultimately, direct vision was ordered eliminated from the Sherman design on 24 June 1942 for cast hulls and 13 August 1942 for welded hulls. It would take some months before the redesigned drivers' hoods could enter production, and several thousand Shermans were built with direct vision. Shown here are the direct vision blocks in the closed position on "Michael" at The Tank Museum at Bovington. This was the second M4A1 built by Lima Locomotive and is the oldest known surviving Sherman.

Shown above are the direct vision blocks and drivers' hoods as installed on the first ALCO M4A2 hull, Serial Number 1405. Current evidence suggests that most or all of the 150 M4A2s built by ALCO had direct vision. The vision block on the driver's side is opened and one can see the small direct vision slit. Photos courtesy of Neil Baumgardner.

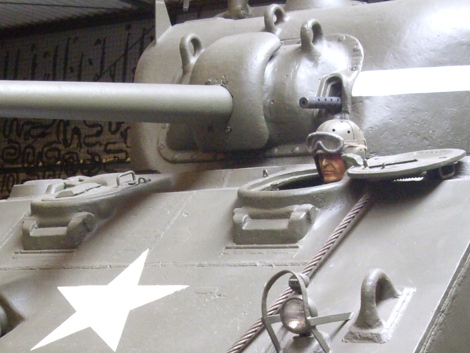

Another early M4A2 with direct vision blocks. The drivers' hatches shown here are in the initial configuration before the Spring 1943 introduction of positive hatch lock mechanisms with equilibrator springs. This particular tank is located at Saint-Martin-de-Varreville near Utah Beach.

Direct Vision blocks and drivers' hood castings as seen on an early M4A4. The minutes of a conference held at Lima Locomotive Works on 27 April 1942 discuss a gap in the direct vision configuration that exposed the drivers to bullet splash. The remedy proposed was the addition of a splash guard in the form of an L-shaped bracket welded in front of the direct vision block. The "remedy" as seen above, is most commonly observed on early production Fisher M4A2s, Chrysler M4A4s and Ford M4A3s.

The protruding drivers' hoods, whether direct vision or the later type, were found to be ballistic weak points. Around August 1943, 10,000 of the so called "hatch guard" modification kits were produced for installation on new production Shermans, as well as those already overseas or scheduled for shipment to combat zones. In the two photos above, one can just see the direct vision blocks hidden behind the drivers' hood applique plates. Note also the positive hatch lock mechanisms with equilibrator springs. This important safety modification was introduced in the Spring of 1943 and was retrofitted to many early Shermans that had been built without it.

These photos provide two views of the drivers' hoods with direct vision as seen on an early M4A1 located near Dompaire, France. Of course, when retrofitted to any direct vision Sherman, the sloped driver's hood plates blocked direct vision and rendered it useless. The Field Service Modification Work Order for these plates was published in August 1943. The modification did not apply to the M4A1 as it was thought that the cast armor in front of the drivers' hoods was better contoured, and not as vulnerable as the protruding hoods used on welded hull Shermans. However, based on a few period photos and surviving examples, it would appear that direct vision M4A1s received this mod during remanufacture, and overseas "in the field" in some instances.

Later, Elongated Driver's Hoods (without Direct Vision)

When the drivers' hoods were redesigned to eliminate direct vision, they were elongated in the front, where an additional, auxiliary periscope was provided. The new hoods were introduced at various times by the various manufacturers, but in general, the changeover came before the end of 1942. The lone exception was Baldwin Locomotive. For some reason, Baldwin continued to build its Shermans with direct vision right up until production was terminated in January 1944. The manufacturers of small hatch M4s and M4A2s made use of "narrow" drivers' hood castings as shown on the left. The lines in red show how the narrow hoods were welded into the glacis. Of course, in ballistics tests, weld joints "exhibit poor resistance to shock" and were the weakest part of any glacis pattern. Only Chrysler M4A4s and Ford M4A3s used "wide" drivers' hood castings on their Shermans. In the photo on the right, note how the "wide" casting included a section of the glacis along with the driver's hood, and how the hood castings were welded together at the centerline of the glacis. The idea of the wide hood castings was to eliminate "welding along the sides of the hoods." However, this configuration "gave with one hand and took away with the other," since there were still quite a few weld joints. In some cases, the "narrow" versus "wide" hood castings can serve as recognition features in attempting to determine the type of small hatch, welded hull Sherman. Right-side photo courtesy of Paul Hannah.

The photos above provide three views of the elongated, "narrow" drivers' hood castings. Notice how the casting tapered up and was rounded at the top. These particular drivers' hood castings were photographed on a Federal Machine and Welder M4A2. They were also used on 1943 production Pullman M4A2s and M4s, as well as ALCO and Pressed Steel Car M4s. Note that the castings seen here are very smooth.

The drivers' hoods featured on this pair of ALCO M4s at Ft. Moore (ex Ft.Benning), Georgia are partially obscured by the addition of the "Sloping Armor Ahead of Drivers' Hatches" modification. We will have to make do since this mod is on pretty much every known surviving example of ALCO and PSC M4s. In any case, it can be seen that these castings differ a bit from those on the Federal Machine M4A2 of the previous caption, in that they are not quite as smooth. We believe that these were simply casting variations, since as best as we have been able to determine, the Part Numbers of all of the elongated drivers' hood castings were D77160 B for the driver's side and D77160 A for the bow gunner's side.

In late 1942, Fisher transitioned from cast drivers' hoods with direct vision to what we call "fabricated" drivers' hoods. These "boxes" were assembled from various plates and consequently present a very sharp, angular appearance. They worked with the standard cast drivers' hatches. As best we have been able to determine, fabricated drivers' hoods were exclusive to Fisher built M4A2s and were designed at the request of the Government in an effort to relieve the country's overtaxed foundry casting capacity.

A little bullet splash (circled) can be seen on some, but not all, Fisher and ALCO built Shermans. It was an official part (i. e., given a drawing part number) that seems to have been introduced around mid 1943 for the purpose of protecting the driver's hatch hinge knuckles. We have yet to discover the reason that this item was not added to other Shermans.

The "wide" drivers hood castings as seen on Ford M4A3 Sherman tanks. In the left photo, one can see the weld seam (arrow) where the castings were joined to form the upper section of the glacis. Note how the bottom of each hood is undercut. We have recorded the Part Numbers from a few surviving examples as E-3714 for the bow gunner's side and E-3715 for the driver's. We have also noticed an "F" stamped into some castings and would guess that all of them were produced at one of Ford's own casting foundries.

Here we see the "wide" drivers hood castings used on Chrysler M4A4s. They are very similar to the Ford hoods although the Part Numbers are different and, incidentally, much easier to read - D70564 for the bow gunner's side and D70563 for the driver's side. Again, note the undercut at the base of each driver's hood.

Of course, the M4A1's entire upper hull casting had to be reconfigured for the elongated drivers' hoods. It is thought that Lima Locomotive and Pressed Steel Car each produced about 250 direct vision M4A1s before transitioning to the updated hull castings starting in August 1942. We haven't been able to do as effective a "head count" regarding this issue at Pacific Car and Foundry, but it seems that the company produced less than 50 DV M4A1s before transitioning to the elongated hoods in August or perhaps September 1942. The photos above provide some idea of the shape of the elongated hatches as formed on the cast hull.

HOME