Most of the information on this page is courtesy of Joe DeMarco and Leife Hulbert, with help from Peter Brown. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

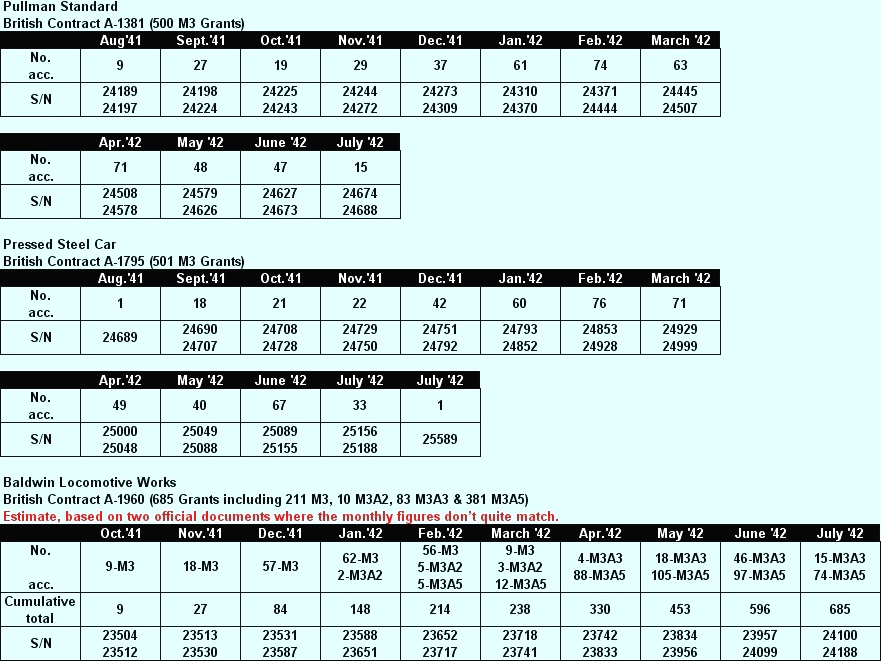

The Pressed Steel Car Co. manufactured 501 M3 Grants at its plant in Hegewisch Station (south Chicago, Illinois), from August, 1941 through July, 1942.

British Contract A-1795: 501 M3 Grants: Serial Numbers 24689 through S/N 25188, plus S/N 25589

The Baldwin Locomotive Works manufactured 685 Grants at its plant in Eddystone, near Philadelphia, Pennsylvania.

Baldwin produced 211 M3, 10 M3A2, 83 M3A3 and 381 M3A5 Grants from October, 1941 through July, 1942.

British Contract A-1960: 685 Grants: Serial Numbers 23504 through S/N 24188

The Grant Serial Number as seen on a few dataplates was the British War Department Number minus the "T" prefix. So, for example, Pullman Standard Serial Number 24189 was British WD Number T-24189, which would have been painted on both sides of the tank.

In the 1930s, as the United States struggled through the Great Depression, the country was overwhelmingly isolationist. These conditions were not conducive to the development of a costly offensive weapon like a Main Battle Tank. The Ordnance Department had designed a few Light Tanks to support the infantry, and similar "Combat Cars" to support the [still] existing horse cavalry. Late 1930s efforts to develop a Medium Tank resulted in the T5 / M2 series (above, left, T5 Phase III in 1938), which were essentially enlarged versions of the M2 series Light Tanks. It was soon realized that the T5's 37mm main gun would be inadequate on the modern battlefield, but the engineers appear to have lacked the knowledge, resources and technical ability to come up with a design that could mount a larger caliber weapon in a revolving turret. As an expedient, in 1939, the T5 Phase III was modified to mount a 75mm pack howitzer in the right front of the hull (above right), in the manner of the French Char B1 bis. The Fall of France in June of 1940 changed the political landscape, and created a sense of urgency that the United States begin mass production of a Medium Tank as soon as possible. A design was needed immediately that could meet the Army's requirements for mobility, protection and firepower, and this resulted in the M3 Medium Tank. From the beginning, the M3 was thought of as an interim design. Its major shortcoming was, of course, the limited traverse of the sponson mounted 75mm main gun. In August 1940, even before the M3's design was finalized, the Ordnance Committee, Technical Staff emphasized that the next step in development would be "modification of the Medium Tank, M3" by "relocating the 75mm gun in the turret." It was intended to replace the M3 in production as quickly as was practical.

The British were not helpful when they classified the various types of Lees and Grants, but limited the nomenclature to “Grant l” and “Grant II.” As defined in the August, 1942 document above, a Grant I, was a Medium M3 with 340 hp Wright [engine], British type turret and riveted hull. The Grant II was a Medium M3A5 with 375 hp G.M. 6-71 (Dual Diesel) with a cast turret and riveted hull. Unlike with the Lees, no nomenclature was provided for the 93 Grants that were built with welded hulls. To avoid confusion, for this piece, we will append “Grant” to mean British turret, to US Army nomenclature. Thus “M3 Grant” will be what the British referred to as the “Grant I.” The M3A2 Grant will be same as the M3 Grant, but with a welded hull. The M3A5 Grant will be the diesel model with a riveted hull, and the M3A3 Grant will be the diesel with a welded hull. These were the only types of M3 Mediums built with Grant turrets, and outfitted to British specifications.

Ordnance Committee Memorandum 15889 dated June 13, 1940 described the military characteristics of the Medium Tank that the US Army chose to produce in quantity. A month later the new design was standardized as the "Medium Tank, M3." It would not be an exaggeration to say that the British hated what they saw of the plans for the M3, with its 10 foot height and sponson mounted main gun. In vain, the Tank Mission led by Michael Dewar sought to persuade US authorities to permit the production of the "Nuffield Cruiser" [A15 Crusader] in US factories. The British who had lost practically all of their tanks in France around this time, had little choice but to place orders for the M3. In August, 1940, Dewar and the British Purchasing Commission submitted the list reproduced above to the US War Department showing the manufacturers they might use for production of what would become the Grant. Ultimately, Baldwin Locomotive and Pullman Standard were awarded contracts a few months later. Pressed Steel Car was not on Dewar's list, but the company's President, John MacEnulty, contacted the BPC, and "sold" them. On October 25, 1940, PSC was awarded a $28,455,000 contract to produce "501 M3, 28 ton tanks, commonly known as the "General Grant."" And so began the long process of refurbishing the plants, procuring machine tools, and finding subcontractors that could produce the myriad components that make up a tank.

The facilities chosen to build the Grants were in various states of disrepair, none more so than Pressed Steel Car's "Ghost Plant" in the Hegewisch neighborhood of south Chicago. This factory, which had been used for the manufacture of railroad cars, had stood empty since the Great Depression, and had "no roof, no floor, no machinery." The British Production Orders provided funds to add to, refurbish and equip the plants, including a late addition in February, 1941, the Lima Locomotive Works in Ohio, originally contracted to produce 400 Grants. The montage above shows the progress at the Hegewisch plant from February through April, 1941, when assembly of the first Grant was started. It should be noted that the Pullman plant in Hammond, Indiana and the PSC plant were situated about 5 miles apart in the southern region of the megalopolis known as "Chicagoland."

As designed, the M3 Medium placed the radio in the hull on the sponson to the left of the driver. The British wanted to mount their No. 19 Radio set in the turret, which was not possible with the small turret of the Lee. They negotiated a redesign of the turret for the Grant, and the photo above, dated November 7, 1940, shows the original wooden mock up on a modified M2 Medium Tank. The British also sought to decrease the height of the US design by replacing the Lee's odd machine gun cupola with a simple low profile "manhole cover," basically a circular split hatch cupola. One of the hatch halves was to be equipped with a rotating periscope. The M3 Medium was fitted with a number of indirect vision devices called "protectoscopes," one of which was positioned on the right rear of the Lee turret. A protectoscope was located in the same general area on the British turret (1), and another was added to the left front. These could be opened in a manner similar to the pistol port of the Sherman. Note the retrofitted reinforcing struts on the top of the M2 Medium hull (2). This was another somewhat quirky feature of the M3 design. The struts helped to support the weight of the 2 ton Lee and 2.75 ton Grant turrets, and also served as bullet splashes, protecting the turret ring area from being jammed by small arms fire or shrapnel. The British considered the splash protection inadequate, and unsuccessfully requested that more protection to be added to the left side and rear of the turret. As with the Lee, the turret crew consisted of 3 men - the tank commander, the [37mm] gunner and the loader. The loader was also tasked with operating the radio which was installed in a bustle at the rear of the turret (3).

A prototype of the British "Radio Turret" was cast and installed on the modified M2 Medium, and photographed on December 13, 1940. In the interim, the British designers had added a few items to the turret, including a "loader's hatch" (1), a loader's periscope (2) and an aperture for a "2 inch bomb thrower", or smoke mortar (3). A certain tension between the British and US design teams came about as the Brits attempted to improve the Grant. The Ordnance Department was anxious to finalize the design, and get the tank into production. They argued that additional changes would result in delays, as new parts would have to be ordered and produced. In the end, in the interest of simplicity, only the bomb thrower was permitted to be added. Imitation is the sincerest form of flattery, and it must be pointed out that the US engineers came to recognize the value of the low profile, split hatch cupola, as well as the loader's periscope, and immediately incorporated them into the design of the Sherman turret. A loader's hatch was also considered, but again rejected in the interest of simplicity. In attempting to incorporate a loader's hatch in the Grant turret, the British had correctly ascertained that the loader would need a hatch directly overhead. With only one hatch in the turret, the breach guard presented an obstacle to the loader as he attempted to escape in emergency situations. Eventually, as a result of numerous combat casualty reports, a loader's hatch was added as a standard item on Sherman turrets in late 1943.

It would appear that a turret mold with the rejected loader's hatch was used in the casting of some early Grant turrets. The scene above shows what we believe is a General Steel turret casting, Serial Number 4, being machined on a Horizontal Boring Mill at the Pullman Plant on May 7, 1941. This was several months before the first Grant was officially accepted there in August. Note the hatch hinge fittings (arrow) that can be seen protruding above the surface of the turret roof.

At present, one Grant turret with the "ghost" of the loader's hatch is known to have survived. It was "discovered" in Australia by a collector. We assume that these "ghost turrets" would have had a limited run at the beginning of production, until the turret pattern wore out or was replaced with a new casting mold with a smooth roof. Thus, it seems odd that this turret, which is either Serial Number 6 or 9, was found in Australia, considering that the first 15 Grants were not exported there until the end of February, 1942. Indeed, the earliest Australian Grants we can account for by "counting heads" were accepted in February, 1942, over 6 months after production commenced in August, 1941. Perhaps this early turret was "lost" in the back of a pile, and became a case of "First in, last out?" Note that this turret casting does not feature a loader’s periscope, as seen in the December, 1940 APG photo of the steel mockup. The loader’s hatch opening on this example was blanked off by having a single piece of plate welded over it. Another theory for this turret’s presence in Australia might be that it was not considered “battle worthy” in the early days, and was set aside in the event that a “For Training Only” turret could be used later?

The photo above is dated September 23, 1941 and is from a Pressed Steel Car photo album. It shows a "pile" of Grant turrets, along with stacks of hull armor plate in the left foreground. Many of the turrets can be seen with the aperture for the 2 inch bomb thrower machined out. We would point out that the turret on the right, nearest to the camera, appears to have a smooth top without the loader's hatch hinge fittings. One Ordnance Department document has it that Pressed Steel Car obtained it turrets from the Union Steel Casting Company with "500...Pcs. on Order." At the time, General Steel had a much greater casting capacity, and was reportedly making Lee turrets for ALCO and Baldwin, along with Grant turrets for Baldwin and Pullman.

The examination of an admittedly small number of surviving Grant turrets shows that Union Steel put its casting information on the exterior, under the radio bustle as shown in the upside-down photo above. The raised figures "W F 2" can be seen in the center. In the British Purchasing Commission’s “General Dimension” drawings of the “British M3 Medium Tank,” WF-2” is labeled as “Body, Turret.” In other words, "W F 2" was the Part Number of the Grant turret and should be found cast into all of them. Next to that is the Union Steel caster's logo, a U on a keystone. (The company’s foundry was in Pennsylvania, the “Keystone State.”) On either side are the raised numbers "357" which we take to be the serial number of this particular turret, recorded from a Grant on display at the Museum at Latrun in Israel. At present, the lowest Union Steel turret serial number we have recorded is 4 from the Grant at the Tank Museum at Bovington. The highest is 605. Photo courtesy of Vladimir Yakubov on SVSM website.

From the start, both Lee and Grant turrets were cast and machined to accommodate three slotted screws on the "roof" of the turret as shown above. US designers were avid to include the high tech feature of gyro-stabilization for both the 37 and 75mm guns. In theory, this device kept the gun level and stable, thereby permitting "fire on the move." The slotted screws held the "upper cylinder bracket" that secured the piston of the 37mm gun's stabilizer assembly (inset). Gyro-stabilizers were reported to have been factory installed in Lees starting around the end of January, 1942. For Grants the introduction date is somewhat cloudy. It was said that the fitment of the gyro for the 37mm "commences in three weeks" (late February), and that the units would not be available for the 75mm "til March." Counting heads suggests that these dates were premature. We assume that if a period photo shows a counterweighted gun, it is an indication that a gyro-stabilizer was installed. From that we would judge that the gyro for the 37mm gun was factory installed on Grants starting in May, 1942, and June for the 75mm. We would observe that the British were not impressed with the performance of the gyro-stabilizer. They decided that if modification kits became available, they would not "require" them for retrofit to their pool of existing Grants.

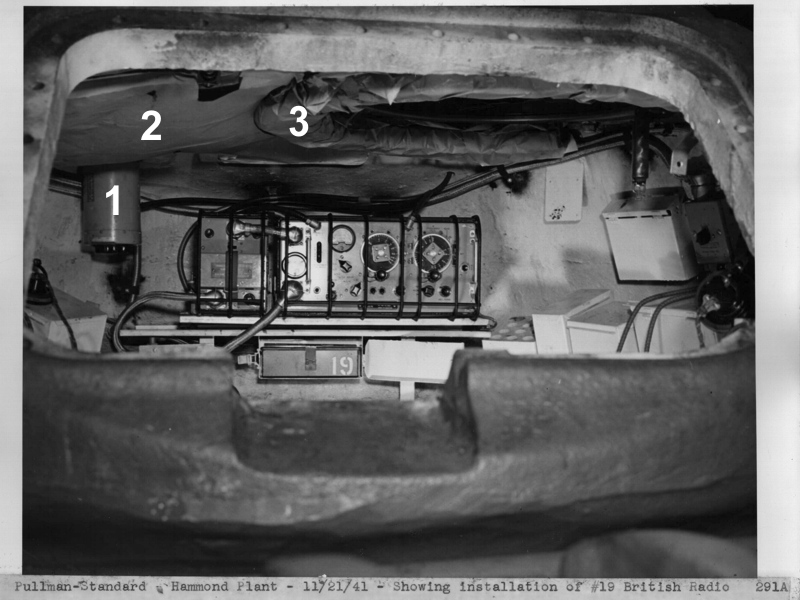

The photo above shows the reason that the British wanted a larger turret for the M3 Medium. Here we see the installation of the "#19 British Radio" in the bustle of a Grant turret at the Pullman plant on November 21, 1941. The WS 19 was designed in 1940 by Pye Radio of Cambridge, UK specifically for use in British tanks and armored cars. It was intended that these would be factory installed, but due to initial shortages, the sets were often shipped separately and installed when the Grants reached their destination. In order to increase output, production was set up in Canada at the beginning of 1942 using the firms Northern Electric, Canadian Marconi and RCA. Shortly thereafter, the WS 19 became a British and Soviet Lend Lease requirement, and sets were manufactured in the US by Zenith, RCA and Philco. These were then provided and installed at US Depots on American built AFVs and tactical vehicles intended for Commonwealth and Soviet Lend Lease. (Many of the sets produced in North America have front panels with both English and Cyrillic lettering.) Note how the unit is "caged in" to protect it from accidental damage in a rough riding tank. The cylindrical object suspended from the turret roof is the radio's aerial variometer (1). Early complaints from the Middle East stated that the protective head padding seen here on the turret roof (2) and around the hatch (3) was not fireproof, and it was ordered removed.

A history from Pye Telecom explains the radio's functions: "Each WS19 radio unit contains three separate systems. The ‘A set’ was a High Frequency (HF) radio transmitter-receiver for communications up to 50 miles. The ‘B set’ was Very High Frequency (VHF) transmitter-receiver for short-range line-of-sight communications up to 1 mile. A separate audio amplifier was provided for intercommunications between members of the crew...A system of remote control boxes (1) was distributed around the vehicle with a microphone/headphone assembly (2) provided for each member of crew." The No. 19 was improved through three Marks, and it is thought that this series of November, 1941 Pullman photos shows a preliminary installation of a Mark I. Pye describes the variometer (3) as "A separate aerial tuning unit...used to match the transmitter output to the 12-foot aerial rod [A set] mounted on the turret or roof of the vehicle." At the time of this photo, the 2 inch bomb throwers were not available to production, but the mounting parts (4), and fittings (5) for the smoke bombs were. Just visible is the rather odd armor piece (6) welded on to cover the bomb thrower's aperture until the guns became available for factory or field installation.

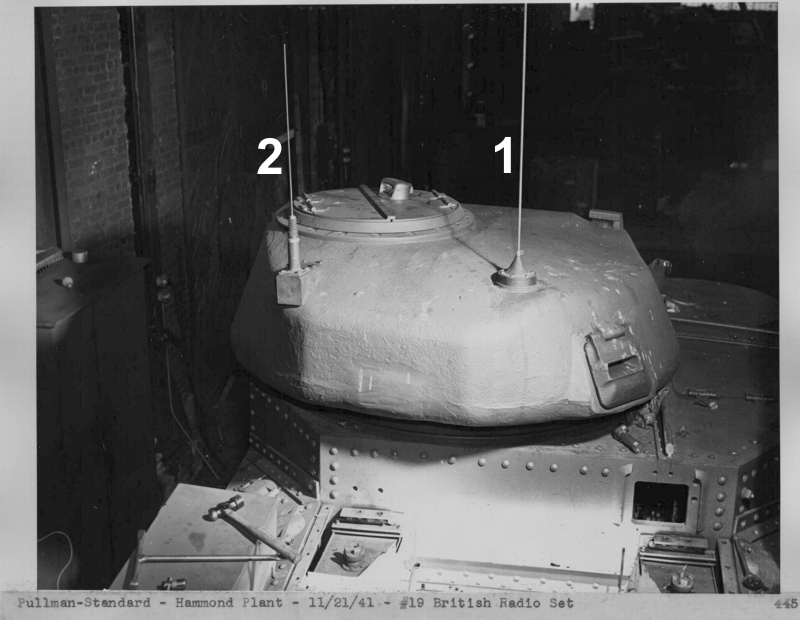

This rear view of the turret shows the standard installation of the aerials on Grants. The A set antenna (1), described by Pye as an "8-16 ft vertical rod or horizontal long-wire," was mounted on the right. (The variometer inside the turret was mounted directly below the A set bracket.) The B set (2), a "25 inch vertical rod (½ wave)" was mounted on the left. In this case, the B set is seen mounted to a wedge-like bracket, while in other instances, it is seen mounted directly to the turret roof. Some British built tanks were made with silver painted interiors, but the evidence from surviving examples "says" that Grant interiors were painted white. The engine decks have not yet been installed on this unit, and the interior color of the engine bay, including the overspray, looks white to our eyes. Regarding the exterior color, in December, 1941, the Dewer files contain a short but confusing series of cypher telegram exchanges including, "Gen. Grant contractors will return to original specification Khaki green No. 3 after present supply coranado tan (sic) runs out." This implies that the original Grant exterior color specification was Khaki Green No. 3, a darkish hue similar to US Olive Drab. It is assumed that the British Purchasing Commission would have ordered adequate supplies of this paint from US sources. On the other hand, the sentence certainly seems to indicate that some Grants (perhaps the one shown here?) were factory painted in Coronado Tan. However, we are unaware of any color photos of Grants fresh off the assembly line that might help to confirm this.

The photo on the top left shows the standard mounting of the antenna bracket on the M3 Lee, while the top right photo shows the plate before installation of the bracket. This fixture was not necessary on the Grant since the radio and antennas were installed in and on the turret. Therefore, the default configuration of the left rear plate on the Grant was clean with no antenna bracket holes. However, it is evident that some Grants were built with pre-drilled plates intended to accommodate the Lee's antenna base. We found no specific mention of this in the Ordnance documents, except the general note that, in order to expedite production, on occasion, the British program was supplied with parts from the US program and vice versa. On the few Grants that used the Lee part, two different methods have been observed for blanking off these holes. “Counting heads” from an admittedly limited sample set of period photos and surviving examples suggests that some early PSC tanks had the holes filled with two rivets (bottom left), with the right-hand rivet being larger than the left. Early Pullman Standard Grants are noted to have had the holes covered with a small bevelled rectangular plate, secured by what appears to have been a slotted domed head screw (bottom right). At present these features have been observed on some PSC and Pullman Grants produced up through October 1941. The third manufacturer, Baldwin, appears to have started out using the same method as Pullman Standard (bottom right), before changing around January 1942 to the twin rivets (bottom left). Hence the rectangular plate has been observed on both early Pullman and early Baldwin Grants, while the twin rivets have been seen on early PSC and later Baldwin Grants. For the moment, we have not seen the twin rivets on any Grants that could be identified as Pullmans.

The M3 Medium stood so high primarily because it was designed around the Wright 975 Radial, an aircraft engine with a proven history in the aviation industry. (An earlier version of this engine powered the Spirit of St. Louis on its epic flight across the Atlantic in 1927.) Wright Aeronautical only produced 750 tank engines up to the end of 1941, after which its production capacity was devoted entirely to the Army Air Corps, which had a higher priority rating than the A-1-G assigned to the Tank Program. In the meantime, the Continental Motor Company was contracted to set up its Detroit facility for the manufacture of license-built Wright 975 tank engines at the initial rate of 20 per day and increasing to 1000 per month by January 1942. At the outset, shortages of machine tools and other fixtures hampered production, which, of course, affected the Medium Tank program. The photo above is dated 8 July 1941 and shows a pair of Wright Radials awaiting installation into the first Grants at the Pullman Plant. There is some confusion about the nomenclature, but as built by Continental Motors, these engines were labeled "R-975-EC2". For our purposes, we shall use this designation to refer to the engines that ran on 91 octane aviation gasoline and were fitted with what is described as a "low outlet exhaust collector ring." In this view, the exhaust manifolds can be seen with their exhaust pipes in the so called "low" position (arrows). These were connected to a pair of mufflers mounted on the lower rear hull plate.

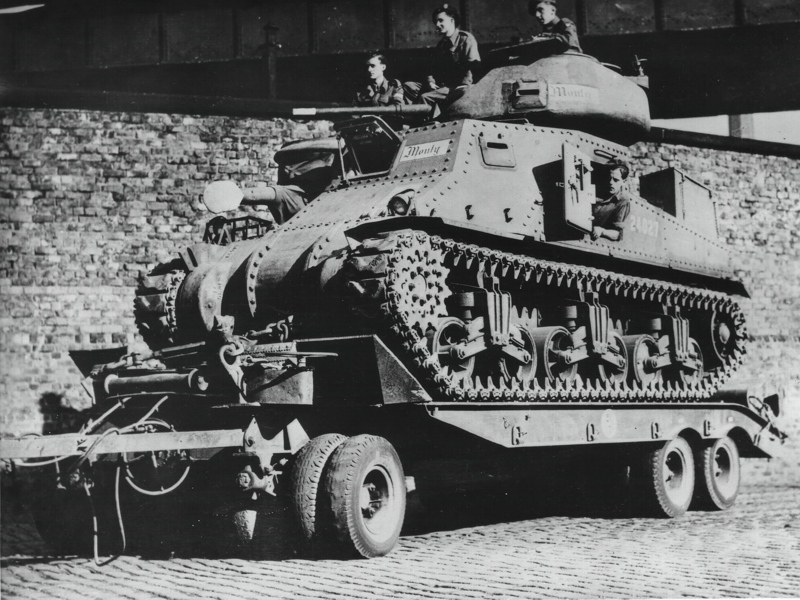

From “counting heads,” we have found that sometimes the given introduction dates of factory modifications were “wishful thinking” dependent on the promised delivery of parts. The photo above shows a pair of Grants and a Lee being offloaded at a port in the UK, 29 June 1942. It clearly shows that the suspended Grant is T-24595, which would have been accepted in May 1942 and would have been the 407th Grant produced by Pullman. According to an Ordnance Department Memorandum dated 2 April 1942, “The quick-fix modification [at Pullman] will be started in the 400th tank produced, which will be shipped about May 1, 1942.” Despite that, this Grant is seen to have the original pepper pot exhaust. This at least suggests that there was not a “hard” change over to the Quick Fix exhaust on May 1st or on the 400th Pullman Grant. It was definitely introduced at Pullman, as a photo on file at the Allen County Historical Society shows 4 Grants preparing to leave the factory with the modification. We will continue to try to count heads, but the issue is complicated by the fact that the Quick Fix became available in the Fall of 1942 as a kit, Field Service Modification Work Order G104-W16, and was distributed to the various theaters. Note that neither the 37mm nor the 75mm gun is counterweighted in the photo of T-24595. This contradicts the memo cited earlier which stated that, on Grants, the gyrostabilizer for the 37mm would be installed starting in late February and not "til March" for the 75mm. For some reason, there are very few photos of Grants in service in the UK. However, we do have a textual listing for T-24595 from the War Diary of the 10th Canadian Armoured Regiment (Fort Garry Horse). It is listed as a tank of C Squadron which was lent to A Squadron for an exercise on 9 August 1942. It appears to have been passed on to another unit, since T-24595 is listed along with Grant T-25053 with the 27th Canadian Armoured Regiment (Sherbrooke Fusiliers) on 30 April 1943. IWM photo H 21046 via Peter Brown.

The Spicer Manufacturing Company designed the "Medium Tank Transmission" in the Summer of 1940. A few months later, the Mack Manufacturing Corp. was contracted for the production of 1508 units for the US Army and 900 for the British Purchasing Commission. These figures were inadequate to meet planned Medium Tank requirements, but it was not until after the passage of the Lend Lease Act in March, 1941 that another manufacturer, the Iowa Transmission Company, was contracted to produce additional powertrains starting in September, 1941. The Grant program relied on these two manufacturers, but as with engines, production was greatly hampered by industrial shortages until the beginning of 1942. The photo above shows the first Pressed Steel Car built Grant, T-24689, during a roll out ceremony on July 13, 1941. Note the odd shaped "dataplate" (circled) affixed to the middle section of the differential housing. Some of the first Mack Transmissions had their "Medium M3 Powertrain" identification plates mounted on the exterior armor, but it was soon repositioned to the interior, where it was mounted above the transmission. The M3 Medium Transmission and Final Drive Unit weighed 7600 pounds, including a 3600 pound 3-piece armor casting that protected the front. The transmission had 5 forward speeds and 1 reverse.

There are several uncommon aspects that the Bovington Grant shares with what is observed in the period photos of T-24689. A friend recently showed us some photos taken at the Tank Museum over 50 (?) years ago. The vehicle can be seen to have a "Mack Medium M3 Powertrain" plate (circled) on the front. Furthermore, it has the "interrupted" row of rivets (arrow) such as seen in the period photos of T-24689. The default number of vertical rivets was obviously 10. However, in historic photos, we have noted a few examples missing 2 (or less often 3) rivets. Counting heads suggests that the missing rivets are more likely to be seen on early production M3s, but there are other instances that suggest that it was scattered randomly throughout Grant and Lee production. We would note that of the 107 or so known surviving Grants and Lees in the world, 3 including the Bovington, have "missing rivets." It is mentioned that PSC Grants 24689 to 24750 were shipped "deficient of sand guards." The final drive bulges on the Bovington show no weld scar evidence of ever having been installed with the fittings (#1 on inset) that held the front sections of the factory installed sand guards. The numbers "689" can be seen painted on within the white circle. "T-24689" (b/w inset) is seen painted on the other side in another photo taken at the same time. Thus, it would appear that at that time, the War Department or T-Number was known; it just got painted over and forgotten down the years.

Above is a close-up photo of the "Mack Medium M3 Power Train" plate affixed to the differential housing of the Bovington Grant. Though heavily painted, it can be seen to be stamped with the very low part serial number of 7. The "41" in the lower right, would indicate 1941 as the year that the powertrain was produced. Going by the Mack monthly production records, the 7th unit would have been accepted in May 1941. Just barely visible behind the serial number are the stamped letters "JKC".

As mentioned previously, only a few of the first Grants and Lees were built with the Mack Power Train plates attached to the exterior of the differential housing. They were immediately moved inside and affixed to the differential as seen above. This plate does not appear to have been made of brass, but it held up to the elements pretty well before the powertrain was scrapped a few years ago. Company records report that the Mack plant in New Brunswick, New Jersey produced a total of 2652 M3 Medium Power Trains plus 361 spares from February 1941 through Feb. 1943. This one can be seen as Serial Number 2136. By the monthly production figures, we'd calculate that this powertrain was accepted in August 1942. It probably took a month or so before it was delivered to a factory and assembled to a tank. By that time, Grant production had ended, and only Baldwin Locomotive was still making M3 Lees, and all were diesel models - M3A3s and M3A5s. So, this powertrain was likely pulled from one of those. Just behind the serial number are the initials "WPB" (inset). Of course, New Jersey was in the New York Ordnance District which was headed by General Walter Putney Boatwright from 1 July 1942 through 13 September 1942, so he accepted this power train on behalf of the Ordnance Department. The "JKC" noted on the powertrain plate of Serial Number 7 at Bovington are the initials of Colonel John Kay Clement who headed the NY Ord. District from 7 December 1941 through 30 June 1942, when he retired at age 60 as required by Army regulations of the time. Photo courtesy of Midwest Military.

As mentioned previously, a few of the first Grants and Lees, including T-24689, were built with two handles on the engine access doors. On the Bovington Grant, the "extra" handle is the one affixed to the left side door. There aren't many surviving M3s that still have their original pepper pot exhausts intact, so we are fortunate to be able to examine this pristine example. Unlike the M3 Medium pilot and some of the first Grants and Lees, period photos show that T-24689 was built with notched flanges where the pepper pots bolt to the hull. We consider this the production configuration. This was done to avoid interference with the rivets circled here. The flanges were not left and right-handed, so they were notched on both sides. The bottom section of the lower rear hull was a casting and can be seen as Part Number D37997 (1), with the keystone (2) indicating it was produced by Union Steel. We suspect that the "2" seen here is the (very low) serial number of the casting.

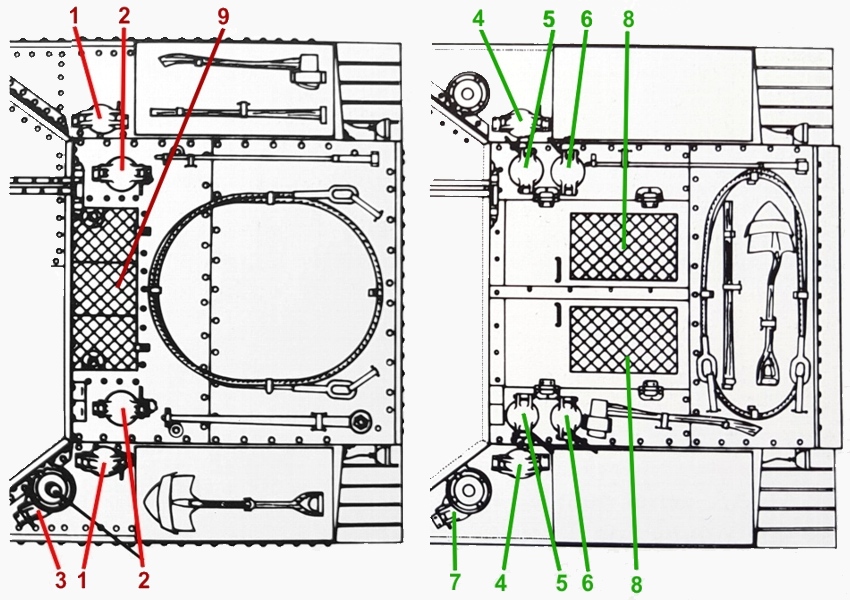

According to the M3 series Technical Manuals, the "Ammunition carried" in the Lee was 50 rounds, 75mm and 178 rounds, 37mm. The above drawing from the TM shows the quantities of the various rounds with their locations throughout the turret and fighting compartment. For instance, the "box on floor crew compartment, right side, directly behind the 75mm gun" (Item 23, highlighted in red) held 41 rounds of 75mm ammo. Not shown in the drawing are 9 rounds of 75mm which were reportedly stored "loose" in three 3-pack cartons. We have included the Lee schematic, because we have found no corresponding drawing of the ammunition stowage of the Grant as originally designed. A "Provisional List of Stowage for Medium M.3. Tanks (British Types)" was included in the October 1941 War Diary for AFV Branch, GHQ, Middle East Forces, and may provide a clue as to the Grant's as built capacity. Fifty rounds of 75mm ammo were reported stowed exactly as with the Lee - 41 rounds in a rack behind the 75mm gun, and 9 rounds in 3 cartons, "Loose, Near Loader." The 37mm capacity of the Grant is given as 182 rounds, 4 more than the Lee's capacity. A 60 round "Ammunition Rack, adjacent left door" is listed, as is a 42 round "Ammunition Rack, [on] sponson R.H. [right hand] rear." This appears to have been the same rack that is shown underneath the turret basket on the hull floor in the Lee sketch (Item 24). In its place, 20 rounds were listed in an "Ammunition Rack, under front of turret basket." The Grant turret basket reportedly held 39 rounds; none were attached to the wall of the turret itself as with the 12 rounds on the Lee. The center rear plate of the fighting compartment (Item 15) of the Lee is shown holding 13 rounds, whereas only 10 were listed on the Grant. Finally, the left rear plate of the fighting compartment (Item 16) is reported to have held 11 rounds on both the Lee and Grant.

The "Provisional List" of the previous caption was sent from British representatives in the US to accompany an August 8, 1941 "Report of the Final Inspection and Packing For Shipment of the First Two Tanks (WD Nos. T.24190 - T.24191.)" A similar Report dated a week later, was filed for T-24192. These tanks were shipped from New York to Alexandria, Egypt in August, and appear to have arrived in October, the first of the 657 Grants ultimately shipped to the Middle East. It is our theory that the "Provisional List" reflected the Grant's as designed stowage configuration, and served as an inventory check off for the tanks upon receipt in Egypt. On the other hand, there are several published sources that list the Grant's ammunition stowage capacity as 65 rounds 75mm and 128 rounds of 37mm. We think that these figures actually reflect the ammo stowage of the Grants that underwent modification in the UK according to the scheme of the Department of Tank Design as shown in the drawing above. The DTD retained the Lee's 41 rounds of 75mm "box on floor crew compartment, right side" (highlighted in red). They then replaced what we think was the Grant's "factory" 37mm ammo rack on the sponson behind the right side door with a rack that held 24 75mm rounds (highlighted in blue). For future reference, we would point out that the sponson ammo rack did not protect the rounds in any way, but simply held them in place with their tips protruding from rear.

British Lend Lease Lees, at least at first, were shipped as built. Period photos certainly show that at least some of the DTD's UK modifications applied to both Grants and Lees. However, in the Lee, it would not have been possible to add a number of the interior modifications as shown in the drawing above, given the different turret, and the fact that the Lee's radio was located on the sponson to the left of the driver. The DTD's configuration of 128 37mm rounds was quite a bit less than the Lee's, or the "as built" Grant's capacity. No doubt the UK designers sacrificed these rounds in favor of other add on items deemed essential to the crew. We believe that the 60 round 37mm bin, "adjacent left door" (highlighted in red) was as designed, and factory installed on the Grants, but not the Lees. It and the items around it could not have been installed in the same space in a Lee due to the presence of the Number 19 Radio. In any case, it has been a challenge trying to determine the historic interior configurations of the Grants and British Lend Lease Lees, since it is obvious that they we were locally modified in each theater to which the tanks were shipped. Another "mysterious" item of interest in this drawing is the exhaust fan (highlighted in blue). This is seen in a few period photos, such as the North Africa combat casualty shown in the inset.

This photo was taken in September, 1941, the second month of Grant production at Pullman Standard. Looking through the right side door, we see the same exhaust fan (1) as in the DTD sketch. This was obviously factory installed, which suggests that the British thought that ventilation of the fighting compartment was necessary from the beginning, whereas the US designers only added ventilators to the Lee starting around May, 1942. The US installation employed 3 passive "dog's bowl" type ventilators, two in the roof of the hull and one in the turret. These ventilators were adopted for use on the Sherman from the outset. The British did a sort of expedient installation of the exhaust fan that used the left front protectoscope as its air outlet, possibly because the crew member most likely to use this protectoscope in the Lee was the radio operator, whose function had been moved along with the radio to the turret of the Grant. Another item the British wanted and received in the Grant design was the driver's periscope (2). Much of the interior stowage can seen to have been labeled, and affixed to the front plate is a box containing “Drivers Periscope” (3). In the DTD sketch, this box of “2 Spare Periscopes” appears to have been repositioned to just above the 12 gallon drinking water tank (4). The Pullman interior photo set doesn't show much of the Grant's ammunition stowage, although a bit of the non skid lid (5) of the 41 round 75mm ammo bin can be seen here. Oddly, the 75mm sponson casting on this Grant appears to have been subjected to some kind of ballistic test, as evidenced by the two scoops (6) on the inside surface of the armor.

We suspect that the exhaust fan was factory installed in all of the Grants, but this has been difficult to confirm, since it is not present in the few surviving examples where we have been able to look into the interior. (Some of the fan's wires may have been dangling in a couple of cases?) We had seen some photos online of the Grant on display at the World War II Military Museum at El Alamein. This tank shows various shot gouges and penetrations, and even has an armor patch by the driver's port, suggesting that it may have been hit on more than one occasion. We can’t help but think that it is an historic battle casualty of the North Africa Campaign, and as such, might accurately reflect the Middle East interior configuration. With that in mind, in November, 2019, Pierre-Olivier flew to Egypt to examine it. His report: “The Grant was covered with many layers of paint, so there was no possibility of finding unit markings or a T-Number. The turret casting marks indicate that it was made by Union Steel, and it appeared to be turret serial number 189. A museum guard, armed with a Kalashnikov rifle, instructed me not to climb on, or even touch the vehicle. For the specific purpose of getting photos of the Grant’s interior, I brought along a tiny camera (inset), that I mounted on a telescopic extension pole. I pushed it through the partially open driver’s hatch, moved it around, and took 41 photos. The image quality is poor, but the exhaust fan (circled) mounted on the protectoscope is clearly visible.

Baldwin Locomotive was the only company that manufactured both Lees and Grants. In late 1940, the firm was awarded contracts at a little over $40 million dollars each for the concurrent production of 685 Grants and 685 Lees. The first Baldwin built Lee was accepted in June, 1941, while the first Grant was not accepted until October. A Baldwin History attributes this delay to the "radical changes" (radio turret, etc.) the British had negotiated for the Grant, "which were at variance with the design adopted by our own Government." Right up to the start of production, the British continued to push for additional modifications, until "ultimately it became necessary to freeze design changes on the British vehicle in order to secure quantity production." This "design freeze" explains why the last Grant was built with features nearly identical to those of the first. However, it should be noted that a few "radical changes" were in fact introduced into Grant production at Baldwin in early 1942. The photo above shows the first Baldwin M3 Lee at a roll out ceremony on April 24, 1941. (As mentioned, this tank was not officially accepted until June.) A "General Steel" water tower can be seen in the right background, as this foundry was right next door to the Baldwin plant.

A few months after the passage of the Lend Lease Act on March 11, 1941, the Ordnance Department took over responsibility for the existing British contracts in the US. The original agreement had been for "cash & carry," but with Lend Lease, the materiel could be provided and shipped "free." In partial exchange, British purchased plant and equipment was transferred to the US as Reverse Lend Lease. In December, 1941, the US Government agreed to give Grant production at Baldwin preference over Lee "in order that tanks needed overseas could be the first to be completed." To accomplish this, Lee components common to the Grant were diverted. Consequently, less than 20 Lees were accepted at Baldwin in the first half of 1942 as opposed to over 500 Grants. In the meantime, the Ordnance Department had successfully tested welded hull M3 prototypes in the Summer of 1941. In September, it was recommended “That the Medium Tank, M3, when equipped with welded hull, be designated: Medium Tank, M3A2.” Noting the great advantages that welding held over riveting, shortly thereafter, the Government determined to eliminate riveted construction from future tank designs. As a consequence of all of this, Baldwin was directed to produce an all welded hull Lee, which was delivered to Aberdeen Proving Ground in November, 1941. After successful evaluation at APG, M3A2 SN 1040 was officially accepted in January, 1942, along with the only other M3A2 Lee, believed to be SN 1082. (It should be noted here that SN 1040 as shown above, had a truly all welded hull. Some riveting was used on production welded hull M3 Mediums, primarily where the 75mm gun sponson casting was joined to the armor plates.) Despite Lend Lease, the British still had a "say" in matters pertaining to the Grant, and after reviewing the test results, they readily agreed to accept welded hull Grants in future production. However, only 10 M3A2 based Grants were built from January through March, 1942, as the Ord. Dept. introduced another "radical change" that affected Grant production at Baldwin.

The introduction of the twin diesel into the M3 Medium design was NOT a case of a simple engine swap, and Baldwin was given a couple of months lead time to procure the necessary parts for the diesel Lees and Grants. The size of the GM Model 6046 necessitated a number of changes to the layouts of both the engine and fighting compartments. For instance, the addition of the transfer case made the power pack longer than the engine compartment. Consequently, the firewall was altered to permit the transfer case to protrude into the fighting compartment. The width of the side by side engines forced the elimination of the two fuel tanks mounted vertically against the firewall in the original design of the M3. Externally, the side armor plates (1) and the upper rear hull plate (2) were extended down and out from the tank in order protect the dual muffler assembly which was mounted across the lower rear hull (inset). With this change, the engine access doors in the lower rear of the Radial M3 were eliminated. However, a pair of engine access doors (3) were added to the engine deck. The first diesel, an M3A5 Lee, was accepted in January, 1942. After that, production at Baldwin was dedicated almost entirely to diesel powered Grants until the British Contract was completed in July, 1942.

The engine deck drawings in the previous caption, show the removable hinge pins of the armored fuel filler caps in two different orientations. The hinges are "short and straight" on the radial engine deck drawing, but are angled on the diesel. As best we can tell from counting heads, the M3 Medium series used the "short and straight" hinge pins throughout production. These are referred to as "holding pins" in the M3 Medium Base Shop Data book. The "long and angled" hinge pins, which would have been easier for users to manipulate, appear to have been part of the Sherman design, as they can be seen in overhead photos of the earliest M4A1s and M4A2s. The photo above shows the holding pins on an early Pullman Grant. They were secured with chains to prevent loss, but we would note that many surviving Grants and Lees no longer have removable hinge pins, presumably because the chains rusted or broke, and the pins fell off. In some cases, restored M3s have had the original straights replaced with angled hinge pins. The inset shows a surviving straight holding pin on M3A5 Lee Serial Number 1355. We photographed this tank years ago when it was on display at Aberdeen Proving Ground. While the pins on the Grant appear to have had round heads, this example looks to be an unthreaded hex head bolt, approximately 7 (?) inches in length, with an eyelet welded on to the bolt head. Note as well the pressed metal label affixed to the top of the fuel filler cap with a pair of machine screws.

Evidence seen on a few surviving diesel M3 Lees and Grants suggests that Baldwin affixed some pressed metal labels on to each of the armored fuel filler covers to help the crews avoid contaminating the tanks with the wrong solutions. Label 1 reads "LUBE OIL", label 2 reads "WATER" and label 3 reads "FUEL OIL." These three fillers are mirrored on the right side of the engine deck. On the left side, there is an additional filler point, label 4 for "GASOLINE" for the auxiliary generator (inset). We would observe that on the Sherman, the labels were welded to the deck near each filler cover, most likely because the labeled covers ended up in the wrong place on occasion. Additionally, on the M4A2 [diesel] Sherman, the fuel type label was elaborated to "DIESEL FUEL OIL." Photos courtesy of Tyler Reid.

The "Report[s] of the Final Inspection and Packing For Shipment..." for T-24190-92 state that "All doors and openings have also been covered with Scotch tape to prevent ingress of moisture." In this instance, "Scotch tape" is not a reference to the small, clear home and office tape, but instead refers to one of the many masking tapes invented by the 3M Company in the 1920s, and used in the painting of cars, etc. at factory and body shops. The British anxiously awaited the advent of the US Tank Depot system, because they were told that many of the modifications that they desired in their Grants could be retrofitted there before the tanks were processed for shipment. However, the Depots were only in the early stage of organization by mid 1942, just as the final Grants were completed, and only a few were processed through them. In the meantime, the builders were responsible for sealing the tanks, and Pullman Grants can be seen covered with light colored tape. The photo above was taken in October, 1941 and shows "Tanks for Britain...sealed and ready to be packed in tarpaulins..." The tank in the foreground is T-24213, which would have been accepted in September. A few of the company's famous Pullman Railroad cars are seen behind the Grants.

The previous photo caption mentioned tarpaulins, and here we see the same "12 M-3 Medium Tanks being shipped at one time." These enormous tarps were custom made to fit over the Grants, and each one is seen with the tank's T-Number and a shipping destination code stenciled on. From front to rear are T-24213, 14 and 15. Our database can not account for the later whereabouts of the first two, but T-24215 is listed in a North Africa Report as a "General Grant Battle Casualty, 6/15/42." It would seem that the tarps were removed at some point during the shipping process, as they do not appear in photos of Grants being loaded, stowed on, or unloaded from ships. Most likely this was because the tarp would have interfered with hoisting operations. The question is what became of them after removal? In the "Provisional List of Stowage for Medium M.3. Tanks (British Types)" two tarpaulins are listed "On engine compartment and tool box." We would assume that the “big tarps” would have been highly valued by crews, and if they remained with the tanks, they would have been the item stowed on the engine compartment.

For a little chronological context, the photo above shows the first Pressed Steel Car M4A1 under assembly on February 11, 1942, not 1941 as is stamped at the top of the photo. Of course, the Sherman rendered the Lees and Grants obsolete, but even so production continued for many months with both the "substitute standard" M3, and the "standard" M4 Mediums sharing the assembly lines in a number of cases. In this photo, the Grant in the right foreground has what is most likely the build sequence number “195” chalked on the side (circled), and another further back has a sign on it with “193.” By the end of February, PSC was about half way through its Grant Production Order with 240 units completed. The M4A1, Serial Number 5, USA 3014761 was the first of eight accepted at the start of Sherman production at PSC in March, 1942. By the end of the Grant Contract in July, PSC had produced 224 M4s and M4A1s. In that month, a number of the M4A1s became part of the Emergency Shipment of Shermans to the British in North Africa. Most of the manufacturers admitted that they had never seen a tank before they took on the M3 Medium contracts. In that sense the program provided a valuable education to the builders and their subcontractors, along with the Army designers and logisticians. The US Army Ordnance Technical Committee officially classified the M3 Medium series as "obsolete" in March, 1944. However, as we shall see, Grants and Lees, in one form or another, continued to serve right up to the end of WW II, and even beyond.

Grants in the U.K.

Three of the first Grants produced (T-24689, T-24193 and T-24195) were exported to Great Britain around September 21, 1941. At that point there was no longer any danger of a German invasion, and the other 306 Grants manufactured in 1941 were allocated and shipped to the fighting front in the Middle East. It was not until late February, 1942 that another 2 Grants (ID'd as Pullmans) were exported to the UK. This was around the same time as the commencement of the first Grant exports to India and Australia. For context, the first Sherman was accepted on the last day of February, 1942 and the manufacturers began tooling up to replace the M3 Medium series with the M4 Sherman series on their assembly lines. Ultimately only 97 Grants, all of them Radials, were exported to the UK between September, 1941 and June 26, 1942. A few were used as test tanks, but most served as training vehicles until they were replaced by Shermans. In the meantime, the Department of Tank Design in Great Britain introduced an extensive series of interior and exterior modifications to the M3 Medium. The sketch above shows the external mods. The Brits had unsuccessfully requested that a number of these changes be introduced in production, including armor protection of the air intake on the engine deck (highlighted in red), and provision for an auxiliary fuel tank (highlighted in blue). We don't find evidence that they asked for factory installation of the mud chutes (highlighted in green). Period photos show that some of the 97 Grants and 119 Lees in the UK were modified with these changes, although the exact number is not known.

The photo above shows T-24500, a Pullman built Grant that would have been accepted in late March 1942. The date would lead us to think that it was one of the 49 "M3 (BR) Gas" exported to the United Kingdom in April 1942. It is the earliest Grant we have recorded that shows the counterweight for the 37mm gun, which we take to be an indication that a gyrostabilizer was installed. However, counting heads (recall T-24595 shown earlier) suggests that it may have been retrofitted in this case as opposed to a factory install. We suspect that some UK Grants and Lees were retrofitted with the stabilizer in the 37mm turret in order to familiarize crews with it, since it was standard equipment in the Ram II and all Shermans with which these units would be equipped in the future. T-24500 most likely arrived in the UK in the Summer of 1942, and we suspect it was upgraded with the UK Modification Package before being issued. The Technical Manual states that the M3 Medium carried 185 gallons of gasoline. US and British reports had it that the Radial averaged about .6 miles per gallon, providing a cruising range of about 110 miles. The "Auxiliary Petrol Tank" appears to have had about a 50-gallon capacity. If so, it would have added another 30 miles to the cruising range. We would note that, to date, the Auxiliary Petrol Tanks have only been seen on Grants and Lees in the UK. The configuration of the mud chutes is shown to good effect here, and again these have only been seen in the UK. T-24500 is on a Spring, 1943 list of 126 Lees and Grants at Mill Hill Workshops for CDL conversion, but "Not yet started." However, the tank must have been in poor condition, because on 25 November 1943, authority was given for T-24500 and 33 other Grants "to be struck off 'A' Vehicle Census and cannibalised to provide spares." With thanks to John Tapsell.

The IWM photo above was taken in front of the Weld Arms Hotel in East Lulworth, UK, most likely during the Summer of 1942. The Grant can be seen as T-25004, indicating April, 1942 production at Pressed Steel Car. This tank and the Lee in front of it (T-78937) have obviously received a good many of the external items of the UK Modification Package. The Auxiliary Petrol Tanks appear to have been the same as what can be seen on the Churchill in this photo. The "Camouflage Net Bin" on the rear of the Lee turret is reported to have fouled the "wireless aerials," and in late May 1942, it was directed to be removed from modified General Lee tanks. We would observe that the fire extinguishers seen on top of the rear stowage bins here and in the photos of T-24500 and T-25064 are the Pyrene 1.5 quart pumps, a nearly ubiquitous safety tool of the time. However, the General Grant I Stowage Sketch shows that it was intended to use the "No. 4 Essex" extinguishers, which indeed became a standard item added to Lend Lease Shermans and other AFVs processed in the UK. We cannot explain the apparent absence of the armor protection of the air intake on the engine decks. Perhaps these tanks were installed with an earlier version of the UK Modifications? In any case, although the US refused to introduce armor protection of the air intake into M3 Medium production, an armored air intake cover was incorporated into the design of M4 and M4A1 Shermans from the start. Researcher John Tapsell provided the authors with a transcription of a list of the T-Numbers of 41 Grants and 15 Lees that were "available for conversion to CDL, January 22, 1943." Our subject, T-25004 was listed as at the AFV School Gunnery Wing [Lulworth Camp], while the Lee, T-78937 was listed as at the AFV School D & M Wing. Thus, the service life of these as training tanks was probably not longer than about 6 months. T-25004 was another Grant authorized "to be struck off 'A' Vehicle Census and cannibalised' in November 1943. So, it would appear that this Grant was never converted to CDL. IWM H 22180, via Peter Brown.

One of the surviving Grants in Great Britain was recovered from the Pirbright Range at MVEE Chertsey in February, 2003. According to an article by John Gilman in the May, 2003 issue of "Tracklink," "It was the first Grant to arrive at Trials Branch in 1941." It "was used extensively for automotive trials between 1941 and 1943, when it became an "armour attack" vehicle used for assessing the lethality of the German Panzerfaust and Panzerschrek weapons." Consequently, the Grant appears to have ended its service career as a live fire platform for the evaluation of various types of armored ammunition bins. The fellows who recovered this reported that they could not find the T-Number, but that they did find traces of "1952" painted on. We had come across a list at the Patton Museum of the M.W.E.E. (Mechanical Warfare Experimental Establishment) Numbers of AFVs tested in the UK, and "1952" was listed as General Grant, T24193 (inset). This leads us to think that this was one of the first 3 Grants shipped to the UK in September, 1941. The hull was sprung during its time as a range target, but the owners were able to reassemble it. They decided to leave a lot of the shot damage in place as shown. Amazingly, this Grant is actually a runner. A few "before" photos show evidence that it was once installed with the UK Modification Package.

We thought readers might like to see these outside the tank photos of the "Mount, machinegun, M27" which held the twin bow machine guns in the M3 Medium Tank. This was acquired by the fellows who own the Grant shown in the previous caption. It consists of a gun cradle supporting two .30 caliber M1919 A4 MGs. A bearing allows the cradle to rotate up and down slightly, but not side to side. Per the Technical Manual, "The guns are elevated manually and have no traverse. Traverse is accomplished by steering the tank. The guns may be fired electrically by pressing switches mounted on the steering levers or manually by conventional triggers." Two ammunition boxes are stowed one on top of the other, with each feeding an MG. If needed, the MGs could be dismounted: "Tripods [2] are carried on the outside of the tank for use with the bow machine guns." The manufacturer's plate (inset) indicates that this mount was built by the F. L. Jacobs Co. of Detroit in 1942. During WW II, Jacobs was a major producer of tank suspension components.

From the foregoing, it can be seen that a number of the Grants and Lees in the UK were being considered for conversion to Canal Defence Lights after they were no longer required as training tanks. Thanks to the research of John Tapsell, it is possible to document the WD Numbers of at least 18 Grants that were "Completed For C.D.L." The CDL program commenced in the early 1930s, when the British began work on the development of “a high intensity searchlight for night use on the battlefield.” By mid 1940, the construction of 300 purpose built searchlight turrets had been approved, and the top secret project code named them “Canal Defence Lights.” In the succeeding years, CDL Schools were established in both the UK and Egypt. Most of the units trained with CDLs based on the Matilda II, although it is reported that one Regiment in the UK “received Churchill CDLs.” It is thought that the combined total of Matilda and Churchill CDL conversions did not exceed 300. In December, 1942, a “Rework Requirement Schedule” for tanks in the UK, ordered that “During 1943, the undermentioned tanks will require modification for C.D.L. : 195 Grant/Lee. These tanks will be withdrawn from the service and modified by the Ministry of Supply.” No other types of tanks were listed, so from this, it would appear that the M3 Medium was ultimately chosen as the most appropriate platform for the CDL going forward. Above shows the stowage arrangement of the "CDL Tank M3" in a drawing revised to May 10, 1944. It can be seen that a number of the stowage bins of the UK Modification Package were part of the design. Although they are obscured by refashioned sand shields, there is a fitting (highlighted in green) that hints at the use of mud chutes. We would observe that the new sand shields and the mud chutes have not been seen in any of the few period photos, or on the two surviving "CDL Tank M3s."

Due to the top secret nature of the project, we have not been able to document the exact number of Grants and Lees that were converted, or the time span of the conversions. Author Richard Hunnicutt quotes General J.F.C. Fuller as stating that “1850 M3s were converted to CDL tanks in Britain.” However, this number seems absurdly high. (We suspect that 185 was the original figure, but a “0” was mistakenly added in the quote.) A clue might be found in the 21st Army Group Tank State for June, 1944, compiled by Peter Brown. Note that under “Miscellaneous Tanks,” 162 Grant CDLs are listed with the 1st Tank Brigade. This unit was made up of the 11th, 42nd and 49th Royal Tank Regiments. They entered the Continent in August, 1944, and were part of the 79th Armoured Division, popularly known as “Hobart’s Funnies,” for its collection of special purpose AFVs. In any case, the fact that the 1st Tank Brigade is listed with its authorized strength of 162 Grant CDLs in June, 1944 (54 CDLs in each of the 3 Regiments), leads us to think that the Ministry of Supply may have completed the 195 Grant/Lee conversions ordered in December, 1942. The photo above is captioned "R.E.M.E. craftsmen working on General Lee and Grant, and other types of tanks in Depot...Sept 4th, 43.” By the date, we believe that the scene depicted shows the CDL conversion process at the Mill Hill Workshops of the Royal Electrical and Mechanical Engineers, located in north London. WD Numbers T-26084, T-78904 and T-26125 can be made out on the first 3 tanks on the right, and in a higher resolution image, T-26085 and T-78892 can be read on the left. All of these correspond to M3 Lees listed as "Completed for C.D.L., 1943.”

No missions were found for the 1st Tank Brigade, and in October 1944, its CDLs were returned to the CDL School at Lowther Castle in England. Two of the component Regiments of the 1st Tank Brigade were disbanded to provide badly needed crews for other British units. In the meantime, the 49th Royal Tank Regiment exchanged its CDLs for Ram Kangaroo Armoured Personnel Carriers. The unit, still attached to the 79th Armoured Division, was renamed the 49th Armoured Personnel Carrier Regiment. From mid-November 1944, until the end of the war, the 49th APCR performed admirably ferrying troops into battle. It was thought that the CDLs might serve their intended purpose during the assault crossings of the Rhine planned for late March 1945. Consequently, 28 were returned to the Continent, and issued to B Squadron of the 49th APCR. One of the reasons that the M3 Medium was chosen to become the standard CDL platform is that the sponson mounted 75mm gun allowed the vehicle to “pack a punch” despite having had its original gun turret replaced with the searchlight turret. The CDL Handbook states that the vehicle carried 77 rounds, as compared to the 50-round stowage of the M3 Medium as designed. Thus, B Squadron was able to provide not only illumination, but firepower during the Rhine crossing operations around Rees, Germany. It was reported that 2 of the CDLs “were put out of action” during the battle. The last combat use of the British CDLs appears to have occurred on April 29, 1945, when B Squadron supported the assault crossings of the Elbe River near Lauenburg. We were hoping to be able to state that “some Grants served in the ETO during WW II in the form of CDLs.” However, we cannot document that at present and due to the absence of any “combat shots” of British CDLs, we instead show one of the well-known “walk around” images of “Giraffe.” The few available period photos show some but not all, British converted CDLs with dummy guns in the turrets. Note the bull’s head insignia (1) of the 79th Armoured Division on the left side of the differential housing. Giraffe can be seen as T-39481, indicating it was converted from a Lee, not a Grant. A “comb” device (circled) is present on the middle differential section. We don’t find evidence that any Grants were shipped with these. The “comb” leads us to think that this unit was converted from one of the 252 M3 (specific type) Lees allocated to the British in March 1943. This was the final allocation of the M3 Medium type to the Brits. It took a few months before these by then obsolete tanks could be reconditioned at various Army facilities. They were then processed at Chester Tank Depot and dispatched to the UK in the Summer of 1943. The M4 bogies (2) are a curious addition, particularly because they feature "upturned" return roller arms, which did not enter the Sherman production pipeline until late 1943, well after the final 252 Lees had been sent. We suspect that this unit was shipped with M3 bogies and the M4 type were retrofitted by the British during the CDL conversion.

Peter Brown's compilation of the 21st Army Group Tank State for the immediate post war (end of June 1945), has it that 28 "Grant CDLs" were "in Depots." We would assume that over 100 other units were still in the inventory of GHQ Home Forces at the CDL School at Lowther Castle in Cumberland. The 43rd Royal Tank Regiment had been training there with CDLs since February 1945, in anticipation that it would take part in the final push against the Japanese in Southeast Asia. However, the Japanese surrendered shortly after the Regiment arrived in India, so its 36 CDLs did NOT see action in Asia during World War II. The single known complete surviving "CDL Tank M3" is on display at the Armoured Corps Museum in Ahmednagar, India. Most likely it is one of the units brought there by the 43rd Royal Tank Regiment. Despite the appellation, “Grant CDL” encountered frequently in official British documents, we suspect most were converted from Lees. During separate visits, both Jim Goetz and Pierre-Olivier looked for the tank's Serial Number on the front and rear tow lugs but there is just too much paint build up. However, the presence of the "comb" device typical of those designed and used by the Chester Tank Depot (circled) starting in late 1942, would lead us to suspect that this was another unit converted from one of the 252 reconditioned M3 Lees shipped to the UK in the Summer of 1943. It is thought that most or all of the British CDL conversions would have been retrofitted with the "Quick Fix" exhaust and air cleaner modification as seen in the photo on the right and in the drawing shown earlier. Of note is the retrofitted black out light (1) above the fixed MG ports. This has been observed in a few period photos of CDLs, although it is not present in the previous photo of "Giraffe". This item was released in the US as Field Service Modification Work Order G104-W45 on 4 May 1943. It has been noted on US CDL conversions. We would guess that the black out light was not necessarily a feature of British CDL conversions; it just came with the reconditioned M3 Lees that were shipped to the UK. Also, "Giraffe" can be seen with what we assume was a mounting plate for the cable(?) reel (2) that is installed on our subject. The guys found that the reel still spins. We are somewhat surprised that the exact purpose of this item does not seem to have been documented. This unit can be seen to have been retrofitted with the armor protection of the air intake (outlined in red and inset). Photos of Giraffe, a preserved CDL hull at the Pakistan Army Museum in Lahore and of a 43rd RTR Lee based CDL (T-39358) also show this feature.

One of the Lend Lease M3 Mediums shipped to the UK was converted to an Armored Recovery Vehicle by the British. This can be identified as having been converted from a Grant, as opposed to a Lee, by the WD Number T-23673 (not visible here), indicating a Baldwin built, M3 Grant accepted in February, 1942. This prototype was designated "Grant ARV Mk I." It was a very simple conversion designed to recover and haul disabled tanks by the use of towing cables or “the Hollybone draw bar secured to the left rear of the tank hull.” The vehicle carried a wrecker type A frame that could be assembled and mounted to the front for hoisting operations. (The British would later conclude that a winch, such as equipped US built Recovery Vehicles, would be necessary in future designs.) T-23673 was filmed in December, 1942 assisting in the recovery of a Churchill tank at the Minehead AFV Range in the UK (source : IWM). In the film, the ARV can be seen with grousers installed struggling to pull a (turretless) Churchill up a rise in a muddy field. Our photo of the "Grant ARV Mk I" shows 12 of the end connectors painted white. No doubt this was an indication of where the grousers would be installed. It is thought that the M3 Medium series was provided with 26 grousers as On Vehicle Materiel. Per the Tech Manual, "The grousers are attached to every eighth track shoe by steel pins and a cap screw..." After trials, the designers preferred a similar ARV based on the lower silhouette of the Churchill Tank, and in the December, 1942 “Rework Requirement Schedule,” it was reported, "D.M.E. [Director of Mechanical Engineering] is arranging to convert 120 Churchills...to Recovery Vehicles." Thus, it is thought that T-23673 was the only example of a Grant ARV Mk I produced. British nomenclature has caused some confusion since all versions of the US produced T2/M31 series (based on Lee conversions) were labeled "Grant ARV Mk II." This has perhaps created the impression that some T2s may have been converted from Grants, but this was not the case. Of the 1686 Grants produced, only 1 was retained in the US (for tests and historic purposes), while all of the others were shipped to the Commonwealth as complete gun tanks.

Grants in North Africa

The legend of the Grant in North Africa begins in August, 1941, when it was reported that 3 of the first Pullmans (T-24190-92) had been shipped to the Middle East. As mentioned previously, the fighting front was given top priority, and all but 3 of the 309 radial based M3 Grants produced in 1941 were supplied to the Middle East. The build up was slow since many of the early production Grants shipped were not complete, missing guns and radios and so forth. On December 16, 1941, 10 "Mediums" were listed in the Middle East - "five of which are at Schools...five in workshops awaiting issue." These "Mediums" would have been Grants, since the the first 7 M3 Lees were reported "On Ship Awaiting Sailing...as at December 19, 1941." The photo above was taken at Pullman Standard on July 25, 1941, and the caption describes them as "the first two tanks built at the Hammond Plant." These were "loaded as deck cargo...8/12/41 [August 12]...for Middle East." (Parts to complete these tanks were shipped in December.) We would note that these were the subject of "Report of the Final Inspection and Packing For Shipment of the First Two Tanks (WD Nos. T.24190 - T.24191.)" mentioned earlier in this piece. The top of the turret of T-24190 shows the "bumps" of the loader's hatch hinges (circled in red in inset 1). Inset 2 shows T-24191 after it had been processed in Egypt. The Dewer Files have it that "28Nov41...Sand guards for Grants now in production by one firm, other two start shortly." In the meantime, sand shields were fabricated in theater to M.E.E. [Mechanisation Experimental Establishment] patterns 112A & B, as part of a series of local modifications. These differed from the sand shields provided and installed at the factories. In the inset, observe the rounded front edge, and the steep angle of the rearmost section. As an aside, we would note that the first Pullman Grant was actually T-24189. For whatever reason, it was shipped "to Suez" months later, on October 27, 1941.

The records of the 3rd & 5th Royal Tank Regiments state that they were supplied with their first Grants at the end of January, 1942. The photo above was taken in Egypt in February, 1942, and shows US Army instructors providing training to crews of the 5th RTR on the operation of the new Grants. The Mechanisation Experimental Establishment (Middle East) produced a continuing series of "Modifications of Medium Tank, M3" starting in December, 1941. These mods were introduced incrementally as they were approved and the necessary parts, if any, were procured. No. 5 Base Ordnance Depot at Tel-el-Kebir, Egypt retrofitted available modifications as the tanks were processed for issue. Many of the mods involved improvements to the armament and the fire control systems. Six modifications were approved in early January, 1942, including "Fitting of sandshields," and "Fitting of mantlet dust cover to 75mm gun." However, while both American (first tank) and British (2nd tank) sand shields can be seen on these Grants, the dust covers do not yet appear to have been available for retrofit. The British sand shields seen in this and the other photos of the series, are a darker color than the tanks, suggesting that they were installed after the Grants had been repainted for the desert. Note that the interior of the side door of the tank in the foreground was not painted lighter from its original factory color. Some other of the authorised January mods were racks, and ""Ds” and straps for securing blankets, etc." One of these racks can be seen on the right front just below the 75mm gun. In April, 1942, "Removal of twin Browning guns and plugging of holes" was approved, but other photos from this February, 1942 series show the fixed Machine Guns still in place. IWM E 8493.

It is thought that the Grant made its combat debut on May 27, 1942, the second day of the Battle of Gazala. The 4th Armoured Brigade made up the tank strength of the 7th Armoured Division, and consisted of the 8th King's Royal Irish Hussars, as well as the 3rd and 5th Battalions of the Royal Tank Regiment. Each unit appears to have started the day with about 20 Grants fit for action. The Brigade was attacked at between 7:30 and 8:00 a.m. The War Diary of the 3rd RTR reported that they were assaulted on their front and flanks by over 100 Mk II and Mk III tanks, and "We destroyed about 15...before being forced to withdraw against superior odds. The enemy was definitely surprised to meet the new Grant tanks which did some good work." For the first time in the North Africa Campaign, British armored forces had a gun in the Grant's 75mm that outranged German tank guns. Nonetheless, the 4th Armoured Brigade could not withstand the onslaught of the 15th Panzer Division, and conducted a fighting withdrawal towards El Adem. The 5th RTR was not directly assaulted in the initial attacks, and survived the day relatively unscathed. On the other hand, the 8th Hussars lost all but 3 of their Grants, while the 3rd RTR reported tank casualties of 16 Grants and 3 Stuarts. One of the 3rd RTR tanks listed as "lost in action" on May 27 was T-23504, the first Baldwin build Grant. This tank appears to have been evacuated back to No. 2 Base Ordnance Workshops at Tel-el-Kebir, Egypt where it was inspected and photographed along with a number of other battle casualties by US Army Ordnance officials in June, 1942. Note the British style sand shields with their curved front fenders (1). Just visible on the left fender is the Jerboa (desert rat) divisional sign of the 7th AD (2), and the “86” Unit Serial Number (USN) (3) on the Arm of Service (AoS) marking identifies this tank as belonging to 3rd RTR. Object 4 looks very much like the vane sight that became standard issue on the Sherman in the Fall of 1943. This may be the "sights device" that C Squadron, 3rd RTR is said to have constructed and tested in early May. In any case, it appears on a number of other Grants in the US Ordnance Dept. Report.

Although not evident on T-23504 in the previous photo, the 3rd RTR records state that on 16 March 1942 "Camouflaging of tanks commenced." The photo above is dated 29 March, and shows T-24243, the last of 19 Grants produced by Pullman Standard in October 1941. According to the Dewer files, this tank was shipped "with accessories" on 17 December 1941, from NY to Alexandria aboard the S.S. Hindanger, a Norwegian Merchantman that was later sunk by a U-Boat in September 1942. On 6 July 1941, the British War Office required "tanks to be numbered before shipment." Photos suggest that the WD Number was painted on in a light color, most likely white, at the 3 plants that manufactured Grants. The Number was positioned about 18 inches behind the side door and centered on 3 small vertical rivets that denote the location of the firewall. In-theater photos such as the above, show that in many cases, the original T-Number was masked off when the tanks were repainted. The camouflage pattern on this example appears to be solid countershading at the upper parts of the turret and hull, with some darker blotches sprayed around below. The bogies were also dark "striped" in the middle. The circle on the turret denotes C Squadron, with “HQ” for “Headquarters Troop” perhaps painted on inside. A cartoon figure in fighting stance is seen painted on in front of the side door. We would consider this a "fresh" paint scheme. Unit Diaries mention that activities and operations were greatly affected by frequent sandstorms or "khamseens." These played havoc with mechanical systems, and "sand blasted" vehicle paint jobs, which, no doubt, altered their appearance. This Grant is equipped with the American or factory installed sand shields said to have been introduced on the 32nd unit made by Pullman, which by our math would have been T-24220, accepted in September 1941. T-24243 was reported "lost in action" on 30 May 1942, when the 3rd RTR "supporting the 22nd Armd Bde," attacked elements of the 21st Panzer Division near Bir El Harmat. “We lost four GRANTS and withdrew.” IWM E 9915.

A modification that was approved in April was "Increase the stowage of 75 amn to 80 rds and armoring bins." On April, 10 the 3rd RTR reported that "All Grant tanks modified for new ammunition basis of 80 – 75 m.m. and 80 – 37 m.m." Thus what we believe was the Grant's as designed 182 37mm round capacity appears to have been decreased in order to make room for 30 additional 75mm rounds to supplement the tank's original capacity of 50. More significant was "armoring bins." From the start, the British were concerned about the vulnerability of the ammunition in the M3 Medium, and later in the Sherman, and made urgent recommendations to the US Ordnance Department. Mostly for production reasons, over a year would pass before changes could be implemented to the Sherman's design to better protect the ammo. One of the photos in the US Army Ordnance Report shows a stowage bin mounted on the sponson just behind the side door on the right. It has holders for 16 75mm rounds, and appears to have been fabricated out of 1/4 inch armor plates. The door of the bin can be seen laying on the sponson “shelf.” Compare this to the unarmored 24 round rack of the UK DTD design shown earlier. Armoring of the bins in a similar manner was a main feature of the US "Quick Fix" ammunition protection modification introduced in the Sherman in the Fall of 1943. It is thought that, in the MEE configuration, the rest of the 75mm rounds were stored in less vulnerable locations on the floor of the tank. Our guess would be that the original unarmored 41 round bin directly behind the main gun remained as built, and that the other 23 rounds were stowed in armored bin or bins in the middle of the hull floor in space that was formerly taken up with 37mm round stowage. “Armoring bins” would also have applied to the 37mm rounds stored in racks, but we suspect that those rounds attached to the turret basket would have remained unprotected. The Grant in the photo was T-24260 (Pullman, Nov. 1941 production, unit unknown), and the caption refers to damage to "extra 75 mm. round containers," but makes no note that they were armored. The hole at the side door shows where a “German 50 mm. A.P.- H.E.” round entered, and “burst just inside..but did not set off any unused rounds.”