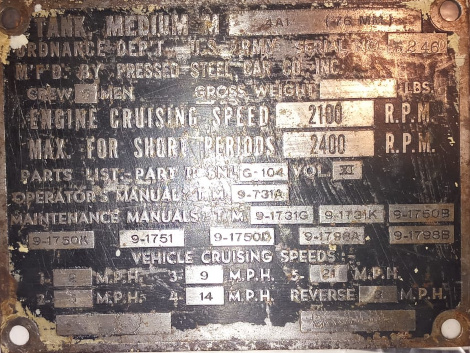

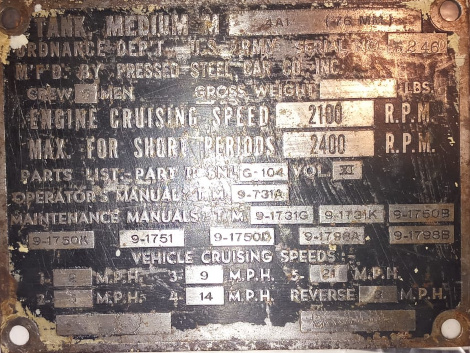

M4A1(76)s manufactured by Pressed Steel Car

Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

Introduction - First trials

In August 1942, a few months

after Shermans began rolling off the assembly lines, the Ordnance

Department

began testing the feasibility of mounting a 76 mm gun in the standard

D50878

turret (below left). The intention was to produce 1000 76mm armed

Medium Tanks

by the end of the year. Ultimately, the project was cancelled because

it was

determined that the small turret was unsuitable. In the meantime,

development

work was initiated on new Medium Tank designs known collectively as the

T20

series. The T23, which mounted a 76mm gun in a larger turret, was never

standardized due to various technical problems (below right). However,

since

the 69 inch diameter turret ring was the same as the Sherman's, the

T23's 76mm

turret was easily adapted for use on the late 1943 revision of the M4

series.

Click on the picture for larger size

____________________________________________________________

First "large hatch" M4A1s

An interesting anomaly that has been observed exclusively on the D82081 turrets used on the earliest M4A1(76)s is the absence of the rear ventilator. Unlike the Sherman, the T23 Medium Tank was designed with a powerful hull ventilation system that did not require a separate turret ventilator. Eventually, the specifications for adapting the T23 turret to the Sherman series called for the addition of a ventilator. However, the Army was anxious to get the 76mm Sherman into production, and Pressed Steel Car was "the only tank facility which would undertake the new type vehicles and promise delivery for a deadline date in January of 160 of these vehicles to meet urgent requirements of the using forces." Thus, in the rush to production, the first M4A1(76)s were manufactured before the ventilator specifications were finalized. The Union Steel Corp. was the main turret supplier to Pressed Steel Car. Many US turrets have their serial numbers cast in fairly large on one or both sides, making it possible to "count heads" on this omission. The ventilator appears to have been added to their turrets at around number 450. In the above photos, one can see how the locations of the various MG stowage fittings differed on the ventless turret compared with the vented.

Another glitch exclusive to the M4A1(76) was also likely related to the rush to production. It was remarked in internal memos that, in the first few months of production, the split hatches didn't open past the vertical position, thereby interfering with the operation of the anti-aircraft machine gun, and making for an uncomfortable traveling position for the loader. The hatches had been redesigned to open outward to 45 degrees, and it was suggested that a field repair order be issued. The above photos show two views of USA 3070707, a 32nd Armored Regiment, 3rd Armored Division Sherman knocked out near Bergerhausen, Germany, circa March 1, 1945. This tank was the 211th M4A1(76) made, and would have been accepted in February 1944. Most likely, it was one of the "UK orphans" described below. In any case, aside from the fact that the crew has reversed the “factory” position of the hatches, this turret reflects the appearance of the early Union Steel - vertical loader's hatches, no ventilator, and "unthreaded" M1A1 gun.

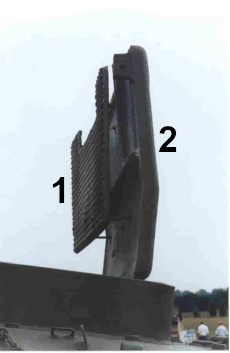

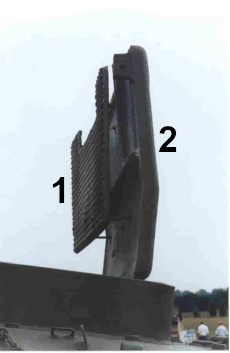

The photo on the left shows the initial, problematic configuration of the loader's split hatch as mounted on a ventless Union Steel turret with serial number 271. Assuming that this hatch is original to turret 271, we would note that this is the highest US turret serial number we have seen with the original loader's hatch. Our friend, Michael Lembo, was able to demonstrate that the hatches would not open past the vertical position. Although this tank had been remanufactured in the early 1950s, the hatch and missing ventilator issues were not addressed. The photo on the right shows the revised loader's split hatch. The positive hatch lock mechanisms (1) that can be seen, are the same type as had been introduced on Shermans starting in the Spring of 1943. It is thought that PSC began the transition to the revised loader's split hatch in March, 1944 at around US turret 260, and that Chrysler used them from the beginning of M4A3(76) production in March, 1944.

An Ordnance Department document states that "All Medium Tanks M4 series (76mm gun) since first 385 produced have been equipped with threaded gun tubes." This suggests that the unthreaded M1A1 guns as seen on the early M4A1(76)s, would have been replaced in production with threaded M1A1C guns sometime in March, 1944. Chrysler began M4A3(76) production in March, and a small number of their first tanks have been noted to have had unthreaded guns as well. The above photos show two views of "Gila Monster," Serial Number 37936, USA 3070533, the 37th M4A1(76) made. It was used in various tests at APG, including May / June 1944 trials of the muzzle brake installation. Some items of interest include the "uncovered" vent between the drivers' hatches (1), the provision for an antenna on the left front of the turret (2), the blanked off fuel filler hole (3), the "vertical" loader's hatches (4), and the early version of the sharp nosed differential housing with cast in steps (5).

Radial engine Shermans had four main fuel tanks, and on the M4 and M4A1(75)s, each had its own filler point. As part of the second generation redesign, M4A1(76)s were plumbed in such a way that only a single filler point was required for the two fuel tanks located on either side of the hull. The photo on the left shows the original four point configuration, as seen on one of the last M4A1(75)s made, a large hatch model. A few early production M4A1(76)s have been seen to have the configuration shown in the middle photo, where excess older parts were used, and the unnecessary holes were simply blanked off. The right side photo shows the standard M4A1(76) configuration. The small tags seen near the armored filler covers read "GASOLINE." The addition of the "LUBRICATING OIL" filler point prompted the use of "GASOLINE" labels at the other 3 filler points on the M4A1(76) and M4(105).

Early M4A1(76)s had straight return roller arms (1), such as can be seen on USA 3070551, a January 1944 production tank that served with the 3rd Armored Division, and was photographed in Chenee, Belgium on September 7, 1944. While Chrysler and Fisher Body had completed the transition to the later upturned return roller arms (inset) by the beginning of 1944, Pressed Steel Car does not appear have completely replaced the earlier straight arms until the Spring. The periscope guards that can be seen were a standard feature of all second generation Shermans.

A few of the earliest M4A1(76)s were built with the first version of the E8543 differential cover that featured cast-in steps (circled). Period documents mention that the cast-in steps interfered with the crew's ability to work the quick release towing shackles. Consequently, the differential castings were altered to eliminate the cast-in steps, and metal strip steps were welded on instead. It is thought that PSC's supply of diffs with cast-in steps would have been exhausted after the first few months of production. Our example shows the M4A1(76) on display in La-Roche-en-Ardenne, Belgium. The serial number is unknown, but the hull number is 3904, suggesting it was built in February 1944. The tank was restored somewhat, so it can't be assumed to have all of its original components. However, it shows no evidence of having had the usual postwar upgrades, and the ventless Union Steel turret with Serial Number 206, the unthreaded 76mm gun, and the early E8543 differential are certainly appropriate to a February 1944 production unit. We strongly suspect that this tank was a WW II battle casualty. Should any readers have any information about its history, please contact us.

In early 1944, a special task force of 156 of the first M4A1(76)s was sent to the UK for familiarization. They evoked little interest from US armored commanders whose troopers had been training for the Invasion for many months with M4 & M4A1(75)s. Confrontations with heavy German armor in Normandy aroused interest in the "orphan" M4A1(76)s sitting idle in England, and General Bradley ordered that they be shipped to France to take part in First Army's upcoming Operation Cobra. 120 were evenly distributed to the 2nd and 3rd Armored Divisions, and they made their combat debut in late July 1944. On the left, a tank of the 67th Armored Regiment, 2nd Armored Division "enters the village of St. Sever Calvados, France. 3 Aug 44." Note the cast in steps on the diff. "Duke," USA 3070582 of the 66th Armored Regiment, 2nd AD (right), was one of the last M4A1(76)s accepted in January 1944. It was photographed in Coutance, France during Operation Cobra. The rubber chevron tracks are the primary type seen in period photos of the "orphan" M4A1(76)s. For future reference, note that Duke has an "unframed" exhaust deflector, and lacks support gussets in the area of the air cleaners.

The photo above shows the M4A1(76) with ventless turret on display in Nehou, France. We suspect that this was one of the 421 M4A1(76)VVSS Shermans remanufactured and supplied to France as Military Assistance in the early 1950s. The upper right section of the remanufacturer's dataplate is shown in the inset, and it can be seen that this tank is Serial Number 37939, which is an exact mathematical match to USA 3070536 shown in the previous caption. Thus, it would seem that this tank survived WW II, and was repatriated back to the US. This Sherman obviously received a number of upgrades during remanufacture, such as a new 76mm gun with muzzle brake and the canvas mantlet cover fittings, but the Union Steel turret Serial Number can be seen as 45 (inset), the same as noted, and in the same location, as in the period photo. The tank currently carries tactical markings in honor of the 35th Tank Battalion, 4th Armored Division. Perhaps at some point it could be remarked to reflect its WW II service with the 32 Armored Regiment, 3rd AD?

The Ford V8 engine was considered superior to the Continental Radial of the M4/M4A1 series, and it was the policy of the US Army to attempt to equip its fighting forces with as many M4A3s as possible. Consequently, the US did not employ large numbers of M4A1(76)s. Indeed, we can find no evidence that the US received any additional units in 1944, and no evidence of combat use outside of the European Theater. The British did not "require" any 76mm Shermans, as they considered the HE round to be inferior to the 75mm's. However, they agreed to accept 1330 M4A1(76)s in 1944, since there weren't enough 75mm Shermans available to meet their Lend Lease requirements for the year. This was almost the entire production of M4A1(76)s up to October 1944. Those allocated to the Mediterranean Theater of Operations were used by British and South African armored units. In the European Theater, the Polish 1st Armoured Division appears to have been the only unit to have utilized the "Sherman Mk IIA" (British nomenclature for M4A1(76)VVSS ). Tank Situation Reports state that they had 51 units at the end of December 1944. By the end of the War in Europe, the Poles are listed as having 181 M4A1/76s along with 40 “17 pdr” (Firefly Shermans). An additional 97 M4A1/76s are reported in 21st Army Group Depots in June 1945. Above shows a Sherman IIA of the Polish 10th Armoured Cavalry Brigade, KO'd in the Netherlands in late 1944.

Much greater use of the Sherman IIA was made by the 15th Army Group in Italy than by the 21st Army Group in Northwest Europe. The first issues appear to have occurred in September, 1944 when the British 1st Armoured Division was reported with 28 units, and the British 6AD with 2. The 1st AD was broken up a month later, due to an inability to replace casualties; however, its 2nd Armoured Brigade survived as an independent entity. At the end of 1944, the 2nd AB was reported with 116 Sherman IIAs on strength, while the 6th AD reported 42, the 7th Armoured Brigade reported 61, and the 6th South African AD reported 134. Thus, total unit holdings were 353 Sherman IIAs with an additional 65 in “Tank Replacement Group.” By the end of the War, total unit holdings had decreased to 329 units, while the “Tank Replacement Group” pool had more than doubled to 144 plus 11 in “Training.” The photo above is captioned “A Sherman tank of 2nd Armoured Brigade crossing the River Rabbi at San Martino, 9 November 1944.” The 2nd Armoured Brigade consisted of The Queen’s Bays, 9th Lancers and 10th Hussars, and this Sherman IIA has been identified as belonging to B Squadron, The Queen's Bays (aka 2nd Dragoon Guards). It features the revised loader's split hatch, introduced at PSC in March, 1944. Courtesy of Imperial War Museum, NA 20043.

The 6th South African Armoured Division appears to have been the largest user of the Sherman IIA in the Mediterranean Theater. Its regiments began replacing some of their 75mm Shermans in November, 1944, and a 15th Army Group AFV Situation Report states that, “as at 30 December, 1944,” they had 134 M4A1(76)s. By the end of the War, this number had decreased by 6, due to losses and “wastage” during the final offensive. The photo above, dated April 20, 1945, shows elements of the Special Service Battalion of the 6th South African AD massing in preparation for the attack on Bologna, Italy. Despite the late date, all of the M4A1(76)s that can be seen have the earlier split loader's hatches. The tank in the center foreground even has a ventless turret. Note that the loader's hatches are open to the standard, 45 degree position. The commander's cupolas are not in the standard or "as built" configuration. It would appear that the unit reoriented the cupolas so that the hatches opened further to the rear. Some Firefly (17 pounder) Shermans can be seen on the far right. The Division was attached to the US 5th Army for the Spring 1945 Offensive, and according to their records, each of the 3 Squadrons of the SSB had 13 M4A1(76), 3 M4A4 based Fireflies and 3 M4(105)s.

The final M4A1(76) allocations to the British were for 150 units a month from August through October, 1944. We estimate that most of these would have been equipped with oval loader's hatches, and perhaps a few from the October production would have included muzzle brakes. However, we have not come across a "combat shot" of any of these in Commonwealth service. These tanks would have arrived in Europe in late 1944 / early 1945, at which point they could not be absorbed, and thus were no longer needed by the shrinking Commonwealth forces. The above shows a nearly as built M4A1(76) with oval hatch on display at the School of Armour in Bloemfontein. On January 3, 1947 the South Africans obtained a “property consent to retransfer” from the US Lend Lease Administrator. As a consequence, it was agreed that, subject to availability, 67 Sherman M4A1(76)s, 15 M4(105)s, 15 M4 based Fireflies, and 1 M32B1 ARV would be transferred from British Military Holdings in Italy to the South African Forces. It is thought that all of these were shipped to South Africa within the year. At any rate, thirty-two M4A1(76)s are listed in an inventory of the 1st Special Service Battalion, Potchefstroom, S.A., March 31, 1948. Most likely, the South Africans would have chosen to purchase unused or low mileage tanks, and the example shown is reported as in running condition. This tank and the other surviving S.A. Shermans, could still have their original dataplates, so if any readers are in the position to examine any of them, we would greatly appreciate a report.

An oval loader's hatch had been added to 75mm turrets in late 1943. In an effort to simplify the original D82081 turret design (left side photo), the Ordnance Department adopted this concept, and replaced the original split hatch with an oval hatch. The new turret casting carries part number 7054366 (right side photo). The split hatch had a machine gun pintle and loader’s periscope built in, so with this change, an MG pintle (1) and loader’s periscope (2) were added to the roof of the turret. Ordnance documents state that all M4A1(76)s built after August 1, 1944 received the new model of turret. The loader's hatch was the same size and shape as the "large" drivers' hatches, that is approximately 24 inches long and 19 inches wide. In comparison, the oval hatches of the 75 and 105mm turrets were about 21 inches long and 16 inches wide. Note that the 7054366 turret was not machined out for the left front antenna, although the casting retained the tell tale "bump out" to the end of production. We would note that, while this "bump out" is present on some other companies' 76mm turrets, it is most prominent on Union Steel castings.

Pressed Steel Car had produced 776 M4A1(76)s by the end of May, 1944. If we assume a loose chronology to the turrets, then we might speculate that Union Steel turrets with 8xx serial numbers would have started to appear in June. The D82081 turrets shown above are 881 on the left and 873 on the right. The left front antenna is NOT machined out on these examples. On Union Steel turret 831, shown in the previous caption, the antenna is machined out. This gives us a fairly good idea of the "eliminate the front antenna" transition point. While we don't assume that surviving Shermans have their original turrets, the tank serial or build sequence numbers of all 3 of these M4A1(76)s indicate that they were accepted in June, 1944.

As mentioned previously, most Union Steel turrets have their serial numbers cast in fairly large on one or both sides. A "1" or "2" is seen above or below the serial number. We believe this indicates that Union Steel 76mm turrets were cast using either mold 1 or mold 2. From "counting heads," mold 2 appears to have been changed from a D82081 (split hatch) casting to a 7054366 (oval hatch) casting at around serial number 1000, whereas mold 1 was changed at around serial number 1350. Thus, one might see an earlier split hatch casting with a higher serial number than a later oval loader's hatch casting. For instance, the photo on the left shows a mold 1 D82081 turret with serial number 1310, while the one on the right is a mold 2 7054366 turret with serial number 1043. (Right side photo courtesy of Tom Gannon.)

As noted above, a sheet metal cover over the ventilator between the drivers' hatches was introduced at Pressed Steel around July, 1944. This was requested by users in order to provide some measure of weather protection. The authors have not found any evidence that modification kits for the covers were sent overseas during WW II, but have noted that many surviving Shermans that obviously didn't have this item factory installed, had it added later during postwar upgrades. The U bolt that can be see on the uncovered example above held the padlocks for the drivers' hatches.

The 20th Armored Division arrived in Le Havre, France in February 1945. They brought their equipment with them, and oddly, at this late stage, most or all of their Medium Tanks appear to have been powered by the Continental Radial engine. Their M4 and M4A1(75)s had been recently remanufactured in the US. Their M4A1(76)s were new production, and included some units with muzzle brakes. The above, dated February 24, 1945, shows soldiers at the Division's depot in Bouchy, France unpacking the contents of the On Vehicle Materiel (OVM) boxes in preparation for installation in and on the tank. An item of interest here is the automobile style horn (1 and inset). The June 1944 M4A1(76) Technical Manual only provides details about the siren that was standard equipment from the beginning. However, it is obvious from period photos that most second generation Shermans were equipped with a horn. PSC appears to have replaced the siren with the horn in the Spring of 1944.

Pressed Steel Car used just about every type of VVSS road wheel on the M4A1(76)s it produced in 1944. In the early months, units were equipped with either the welded spoke (A) or pressed spoke wheels (B). The welded spoke with "small holes" (C) and the solid, concave wheels (D) appear to have replaced the earlier types in the Fall of 1944.

The snapshot above was found in a photo album of the 143rd Armored Signal Photo Company. It is entitled "Bridging the Wesser," which 3rd Armored Division records report was done starting 7 April 1945. We like to record turret serial numbers, when possible, but despite a close examination of the original print, we could only discern that the SN was "probably" 2165. In any case, it is pretty high. For what it is worth, the highest Union Steel turret serial number we have noted in an overseas WW II photo appears to be 2237, seen on an M4A1(76)VVSS of the 741st Tank Battalion photographed in western Czechoslovakia shortly before or after VE-Day, 8 May 1945. In the photo above, the larger diameter hubs suggest that the road wheels are the "welded spoke with small holes" type. This tank has what appears to be an armor plate attached to the front. The broken extended end connectors illustrate the problem with these fittings. The fact that this tank barely fits on the runners of the pontoon bridge illustrates why the Engineer Corps "non-concurred" with any changes that made the Sherman longer, wider or heavier than the original design..

Above shows Serial Number 67743 / USA 30125772, photographed at Aberdeen Proving Ground shortly after it was accepted in December, 1944. Towards the end of M4A1(76)VVSS production, along with the welded spoke with "small holes" wheels, PSC employed the solid, concave wheels seen here. Although “mixed” road wheels can be seen in many photos of tanks in service, it is thought that a single type was factory installed on each unit by the original builder. Also towards the end, metal tracks appear more frequently than rubber. On this unit, the Union Steel turret serial number looks to be 2103. Other items of interest include the installed rear view mirrors (1), and the installed "driver's hatch hood" (2) for use in foul weather. For power, the windshield wiper and defroster were plugged into a utility outlet on the instrument panel. When not in use, this item was stored on a shelf above the transmission.

The French Army received a small number of M4A1(76)s during WW II. These were not officially "charged" as Lend Lease but were provided as replacement tanks from US Army stocks. An example is provided in the 17 February 1945, document reproduced above. It states that 5 M4A1(76)s that came in through "Delta Base" (Marseilles) "were later reloaded and shipped to the French First Army." The USA Registration Numbers given indicate that all of these had been accepted in October 1944. During WW II, it took on average 4 to 5 months to get a newly built tank from factory into the hands of combat troops. This appears to have been the case with these M4A1s, as most likely, it would have taken another week or so for these tanks to have been shipped, processed and delivered to French troopers. Due to the logistics, very few Shermans built in December 1944 or later ever served in combat in any theater during WW II. The M4A1(76)s listed may have been issued to the 2ème Régiment de Cuirassiers since they reported receiving some on 22 February 1945.

Most of the world's surviving M4A1(76)s were rebuilt in the US postwar. A few examples on display in Europe are still in close to WW II configuration. We believe Serial Number 52370 was one of the few M4A1(76)s received by the French as replacements in early 1945. It has the "serial number stamped inside a box" (inset) seen on many surviving French Shermans. It would have been accepted in October 1944. The corresponding Registration Number for SN 52370 is USA 3084967, and this number is listed in the French transfer document of 17 February. Some clues of WW II configuration would be the presence of spot light (1) and smoke mortar (2) fittings, and the absence of muzzle brake and mantlet cover fittings. An original "two fingers" gun travel lock (3) would also provide a hint. The Union Steel turret serial number is 1689, and in one photo of Rivoli II, the turret SN also appears to begin with 16. This tank does not show any penetration damage, so we would guess it continued to serve with the French Army after WW II. It was probably cannibalized for parts, before being placed on display as a monument. Update: This Sherman has since been restored to running condition, and as of 2021, it was located in Saint-Méloir-des-Ondes, near Cancale in Britanny.

We have not as yet come across any documents that state the exact number of M4A1(76)s with HVSS that were produced by Pressed Steel. A handwritten note dated 9 April 1946 reads, "Crowley says that all acceptances from Pressed Steel and Fisher after 1 Jan 45 were wide track." We take this to mean that the 1255 M4A1(76)s built in 1945 were all HVSS. If accurate, it would indicate Serial Numbers 67911 and higher. This is confirmed by our "counting heads" method, although PSC may have done a few "test shots" in December 1944. For instance, SN 67901 was reported as "equipped with horizontal volute suspension (E8) and T-80 center guide tracks" and used in various tests at Chrysler's Tank Arsenal Proving Ground from January through April 1945. Above shows Serial Number 67927, a January 1945 production unit. Note that the round fender supports used on the M4A1(76)HVSS were adjustable to the contours of the cast hull. For comparison, the supports used on welded hull models are shown in the inset. PSC completed the transition from the original T66 tracks seen here to the superior T80 tracks by March or April.

Between April 6 and April 24, 1945, 169 "M4A1 (76mm gun) 23" track" are reported to have been allocated to units of the US 12th Army Group. Keep in mind that "allocation" is not the same as "reception." Considering that most of the US Army in the ETO had "ceased combat operations" before the end of April, it seems unlikely that many of these could have been shipped and processed in time to have "fought" before V-E Day, May 8th. The photo above presents an interesting possibility. It is part of a series G.I. snapshots taken in the ETO, in what was either the Spring or Summer 1945. Unfortunately our subject is undated and uncaptioned, but shows an M4A1(76)HVSS with that sort of “lived in” look of a combat tank. The M4A3(76)VVSS behind it can be seen with the tactical markings of the 17th Tank Battalion, 7th Armored Division. We would note that the 17th TB was engaged in active combat operations right up to May 8, 1945. The trees are in full foliage in the photo, which may or may not provide a clue as to whether this could have been taken before the German surrender? At any rate, this tank can be seen with the same T66 tracks as in the photo of the January, 1945 production unit of the previous caption, but it differs in that it has the M3 Lee type drive sprocket (1), and the mantlet cover fittings (2), although not the cover itself. No doubt this tank would have had a muzzle brake factory installed, although here it is obscured by a cover. The M4A3(76) in the photo can be seen with a muzzle brake, but it looks kind of “German” to our eyes. In early February, 1945, the 17th TB “had an opportunity to test the comparative merits of the muzzle break (sic) on the 76mm tank gun...The gunner firing the gun with the muzzle break was able to sense every round that he fired whereas the gunner using the gun without the muzzle break could only sense about one third of the rounds that he fired due to the smoke and flash that covered his sight. All of our gunners are really sold on the muzzle break and we are anxious to get them on all the tank guns.” Indeed, the tankers of the 7th AD appear to have been anxious enough to have procured some muzzle brakes from outside of regular channels. We have seen period photos of at least six 7th AD M4A3(76)VVSS Shermans retrofitted with what appear to be German (Panther?) muzzle brakes.

A bit of minutia regarding the little "bump stops" circled in the above photo and in the inset is that they are rarely seen in period photos or on surviving HVSS Shermans made by Chrysler. On the other hand, they are almost always present on Pressed Steel Car and Fisher Body Shermans. The original Chrysler design did not include the bump stops, but since PSC and Fisher started HVSS production over 4 months later, their initial orders must have been for the revised parts, with the stops added as a safety feature. Fisher designed the alternate, fabricated HVSS suspension arms that can be seen on the middle bogie of our example on display in Rosenau, France.

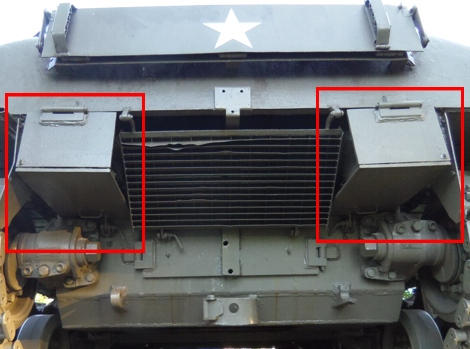

A number of other changes were introduced on the M4A1(76) in 1945. It has been difficult to "count heads" on the canvas mantlet cover due to the fact that it was almost universally retrofitted to post war rebuilds. We would guess that it was factory installed by PSC starting in February or March, 1945. A Technical Bulletin had been released in September 1944 noting that "The grouser compartment plate...is very often bent in when the track is thrown, resulting in damage to the air cleaner." Specifications were given for the addition of scrap steel reinforcing plates. These were added "in the field" to some M4 and M4A1 Shermans, but PSC doesn't appear to have factory installed them until February or March, 1945. The above shows Serial Number 68252, a March production unit which was the subject of an Inspection Control Test at APG. Both the reinforcing plates (1) and the mantlet fittings (2) can be seen. Other items of interest include the single rear towing lug (3), the "framed" exhaust deflector (4) and the M3 Lee type drive sprocket (5). Note as well the absence of the armored first aid box.

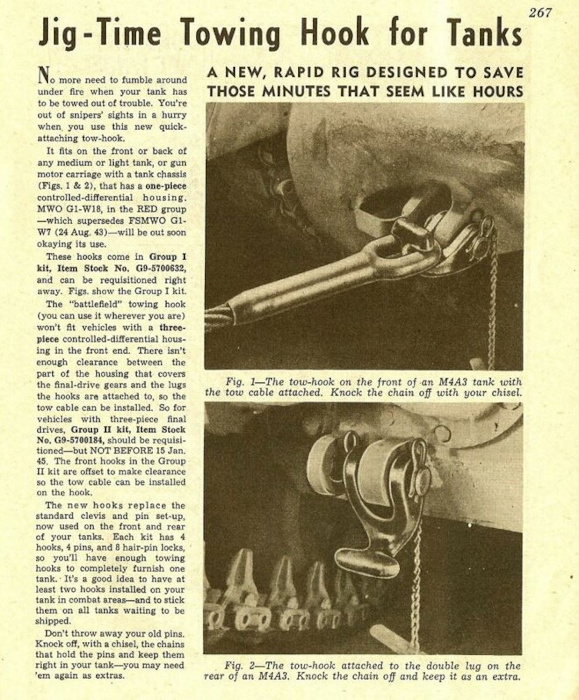

As mentioned previously, the original quick release towing fixtures (left) were replaced at PSC with "even quicker" release T-shaped shackles around October 1944. A tow cable could be hooked on to the new shackles without removing them. This saved crews a few seconds when attempting to retrieve a tank while under fire. It was no longer necessary to have two tow lugs per side with the new shackles, but the "extra" lugs on the differential were retained since they also provided attachment points for the steps. In the rear, the examination of surviving M4A1(76)s suggests that production began with double rear tow lugs, and the transition to single lugs was completed in December 1944. Thus, we have a few of the final VVSS units made in December 1944, and all of the M4A1(76)s built with HVSS with the singles. Restorers and modelers should note that the T-shaped shackles are not seen in WW II combat photos before 1945.

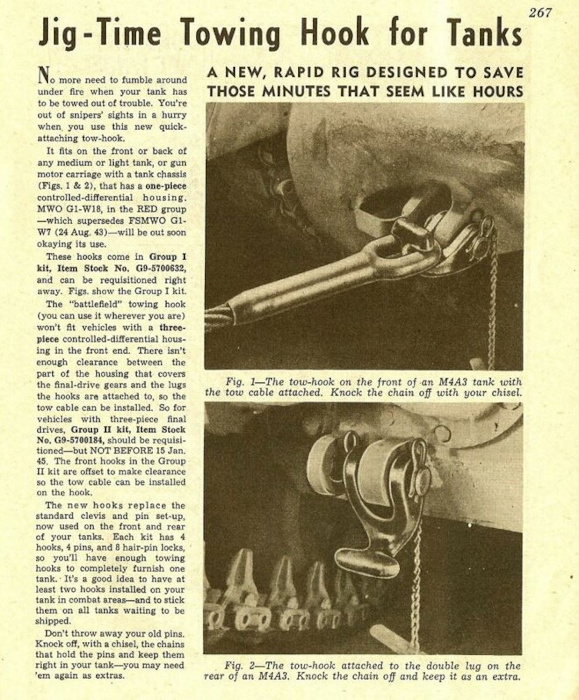

Here is a page from the December 1944 issue of "Army Motors" magazine that details the installation and use of "A new rapid rig designed to save those minutes that seem like hours." Modification Work Order G1-W18 "will be out soon okaying its use." In other words, the kits would be available for requisition "soon" and could be retrofitted "on the front or back of any medium or light tank, or gun motor carriage with a tank chassis that has a one-piece controlled differential housing." The article describes the T-shaped shackle as "the "battlefield" towing hook" which seems as good a name as any. "Army Motors" was published from May 1940 through September 1945 and featured a number of cartoon characters created by comics pioneer Will Eisner who had been drafted into the Army shortly after Pearl Harbor. Most memorable was "Joe Dope...a lazy, corner-cutting goldbricking private who did everything wrong. Eisner created the character and used him (and comics) to teach the new GIs what to do and not to do with their equipment; how to use and take care of it and keep it running in combat conditions. This was a new concept to the military and took a bit of selling. It proved to be a huge success and Eisner's instructive comics appeared first in the magazine Army Motors and later in PS Monthly during the Korean War."

The photo on the left shows the air deflector as originally designed by the Barber-Colman Co. in January, 1943. This was used on M4A1(76)s until "late 1944," when a slightly more rigid version with "framed" sides was introduced.

The first tanks produced by Pressed Steel Car were M3 Grants. PSC continued to use the M3 Medium type of drive sprockets on their Shermans until the beginning of 1943, when they transitioned to what we informally call the "plain" sprocket, as shown on the left above. These were used by PSC until 1945, when a sprocket with an M3 type appearance (above right) was (re)introduced. No doubt, the "breaking teeth" problem that plagued the originals had been remedied. Period photos suggest that these were used along with the plain type to the end of production.

The armored first aid box can be seen in photos of both the M26 and M24 in Europe before VE-Day. Initial supplies were reserved for these new models. They appear to have become available for installation on both new and remanufactured Shermans starting around March, 1945. There are quite a few surviving M4A1(76)s on display in the US and Europe. The armored first aid box (circled in red) appears on some but not all of them, suggesting that there was no later production of the boxes after 1945. Our examination of extant units for the boxes or tell tale weld scars indicates that PSC began to install these beginning in March, and that all units made from April, 1945 to the end of production were factory equipped with them.

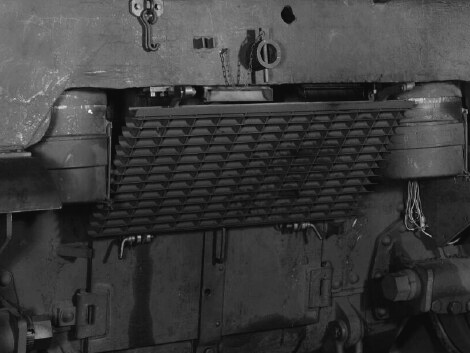

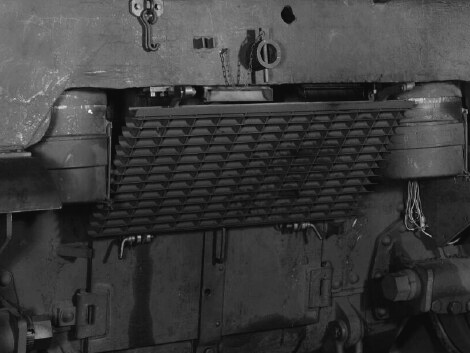

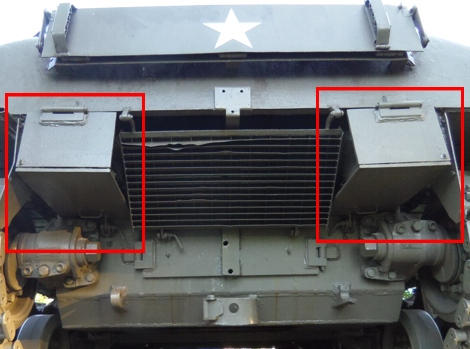

From the beginning, battlefield reports had mentioned that the externally mounted air cleaners on the M4 and M4A1 were vulnerable to combat damage. Some units attempted to protect the air cleaners by simply welding steel plates in front of them, such as can be seen on a pair of M4 Composites photographed during the Leyte Campaign in October, 1944 (left). A "protector assembly" was designed in late 1944. As with the first aid boxes, the protectors are on only some surviving M4A1(76)HVSS's, suggesting that there was no later production after 1945. Supplies of these appear to have become available to PSC in May, 1945, and we would judge that not more than 250 of the last M4A1(76)s produced had these factory installed. Above right shows the hinged configuration of the boxes as seen on Serial Number 68975 on display in Toulon, France. This was one of the last units accepted in May, 1945.

Above shows the M4A1(76) displayed on a section of the Maginot Line in Hatten, France. This tank has only "evidence" of the air cleaner protectors in the form of the various fittings (circled). The Serial Number of this unit is unknown, but the build number stamped on the left rear is 620, suggesting it was accepted in March 1945. This is the only non-May 1945 or later example we have encountered, and there are about a dozen surviving units built after this that do not show evidence of the protectors. Perhaps it was an early trial installation, or a post-production retrofit? We suspect that the factory installation of the protectors was limited to late PSC M4A1(76)s and perhaps some of the M7 Priests produced by Federal Machine and Welder. At present, we haven't come across any documentation placing or showing them on any 1945 new production or remanufactured M4(75), M4(105) or M4A1(75).

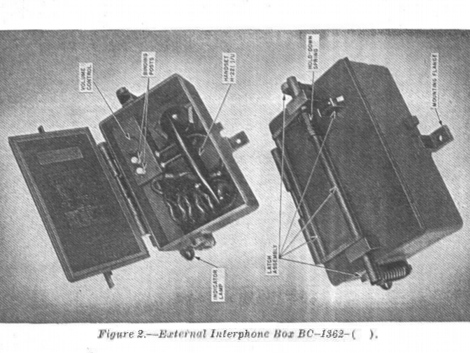

A less common method of accommodating the infantry phone is seen more often in period photos than on surviving M4A1(76)s. In this case, only the spare track holder on the right was removed, and the entire fixture was mounted on to the turret on the right side. We suspect this method was used by either Rock Island Arsenal or Brown & Root. The M4A1(76)VVSS on display at the Pilzen Zoo in Czechoslovakia can be seen with this configuration.

An August 1948 Inventory has it that there were 1956 M4A1(76)s in the US. The vast majority were in storage depots, with only 319 "Ready For Issue." As noted earlier, 1272 were listed as "w/HVSS." Exactly one M4A1(76)HVSS was listed as in service with the troops. In late 1948, the US began a rebuilding program in order to provide tanks to its Cold War Allies. France was the principal Mutual Defense Assistance Program (MDAP) recipient of the M4A1(76), and beginning in 1950, is reported to have received 421 VVSS and 833 HVSS units by early 1954. Belgium is reported to have received 15 VVSS and 65 HVSS units during the same period, and The Netherlands is reported to have received 50, although the suspension type was not listed in the documents we examined. No doubt other countries received some M4A1(76)s. For instance, there is a surviving M4A1(76)HVSS in Portugal, which is reported to have received 5 units, listed generically as "Tank, Med, 76mm Gun, M4 Series." The above shows the scene at the New York Port of Embarkation in 1950, as some MDAP M4A1(76)s, neatly shrink wrapped, await shipment to Europe.

Bowen-McLaughlin-York, Inc. was the principal contractor tasked with rebuilding the M4A1(76)s, and preparing them for MDAP shipment. The Signal Corps photo above was taken at the Letterkenney Ordnance Depot in Chambersburg, Pennsylvania in the Summer of 1950. The petroleum silos in the background were WW II surplus, and many of the tanks at the depot had been stored inside them. In order to reduce damage to the roads, local officials had asked that the turrets and hulls be shipped separately during the 30 or so mile trip from Chambersburg to the BMY facility in York, Pa. The matching letters and numbers painted on the hulls and turrets indicate that it was intended to restore the original components, although we doubt it would have been possible to do that in every case.

The 1950's rebuild specifications included an order to convert the tanks to dry stowage. The "wet" part of "wet stowage" had been somewhat questionable from the start. Each 5 round 76mm ammunition rack had 3 sealed chambers that were filled with liquid. It was thought that if the ammo rack was penetrated, the liquid would be dispersed, and at least slow the progress of an ammunition fire in order to give the crew a few more seconds to escape. Above, several of the racks are shown in place. We've circled the filler plugs of the liquid containers, including the one for the 6 round ready rack mounted on the turret basket floor. Some of the men involved in the wet stowage program were not convinced of the worth of the liquid chambers, and requested additional comparative trials. They noted that relocating the ammo bins to better protected positions on the floor of the hull (as the British had requested in 1942) was the most effective part of the modification. They also mentioned that tankers wanted to carry as much ammo as possible, and the inclusion of the liquid chambers came at the expense of an additional 10 to 12 rounds. In any case, the rebuild specification directed that the ammo racks be drained, and the filler holes plugged.

Although they were not part of the original design of the Sherman, from about mid 1943 until the end of production, the Ordnance Department required the factory installation of sand shields. They were NOT popular with the troops. "Experience in this theater indicates that sand shields on tanks are superfluous, and are quickly taken off or knocked off by troops. Recommend that War Department be advised and tanks be shipped without sand shields." Even so, Shermans continued to have them factory installed until the end of production. For instance, they can be seen in our earlier July 1945 "View of Pier Area" photo. However, while not listed in the rebuild specifications, photographic evidence suggests that sand shields were eliminated from the MDAP M4A1(76)s. Above left shows USA 30126829 with sand shields on its way to Bowen McLaughlin in Summer 1950, while the photo on the right shows 30126687 without them arriving in Cherbourg later in the year.

Earlier we mentioned that, starting in the Summer of 1944, the left front of the turret was no longer machined out to provide for an antenna. Ironically, the vast majority of surviving M4A1(76)s have a steel bracket (inset) welded on, along with a small hole in this area. We consider this to be a good clue of a postwar rebuild. The photo above is dated June 14, 1951, and shows US Congressmen inspecting some MDAP M4A1(76)s of the French 6th Régiment de Chasseurs d’Afrique (Armored Regiment) in Speyer, Germany. Note the antenna mast bases mounted on the left front fittings of these tanks.

Not all of the post war M4A1(76)s were shipped overseas as MDAP. Several hundred remained in the US. The Army's preference at the time, as during WW II, was to equip its troops with as many Ford V8 engined tanks as possible. Of course, the M26 was the most desired type, but not enough had been produced, so that the M4A3(76)HVSS was considered an acceptable substitute. These two types served in the Korean War. While the M4A1(76)HVSS was characterized as the next best acceptable substitute after the M4A3(76)HVSS, there is no evidence that any fought in Korea. They were used in the US by the Army and National Guard as test and training tanks well into the 1950s. The above shows a platoon of M4A1(76)HVSS's of the 106th Tank Battalion, 33rd Infantry Divison on a target range at Camp Ripley, Minnesota in the Summer of 1954.

Unlike the MDAP M4A1(76)s in Europe, the majority of the 40 or so surviving examples in the US don't show evidence of ever having had infantry phones installed. Some of them have plates affixed to the front indicating that they were "Overhauled" by Watertown Arsenal (Massachusetts) in 1950 (inset). Evidently, Watertown's contract did not provide for the installation of the phones. The above photos, courtesy of Jim Goetz, provide two views of Serial Number 68146, USA 30126125 on display in Kingman, Kansas. This is one of the few surviving Shermans that has somehow managed to retain its original USA Registration Number. This tank would have been accepted in February 1945. We don't think that ANY Shermans were built with the T84 rubber chevron tracks seen here. Most likely, the initial design, "two fingers" gun travel lock was installed on 68146 as original equipment. Like the T84 track, the more secure "clamp" type gun travel lock, which can be seen on most surviving M4A1(76)s, was designed during WW II based on user feedback. However, neither of these items appear to have been available before the end of Sherman production in July 1945.

Recently, we were asked by a modeler friend if we had come across any documentation that would indicate that there was a difference significant enough to mention between the hull castings made by General Steel and Continental. The answer is no. However, after having reviewed a sizeable number of photos of surviving M4A1(76)s, a comparison of the hull castings with General Steel logos to those without, presumably all Continental-Wheelings, suggests that the GS hull castings are more symmetrical and have sharper edges in the areas where they project out from the drivers' hatches. Under the right light conditions, it does appear that, on the C-W castings, the bulge in front of the bow gunner's hatch is noticeably more pronounced than the bulge on the driver's side. Furthermore, the "eyebrow" bulge above the bow machine gun aperture is "barely there," or in any case, smaller and semicircular on GS hulls. On the Continentals, it is larger and not semicircular, but curves off towards the center. Finally, we might observe that on this example and many others, the dust cover fitting appears to be an inch or so wider on the C-Ws. The upshot is that if it were possible to line up, say, 10 GS and 10 C-W M4A1(76)s in random order, and hide the GS logo, it wouldn't be hard to distinguish between the two based on the bulges.

As a matter of Sherman minutia, Pierre-Olivier has observed the "E8595" part number cast on the front of five surviving General Steel hulls that he has been able to enter. Note that there are two sets of markings (circled and inset) visible on this example and that they are reversed and upside down. P-O has been able to look around inside a small number of Continental hulls but reports that he has not seen these markings so far.

Ram, M3A1 Medium and M4A1 Sherman hull castings have been noted with "indentations" on the edges of the opening for the engine deck. Pierre-Olivier has done a head count of over 100 M4A1(76) hulls and has found that General Steel E8595 castings are consistently seen with "indents" on the rear corners of the engine deck opening as shown above on the left, circled in red. P-O' s shorthand for this was "bottom corners." On the other hand, C-W hulls examined did NOT have the rear indents or "no bottom corners." This "positive/negative" provides us with another minor distinguishing feature between the two companies' hull castings. Going a bit further, C-W hulls are consistently noted with indents machined out in the front corners in the configuration shown above in the middle. We are constrained somewhat by a lack of photos, but can mention that some GS hulls have been observed with straight or more frequently, half round indents on the front sides as shown above on the right.

The highest Union Steel turret serial number we have recorded is 3623, as seen above on a beautifully restored June 1945 production unit. 3623 is about 200 more turrets than would have been needed, but Pressed Steel was awarded several more contracts in 1945. One called for an additional 1560 M4A1(76)HVSS, and another was for 1030 units of a new type, the M4(76)HVSS. These contracts were let in the event that the war with Japan continued past 1945, but were terminated with the end of World War II. In October 1944, PSC had been given a contract to produce 150 M4A2(76)HVSS, and actually did manufacture a total of 21 in April and May 1945 before that contract was terminated. Three 7054366 turrets made by Ordnance Steel Foundry have been seen on surviving M4A1(76)s. Their Serial Numbers are 8, 84 and 94, which suggests they were produced in small numbers, perhaps not more than 100. They must have been introduced a month or two after the "eliminate the smoke mortar" directive was issued in January 1945, as none of them were drilled out for the smoke mortar. Our head count suggests Union Steel turrets 2721 and higher were undrilled.

While Chrysler and Fisher stamped the Serial Number on the rear towing lugs of their large hatch Shermans, Pressed Steel Car does not appear to have stamped it anywhere on the exterior of the AFVs they produced. However, some surviving French M4A1(76)s have been observed with the serial number stamped on the front of the hull as shown in the left side photo. PSC built M4A1s (both small and large hatch) have been noted to have a loose build sequence number stamped on either side of the hull in the rear. In the event the serial number cannot be found, the sequence number has some chronological value.

HOME

Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

Pressed Steel Car was the only manufacturer of the

M4A1(76), and produced a total of 3426 units from January 1944 through July

1945.

Production Order T-4166/2 : 1130 tanks with VVSS manufactured: Serial Number 37900 / USA 3070497 through S/N 39029 / USA 3071626

Production Order T-4344/1 : 831 tanks with VVSS manufactured: Serial Number 51850 / USA 3084447 through S/N 52680 / USA 3085277

Production Order T-14608/1 : 1327 tanks with VVSS or HVSS manufactured: Serial Number 67701 / USA 30125680 through S/N 69027 / USA 30127006

Production Order T-14608/2 : 113 tanks with HVSS manufactured: Serial Number 71654 / USA 30135486 through S/N 71766 / USA 30135598

Production Order T-14608/3 : 25 tanks with HVSS manufactured: Serial Number 73836 / USA 30140226 through S/N 73860 / USA 30140250

Production Order T-4166/2 : 1130 tanks with VVSS manufactured: Serial Number 37900 / USA 3070497 through S/N 39029 / USA 3071626

Production Order T-4344/1 : 831 tanks with VVSS manufactured: Serial Number 51850 / USA 3084447 through S/N 52680 / USA 3085277

Production Order T-14608/1 : 1327 tanks with VVSS or HVSS manufactured: Serial Number 67701 / USA 30125680 through S/N 69027 / USA 30127006

Production Order T-14608/2 : 113 tanks with HVSS manufactured: Serial Number 71654 / USA 30135486 through S/N 71766 / USA 30135598

Production Order T-14608/3 : 25 tanks with HVSS manufactured: Serial Number 73836 / USA 30140226 through S/N 73860 / USA 30140250

Introduction - First trials

Click on the picture for larger size

____________________________________________________________

First "large hatch" M4A1s

The small size of the drivers'

hatches of the original Sherman design was reported to have caused a number

of crew injuries, particularly during exits in emergency situations. The hatches

were enlarged as part of the "second generation" redesign program. The first

M4A1s with large hatches were equipped with 75mm guns, and were manufactured by

Pressed Steel Car in December 1943. They retained the "dry stowage" of the

original design, where the 75mm ammunition bins were mounted in vulnerable

positions on the sponsons. In the right side photo above, we've pointed out what

we informally label "cast in appliqué." These "bumps" were incorporated

into the hull casting in the area of the sponson mounted ammo bins, thus

eliminating the need for welding on the one inch armor plates that were mandated

to be factory installed or retrofitted on dry stowage Shermans starting in the

Summer of 1943. It is thought that only Montreal Locomotive and Pressed Steel

Car produced M4A1(75)s with "cast in appliqué" hulls. They appear on the last 75

or so Grizzlies (all small hatch), as well as the last 500 or so PSC built

M4A1(75)s (approximately 400 small hatch units and 100 large hatch). Many of the

large hatch M4A1(75)s were converted to Duplex Drive Swimming Tanks, and a

couple of these DDs are on display in France and Great Britain. The above photos

(courtesy of Alf Adams) show the DD that was recovered from the sea, and serves

as a monument at Slapton Sands in the UK.

Here we see an example of a large hatch M4A1(75) of B Co. 774th TB, bogged down in a stream in southern Germany, and photographed by a recovery crew shortly before or after VE Day. Although not immediately obvious, the front fenders (1) on this tank and certain other fittings and weld scars indicate that it had once been a DD. Note the absence of the typical M4/M4A1 air cleaners (asterisk). On DD conversions, the air cleaners were moved into the engine compartment because they interfered with the operation of the DD's propellers. Indeed, the rear engine deck plate is ajar, and the right side air cleaner is just visible (inset). This unit can be seen with a high bustle turret with loader's hatch, and it is thought that all of the large hatch M4A1(75)s would have been built with such turrets. The .50 cal Machine Gun stowage fittings on the turret bustle (2) would have been retrofitted, since this modification was not available until mid 1944.

Early M4A1s with 76mm

main gun

Here we see an example of a large hatch M4A1(75) of B Co. 774th TB, bogged down in a stream in southern Germany, and photographed by a recovery crew shortly before or after VE Day. Although not immediately obvious, the front fenders (1) on this tank and certain other fittings and weld scars indicate that it had once been a DD. Note the absence of the typical M4/M4A1 air cleaners (asterisk). On DD conversions, the air cleaners were moved into the engine compartment because they interfered with the operation of the DD's propellers. Indeed, the rear engine deck plate is ajar, and the right side air cleaner is just visible (inset). This unit can be seen with a high bustle turret with loader's hatch, and it is thought that all of the large hatch M4A1(75)s would have been built with such turrets. The .50 cal Machine Gun stowage fittings on the turret bustle (2) would have been retrofitted, since this modification was not available until mid 1944.

The

M4A1 with 76mm main gun entered production in January 1944. As part of

the "second generation" design, these tanks had "wet stowage" where the

ammunition bins were relocated from the sponsons to better protected

positions on the floor of the hull. However, on the sides of the

earliest 76mm hulls, one can see what appears to be traces of the "cast

in appliqué" of the dry stowage, large hatch M4A1(75) hulls as described

above. The roughness on the hull sides could indicate that the cast in

"bumps" were simply removed from the 75mm E8550 hull mold to come up

with the E8595 (76mm, wet stowage) casting. The left side photo shows an

early M4A1(76) (S/N 37914 / USA 3070511) in "as built" condition. For

future reference, note that this unit, which would have been the 15th

produced by PSC, can be seen with the "final" type of E8543 differential

housing with metal strip steps. The right side photo (courtesy of

Michael Lembo) shows the oldest known surviving M4A1(76) (the fourth

production unit, S/N 37903), on display at an army base at Grafenwöhr,

Germany. This tank has a number of upgraded features, as it was rebuilt

after the war. Both tanks have the early "ventless" D82081 turrets,

described below.

An interesting anomaly that has been observed exclusively on the D82081 turrets used on the earliest M4A1(76)s is the absence of the rear ventilator. Unlike the Sherman, the T23 Medium Tank was designed with a powerful hull ventilation system that did not require a separate turret ventilator. Eventually, the specifications for adapting the T23 turret to the Sherman series called for the addition of a ventilator. However, the Army was anxious to get the 76mm Sherman into production, and Pressed Steel Car was "the only tank facility which would undertake the new type vehicles and promise delivery for a deadline date in January of 160 of these vehicles to meet urgent requirements of the using forces." Thus, in the rush to production, the first M4A1(76)s were manufactured before the ventilator specifications were finalized. The Union Steel Corp. was the main turret supplier to Pressed Steel Car. Many US turrets have their serial numbers cast in fairly large on one or both sides, making it possible to "count heads" on this omission. The ventilator appears to have been added to their turrets at around number 450. In the above photos, one can see how the locations of the various MG stowage fittings differed on the ventless turret compared with the vented.

Another glitch exclusive to the M4A1(76) was also likely related to the rush to production. It was remarked in internal memos that, in the first few months of production, the split hatches didn't open past the vertical position, thereby interfering with the operation of the anti-aircraft machine gun, and making for an uncomfortable traveling position for the loader. The hatches had been redesigned to open outward to 45 degrees, and it was suggested that a field repair order be issued. The above photos show two views of USA 3070707, a 32nd Armored Regiment, 3rd Armored Division Sherman knocked out near Bergerhausen, Germany, circa March 1, 1945. This tank was the 211th M4A1(76) made, and would have been accepted in February 1944. Most likely, it was one of the "UK orphans" described below. In any case, aside from the fact that the crew has reversed the “factory” position of the hatches, this turret reflects the appearance of the early Union Steel - vertical loader's hatches, no ventilator, and "unthreaded" M1A1 gun.

The photo on the left shows the initial, problematic configuration of the loader's split hatch as mounted on a ventless Union Steel turret with serial number 271. Assuming that this hatch is original to turret 271, we would note that this is the highest US turret serial number we have seen with the original loader's hatch. Our friend, Michael Lembo, was able to demonstrate that the hatches would not open past the vertical position. Although this tank had been remanufactured in the early 1950s, the hatch and missing ventilator issues were not addressed. The photo on the right shows the revised loader's split hatch. The positive hatch lock mechanisms (1) that can be seen, are the same type as had been introduced on Shermans starting in the Spring of 1943. It is thought that PSC began the transition to the revised loader's split hatch in March, 1944 at around US turret 260, and that Chrysler used them from the beginning of M4A3(76) production in March, 1944.

An Ordnance Department document states that "All Medium Tanks M4 series (76mm gun) since first 385 produced have been equipped with threaded gun tubes." This suggests that the unthreaded M1A1 guns as seen on the early M4A1(76)s, would have been replaced in production with threaded M1A1C guns sometime in March, 1944. Chrysler began M4A3(76) production in March, and a small number of their first tanks have been noted to have had unthreaded guns as well. The above photos show two views of "Gila Monster," Serial Number 37936, USA 3070533, the 37th M4A1(76) made. It was used in various tests at APG, including May / June 1944 trials of the muzzle brake installation. Some items of interest include the "uncovered" vent between the drivers' hatches (1), the provision for an antenna on the left front of the turret (2), the blanked off fuel filler hole (3), the "vertical" loader's hatches (4), and the early version of the sharp nosed differential housing with cast in steps (5).

The M4A1(76) model added a new armored

filler cover to the rear engine deck plate. This was for the "engine

oil tank." The small curved tag seen in the left photo appears to be

the same size and shape as the "LUBRICATING OIL" labels used

on the M4A2 diesel model. Note how the cover is surrounded by a

cast bullet splash. The standard tool stowage, blanket roll rack and

spare track holders can be seen in the above illustration from the

Technical Manual. This particular M4A1(76) looks to have US turret 359

(inset). While it "still" lacks the ventilator, it does have the

revised loader's hatch with positive hatch lock mechanisms.

Radial engine Shermans had four main fuel tanks, and on the M4 and M4A1(75)s, each had its own filler point. As part of the second generation redesign, M4A1(76)s were plumbed in such a way that only a single filler point was required for the two fuel tanks located on either side of the hull. The photo on the left shows the original four point configuration, as seen on one of the last M4A1(75)s made, a large hatch model. A few early production M4A1(76)s have been seen to have the configuration shown in the middle photo, where excess older parts were used, and the unnecessary holes were simply blanked off. The right side photo shows the standard M4A1(76) configuration. The small tags seen near the armored filler covers read "GASOLINE." The addition of the "LUBRICATING OIL" filler point prompted the use of "GASOLINE" labels at the other 3 filler points on the M4A1(76) and M4(105).

Early M4A1(76)s had straight return roller arms (1), such as can be seen on USA 3070551, a January 1944 production tank that served with the 3rd Armored Division, and was photographed in Chenee, Belgium on September 7, 1944. While Chrysler and Fisher Body had completed the transition to the later upturned return roller arms (inset) by the beginning of 1944, Pressed Steel Car does not appear have completely replaced the earlier straight arms until the Spring. The periscope guards that can be seen were a standard feature of all second generation Shermans.

A few of the earliest M4A1(76)s were built with the first version of the E8543 differential cover that featured cast-in steps (circled). Period documents mention that the cast-in steps interfered with the crew's ability to work the quick release towing shackles. Consequently, the differential castings were altered to eliminate the cast-in steps, and metal strip steps were welded on instead. It is thought that PSC's supply of diffs with cast-in steps would have been exhausted after the first few months of production. Our example shows the M4A1(76) on display in La-Roche-en-Ardenne, Belgium. The serial number is unknown, but the hull number is 3904, suggesting it was built in February 1944. The tank was restored somewhat, so it can't be assumed to have all of its original components. However, it shows no evidence of having had the usual postwar upgrades, and the ventless Union Steel turret with Serial Number 206, the unthreaded 76mm gun, and the early E8543 differential are certainly appropriate to a February 1944 production unit. We strongly suspect that this tank was a WW II battle casualty. Should any readers have any information about its history, please contact us.

In early 1944, a special task force of 156 of the first M4A1(76)s was sent to the UK for familiarization. They evoked little interest from US armored commanders whose troopers had been training for the Invasion for many months with M4 & M4A1(75)s. Confrontations with heavy German armor in Normandy aroused interest in the "orphan" M4A1(76)s sitting idle in England, and General Bradley ordered that they be shipped to France to take part in First Army's upcoming Operation Cobra. 120 were evenly distributed to the 2nd and 3rd Armored Divisions, and they made their combat debut in late July 1944. On the left, a tank of the 67th Armored Regiment, 2nd Armored Division "enters the village of St. Sever Calvados, France. 3 Aug 44." Note the cast in steps on the diff. "Duke," USA 3070582 of the 66th Armored Regiment, 2nd AD (right), was one of the last M4A1(76)s accepted in January 1944. It was photographed in Coutance, France during Operation Cobra. The rubber chevron tracks are the primary type seen in period photos of the "orphan" M4A1(76)s. For future reference, note that Duke has an "unframed" exhaust deflector, and lacks support gussets in the area of the air cleaners.

The photos above show what appears to be E-3 of

the 2nd Battalion, 32nd Armored Regiment, 3rd Armored Division advancing down

Venloerstraße in Cologne on March 6, 1945.

Many

of the AFVs of the 32nd AR are seen with the USA Registration Number

painted on the front and rear. In the still photo on the left, the

number has been censored somewhat, but it appears

intact in the motion picture frame on the right. USA 3070536 would have

been a January, 1944 production unit, and the inset shows a very low Union Steel turret Serial Number of 45.

It is highly

likely that this was one of the "orphan" M4A1(76)s shipped over from the

UK before the start of Operation Cobra in late July, 1944.

The photo above shows the M4A1(76) with ventless turret on display in Nehou, France. We suspect that this was one of the 421 M4A1(76)VVSS Shermans remanufactured and supplied to France as Military Assistance in the early 1950s. The upper right section of the remanufacturer's dataplate is shown in the inset, and it can be seen that this tank is Serial Number 37939, which is an exact mathematical match to USA 3070536 shown in the previous caption. Thus, it would seem that this tank survived WW II, and was repatriated back to the US. This Sherman obviously received a number of upgrades during remanufacture, such as a new 76mm gun with muzzle brake and the canvas mantlet cover fittings, but the Union Steel turret Serial Number can be seen as 45 (inset), the same as noted, and in the same location, as in the period photo. The tank currently carries tactical markings in honor of the 35th Tank Battalion, 4th Armored Division. Perhaps at some point it could be remarked to reflect its WW II service with the 32 Armored Regiment, 3rd AD?

The Ford V8 engine was considered superior to the Continental Radial of the M4/M4A1 series, and it was the policy of the US Army to attempt to equip its fighting forces with as many M4A3s as possible. Consequently, the US did not employ large numbers of M4A1(76)s. Indeed, we can find no evidence that the US received any additional units in 1944, and no evidence of combat use outside of the European Theater. The British did not "require" any 76mm Shermans, as they considered the HE round to be inferior to the 75mm's. However, they agreed to accept 1330 M4A1(76)s in 1944, since there weren't enough 75mm Shermans available to meet their Lend Lease requirements for the year. This was almost the entire production of M4A1(76)s up to October 1944. Those allocated to the Mediterranean Theater of Operations were used by British and South African armored units. In the European Theater, the Polish 1st Armoured Division appears to have been the only unit to have utilized the "Sherman Mk IIA" (British nomenclature for M4A1(76)VVSS ). Tank Situation Reports state that they had 51 units at the end of December 1944. By the end of the War in Europe, the Poles are listed as having 181 M4A1/76s along with 40 “17 pdr” (Firefly Shermans). An additional 97 M4A1/76s are reported in 21st Army Group Depots in June 1945. Above shows a Sherman IIA of the Polish 10th Armoured Cavalry Brigade, KO'd in the Netherlands in late 1944.

On

December 26, 1944, the US 12th Army Group sent an urgent communication

to the British 21st Army Group “requesting immediate release of 500

tanks” to provide replacements for losses suffered during the Battle of

the Bulge. Commonwealth Vehicle Parks were scoured, and in the end,

maintenance teams prepared and shipped 351 Shermans by the first week of

January 1945. The most modern model included in this emergency transfer

was the M4A1(76). As mentioned, the Brits did not really want these due

to their lack of an acceptable HE round, but even so, only provided 87

such units, with the rest being older 75mm Shermans, including M4/M4A1s,

M4A2s and M4A4s. The M4A1(76)s were doled out to the various Armored

Divisions and Tank Battalions of the First US Army. The 743rd Tank

Battalion was allocated 5, and it is thought that the unit shown above

was one of them. A number of these transfers have been noted to have

inappropriate 6 digit “Registration Numbers,” some with “X” prefixes

such as “X 309084” seen here. We believe that these were British War

Department Numbers specifically assigned to the Shermans transferred. At

present, we have recorded about 20 such numbers ranging from 309012

through 309237. This

Signal Corps photo is dated 6 January 1945, in Ster, Belgium and

identifies the unit as Company C, 743rd Tank Battalion. Part

of the caption reads, “Tank crewmen knock off connectors on tank track

prior to putting on new duck bills that will enable vehicle to travel

over muddy ground.” Note

the welded spoke with "small holes" road wheels (1) introduced in

production at PSC in the Fall of 1944. We would guess that this unit was

never issued to a Commonwealth unit before the transfer and was one of

the 150 M4A1(76)s allocated as Lend Lease to the UK in September 1944.

Much greater use of the Sherman IIA was made by the 15th Army Group in Italy than by the 21st Army Group in Northwest Europe. The first issues appear to have occurred in September, 1944 when the British 1st Armoured Division was reported with 28 units, and the British 6AD with 2. The 1st AD was broken up a month later, due to an inability to replace casualties; however, its 2nd Armoured Brigade survived as an independent entity. At the end of 1944, the 2nd AB was reported with 116 Sherman IIAs on strength, while the 6th AD reported 42, the 7th Armoured Brigade reported 61, and the 6th South African AD reported 134. Thus, total unit holdings were 353 Sherman IIAs with an additional 65 in “Tank Replacement Group.” By the end of the War, total unit holdings had decreased to 329 units, while the “Tank Replacement Group” pool had more than doubled to 144 plus 11 in “Training.” The photo above is captioned “A Sherman tank of 2nd Armoured Brigade crossing the River Rabbi at San Martino, 9 November 1944.” The 2nd Armoured Brigade consisted of The Queen’s Bays, 9th Lancers and 10th Hussars, and this Sherman IIA has been identified as belonging to B Squadron, The Queen's Bays (aka 2nd Dragoon Guards). It features the revised loader's split hatch, introduced at PSC in March, 1944. Courtesy of Imperial War Museum, NA 20043.

The 6th South African Armoured Division appears to have been the largest user of the Sherman IIA in the Mediterranean Theater. Its regiments began replacing some of their 75mm Shermans in November, 1944, and a 15th Army Group AFV Situation Report states that, “as at 30 December, 1944,” they had 134 M4A1(76)s. By the end of the War, this number had decreased by 6, due to losses and “wastage” during the final offensive. The photo above, dated April 20, 1945, shows elements of the Special Service Battalion of the 6th South African AD massing in preparation for the attack on Bologna, Italy. Despite the late date, all of the M4A1(76)s that can be seen have the earlier split loader's hatches. The tank in the center foreground even has a ventless turret. Note that the loader's hatches are open to the standard, 45 degree position. The commander's cupolas are not in the standard or "as built" configuration. It would appear that the unit reoriented the cupolas so that the hatches opened further to the rear. Some Firefly (17 pounder) Shermans can be seen on the far right. The Division was attached to the US 5th Army for the Spring 1945 Offensive, and according to their records, each of the 3 Squadrons of the SSB had 13 M4A1(76), 3 M4A4 based Fireflies and 3 M4(105)s.

The final M4A1(76) allocations to the British were for 150 units a month from August through October, 1944. We estimate that most of these would have been equipped with oval loader's hatches, and perhaps a few from the October production would have included muzzle brakes. However, we have not come across a "combat shot" of any of these in Commonwealth service. These tanks would have arrived in Europe in late 1944 / early 1945, at which point they could not be absorbed, and thus were no longer needed by the shrinking Commonwealth forces. The above shows a nearly as built M4A1(76) with oval hatch on display at the School of Armour in Bloemfontein. On January 3, 1947 the South Africans obtained a “property consent to retransfer” from the US Lend Lease Administrator. As a consequence, it was agreed that, subject to availability, 67 Sherman M4A1(76)s, 15 M4(105)s, 15 M4 based Fireflies, and 1 M32B1 ARV would be transferred from British Military Holdings in Italy to the South African Forces. It is thought that all of these were shipped to South Africa within the year. At any rate, thirty-two M4A1(76)s are listed in an inventory of the 1st Special Service Battalion, Potchefstroom, S.A., March 31, 1948. Most likely, the South Africans would have chosen to purchase unused or low mileage tanks, and the example shown is reported as in running condition. This tank and the other surviving S.A. Shermans, could still have their original dataplates, so if any readers are in the position to examine any of them, we would greatly appreciate a report.

An oval loader's hatch had been added to 75mm turrets in late 1943. In an effort to simplify the original D82081 turret design (left side photo), the Ordnance Department adopted this concept, and replaced the original split hatch with an oval hatch. The new turret casting carries part number 7054366 (right side photo). The split hatch had a machine gun pintle and loader’s periscope built in, so with this change, an MG pintle (1) and loader’s periscope (2) were added to the roof of the turret. Ordnance documents state that all M4A1(76)s built after August 1, 1944 received the new model of turret. The loader's hatch was the same size and shape as the "large" drivers' hatches, that is approximately 24 inches long and 19 inches wide. In comparison, the oval hatches of the 75 and 105mm turrets were about 21 inches long and 16 inches wide. Note that the 7054366 turret was not machined out for the left front antenna, although the casting retained the tell tale "bump out" to the end of production. We would note that, while this "bump out" is present on some other companies' 76mm turrets, it is most prominent on Union Steel castings.

Pressed Steel Car had produced 776 M4A1(76)s by the end of May, 1944. If we assume a loose chronology to the turrets, then we might speculate that Union Steel turrets with 8xx serial numbers would have started to appear in June. The D82081 turrets shown above are 881 on the left and 873 on the right. The left front antenna is NOT machined out on these examples. On Union Steel turret 831, shown in the previous caption, the antenna is machined out. This gives us a fairly good idea of the "eliminate the front antenna" transition point. While we don't assume that surviving Shermans have their original turrets, the tank serial or build sequence numbers of all 3 of these M4A1(76)s indicate that they were accepted in June, 1944.

As mentioned previously, most Union Steel turrets have their serial numbers cast in fairly large on one or both sides. A "1" or "2" is seen above or below the serial number. We believe this indicates that Union Steel 76mm turrets were cast using either mold 1 or mold 2. From "counting heads," mold 2 appears to have been changed from a D82081 (split hatch) casting to a 7054366 (oval hatch) casting at around serial number 1000, whereas mold 1 was changed at around serial number 1350. Thus, one might see an earlier split hatch casting with a higher serial number than a later oval loader's hatch casting. For instance, the photo on the left shows a mold 1 D82081 turret with serial number 1310, while the one on the right is a mold 2 7054366 turret with serial number 1043. (Right side photo courtesy of Tom Gannon.)

Muzzle

brakes began to enter the production line in October 1944, and we

estimate that PSC completed the transition to them by November. Thus

about half of the entire output of the M4A1(76) would have had these

factory installed. Even so, they are rarely seen in WW II combat photos

of Shermans of any type due to their late date of introduction. The

first M4A3s with muzzle brakes made their appearance on the front lines

in Northwest Europe at the end of December 1944. "The first "combat shots" of M4A1(76)s with the brakes that we have seen are dated March 1945. The above 5th April 1945 photo, shows a unit

of the 771st Tank Battalion advancing through Muenster, Germany. We

would estimate that the sheet metal cover over the vent between the

drivers' hatches (1) and the rear view mirror (2 - only the fitting is

seen) were installed by PSC starting in July, 1944. The smoke mortar cap

and chain (3) and the T-shaped towing shackles (4) appear to have been

introduced in October. The 3 bar cleat steel tracks (5) are seen in a

few other 1945 M4A1(76) photos.

As noted above, a sheet metal cover over the ventilator between the drivers' hatches was introduced at Pressed Steel around July, 1944. This was requested by users in order to provide some measure of weather protection. The authors have not found any evidence that modification kits for the covers were sent overseas during WW II, but have noted that many surviving Shermans that obviously didn't have this item factory installed, had it added later during postwar upgrades. The U bolt that can be see on the uncovered example above held the padlocks for the drivers' hatches.

The 20th Armored Division arrived in Le Havre, France in February 1945. They brought their equipment with them, and oddly, at this late stage, most or all of their Medium Tanks appear to have been powered by the Continental Radial engine. Their M4 and M4A1(75)s had been recently remanufactured in the US. Their M4A1(76)s were new production, and included some units with muzzle brakes. The above, dated February 24, 1945, shows soldiers at the Division's depot in Bouchy, France unpacking the contents of the On Vehicle Materiel (OVM) boxes in preparation for installation in and on the tank. An item of interest here is the automobile style horn (1 and inset). The June 1944 M4A1(76) Technical Manual only provides details about the siren that was standard equipment from the beginning. However, it is obvious from period photos that most second generation Shermans were equipped with a horn. PSC appears to have replaced the siren with the horn in the Spring of 1944.

Pressed Steel Car used just about every type of VVSS road wheel on the M4A1(76)s it produced in 1944. In the early months, units were equipped with either the welded spoke (A) or pressed spoke wheels (B). The welded spoke with "small holes" (C) and the solid, concave wheels (D) appear to have replaced the earlier types in the Fall of 1944.