PAGE 1/2

Go to page 2

Chrysler

manufactured most of the large hatch M4A3(76) Shermans. It

produced 4017 M4A3(76)W from March 1944

to April 1945.

Production

Order T-9872/1 : 238 M4A3(76)W with VVSS : Serial Number 43528 / USA

3099762 through S/N 43765 / USA 3099999

Production

Order T-9872/2 : 462 M4A3(76)W with VVSS :

Serial Number 43766 / USA 30100000 through S/N 44227 / USA 30100461

Production

Order T-10151 : 671 M4A3(76)W with VVSS and 2 M4A3(76)W with HVSS :

Serial Number 44808 / USA 30101042 through S/N 45480 / USA 30101714

Production

Order T-10888/2 : 29 M4A3(76)W with VVSS and 824 M4A3(76)W with HVSS :

Serial Number 59719 / USA 3031582 through S/N 60571 / USA 3032434

Production

Order T-11168 : 1466 M4A3(76)W with HVSS :

Serial Number 60572 / USA 30113594 through S/N 62037 / USA 30115059

Production

Order T-14596/1 : 200 M4A3(76)W with HVSS :

Serial Number 67501 / USA 30123237 through S/N 67770 / USA 30123436

Production

Order T-14596/2 : 125 M4A3(76)W with HVSS :

Serial Number 72767 / USA 30136599 through S/N 72891 / USA 30136723

Fisher also manufactured some M4A3(76)W from September to December 1944.

Production

Order T-11315/2 : 525 M4A3(76)W with

VVSS :

Serial Number 62860 / USA 30115882 through S/N 63384 / USA 30116406

The evolution of the M4A3(76)

started in early 1942 when the Ford Motor Company was contracted to manufacture

Medium Tanks powered by an in house designed 500 HP V8 engine. Since the engine

was new and untested, M4A3s initially served as training tanks in the US,

giving the company the opportunity to "iron out the bugs." In

comparison tests, the Ford GAA engine was found to be superior to the other

tank power plants, and in June 1943, it was declared "suitable for

overseas supply." It was further decided that production of M4A3s would be

reserved for US troops, both at home and abroad. While Ford left the Sherman

program in September 1943, it continued to supply engines to Chrysler and

Fisher Body for the 1944/45 production of M4A3s and M26s. During WW II, Ford's

Lincoln plant (above) produced 26,954 V8 tank engines.

The evolution of the M4A3(76)

started in early 1942 when the Ford Motor Company was contracted to manufacture

Medium Tanks powered by an in house designed 500 HP V8 engine. Since the engine

was new and untested, M4A3s initially served as training tanks in the US,

giving the company the opportunity to "iron out the bugs." In

comparison tests, the Ford GAA engine was found to be superior to the other

tank power plants, and in June 1943, it was declared "suitable for

overseas supply." It was further decided that production of M4A3s would be

reserved for US troops, both at home and abroad. While Ford left the Sherman

program in September 1943, it continued to supply engines to Chrysler and

Fisher Body for the 1944/45 production of M4A3s and M26s. During WW II, Ford's

Lincoln plant (above) produced 26,954 V8 tank engines.

Click on the picture for larger size

Click on the picture for larger size

In August 1942, a few months

after Shermans began rolling off the assembly lines, the Ordnance Department

began testing the feasibility of mounting a 76 mm gun in the standard D50878

turret (above left). The intention was to produce 1000 76mm armed Medium Tanks

by the end of the year. Ultimately, the project was cancelled because it was

determined that the small turret was unsuitable. In the meantime, development

work was initiated on new Medium Tank designs known collectively as the T20

series. The T23, which mounted a 76mm gun in a larger turret, was never

standardized due to various technical problems (above right). However, since

the 69 inch diameter turret ring was the same as the Sherman's, the T23's 76mm

turret was easily adapted for use on the late 1943 revision of the M4 series.

The original design of the

welded hull Sherman featured a rather elaborate glacis made up of armor plate

combined with various cast or "fabricated" components such as the

drivers' hoods. The photo above shows an October, 1942 production Ford built

M4A3(75), and provides an idea of one of the early glacis configurations. Ballistic

tests revealed the inherent weakness of the numerous weld joints and

protrusions. In March 1943 the Armor Branch determined "that these

weaknesses cannot be substantially eliminated by changes in the present

designs."

The original design of the

welded hull Sherman featured a rather elaborate glacis made up of armor plate

combined with various cast or "fabricated" components such as the

drivers' hoods. The photo above shows an October, 1942 production Ford built

M4A3(75), and provides an idea of one of the early glacis configurations. Ballistic

tests revealed the inherent weakness of the numerous weld joints and

protrusions. In March 1943 the Armor Branch determined "that these

weaknesses cannot be substantially eliminated by changes in the present

designs."

Click on the picture for larger size

Click on the picture for larger size

In the meantime, in February

1943, the Army Medical Research Lab had concluded that the original drivers'

hatches were too small, and were the cause of numerous injuries, particularly

when crew members attempted to enter or exit their tanks in a hurry. Larger

hatch dimensions were submitted, but it was found that "increased size not

possible of application to present hull design." Thus, development work

was begun to reconfigure the front of the Sherman.

Chrysler Corporation submitted

a cast front design that addressed the deficiencies, and in June 1943, the

Ordnance Department approved of making all subsequent welded hull Shermans in

the so called "Composite" configuration as shown above left. However,

in that same month, Fisher Body submitted an alternate large hatch design based

on the M10 Tank Destroyer that they had developed in early 1942. It featured a

single 2 1/2 inch glacis plate that was mounted at a 47 degree angle, so that

the drivers' hatches could be repositioned in the roof of the hull. The

"Fisher front end" was found to be superior to the Chrysler Composite

concept, and became the basis for the "ultimate" or "second

generation" series of welded hull Shermans.

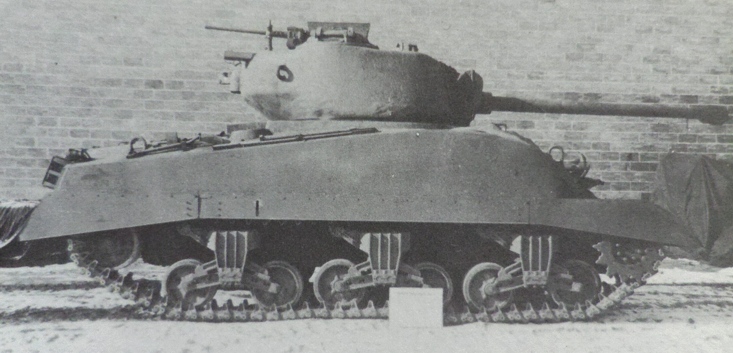

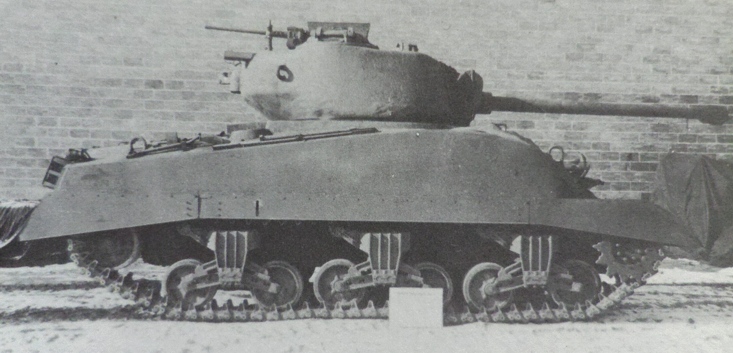

Above is shown the M4A3(76)

pilot model, USA 3054892, photographed at Chrysler in early 1944. The

Registration Number indicates that this tank was built by Ford as a small hatch

M4A3(75) in September, 1943. One can see that a large hatch front casting was

retrofitted to this particular prototype, reflecting the very brief competition

between the Chrysler and Fisher design concepts during development of the

"second generation" series of welded hull Shermans. Of course,

production M4A3(76)s would feature the "Fisher front end" as

explained above. Note that the pilot's turret was fitted with the less complex,

original version of the canvas mantlet cover. This suggests that it was

intended to equip 76mm turrets with a mantlet cover from the start. However, we

suspect that unresolved issues about the final design of the cover may have

delayed its introduction for nearly a year.

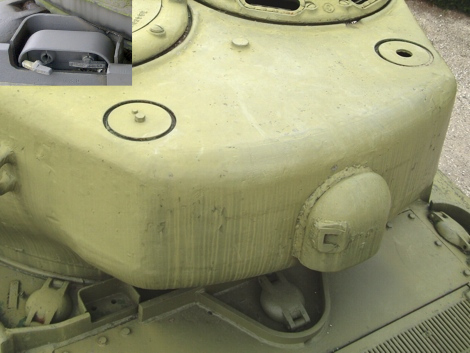

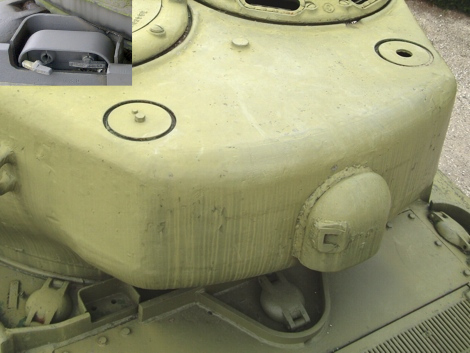

The official nomenclature for our subject, as seen on dataplates

(inset), is "Tank, Medium, M4A3, 76MM Gun, Wet." "Wet" was shorthand for

"wet stowage." Thirteen five round ammunition racks were located on the

floor of the hull below the turret. Each five round rack had 3 sealed

chambers that were filled with a liquid "quenching solution." It was

thought that if an ammo rack was penetrated, the "quenching solution"

would be dispersed, and at least slow the progress of an ammunition fire

in order to give the crew a few more seconds to escape. For the tests,

the first solution tried was plain water. The second was water mixed

with ethylene glycol to prevent freezing. This was "suspected of being

inflammable" and a third solution "ethyl sodium potassium phosphate"

known as "Ammudamp" was substituted. Above, several of the racks are

shown in place. We've circled the filler plugs of the liquid chambers,

including the one for the six round ready rack mounted on the turret

basket floor. Some of the men involved in the wet stowage program

reported that the results of the tests "cast[s] doubt on the utility of

water protection...it is recommended that we fully investigate its

effectiveness, conducting tests if necessary to determine if it can be

eliminated. While a large number of people feel that is has no real

effect, Col. Cox says it has a definite morale effect on the crews." It

was noted that enclosing the bins in armor and relocating them to better

protected positions on the floor of the hull (as the British had

requested as early as June 1942) were the effective parts of the wet

stowage modification. They also mentioned that tankers wanted to carry

as much ammo as possible, and the inclusion of the liquid containers

came at the expense of an additional 10 to 12 rounds.

The official nomenclature for our subject, as seen on dataplates

(inset), is "Tank, Medium, M4A3, 76MM Gun, Wet." "Wet" was shorthand for

"wet stowage." Thirteen five round ammunition racks were located on the

floor of the hull below the turret. Each five round rack had 3 sealed

chambers that were filled with a liquid "quenching solution." It was

thought that if an ammo rack was penetrated, the "quenching solution"

would be dispersed, and at least slow the progress of an ammunition fire

in order to give the crew a few more seconds to escape. For the tests,

the first solution tried was plain water. The second was water mixed

with ethylene glycol to prevent freezing. This was "suspected of being

inflammable" and a third solution "ethyl sodium potassium phosphate"

known as "Ammudamp" was substituted. Above, several of the racks are

shown in place. We've circled the filler plugs of the liquid chambers,

including the one for the six round ready rack mounted on the turret

basket floor. Some of the men involved in the wet stowage program

reported that the results of the tests "cast[s] doubt on the utility of

water protection...it is recommended that we fully investigate its

effectiveness, conducting tests if necessary to determine if it can be

eliminated. While a large number of people feel that is has no real

effect, Col. Cox says it has a definite morale effect on the crews." It

was noted that enclosing the bins in armor and relocating them to better

protected positions on the floor of the hull (as the British had

requested as early as June 1942) were the effective parts of the wet

stowage modification. They also mentioned that tankers wanted to carry

as much ammo as possible, and the inclusion of the liquid containers

came at the expense of an additional 10 to 12 rounds.

This Signal Corps photo is

captioned, "Tec 5 Benny G. Smith of Hartown, Ga., a member of a tank

crew, checks up on his supply of ammunition ...Welsfrang, [sic]

Luxembourg...20 Nov. 1944" It was taken through the round loader's

hatch of the original 76mm turret used on the Sherman, sometimes

referred to as the "T23 turret." It provides an idea of the cramped

conditions under which the loader had to work. Note how the handles of

the smoke mortar and coaxial .30 caliber guns are inches from his head.

The rounds are positioned on an angle, and a couple of the wet stowage

plugs are visible. Based on the location, Welfrange, and the date, we

suspect that T/5 Smith served with C Company, 774th Tank Battalion, and

that the Sherman was an M4A3(76). As a matter of minutia, we would

observe that other photos and diagrams show the 76mm rounds stowed tip

up.

In order to provide the loader

with easier access to the ammunition, the turret basket of the 76mm Sherman was

essentially cut in half. The view above was filmed at the 725th Ordnance Depot

in Korea in May 1951. One can see that the turret basket floor was reduced to a

little less than a half round shape. The six round ready rack (1) can be seen

to overhang the turret basket floor by a few inches. It is to be noted that the

M4A3(75)W retained a full turret basket floor that had ammunition access

hatches. Howitzer Shermans were NOT "wet stowage," and some of the

ammunition continued to be stowed "up high" on the sponsons, as on

the original Sherman design. As an aside, we would point

out that maintenance personnel were instructed NOT to use the gun mantlet's

lifting rings to hoist the turret, such as shown in the scene above, because it

could result in misalignment or other damage to the gun.

Chrysler began manufacturing

the M4A3(76) in March 1944. Most of the first 4 months' production was

scheduled for automatic shipment to Europe. The tanks were processed at US

Depots, and delivered to ports on the East Coast when completed. The first

allotment of 48 M4A3(76)s, marked with the shipping code "GLUE," was

"afloat" by the middle of June. "GLUE," which can be seen

in some period photos and on a few surviving tanks, is described as Zone II for

the receipt of cargo in the UK. It "included the southern portions of

England and Wales, and the ports of the Bristol Channel and Plymouth,

Southampton and London." In the early stages of the Normandy campaign, the

tanks continued to be shipped to GLUE, where they were transferred to LSTs, and

subsequently delivered over the beaches in Normandy. When port facilities, such

as Cherbourg, became available on the Continent, the tanks were shipped direct.

Above shows Serial Number 44220, a June 1944 production unit on display in

Germany. Unlike most surviving Shermans, this tank is in close to "as

built" configuration, although there is evidence that it was retrofitted

with a bulldozer blade. We would guess 44220 served with the US Army during WW

II, and may have been a battle casualty. "Paint archeology" has

revealed what appears to be the original "GLUE" shipping code, as

shown in the inset.

Click on the picture for larger size

Click on the picture for larger size

The scene above was filmed in

La Cambe on the Normandy coast on August 12, 1944. The 948th Ordnance Motor

Vehicle Distribution Company appears to have completed the process of preparing

these tanks for issue. The shipping sealant has been removed, although some

remaining traces of it can be seen as dark spots. Chalked notes on the foremost

Sherman indicate that the radio and "artillery" have been checked, and

gasoline has been added. Chrysler shipped these tanks

with the USA Number painted on the rear sides rather small in blue drab. In mid 1943, a directive

was issued that the number was to be painted on larger and in white. Directives

were not always heeded, but most of the US Shermans that took part in the

Normandy Campaign can be seen with the larger, white Registration Numbers. We

recorded the M4A3(76) in the foreground as USA 3099839, indicating April 1944

acceptance. The USA Number is the brightest thing on these tanks, so we would

guess it was painted on by the 948th. Some items of interest are the extra

lifting ring (1) and the absence of the machine gun fittings (2) on the turret,

the "early" position of the forward cable clamp (3), and the siren

(4).

Click on the picture for larger size

Click on the picture for larger size

In Italy, Company A of the

13th Tank Battalion, 1st Armored Division was the one of the first units to

receive the new tanks, and the scene above was filmed on a range near Pisa,

August 19, 1944. The problem of smoke obscuration is evident, and it was thought

that a muzzle brake would provide a remedy. However, tests had shown that, by

itself the muzzle brake was insufficient, and "long primer"

ammunition was developed at the same time. This combination helped to cut down

the smoke and blast effects. Company A's guns can be seen to be the second

version of the 76mm - the M1A1C. These were "threaded" to accept

muzzle brakes when they became available in late 1944. In the meantime the

threads were protected with a "collar." These tanks feature

"extra lifting ring" turrets. Of note is that the commander's cupolas

are not in their factory installed positions, but have been reoriented so that

the hatches open further to the rear. In some correspondence from the

Mediteranean Theater of Operations to the Ordnance Department, it was suggested

that this should be the standard orientation of the cupola.

Click on the picture for larger size

While Ford engined Shermans

were reserved for US Army use, the combat debut of the M4A3(76) may have been

with the French 2nd Armored Division. The Division was attached to

the US Third Army, and received a few of the first M4A3(76)s as replacements in

late August. "Champagne," Number 55, served with the 3rd Squadron of the

12th Régiment de Chasseurs d’Afrique. On August 25, 1944, during the battle for

Paris, her crew was credited with firing the "kill shot" that knocked

out a Panther in the Place de la Concorde. In general, the French painted out

the US Army Registration Numbers of their Lend Lease vehicles, and applied their

own "matricule" numbers. However, in the crew snapshot above, one can

see that Champagne "still" had the USA Number painted on in the same

manner as the tanks seen in the August 12th La Cambe photo. "3099828

S" was the 67th M4A3(76) made by Chrysler, and would have been accepted in

April, 1944. (The "S" often seen at the end of USA Numbers is

frequently mistaken for a "5," but it signifies that the vehicle was

equipped with a Radio Interference Suppression System.). Photo courtesy of Musée de la libération-Jean Moulin-Ville de Paris.

Click on the picture for larger size

While Ford engined Shermans

were reserved for US Army use, the combat debut of the M4A3(76) may have been

with the French 2nd Armored Division. The Division was attached to

the US Third Army, and received a few of the first M4A3(76)s as replacements in

late August. "Champagne," Number 55, served with the 3rd Squadron of the

12th Régiment de Chasseurs d’Afrique. On August 25, 1944, during the battle for

Paris, her crew was credited with firing the "kill shot" that knocked

out a Panther in the Place de la Concorde. In general, the French painted out

the US Army Registration Numbers of their Lend Lease vehicles, and applied their

own "matricule" numbers. However, in the crew snapshot above, one can

see that Champagne "still" had the USA Number painted on in the same

manner as the tanks seen in the August 12th La Cambe photo. "3099828

S" was the 67th M4A3(76) made by Chrysler, and would have been accepted in

April, 1944. (The "S" often seen at the end of USA Numbers is

frequently mistaken for a "5," but it signifies that the vehicle was

equipped with a Radio Interference Suppression System.). Photo courtesy of Musée de la libération-Jean Moulin-Ville de Paris.

The M4A3(76) on display as a

monument in Ville-sur-Illon, France has the serial number 43594 stamped on the

rear towing lugs. There is a mathematical correlation between the Ordnance

Serial Number and the USA Number of Shermans, and 43594 is an exact match to

USA 3099828, confirming that this is the "real" Champagne. She was

knocked out on September 13, 1944, not far from where she now stands. The crew

managed to escape as the tank caught fire. In the photo above, it can be seen

that the intensity of the fire melted most of the rubber from the tracks and

road wheels. Champagne was one of the few M4A3(76)s to come equipped with the

"unthreaded" M1A1 gun. Pressed Steel Car began M4A1(76) production in

January 1944, two months before Chrysler began manufacture of the M4A3(76). An

Ordnance Department document states that "All Medium Tanks M4 series (76mm

gun) since first 385 produced have been equipped with threaded gun tubes."

Thus, the M1A1 is more commonly seen on early M4A1(76)s. Our counting heads

method suggests that Chrysler was distributed less than 100 M1A1s, and

completed the transition to the threaded M1A1C guns in April 1944, the same month

that Champagne was built.

The M4A3(76) on display as a

monument in Ville-sur-Illon, France has the serial number 43594 stamped on the

rear towing lugs. There is a mathematical correlation between the Ordnance

Serial Number and the USA Number of Shermans, and 43594 is an exact match to

USA 3099828, confirming that this is the "real" Champagne. She was

knocked out on September 13, 1944, not far from where she now stands. The crew

managed to escape as the tank caught fire. In the photo above, it can be seen

that the intensity of the fire melted most of the rubber from the tracks and

road wheels. Champagne was one of the few M4A3(76)s to come equipped with the

"unthreaded" M1A1 gun. Pressed Steel Car began M4A1(76) production in

January 1944, two months before Chrysler began manufacture of the M4A3(76). An

Ordnance Department document states that "All Medium Tanks M4 series (76mm

gun) since first 385 produced have been equipped with threaded gun tubes."

Thus, the M1A1 is more commonly seen on early M4A1(76)s. Our counting heads

method suggests that Chrysler was distributed less than 100 M1A1s, and

completed the transition to the threaded M1A1C guns in April 1944, the same month

that Champagne was built.

An

anomaly seen on many of the early Chrysler M4A3(76)s is the presence of

what is informally referred to as "the extra lifting ring" in front of the

loader's hatch. This is a vestige of Chrysler's abortive T23 program.

The T23 featured a boom for raising the power pack, and the extra

lifting ring served to support part of the boom's rigging. While the

extra lifting ring did no harm on the Sherman (crews like to hang stuff

on it), it was eliminated from subsequent turret molds. As best as can

be determined, about 500 "XLR" turrets were mixed in with the first four

month's M4A3(76) production at Chrysler. Chrysler was supplied with

turrets made by American Steel Foundries & Continental Steel, and

their casting logos are the only ones that have been seen on surviving

"XLR" turrets. At left, the extra lifting ring as seen on the turret of

an actual T23 Medium Tank, and the same thing at right on Champagne.

Note that the turret on the T23 has the caster's logo of

Continental-Hubbard (H in a C) (1) while Champagne has an American Steel

Foundries-Granite City (G in an octagon) logo (2). As a matter of

minutia, we would note that Continental turret castings have been

observed with "hard edges" (arrow) on the sides at the bottom, while

ASF turret molds have "soft edges" such as seen on Champagne.

An

anomaly seen on many of the early Chrysler M4A3(76)s is the presence of

what is informally referred to as "the extra lifting ring" in front of the

loader's hatch. This is a vestige of Chrysler's abortive T23 program.

The T23 featured a boom for raising the power pack, and the extra

lifting ring served to support part of the boom's rigging. While the

extra lifting ring did no harm on the Sherman (crews like to hang stuff

on it), it was eliminated from subsequent turret molds. As best as can

be determined, about 500 "XLR" turrets were mixed in with the first four

month's M4A3(76) production at Chrysler. Chrysler was supplied with

turrets made by American Steel Foundries & Continental Steel, and

their casting logos are the only ones that have been seen on surviving

"XLR" turrets. At left, the extra lifting ring as seen on the turret of

an actual T23 Medium Tank, and the same thing at right on Champagne.

Note that the turret on the T23 has the caster's logo of

Continental-Hubbard (H in a C) (1) while Champagne has an American Steel

Foundries-Granite City (G in an octagon) logo (2). As a matter of

minutia, we would note that Continental turret castings have been

observed with "hard edges" (arrow) on the sides at the bottom, while

ASF turret molds have "soft edges" such as seen on Champagne.

Unlike

the early M4A1(76)s, the turrets installed on Chrysler M4A3(76)s were

"up to spec" as regards the ventilator and the "standard" loader's split

hatch. However, period photos, such as the one taken at La Cambe, show

that some of the first Chryslers were "out of spec" as they were missing

the L-shape MG barrel stowage brackets on the turret rear. Note that on

Champagne, one can see "weld scars" on the ventilator where the machine

gun stowage pintle was once installed, but there is no evidence that

this tank ever had the L-shaped brackets. Also, observe that the

surround protecting the fire extinguisher housing is intact, that is, it

is the same height all around. A small number of surviving M4A3(76)s

are seen with a bit of the surround cut out (inset), most likely to

ensure that the turret didn't hit it. The evidence suggest that all 2nd

Generation Shermans were built with the surround intact, but that some

were cut out on M4A3(76)s, perhaps during post war rebuilds.

The examination of surviving examples makes it obvious that, at some

point fairly early on, it was decided not to machine out and provide for

the forward antenna socket on the turret. The above photos show what local researchers believe to be a combat casualty of B Company,

2nd Tank Battalion, 9th Armored Division, knocked out on or about 17

December 1944, in Clervaux, Luxemburg. This tank has been on display at

the castle in Clervaux for many years and we recorded the serial number

from one of the rear tow lugs as 43911, indicating May 1944 production.

Note that "the extra lifting ring" has been eliminated from the

Continental-Hubbard, "hard edged" turret mold, and that there is only

the "ghost" of the former antenna socket, circled in red. The blanks

over the smoke mortar hole and other openings were no doubt added for

the display, but otherwise this tank, complete with shot gouges, appears

to be a true battle relic. The US Army’s Ordnance Maintenance personnel

had an excellent record of recovering or salvaging battlefield wrecks.

Tanks that had burned were considered unrecoverable and often left in

place. 43911 does not appear to have burned, so we wonder why she was

not recovered? Update: We were informed that in 2024 this Sherman was

refurbished and placed back on display in a covered setting at Clervaux

Castle. With thanks to André Flener.

The examination of surviving examples makes it obvious that, at some

point fairly early on, it was decided not to machine out and provide for

the forward antenna socket on the turret. The above photos show what local researchers believe to be a combat casualty of B Company,

2nd Tank Battalion, 9th Armored Division, knocked out on or about 17

December 1944, in Clervaux, Luxemburg. This tank has been on display at

the castle in Clervaux for many years and we recorded the serial number

from one of the rear tow lugs as 43911, indicating May 1944 production.

Note that "the extra lifting ring" has been eliminated from the

Continental-Hubbard, "hard edged" turret mold, and that there is only

the "ghost" of the former antenna socket, circled in red. The blanks

over the smoke mortar hole and other openings were no doubt added for

the display, but otherwise this tank, complete with shot gouges, appears

to be a true battle relic. The US Army’s Ordnance Maintenance personnel

had an excellent record of recovering or salvaging battlefield wrecks.

Tanks that had burned were considered unrecoverable and often left in

place. 43911 does not appear to have burned, so we wonder why she was

not recovered? Update: We were informed that in 2024 this Sherman was

refurbished and placed back on display in a covered setting at Clervaux

Castle. With thanks to André Flener.

The 2 inch smoke mortar was

standard at the beginning of M4A3(76)W production. At Chrysler, the mortar hole

was level with the armor at first, but later production units can be seen with

a protruding sleeve. A weatherproofing cap with retaining chain was finally

added in late 1944. Fisher Body appears to have installed the weatherproofing

cap on its entire run of 525 M4A3(76)s. In January, 1945 the Ordnance

Department ordered the elimination of the smoke mortar. It is thought that the

builders would have implemented this directive in the following months. Any

remaining turrets with the smoke mortar hole would have had it covered over or

filled in, and later turrets would have been “undrilled” for the smoke mortar.

Most surviving Shermans can be seen with the mortar hole blanked off or filled

in. This would have been done during the course of their post war service, or

as part of an early 1950’s remanufacture. Thus, an intact mortar fitting on a

surviving Sherman, such as Champagne, is a clue that “time stopped” for that

tank during World War II.

Small changes were

incorporated by Chrysler during the course of production. From the outset until

around August 1944, Chrysler M4A3(76)s had what the authors think of as the

"early" glacis pattern. This featured inboard hull lifting rings and

"long" bullet splashes in front of the drivers' auxiliary periscopes

(circled in red). The top edge of the glacis plate was neatly beveled.

Chrysler transitioned to the "mid"

glacis pattern around August. The bullet splashes were shortened so

that they were only welded on directly in front of the auxiliary

periscopes. The top edge of the glacis plate was no longer beveled

flat, but was square cut, resulting in a sharp or peaked appearance as

seen above. The rear view mirrors appear to have been introduced at

about the same time as the mid glacis pattern. Photo on the far

right courtesy of Vladimir Yakubov.

Chrysler transitioned to the "mid"

glacis pattern around August. The bullet splashes were shortened so

that they were only welded on directly in front of the auxiliary

periscopes. The top edge of the glacis plate was no longer beveled

flat, but was square cut, resulting in a sharp or peaked appearance as

seen above. The rear view mirrors appear to have been introduced at

about the same time as the mid glacis pattern. Photo on the far

right courtesy of Vladimir Yakubov.

The "late" or

"final" glacis pattern was introduced by Chrysler around November

1944. It was identical to the mid pattern except that the hull lifting rings

were repositioned "outboard" to the edge of the glacis.

The

U-shaped ventilator opening between the drivers' hatches was quite

wide, about 1 inch. Thus rain water and debris could easily fall into

the ductwork below it, and threaten damage to the blower motor. Based

on user feedback, a sheet metal cover with screen was introduced around

August, 1944. We have not found any evidence that modification kits for

the covers were shipped overseas during WW II, but have noted that many

surviving Shermans that obviously didn't have this item factory

installed, had it added later during postwar upgrades. The U bolt

that can be see on the uncovered example above held the padlocks for

the drivers' hatches. Based on questions from a few modelers, we would

suggest that "uncovered" should be the default configuration for model

companies attempting to recreate a 2nd Generation welded hull Sherman

with the early glacis pattern.

The

U-shaped ventilator opening between the drivers' hatches was quite

wide, about 1 inch. Thus rain water and debris could easily fall into

the ductwork below it, and threaten damage to the blower motor. Based

on user feedback, a sheet metal cover with screen was introduced around

August, 1944. We have not found any evidence that modification kits for

the covers were shipped overseas during WW II, but have noted that many

surviving Shermans that obviously didn't have this item factory

installed, had it added later during postwar upgrades. The U bolt

that can be see on the uncovered example above held the padlocks for

the drivers' hatches. Based on questions from a few modelers, we would

suggest that "uncovered" should be the default configuration for model

companies attempting to recreate a 2nd Generation welded hull Sherman

with the early glacis pattern.

The earliest M4A3(76)s were

made with two small weep holes in the rear of the turret splash. It was found

that the small holes could become clogged with debris, causing water to back up

and foul the gasoline supply of the auxiliary generator, and/or cause a build

up of dirt in the turret bearing race. It was thought that a single, large hole

would alleviate these problems. This transition appears to have been made in

July 1944. Some of Chrysler’s early 105 Shermans can be seen to have the gap

(1) between the turret splash and the fuel cap bullet splash filled in by

welding. We have not seen any evidence of the “closed gap” on any Fisher or

Chrysler M4A3(76)s.

The earliest M4A3(76)s were

made with two small weep holes in the rear of the turret splash. It was found

that the small holes could become clogged with debris, causing water to back up

and foul the gasoline supply of the auxiliary generator, and/or cause a build

up of dirt in the turret bearing race. It was thought that a single, large hole

would alleviate these problems. This transition appears to have been made in

July 1944. Some of Chrysler’s early 105 Shermans can be seen to have the gap

(1) between the turret splash and the fuel cap bullet splash filled in by

welding. We have not seen any evidence of the “closed gap” on any Fisher or

Chrysler M4A3(76)s.

From the start of production

through about June 1944, Chrysler M4A3(76)s featured one-piece rear most engine

deck plates, as seen on Champagne in the photo on the left. Starting around

July, the rear plate was divided into two pieces to make it easier for crew

members to lift. The large, grated engine deck doors were heavy, and door

bumpers (item 1) were added to the "ultimate" M4A3 series. The

standard tool stowage arrangement can be seen above right on the restored

August 1944 production unit, formerly of the Littlefield Collection. Right side photo

courtesy of Chris Hughes.

Another early production clue

has to do with the location of the forward cable clamp (circled, above left).

Starting around July 1944, Chrysler installed the clamp more towards the front

of the tank (above right). We think of this as the “standard” position, since

it is seen on the vast majority of large hatch, welded hull Shermans. Note that

on all of its large hatch Shermans, except for a few of the first M4A2(75)s,

Fisher appears to have mounted the cable clamp in the "standard"

position from the start.

76mm and 105mm Shermans were

equipped with the same gun travel lock. It was about 4 inches taller than the

one used on 75mm tanks. Many surviving Shermans have been upgraded with a

single piece locking arm, but the less stable WW II configuration consisted of

a two "fingers" or "scissors jaw" configuration.

76mm and 105mm Shermans were

equipped with the same gun travel lock. It was about 4 inches taller than the

one used on 75mm tanks. Many surviving Shermans have been upgraded with a

single piece locking arm, but the less stable WW II configuration consisted of

a two "fingers" or "scissors jaw" configuration.

During the course of their M3

Lee program, Chrysler designed the pressed metal type of bogie (1) and idler

wheels (3). They used them throughout production on their VVSS

equipped Shermans. Their distinctive drive sprocket (2) was also employed throughout,

including HVSS production. Both Chrysler and Fisher M4A3(76)VVSS Shermans were

equipped with upswept return roller arms (4) from the start of production.

Chrysler’s Kercheval plant in Detroit was tasked with assembling bogie units.

Anything with a date is valuable to our research, and one of Chrysler’s prime

suppliers of bogie bracket castings was the National Malleable and Steel

Castings Company, whose logo was an “N in a circle” (inset, from another M4A3(76)). They included a production

date on their bogie castings. In general, original component parts will predate

the acceptance of the tank by several months. So, for instance, we know by the

serial number that the M4A3(76) in Clervaux (shown above) was made in May of

1944, and it can be seen that most of its bogies are dated 2-44.

During the course of their M3

Lee program, Chrysler designed the pressed metal type of bogie (1) and idler

wheels (3). They used them throughout production on their VVSS

equipped Shermans. Their distinctive drive sprocket (2) was also employed throughout,

including HVSS production. Both Chrysler and Fisher M4A3(76)VVSS Shermans were

equipped with upswept return roller arms (4) from the start of production.

Chrysler’s Kercheval plant in Detroit was tasked with assembling bogie units.

Anything with a date is valuable to our research, and one of Chrysler’s prime

suppliers of bogie bracket castings was the National Malleable and Steel

Castings Company, whose logo was an “N in a circle” (inset, from another M4A3(76)). They included a production

date on their bogie castings. In general, original component parts will predate

the acceptance of the tank by several months. So, for instance, we know by the

serial number that the M4A3(76) in Clervaux (shown above) was made in May of

1944, and it can be seen that most of its bogies are dated 2-44.

Click on

the photo for larger size

It is thought that all of the

525 M4A3(76)s manufactured by Fisher Body from September to December 1944 would

have featured Vertical Volute Spring Suspension and the late glacis pattern. We

estimate that Fisher completed the transition to the D7054366 turret with oval

loader's hatch, and the M1A2 gun with muzzle brake in October, 1944. The tank

pictured above can be seen to be USA 30116364, indicating December, 1944

acceptance. A couple of clues as to its Fisher (as opposed to Chrysler) origin

can be found in the "plain" drive sprocket (1), and the solid concave

road wheels (2). By mid 1944, two types of road wheels were prevalent on Fisher

VVSS Shermans - the solid, and the "welded spoke with small holes"

(inset). The improved T-shaped towing shackles (3) were introduced in October. A

close look at the USA Number (4) shows that it was also welded on. This was a

practice of the 1st Armored Division in Italy, and indeed their records

indicate that 30116364 was issued to the 13th Tank Battalion on April 1, 1945. The photo was taken at Ft. Monmouth,

New Jersey 3 years later on April 3, 1948. This

tank is what we informally call a "bring back." Most likely it would

have been retrofitted with HVSS during the remanufacture program of the early

1950s.

Click on

the photo for larger size

It is thought that all of the

525 M4A3(76)s manufactured by Fisher Body from September to December 1944 would

have featured Vertical Volute Spring Suspension and the late glacis pattern. We

estimate that Fisher completed the transition to the D7054366 turret with oval

loader's hatch, and the M1A2 gun with muzzle brake in October, 1944. The tank

pictured above can be seen to be USA 30116364, indicating December, 1944

acceptance. A couple of clues as to its Fisher (as opposed to Chrysler) origin

can be found in the "plain" drive sprocket (1), and the solid concave

road wheels (2). By mid 1944, two types of road wheels were prevalent on Fisher

VVSS Shermans - the solid, and the "welded spoke with small holes"

(inset). The improved T-shaped towing shackles (3) were introduced in October. A

close look at the USA Number (4) shows that it was also welded on. This was a

practice of the 1st Armored Division in Italy, and indeed their records

indicate that 30116364 was issued to the 13th Tank Battalion on April 1, 1945. The photo was taken at Ft. Monmouth,

New Jersey 3 years later on April 3, 1948. This

tank is what we informally call a "bring back." Most likely it would

have been retrofitted with HVSS during the remanufacture program of the early

1950s.

Ordnance documents state that

the Muzzle Brake, M2 was standardized, and 300 had been produced by the end of

August 1944. Production was scheduled at the rate of 100 per day "until

requirements are met." Internal items were necessary, including a

counterweighted breech guard, to balance the 87 pound muzzle brake. US Armored

Forces in Europe began requesting muzzle brake modification kits and long

primer ammunition in early September, 1944. In general, priority for new items

was given to the tank manufacturers. Modification kits for Tank Depot and Field

installation were produced only after manufacturers' requirements were met. When

the Ordnance Department informed the ETO that Modification kits would not

become available until early 1945, the response was that this was "not

satisfactory. Urgent requirement exists." The ETO insisted on the

immediate air shipment of 3 stand alone muzzle brakes, and a further 600 by

fast water transport, with the note "counterweights can be added by Field

Modification." As it was, these items were shipped in late December, just

as the first M4A3(76)s with muzzle brakes and HVSS were distributed to troops

in Europe. We've reproduced a few pages of the Modification Work Order above. It

is dated July 25, 1945, not quite the "early 1945" availability that

Ordnance had given to the ETO. No doubt other factors were involved, but it is

likely that the diversion and shipment of the 603 muzzle brakes may have played

a role in the delayed release of the MWO.

Ordnance documents state that

the Muzzle Brake, M2 was standardized, and 300 had been produced by the end of

August 1944. Production was scheduled at the rate of 100 per day "until

requirements are met." Internal items were necessary, including a

counterweighted breech guard, to balance the 87 pound muzzle brake. US Armored

Forces in Europe began requesting muzzle brake modification kits and long

primer ammunition in early September, 1944. In general, priority for new items

was given to the tank manufacturers. Modification kits for Tank Depot and Field

installation were produced only after manufacturers' requirements were met. When

the Ordnance Department informed the ETO that Modification kits would not

become available until early 1945, the response was that this was "not

satisfactory. Urgent requirement exists." The ETO insisted on the

immediate air shipment of 3 stand alone muzzle brakes, and a further 600 by

fast water transport, with the note "counterweights can be added by Field

Modification." As it was, these items were shipped in late December, just

as the first M4A3(76)s with muzzle brakes and HVSS were distributed to troops

in Europe. We've reproduced a few pages of the Modification Work Order above. It

is dated July 25, 1945, not quite the "early 1945" availability that

Ordnance had given to the ETO. No doubt other factors were involved, but it is

likely that the diversion and shipment of the 603 muzzle brakes may have played

a role in the delayed release of the MWO.

Click on

the photos for larger size

Click on

the photos for larger size

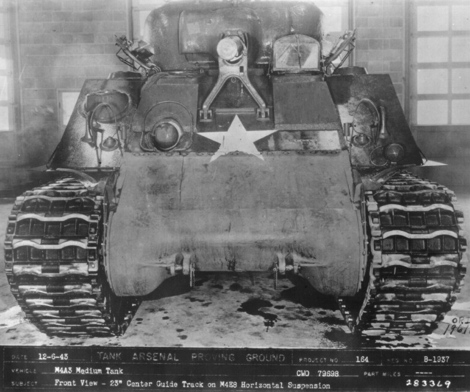

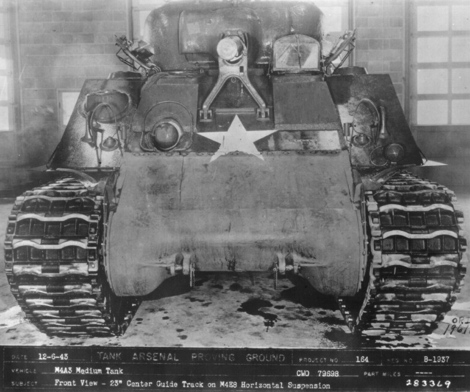

In the Summer of 1943, the

Chrysler Corporation began development of "horizontal volute spring

suspension and 23” center guided tracks for Medium Tank, M4 series." The

"E8" modification was an effort to improve the ride and increase the

mobility of the Sherman series. The photos above show one of the pilots, a

September 1943 Ford M4A3(75), at Chrysler's Tank Arsenal Proving Ground on

December 6, 1943. HVSS was released for production in April, 1944, and Chrysler

completed the transition to the manufacture of all HVSS Shermans in September. Fisher

Body and Pressed Steel Car completed the changeover on January 1, 1945. Fisher

produced 525 M4A3(76)s from September through December, 1944, and it is thought

that all of them were made with VVSS. Thus Chrysler was solely

responsible for series production of the M4A3(76) with HVSS.

The average shipping time of a

new tank from factory to combat troops was 4 to 5 months. The first M4A3(76)s

with HVSS appear to have been distributed at the end of December, 1944. For

instance on December 30, the 37th Tank Battalion, 4th Armored Division reported

that they had 5 "76mm - new suspension." The Signal Corps photo above

is datelined Bastogne, Belgium, January 8, 1945. The caption simply reads,

"Tanks of the 4th Armd Div ready for action in front lines." While

not the most informative shot, we have included it because it shows what may be

the earliest appearance of both HVSS and the muzzle brake in a combat theater. The

.50 caliber Machine Gun appears to be positioned pretty far forward and to the

left on the turret, suggesting that it may be the earlier D82081 turret, with

the MG mounted on the pintel of the loader's split hatch. Chrysler began

factory installation of the muzzle brake in October, and introduced the later

7054366 turret with oval loader's hatch in that same month. Due to the

transitional nature of the introduction of changes, some examples of earlier

turrets can be seen with guns with muzzles brakes, while some later turrets can

be seen without them.

The Signal Corps shot a

"walk around" of USA 3031867, an October 1944 production

M4A3(76)HVSS. The design of the muzzle brake was "borrowed" from the

Germans, and in order to avoid friendly fire incidents, an effort was made to

alert Allied Troops to the presence of muzzle brakes on new production

Shermans. 3031867 was photographed on January 17, 1945 as it was being

processed for issue by the 98th Ordnance Heavy Maintenance Company (Tank) based

near Charmes in the Lorraine area of France. The stencil on the front (1) reads

"American Export Modification, November 6, 1944," indicating that

this tank was still at a US Tank Depot on that date. The original stars and

shipping code have been scrubbed out, but we suspect 3031867 came in through

the port of Marseilles, whose destination code was "LEGS." The newly

painted "stars in a circle" are much more commonly seen on tanks

processed by Ordnance units in Italy and southern France. The automobile style

horn (2) replaced the siren in production in the summer of 1944. The shipping

brackets (3) on the front and rear bogies were directed to be removed upon

final delivery. "Failure to remove this bracket when unloading the vehicle

from the freight car often results in damage to the tracks when operated over

rough terrain."

The Signal Corps shot a

"walk around" of USA 3031867, an October 1944 production

M4A3(76)HVSS. The design of the muzzle brake was "borrowed" from the

Germans, and in order to avoid friendly fire incidents, an effort was made to

alert Allied Troops to the presence of muzzle brakes on new production

Shermans. 3031867 was photographed on January 17, 1945 as it was being

processed for issue by the 98th Ordnance Heavy Maintenance Company (Tank) based

near Charmes in the Lorraine area of France. The stencil on the front (1) reads

"American Export Modification, November 6, 1944," indicating that

this tank was still at a US Tank Depot on that date. The original stars and

shipping code have been scrubbed out, but we suspect 3031867 came in through

the port of Marseilles, whose destination code was "LEGS." The newly

painted "stars in a circle" are much more commonly seen on tanks

processed by Ordnance units in Italy and southern France. The automobile style

horn (2) replaced the siren in production in the summer of 1944. The shipping

brackets (3) on the front and rear bogies were directed to be removed upon

final delivery. "Failure to remove this bracket when unloading the vehicle

from the freight car often results in damage to the tracks when operated over

rough terrain."

This photo of 3031867 provides

a good view of the mid glacis. Note the "sharpness" (1) of the square

cut upper edge, a characteristic of mid and late glacis plate patterns. The

extended smoke mortar (2) is simply taped over. While Fisher Body began to install

the smoke mortar cap with retaining chain to its Shermans in July 1944,

Chrysler doesn't appear to have added it until December, at about the same time

as the introduction of the fittings for the canvas mantlet cover. The T80

tracks (3) were considered greatly superior to Chrysler's original design T66

tracks. Internal correspondence mentions that Chrysler ran short of track, and

shipped some of its HVSS Shermans to depots without them. Fisher Body and

Pressed Steel Car were accumulating 23 inch tracks in anticipation of their

change over to HVSS, and they diverted some of their supplies to the depots, so

that the Chrysler tanks could be completed and shipped out.

Second generation Shermans

started out with the quick release towing fixtures shown on the left. An

Ordnance Dept. "Report of Modifications Entering Production at

Facilities" states that the "Cross Bar Towing Hooks" were

installed on M4A3(76)s at the Detroit Tank Arsenal starting on December 12,

1944 at Serial Number 60798. We interpret this to be a reference to the T

shaped towing shackles shown in our right side photo. A tow cable could be

hooked on to the new shackles without removing them. This saved crews a few

seconds when attempting to retrieve a tank while under fire. It was no longer

necessary to have two tow lugs per side with the new shackles, but the

"extra" lugs on the differential were retained since they also

provided attachment points for the steps. We suspect that only one rear tow lug

was used at or shortly after the introduction of the new shackles. At present, all of the the surviving M4A3(76)HVSS Shermans

that we have examined with Serial Numbers 60980 and above have single towing

lugs in the rear. Restorers and modelers

should note that the T-shaped shackles are not seen in WW II combat photos

before 1945.

As mentioned previously, it averaged between 4 and 5 months to deliver a

new tank into the hands of combat troops. For all intents and purposes,

this rendered the entire US 1945 production of AFVs extraneous to the

war effort. It would appear that Chrysler began to factory install the

fittings for the 76mm canvas mantlet cover in December 1944, but the

actual covers seem to appear randomly at first, perhaps sent along as

supplies began to trickle in. The photo above, dated March 31, 1945, is

the earliest one we have found that shows the mantlet cover in the ETO.

This tank was being processed for issue by the 561st Ordnance Heavy

Maintenance Company (Tank) in München Gladbach, Germany. It is to be

noted that only the "final" version of the mantlet cover is seen on

Chrysler M4A3(76)s. Evidence suggests that the 540 M4A3(76)s with VVSS

produced by Fisher never had the fittings/covers factory installed. The

less complex, original type mantlet cover was installed on the 76 mm

pilot turret, as well as on Fisher M4A2(76)s made in March and April

1945 (inset). The final version was almost universally retrofitted to

76mm Shermans in the postwar years.

The above Signal Corps photo is much larger, but we have zoomed in to

the Sherman, since it is one of the few WW II "combat shots" that shows

an installed canvas mantlet cover. The caption is dated 8 April 1945 and

shows an M4A3(76)HVSS of the 47th Tank Battalion, 14th Armored Division

working with men of the 19th Armored Infantry Battalion to round up

prisoners in the town of Hesselbach, Germany. The 14th AD made elaborate

use of sandbags on its light and medium tanks in 1945. Because of this,

units often painted their tactical markings on the tanks' gun barrels,

as seen here. A T shaped towing shackle (circled) is just visible. Again,

these were reported to have been installed by Chrysler on 12 December

1944 at Serial Number 60798.

Here

we see that the original sheet metal exhaust deflector has survived in

remarkably good condition on the historic Champagne. The "prop up" rod has been broken off, so we offer an example from another Sherman as an inset. Many

surviving M4A3(76)s were retrofitted with the armored exhaust deflector

in the course of their post war service, so the presence of the

original deflector can be a minor clue that "time stopped" for a

particular tank during WW II. The

deflector was designed for the single purpose of directing engine

exhaust out and away from the vehicle. However, reports from the

fighting fronts indicated that the engine's radiators were being damaged

by shrapnel from ground bursts and the like. In response, Ordnance came

up with a two section deflector made of "armor plate strips." As we

shall see Chrysler reported that they began factory installing these at

the beginning of 1945. The Modification Work Order is dated 2 April,

1945, and directs that the armored deflectors "be applied to all of the

subject vehicles in or destined to be shipped to theaters of operation

that are not so equipped." Furthermore, the applicable AFVs, which

included the entire M4A3 series, as well as M32B3 Retrievers, M7B1

Priests and M36 and M36B1 Tank Destroyers "will not be shipped overseas

after 15 May 1945 unless this work order has been applied." Of course

this was too late for WW II, and it is thought that most or all of these

kits were placed in storage (the MWO directs that excess kits

be returned to Rock Island Arsenal), and were retrofitted post war at

Base Shops or during rebuild programs.

The "Report of

Modifications..." has it that the "Armor Plate Exhaust

Deflector" was installed on Chrysler M4A3(76)s starting January 1, 1945 at

Serial Number 61235. We cannot verify that through "counting heads,"

since this item was retrofitted to large numbers of Ford engined AFVs by a

Modification Work Order Kit that became available in April 1945. The photo

above shows M4A3(76)HVSS and M4A3(105)HVSS Shermans at the Detroit Tank Arsenal

with the new deflectors mostly in the "up" position. Canvas mantlet covers

have been installed as well. While most of these units can be seen to have the

later T80 tracks, a few have the earlier T66, as evidenced by the protruding

center guides on the spares (circled). The center guides were integral on the

T66 type, whereas they were separate parts on the T80. Note that the Armored

First Aid Boxes are not present on these tanks.

Occupation

Zones had been agreed upon at the Yalta Conference, and most

US/Commonwealth units were already in the Soviet Zone by late April,

when they were ordered to halt and cease offensive operations. Elements

of the US Third Army, including the 4th Armored Division, continued to

advance during the final days of the war in Europe. Their objective was

Prague, but they were ordered to halt in the vicinity of Lnare,

Czechoslovakia on May 6, 1945, two days before VE-Day. There are a few

period photos that show two different 4th AD M4A3(76)s with HVSS in

Czechoslovakia. At present these are the only WW II "combat shots" we

have come across that show such Shermans with the armored exhaust

deflectors installed. The example above was photographed in Strakonice

on May 6.

The armored first aid box can

be seen in photos of both the M26 and M24 in Europe before VE-Day. Initial

supplies were reserved for these new models. They appear to have become

available for installation on both new and remanufactured Shermans starting around

March, 1945. However, while Chrysler ended M4A3(76) production in April, we

have not been able to find any evidence that any units were factory equipped

with the First Aid Box. "Counting heads" is complicated by the fact

that this item was retrofitted to many M4A3(76)s in the post war years.

The photo above shows an M26 of the 14th Tank Battalion, 9th Armored Division

near Vettweiss, Germany on March 1, 1945. The first aid box is circled,

and can be seen more completely in the inset. The few M26s that saw WW II

service would have been made by Fisher Body in late 1944, early 1945. Like

early M4A3(76)s, they were characterized by an "extra lifting ring"

(arrow), which was later eliminated. Chrysler didn't begin M26 production until

March, 1945.

The armored first aid box can

be seen in photos of both the M26 and M24 in Europe before VE-Day. Initial

supplies were reserved for these new models. They appear to have become

available for installation on both new and remanufactured Shermans starting around

March, 1945. However, while Chrysler ended M4A3(76) production in April, we

have not been able to find any evidence that any units were factory equipped

with the First Aid Box. "Counting heads" is complicated by the fact

that this item was retrofitted to many M4A3(76)s in the post war years.

The photo above shows an M26 of the 14th Tank Battalion, 9th Armored Division

near Vettweiss, Germany on March 1, 1945. The first aid box is circled,

and can be seen more completely in the inset. The few M26s that saw WW II

service would have been made by Fisher Body in late 1944, early 1945. Like

early M4A3(76)s, they were characterized by an "extra lifting ring"

(arrow), which was later eliminated. Chrysler didn't begin M26 production until

March, 1945.

It was the intention of

the Army to provide its fighting troops with the best possible armor technology

as it became available during the relatively brief span of US involvement in

World War II. To that end, an attempt was made to distribute improvements such

as 76mm guns, muzzle brakes, better ammunition, Ford engined tanks and HVSS on

an equal basis. By VE-Day about 2200, or approximately half of the surviving

Shermans in the European Theater, were armed with the 76mm gun. About 1000 of

those had HVSS. There were about 100 of the Sherman's replacement, the M26, on

strength in May, 1945. The docks and depots on the Continent were teeming with

thousands of additional AFVs. Many of these would have been reprocessed for

direct shipment to the Pacific. The document above shows the March 3rd, 1945

allocation of tanks to the 12th Army Group, and remarks that, "Effort is

being made to get the 76mm gun tank in the hands of troops, therefore no 75mm

gun tanks are being allocated." In fact, the last allocation of 75mm

Shermans was on February 9th.

It was the intention of

the Army to provide its fighting troops with the best possible armor technology

as it became available during the relatively brief span of US involvement in

World War II. To that end, an attempt was made to distribute improvements such

as 76mm guns, muzzle brakes, better ammunition, Ford engined tanks and HVSS on

an equal basis. By VE-Day about 2200, or approximately half of the surviving

Shermans in the European Theater, were armed with the 76mm gun. About 1000 of

those had HVSS. There were about 100 of the Sherman's replacement, the M26, on

strength in May, 1945. The docks and depots on the Continent were teeming with

thousands of additional AFVs. Many of these would have been reprocessed for

direct shipment to the Pacific. The document above shows the March 3rd, 1945

allocation of tanks to the 12th Army Group, and remarks that, "Effort is

being made to get the 76mm gun tank in the hands of troops, therefore no 75mm

gun tanks are being allocated." In fact, the last allocation of 75mm

Shermans was on February 9th.

Click on

the photos for larger size

Click on

the photos for larger size

Shipments of M4A3(76)s

to the US Fifth Army in Italy were more or less evenly distributed as

replacements. By the time of the 1945 Spring Offensive, the US Tank Battalions

there had a preponderance of the newer Shermans. Indeed, all but one of the

Battalions had collected a company's worth (~17) of reserve M4A3(76)s for

immediate replacement of losses. The 752nd Tank Battalion had completely

replaced it's 39 M4 and M4A1(75)s with 54 M4A3(76)s by March 7th. However, in

early April, the unit put a platoon of M4A3(76)s from each Company in reserve,

and replaced them with older 75mm Shermans for use as expendable "point

tanks" in the upcoming campaign. The well known Signal Corps photo above

was taken in the Plaza Emanuel in Bologna, April 21, 1945. It shows elements of

the 752nd with mostly 76mm Shermans, along with the M18s of the 805th Tank

Destroyer Battalion. Loads of Fisher built M4A3(76)s arrived in Italy in early

1945, and we believe the units with the late glacis patterns and muzzle brakes

would be some of them. Note the various non standard orientations of the

commander's cupolas. Aside from new M4A3s armed with 76mm and 105mm guns, the

752nd had replaced its Company of M5 series Light Tanks with M24s by March

12th. However, in the photo, the Light Tanks can be seen to be M5A1s. Battalion

records note that "On the 5th of April, the light tank company lost its

new M24s to the First Armored." The wasted training, and the loss of the

M24's 75mm firepower occasioned much griping.

The

photo above is dated March 24, 1945 at the Peninsula Base Section

Vehicle Park near Livorno, Italy. The M4A3(76)HVSS can be seen as USA

30114244, indicating that it was Chrysler built, and accepted in early

January, 1945. 1945 production AFVs "in theater" are rare, and

in fact, this is the highest M4A3(76) Registration Number we have recorded from

an overseas WW II photo or unit roster. Oddly, considering that there would

have been sufficient time to distribute this tank, we have no evidence that any

units of the Fifth Army employed any M4A3(76)HVSS before the German surrender

in Italy on May 2nd. The M4A3(76)VVSS Shermans in the photo can be identified

as Fisher built by their "plain" drive sprockets, along with the

concave and/or "small holes" type road wheels. One example is

equipped with the T49 “interrupted parallel type grouser” steel tracks. At

least 2 M4A3(105)s can be seen. As they became available, they

replaced the M7 Priests in the US Tank Battalions of the Fifth Army. It might

be noted that, due to the mountainous terrain of Italy, many crews preferred

the open top of the M7 over the turreted M4A3(105).

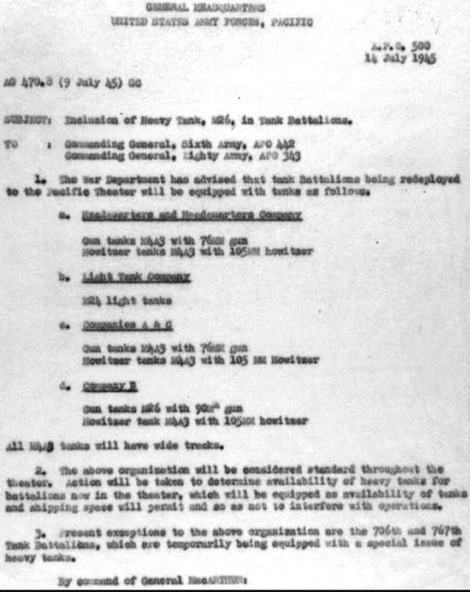

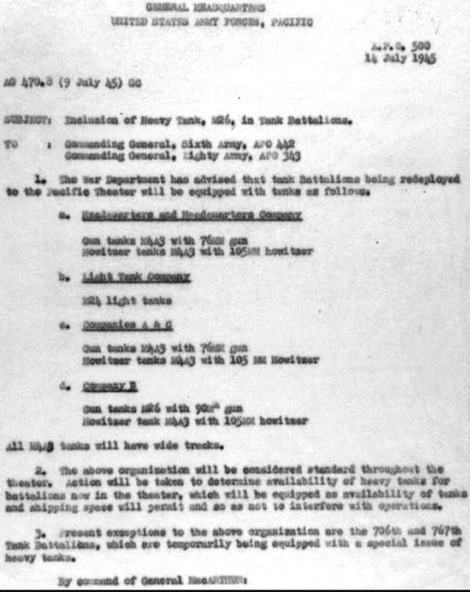

While no 76mm Shermans, (or

M26s for that matter) were used in combat in the Pacific Theater, plans for the

Invasion of Japan envisioned the employment of 12 or more Tank Battalions,

equipped with the most modern AFVs. It was intended to outfit each Army Battalion with M26s, M4A3(76)s and

M4A3(105)s with HVSS, and M24 Light Tanks as shown in

the proposed July 1945 TO&E reproduced above. The Marines continued to

prefer the 75mm Sherman over the 76, and their plans included the use of

M4A3(75)s and M4A3(105)s with HVSS in the 3 Battalions slated to take part. Documentation courtesy

of Trent Telenko. For more information about the plans for the invasion of

Japan, see his “Secrets of the Pacific Warfare Board -- Pershing Tanks for

Operation Olympic.” http://chicagoboyz.net/archives/43946.html

M4A3(76) production was

terminated in April 1945 after 4542 units had been built. Officially, 1925 were

VVSS models and 2617 were HVSS. The planners had to assume that there would be

an invasion of Japan, and that the campaign might drag on for many months or

even years. To this end, Fisher Body and Chrysler were contracted to produce

7500 M26s to replace the Sherman as the Army's main battle tank. As it turned

out, M26 production was terminated in October 1945, after only 2202 had been

manufactured. With the onset of the Cold

War, it was realized that this number would be insufficient to meet the Army's

requirements, and thus the M4A3(76)HVSS was continued in service as an

acceptable substitute for the M26. The photo above

shows the M24, the M4A3(76)HVSS and the M26 - "the three primary tanks of

the Army" at Camp Hood, Texas in October, 1947.

PAGE 1/2

Go to page 2

HOME