Sherman 75mm turret

types

Most

of the information on this page is courtesy of Joe DeMarco. Note: some of the information on

this page was compiled using a

technique informally referred to as "counting heads".

It is based on the ongoing study of period documents and

photographs, as well as surviving Shermans. Due to the

limited nature of available reference

sources, some of the information presented here must be

considered as "educated guesswork"

.

Synthesis / evolution of the 75mm turret

___________________________________________________________

First D50878 Turret as Seen on the T6 Pilot

The initial

design of the Sherman 75mm turret can be seen on the T6 pilot above.

This turret featured a gunner's rotor sight device (1), pistol ports

with M3 Lee style protectoscopes (2) on both the left and right sides,

the M3 Lee machine gun cupola (3), and a very simple gun shield (4)

without any sort of protection for the gun's rotor (5). Note that

the turret and the gun shield were not equipped with lifting rings.

The challenge in the development of the US Medium Tank was to

design a superstructure that could carry a turret large enough to

accommodate three men and mount a 75mm gun. For this purpose, it was

thought that the turret ring would need to have an inside diameter of 69

inches. In retrospect, this was one thing the designers "got right"

from the start. It was determined that the turret of the new Medium Tank

would be cast armor, while the upper hull would be of either welded or

cast armor construction. Above shows a left rear view of the T6 turret.

On subsequent turrets, the M3 type protectoscope (1) was replaced with a

solid door, and the pistol port on the right side was eliminated from

the design altogether. Originally, the T6 turret did not have lifting

rings (2). These were added to the turret and gun shield during

development and became standard. The 30 October 1941 date of the photo

gives an idea of the chronology. Another item that was retrofitted to

the T6 turret is the secondary antenna bracket (3) which also became a

standard feature. The turret basket was encased in steel mesh (4). It

wasn't until early 1943 that the Ordnance Department acknowledged that

this was a safety issue, since the mesh "trapped" the turret crew, and

isolated the drivers. In April, work was begun to redesign

("skeletonize") the turret basket. In August 1943, as part of a more

comprehensive "Quick Fix" Modification, the mesh was instructed to be

removed from existing Shermans.

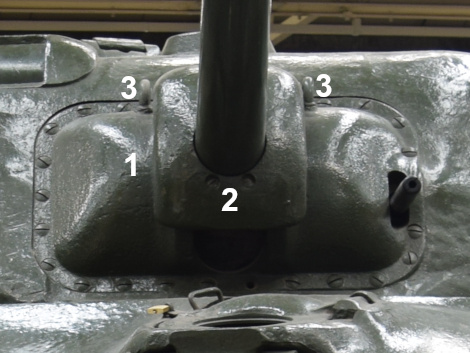

In this view

through the commander's hatch opening, note the brackets (1) installed

in the turret bustle. They could accommodate either the US or British

standard tank radio. The commander's (2) and loader's seat (3) were

affixed to the turret basket wall and were height adjustable. A bit of

the 75mm gun's breach and breach guard (4) can be seen. With only one

hatch in the turret, the breach guard presented an obstacle to the

loader as he attempted to escape in emergency situations. During the

initial design work, a loader's hatch was considered, but rejected in

the interest of simplicity. As a result of numerous combat reports, a

loader's hatch was added as a standard item on Sherman turrets in late

1943. Twelve ready rounds can be seen mounted to the wall of the turret

basket. Ready rounds were very popular with tank crews but were

extremely vulnerable. Along with the steel mesh around the turret

basket, the "Quick Fix" Modification ordered the elimination of the

ready rounds. Not only were they vulnerable, but as is evident here,

when in place, they also blocked the crew's escape.

"Low Bustle" D50878 75mm Turrets

The Sherman design was still being

revised as the first tanks rolled off the assembly lines. Some early

M4A1(75)s can be seen to have rotor sights as on the T6 pilot turret.

The exact number is unknown, but a Lima memo dated 21 January 1942

provides a clue when it states, "First 30 tanks using Rotor Device." It

is thought that 10 or so of the early Pressed Steel Car M4A1s also had

rotor sight turrets. The rotor sight was vulnerable to being fouled by

bullet splash and by April 1942, a revised D50878 casting that

incorporated a gunner's periscope replaced it in production. As best we

can tell, no other company's Shermans used the rotor sight device, so

this should only be seen on very early Lima and PSC M4A1s. The rotor

sight device was considered "not-battle worthy", and such turrets were

not to be shipped overseas to combat units. However, at least one

slipped through the cracks - a period photograph (right side) shows a "rotor

sight" M4A1 on a Sherman of the 751st Tank Battalion near Montemarano,

Italy on September 29, 1943.The left side photos above provide front and rear

views of the rotor sight casting on the only surviving Sherman known to

have this feature. This is "Michael", the second M4A1 produced by Lima

Locomotive Works. It would have been accepted in March 1942 and is the

earliest surviving Sherman in the world. It is on display at the Tank

Museum at Bovington in the UK.

The

rather simple gun shield used on the T6 pilot was replaced with a

heavier casting (1), Part Number D50880 as seen here on "Michael" at

Bovington. A rotor shield (2) was added to protect the gun works from

bullet splash. This combination of gun, gun shield and "narrow" rotor

shield was labeled "M34 Gun Mount." The

gun shield was equipped with lifting rings (3) and on some early

production Shermans, they were welded on very close to the rotor shield

as seen here. Some of these "close mounted" lifting rings got damaged

and bent inward in service, which caused them to foul against the rotor

shield, and disable the elevation of the gun. Consequently, in the

Summer of 1942, the lifting rings were ordered to be mounted further

away from the rotor shield.

The original design of the T6 pilot included the odd machine gun cupola

as used on the M3 Lee. However, in a conference on "presentation day," 3

September 1941, it was determined to replace it with a commander's

split hatch cupola similar to the one the British had designed for the

turrets of their M3 Grants. The photo above shows the hatch on

"Michael." It can be seen that both the hatch ring (1) and the hatch

halves (2) were castings, and we would point out to plastic model

companies that the hatch halves included "ridges" (3) on their outer

edges. On this example, the anti-aircraft machine gun pintle (4) that

was part of the hatch ring casting is small and includes some sort of

tightening fixture bolted on (inset). We suspect that the use of this

"small pintle" casting was limited like the rotor sight, to some of the

first few M4A1s produced by Lima and Pressed Steel Car. If one assumes

that the factory orientation of the pintle was facing front, then it can

be said that the revolving periscope (5) was mounted in the right-side

hatch "flap" as the British called it. For some reason, the British did

not include a lifting handle on their Grant cupolas, and the omission of

this simple component appears to have carried over to the Sherman

series for the first several months of production. Just looking at the

photo above, one wonders how users were supposed to lift the hatches.

The original design of the T6 pilot included the odd machine gun cupola

as used on the M3 Lee. However, in a conference on "presentation day," 3

September 1941, it was determined to replace it with a commander's

split hatch cupola similar to the one the British had designed for the

turrets of their M3 Grants. The photo above shows the hatch on

"Michael." It can be seen that both the hatch ring (1) and the hatch

halves (2) were castings, and we would point out to plastic model

companies that the hatch halves included "ridges" (3) on their outer

edges. On this example, the anti-aircraft machine gun pintle (4) that

was part of the hatch ring casting is small and includes some sort of

tightening fixture bolted on (inset). We suspect that the use of this

"small pintle" casting was limited like the rotor sight, to some of the

first few M4A1s produced by Lima and Pressed Steel Car. If one assumes

that the factory orientation of the pintle was facing front, then it can

be said that the revolving periscope (5) was mounted in the right-side

hatch "flap" as the British called it. For some reason, the British did

not include a lifting handle on their Grant cupolas, and the omission of

this simple component appears to have carried over to the Sherman

series for the first several months of production. Just looking at the

photo above, one wonders how users were supposed to lift the hatches.

As mentioned, the T6's turret had pistol ports with M3 Lee style

protectoscopes on both the left and right sides. Production D50878

turrets had a pistol port on the left side only, and the solid door

casting was somewhat larger than the protectoscope. On "Michael," the

door's part number can be seen as D 51289 with the "S in a circle" logo

indicating the piece was cast by Symington-Gould of Rochester, New York.

The same logo is seen on the armored gas cap covers (1). Indeed, the "S

in a circle" logo appears on many of the cast components of "Michael"

including the drivers' hatches and direct vision blocks. The fire

extinguisher pull housing (2) is mounted in a non-standard position

facing up. The standard position was facing to the rear.

As mentioned, the T6's turret had pistol ports with M3 Lee style

protectoscopes on both the left and right sides. Production D50878

turrets had a pistol port on the left side only, and the solid door

casting was somewhat larger than the protectoscope. On "Michael," the

door's part number can be seen as D 51289 with the "S in a circle" logo

indicating the piece was cast by Symington-Gould of Rochester, New York.

The same logo is seen on the armored gas cap covers (1). Indeed, the "S

in a circle" logo appears on many of the cast components of "Michael"

including the drivers' hatches and direct vision blocks. The fire

extinguisher pull housing (2) is mounted in a non-standard position

facing up. The standard position was facing to the rear.

The montage above shows the pistol port in the open and closed positions

from both inside and outside the turret. One of the authors recently

had the opportunity to operate a pistol port, and his first impression

was that it was much heavier than expected. The L shaped handle or

“lever,” served as a simple prop, which held the door open, and locked

it into position by means of a “lever locking pin” (1) which could be

slipped into a “notch” (2) with a rotation of the handle. To secure the

pistol port door in the closed position, the handle was rotated until a

fixed “latch” (3) contacted a fitting (4) welded on just above the

pistol port opening. The “lever handle” (5) was installed with a rubber

bicycle type grip which is missing from this example.

The montage above shows the pistol port in the open and closed positions

from both inside and outside the turret. One of the authors recently

had the opportunity to operate a pistol port, and his first impression

was that it was much heavier than expected. The L shaped handle or

“lever,” served as a simple prop, which held the door open, and locked

it into position by means of a “lever locking pin” (1) which could be

slipped into a “notch” (2) with a rotation of the handle. To secure the

pistol port door in the closed position, the handle was rotated until a

fixed “latch” (3) contacted a fitting (4) welded on just above the

pistol port opening. The “lever handle” (5) was installed with a rubber

bicycle type grip which is missing from this example.

We might

generalize that early production D50878 turrets had the lifting rings

mounted "high" as seen on the left. We can narrow it down a bit further,

since the "highs" appear mostly on Shermans built by Lima Locomotive,

Pressed Steel Car and Fisher Body. Counting heads suggests that Lima and

PSC transitioned to the "low" position before the end of the Summer of

1942. ALCO, Baldwin, and Federal Machine appear to have started

production with the "lows", while Chrysler, Ford and Pullman produced

one or two of their first tanks with the "highs" before changing over to

the "lows." For some reason, Fisher Body manufactured M4A2s with high

turret lifting rings up until at least February 1943.

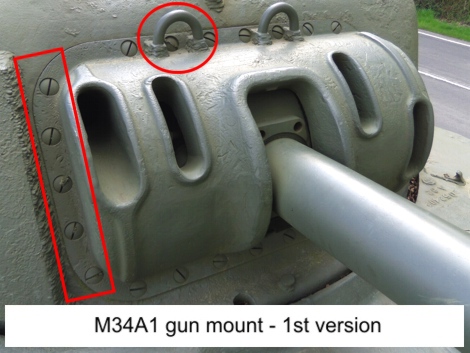

Based

on feedback from the

using arms, a number of changes were introduced into production in

early 1943.

A direct sight telescope was added, & to protect it &

the coaxial MG,

the rotor shield was widened. The new configuration was

labeled

"M34A1 Gun Mount".

Based

on feedback from the

using arms, a number of changes were introduced into production in

early 1943.

A direct sight telescope was added, & to protect it &

the coaxial MG,

the rotor shield was widened. The new configuration was

labeled

"M34A1 Gun Mount".

The first version of the M34A1 gunshield had

lifting rings & attachment flanges on the

top, bottom & right

side (left-side photo).

The final version of the gunshield eliminated the lifting rings,

&

moved the right side attachment points to the inside of the

turret,

thus dispensing with the outer flange on that side.

There were a number of reports of crew injuries because the locks of the

original design of all of the Sherman's hatches were insufficient. When

in the open position, the heavy hatches were liable to slam down when

they brushed against tree branches or when the tank bounced around

violently as tanks do. As a result, positive hatch lock mechanisms were

introduced into production (circled in red) beginning around the Spring

of 1943, and modification kits for all of the hatches were provided for

depot and field retrofit.

There were a number of reports of crew injuries because the locks of the

original design of all of the Sherman's hatches were insufficient. When

in the open position, the heavy hatches were liable to slam down when

they brushed against tree branches or when the tank bounced around

violently as tanks do. As a result, positive hatch lock mechanisms were

introduced into production (circled in red) beginning around the Spring

of 1943, and modification kits for all of the hatches were provided for

depot and field retrofit.

A spot light (circled in red

on the center picture) was also introduced in early

1943. Many of the

earlier turrets that lacked the spot light & its

fittings (left-side

photo), had them retrofitted during later upgrades. The

right-side photo

shows how the spotlight was mounted on the fitting.

A spot light (circled in red

on the center picture) was also introduced in early

1943. Many of the

earlier turrets that lacked the spot light & its

fittings (left-side

photo), had them retrofitted during later upgrades. The

right-side photo

shows how the spotlight was mounted on the fitting.

Two sections of the right front interior of the turret were thinned or

scooped out to prevent "the knuckles of the operator from being skinned

or barked when using the hand traversing mechanism." As the Sherman

entered combat, reports came in that the enemy aimed for these "thin

spots." To protect this area, a patch on the right front of the turret

was introduced around Spring 1943, and modification kits were provided

for depot and field installation. The photo on the left shows the thin

spots on the interior turret wall, while the photo on the right shows

the modification installed on the exterior. The "turret patch" consisted

of two castings welded together in the middle as seen here. Each

casting is listed as having been 1 1/2 inches thick.

Heretofore, all 75mm turrets were cast with a pistol port on the left

side towards the rear (left-side photo). However, in April 1943 the

Ordnance Department determined that the pistol port was a ballistic

hazard and called for its elimination. Consequently, the D50878 turret

was redesigned without the pistol port as shown on the right.

As part of the same redesign, the "thin spot" was remedied with what

modelers call the "cast in, thickened cheek" on the right front (circled

in red in the left side photo), thereby eliminating the need to weld on

the turret patch. The extent of the "bump out" of the "cast in,

thickened cheek" can be seen right where "Cornouailles" is painted.

Pierre-Olivier photographed the interiors of a few no pistol port, "cast

in, thickened cheek" D50878 turrets and as can be seen in the photo on

the right, the armor surface is flat with no scooped-out areas. There

does appear to be a little outward bulge. This leads us to think that

the armor in this area of the turret shell was actually moved out a bit

to give the operator room to work the traversing mechanism without

scraping his knuckles on the turret wall. On the exterior, we suspect

that the protruding part of the turret casting was not really

"thickened" but was intended to maintain the as designed armor basis of 3

inches on the front and 2 inches on the sides. We have no way of

measuring this, but if we are right, the useful descriptive term "cast

in, thickened cheek" would be something of a misnomer.

One of the interesting historical anomalies of French Lend Lease

Shermans, is that some are noted with the unnecessary application of the

"thin spot" patch on no pistol port, "cast in, thickened cheek" D50878

turrets. "Valois", "Massaoua" and "Chemin des Dames" are surviving

examples. The patch consisted of two cast sections, and the pieces were

not made to fit the contours of the revised turret. Consequently, the

patch was ill fitting with a noticeable gap between the two sections.

The surviving French 2nd Armored Division veteran M4A2, "Massaoua" above

shows a particularly poor fit. Lack of direction from US Ordnance

personnel, and/or simply a language barrier misunderstanding were the

likely culprits in the case of the unneeded turret appliqué.

The "no pistol port" turrets

began to enter the production lines in the summer of 1943, but in the

meantime, factories and depots were directed to weld up any remaining

pistol port turrets that were in the pipeline. The "window" where

turrets were welded up appears to have run from about May to September

1943, even though the pistol port was "reinstated" on 23 July 1943. Of

course, not every pistol port was welded up. During this period,

inspectors at factories and depots reported incidences of Shermans

passing through with working pistol ports. Counting heads suggests

that, in most cases, the pistol port itself was used as the "blank off"

with the hinge barrels on the casting burned off or otherwise

removed. This may have been to ensure a watertight seal. The pistol

port was then welded on, both outside and inside. The photos above show

a typical job on the unusual "half a tank" monument in Wibrin, Belgium.

This M4 appears to be a US Army WW II battle casualty. The Serial

Number is not known, but the appearance suggests it would have been

accepted at ALCO in July or August 1943. For what it is worth, the

turret was cast by General Steel-Eddystone and is serial number 3663.

From "counting heads," we believe this turret would have been cast in

late April or early May 1943. Based on the similarity of the

welded-up pistol port to a few other GS-E turrets, we wouldn't be

surprised if the weld up job was done at Eddystone before the turret

was shipped out.

The "no pistol port" turrets

began to enter the production lines in the summer of 1943, but in the

meantime, factories and depots were directed to weld up any remaining

pistol port turrets that were in the pipeline. The "window" where

turrets were welded up appears to have run from about May to September

1943, even though the pistol port was "reinstated" on 23 July 1943. Of

course, not every pistol port was welded up. During this period,

inspectors at factories and depots reported incidences of Shermans

passing through with working pistol ports. Counting heads suggests

that, in most cases, the pistol port itself was used as the "blank off"

with the hinge barrels on the casting burned off or otherwise

removed. This may have been to ensure a watertight seal. The pistol

port was then welded on, both outside and inside. The photos above show

a typical job on the unusual "half a tank" monument in Wibrin, Belgium.

This M4 appears to be a US Army WW II battle casualty. The Serial

Number is not known, but the appearance suggests it would have been

accepted at ALCO in July or August 1943. For what it is worth, the

turret was cast by General Steel-Eddystone and is serial number 3663.

From "counting heads," we believe this turret would have been cast in

late April or early May 1943. Based on the similarity of the

welded-up pistol port to a few other GS-E turrets, we wouldn't be

surprised if the weld up job was done at Eddystone before the turret

was shipped out.

Pistol ports were

welded up in a number of different ways. Here we present two somewhat

common examples. The left side photo shows the welding

technique typically noted on Chrysler M4A4s. On the right we have

a method where the center hinge holder (1) was ground down and

the pistol port casting was welded on in such a way that it stood

out a bit. This particular job is on a General Steel-Commonwealth

turret with a casting date of "4-43" [April 1943]. Despite the

unpopularity of the elimination of the pistol port, it is evident

that the majority of US Army M4 and M4A1 75mm Shermans that fought

in the Normandy Campaign and beyond had either welded up or no pistol

port turrets.

This Signal Corps photo is dated "24 July [1944]...near La Commune, France." It demonstrates how, without

the pistol port, it often took three men to load ammunition. A man on

the ground passed rounds up to a man standing highly exposed on the

tank, who passed the rounds through to a man in the commander's hatch.

Only one man on the ground, and somewhat protected by the tank, was

needed to pass ammunition through to a man at the pistol port. This M4A1

can be seen as USA 3036927 indicating that it was produced by Pressed

Steel Car in May 1943. This appears to be a case where the actual pistol

port casting was not used to blank off the opening. A beveled piece of

armor seems to have been employed instead. The inset shows a similar

application on a surviving turret cast by Union Steel, PSC's main

supplier of turrets. Some motion picture footage taken in Normandy shows

that USA 3036927 was a dozer tank named "Marauder" probably of the 2nd

Armored Division.

This Signal Corps photo is dated "24 July [1944]...near La Commune, France." It demonstrates how, without

the pistol port, it often took three men to load ammunition. A man on

the ground passed rounds up to a man standing highly exposed on the

tank, who passed the rounds through to a man in the commander's hatch.

Only one man on the ground, and somewhat protected by the tank, was

needed to pass ammunition through to a man at the pistol port. This M4A1

can be seen as USA 3036927 indicating that it was produced by Pressed

Steel Car in May 1943. This appears to be a case where the actual pistol

port casting was not used to blank off the opening. A beveled piece of

armor seems to have been employed instead. The inset shows a similar

application on a surviving turret cast by Union Steel, PSC's main

supplier of turrets. Some motion picture footage taken in Normandy shows

that USA 3036927 was a dozer tank named "Marauder" probably of the 2nd

Armored Division.

The

feedback from the using arms concerning the elimination of the

pistol port was so negative, that in July 1943, Ordnance voted to

reinstate it.

Feedback also stressed the need for a loader's hatch, so once again,

the D50878

turret was redesigned to include the pistol port as well as introduce

the

"oval loader's hatch." These turrets continued to have the

"thickened cheek" on the right front (all the items circled in red on

the photos above). Pressed Steel Car seems to have been the first

manufacturer

to introduce the D50878 turret with loader's hatch in late October 1943.

The first

ones were low bustle turrets like the one shown above. As Fisher-built

M4A2s

pretty much disappeared to Lend Lease (hence some difficulties in photo

and

surviving vehicles study) , we can only observe that

the oval

loader's hatch appears to have

been introduced on M4A2(75)s very

late in 1943 or early 1944. There are a few pictures of Soviet big

hatch

M4A2(75)s with low bustle turrets with loaders' hatches, which are

presumed to

be D50878s.

The commander's hatch was improved with the introduction of "turret

hatch D69993 with equilabrator." The hatch hinges were equipped with

integral springs (1) which made it easier for the crew to open and close

the heavy hatches. It is assumed that a more robust internal locking

mechanism was included with the new design, since the external hatch

locks (circled in the photo of the older model on the right) were no

longer installed. The redesigned hatch was released as a "critical

modification" with "No tanks without this item to be accepted after

11/8/43 [8 November 1943]." We can't confirm if the freeze date was

absolute, but we can observe that many Shermans produced in late 1943

are seen with the new hatches. Of course, the design carried over to the

D78461 high bustle turrets when they were introduced starting in late

November 1943.

____________________________________________________________

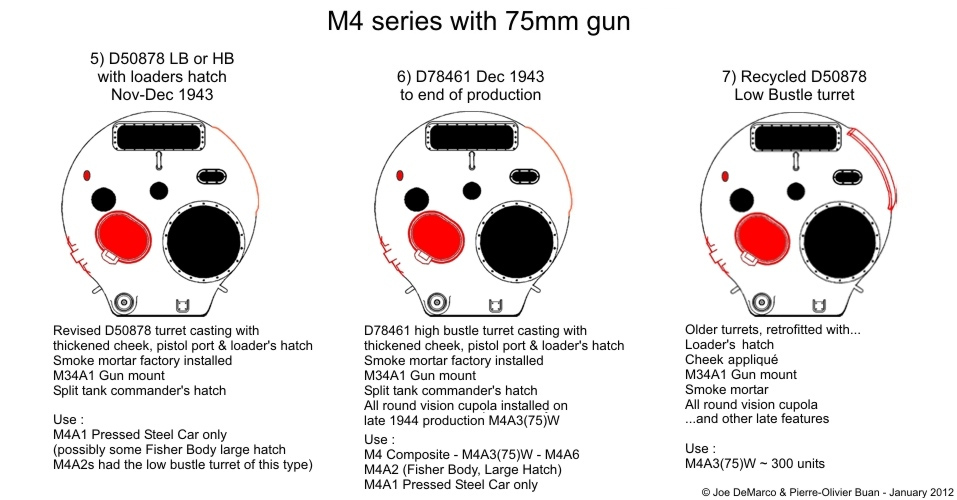

"High

bustle" turrets - From the D50878 turret to the

D78461 turret

The 75mm turret rear profile

was raised a few inches to improve clearance for the larger drivers'

hatches of

the later hull designs. This clearance change resulted in the "high

bustle" turret, with older turrets termed as "low bustle". These

are modelers' terms only, the Army would have referred to the turrets

by

drawing number.

The

vast majority of high

bustle turrets were produced with a new Part Number - D78461. However

in November 1943, when Pressed Steel Car transitioned to the high bustle

turret,

the evidence suggest they continued to carry the old D50878

Part Number. Without more data, we can only speculate that PSC

might have used between 300 & 400 low bustle, loader's hatch D50878 turrets,

and between 200 and 300 high bustle, loader's hatch D50878

turrets.

Fisher Body used D78461

turrets on their M4A3(75)Ws right from the start in Feb, 1944. At

present, it

is not known if they used any high bustle D50878s as part of their

M4A2(75)

program.

From counting heads, it is

thought that Chrysler transitioned directly from the D50878 low bustle,

no

pistol port turret to the D78461 high bustle in late November, 1943.

"Low bustle"

75mm turret (part number D50878)

"High bustle"

75mm turret (part number D50878 or D78461)

Late "High bustle"

75mm turret (part number D78461)

As supplies became available

in late 1944, 75mm turrets were factory equipped with the commander's

vision

cupola (left side photo). Modification kits were also supplied for

retrofit. Late

high bustle D78461 turrets have a bulge to better accomodate the

commander's

vision cupola (right side photo). This modification seems to have

appeared on

turrets cast from November 1944 onward.

As supplies became available

in late 1944, 75mm turrets were factory equipped with the commander's

vision

cupola (left side photo). Modification kits were also supplied for

retrofit. Late

high bustle D78461 turrets have a bulge to better accomodate the

commander's

vision cupola (right side photo). This modification seems to have

appeared on

turrets cast from November 1944 onward.

Recycled

"Low bustle" turrets

Due to the critical

foundry situation, Fisher Body agreed to accept 300 used D50878 turrets

left over from the retriever conversion program. They were to be

updated to

current standards, with M34A1 gun mounts & turret patches where

needed. A

loader's hatch was to be cut in. They were to be installed on large

hatch

M4A3(75)Ws at the rate of 100 per month starting in November 1944.

There are a

number of period photos of these, including some tanks with HVSS. Most

or all

of them appear to have been equipped with the commander's all round

vision

cupola. Perhaps a small number of them saw some combat in the ETO in

the

closing days. It's common knowledge that the low bustle turret caused

some

interference issues when mounted on a "big hatch" Sherman. However,

that didn't seem to have been a problem with all the low bustle, no

pistol port

turrets on many M4 Composites. In any case, the Fisher docs mention

that the

recycled turrets "would require flame cutting of some stock on the

lower

rear corners of the radio bulge to eliminate interference with the

drivers'

doors". These photos of a 1942 production Union Steel turret (S/N 871)

that was certainly recycled show hints of how some material was removed

from

the bottom corners of the turret bustle. The loader's hatch was also

neatly

welded in.

It is thought that some more low bustle bustle turrets received the

same

upgrade in the early 1950s. In that case, the 75mm gun was replaced

with a 76mm.

These "upgunned" Shermans were sent out as Military Assistance.

The way to distinguish between a recycled D50878 turret & a

late 1943

production D50878 with low bustle and loader's hatch is that the late

production will have a cast in thickened cheek, whereas the recycled

turret

will have the armor patch on the right front (as shown above). Also if

the

serial numbers can be read, the recycled turrets will have much lower

serial

numbers than the late productions ( the few late production turrets

identified

have S/Ns in the 4000 & 5000 range).

HOME