Sherman 76mm

turret (a.k.a. T23 turret) types

Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads". It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork" .

Introduction - First trials

In August 1942 , a few months

after Shermans began rolling off the assembly lines, the Ordnance Department

began testing the feasibility of mounting a 76 mm gun in the standard D50878

turret (below left). The intention was to produce 1000 76mm armed Medium Tanks

by the end of the year. Ultimately, the project was cancelled because it was

determined that the small turret was unsuitable. In the meantime, development

work was initiated on new Medium Tank designs known collectively as the T20

series. The T23, which mounted a 76mm gun in a larger turret, was never

standardized due to various technical problems (below right). However, since

the 69 inch diameter turret ring was the same as the Sherman's, the T23's 76mm

turret was easily adapted for use on the late 1943 revision of the M4 series.

The turrets of the few surviving T23s have been noted to have part number

D82081. This is significant, because the early 76mm Sherman turrets have the

same part number, confirming that the identical design was used, and hence the

informal reference to the Sherman's 76 mm turret as "the T23 turret".

Click on the picture for larger size

____________________________________________________________

Early M4A1(76) Sherman tanks

Click on the picture for larger size

The M4A1(76) was the first model to enter production in January 1944. 156 of the first units were sent to the UK for familiarization. They evoked little interest from armored commanders whose troopers had been training for the Invasion for many months with M4 & M4A1(75)s. Confrontations with heavy German armor in Normandy aroused interest in the "orphan" M4A1(76)s sitting idle in England, and General Bradley ordered that they be shipped to France to take part in First Army's upcoming Operation Cobra. 120 were evenly distributed to the 2nd and 3rd Armored Divisions, & first entered combat in late July 1944.

Photos: Two Jan. 1944 production M4A1(76)s: a useful overhead view showing the general layout of the D82081 turret on "Gila Monster" (USA 3070533) as photographed at Aberdeen Proving Ground, MD on March 3, 1944 (above left); and USA 3070551 of the 3rd Armored Division in Chenee, Belgium, September 8, 1944.

An interesting anomaly that has been observed on the D82081 turrets used on the earliest M4A1(76)s is the absence of the rear ventilator. Unlike the Sherman, the T23 Medium Tank was designed with a hull ventilation system that did not require a separate turret ventilator. The specifications for adapting the turret to the Sherman series called for the addition of the ventilator. The manufacturing process requires good liaison between the designer & the builder, along with sufficient lead time to allow the manufacturer to obtain the parts required. In the rush to production, the ventilator appears to have "slipped through the cracks." The Union Steel Corp. was the turret supplier to Pressed Steel Car, the manufacturer of the M4A1(76). US turrets have their serial numbers cast in fairly large on each side, making it possible to "count heads" on this glitch. The ventilator appears to have been added to their turrets at around number 450. In the above photos, one can see how the locations of the various MG stowage fittings differed on the ventless turret compared with the vented.

Click on the picture for larger size

Another glitch likely related to the rush to production was mentioned in internal memos. It was remarked that in the first few months of M4A1(76) production, the split hatches didn't open past the vertical position, thereby interfering with the operation of the anti-aircraft machine gun, and making for an uncomfortable traveling position for the loader. As designed, the hatches were to open outward to 45 degrees. The manufacturer had corrected the problem, and it was noted that the problem might be repairable in the field. The above photo shows a 3rd Armored Division combat casualty near Bergerhausen, Germany, ca. March 1, 1945. This was likely one of the "UK orphan" M4A1(76)s, but in any case, the turret reflects the appearance of the early Union Steel - no ventilator, "unthreaded" M1A1 gun, and vertical hatches. If there ever was a field fix issued, this Sherman soldiered on without it.

Early M4A3(76) Sherman tanks

Click on the picture for larger size

The Chrysler Corporation began producing the M4A3(76) in March 1944. Many of their first units arrived almost simultaneously in France & Italy in August 1944. Some of the first M4A3(76)s (above left) await processing in La Cambe, France, ca. August 12, 1944. At right, members of A Company, 13th Tank Battalion, 1st Armored Division at gunnery practice with their new tanks, near Pisa, Italy circa August 19, 1944.

The French 2nd Armored Division received a small number of M4A3(76)s just prior to their dash to liberate Paris. They were probably the first to use this model in combat. Above, a French monument tank named Champagne, said to be an actual veteran of the Paris Campaign. The turrets installed on Chrysler Shermans were "up to spec" as regards the ventilator and the loader's split hatch. However, period photos, such as the one taken at La Cambe, show that some of the first Chryslers were "out of spec" when it came to the L-shape MG barrel stowage brackets on the turret rear. Note that on Champagne, one can see "weld scars" on the ventilator where the machine gun stowage pintle was once installed, but there is no evidence that this tank ever had the L-shaped brackets.

Champagne has an "unthreaded' M1A1 gun as on the early M4A1(76)s (left side photo above). Oldsmobile was the sole producer of 76mm guns, and it was noted that their first 385 units would be of this type. A muzzle brake was mandated for all future guns, and the ends of the barrels of subsequent units were threaded for a muzzle brake. The threads were protected by a collar, in anticipation of retrofitting muzzle brakes as they became available (right side photo above). 76 mm guns with the protective collars were labeled M1A1C, and period photos of early M4A3(76)s show that they were beginning to replace the "unthreaded" M1A1s as the tanks arrived in Europe in late Summer 1944.

An anomaly seen on many of the early Chrysler M4A3(76)s is the presence of what is informally referred to as "the extra lifting ring" in front the loader's hatch. This is a vestige of Chrysler's abortive T23 program. The T23 featured a boom for lifting the power pack, and the extra lifting ring served to support part of the boom's rigging. While the extra lifting ring did no harm on the Sherman (crews like to hang stuff on it), it was eliminated from subsequent turret molds. As best as can be determined, about 500 "XLR" turrets were mixed in with the first four month's M4A3(76) production at Chrysler. Chrysler was supplied with turrets made by American Steel Foundries & Continental Steel, and their casting logos are the only ones that have been seen on surviving "XLR" turrets. At left, the extra lifting ring as seen on the turret of an actual T23 Medium Tank (photo courtesy of Neil Baumgardner), & the same thing at right on Champagne.

Evolution of the T23 turret design

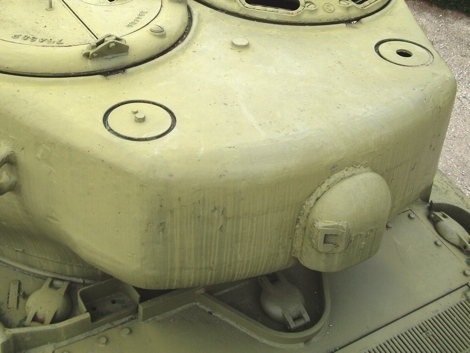

Although, the authors found no mention in Government documents, the examination of surviving examples makes it obvious that, at some point fairly early on, it was decided not to machine out the forward antenna socket. The above photo shows what is thought to be a US Army WW II combat casualty M4A3(76) on display in Clervaux, Luxembourg. Note the "ghost" of the former antenna socket, circled in red.

In an effort to simplify the T23's original D82081 design, the Ordnance Department substituted an oval loader's hatch for the split hatch. The "new" turret can be seen to have part number 7054366. The oval hatch was a little larger, and therefore more user friendly, than the one on late 75mm turrets. It was essentially the same size as the drivers' hatches. Because the "split ring" loader's hatch had an A.A. machine gun pintle built in, a pintle stand was provided and located in a rather awkward position between and slightly to the rear of the hatches. Period photos show that many crews relocated the pintle to suit their preference. An Ordnance Department Memo of June 1944, "expected" the new hatch would be on all M4A1(76)s built after August 1, & all M4A3(76)s after August 15. These expectations were usually somewhat optimistic; however, the authors' own "head count" seems to confirm that the goal was met with the M4A1s, whereas the transition appears to have occurred in October, 1944 with the M4A3s. The oval hatches start to show up overseas at the beginning of 1945, along with the factory installed muzzle brake.

Click on the picture for larger size

A canvas mantlet cover was designed, and Chrysler began to install the fittings for it around October, 1944. We can only conclude that they had a problem finding a contractor to provide the actual canvas cover, as these don't appear to have been factory installed until January 1945. Also in the Fall, a cap with retaining chain was installed over the smoke mortar aperture. M4A3(76)s with just the mantlet cover fittings begin to show up in Europe in early February, 1945. The earliest period photo (above) we know of that shows the actual canvas cover installed was taken March 31, and shows an Ordnance outfit in Germany preparing to process the tank for distribution.

Two photos that show the canvas mantlet cover mounted on the turret of a preserved M4A1(76).

Click on the picture for larger size

Fisher Body began to manufacture the M4A2(76) in May 1944. Not much is known about them, since they pretty much "disappeared" to Soviet Lend Lease. It is assumed the chronology of the turret changes closely mirrored Chrysler. Fisher also produced 525 M4A3(76)VVSS, starting in September 1944. Again, it is thought that the chronology of the turret changes closely followed Chrysler, and thus, the bulk of them would have been built with the later 7054366 turret. Above, a Soviet Lend Lease M4A2(76) on the Emms River Bridge in Leizen, Austria, early June, 1945. The turret can be seen to be a D82081 with split loader's hatch & "threaded" M1A1C gun.

Click on the picture for larger size

Our final photo shows a mix of Shermans of the 736th Tank Battalion passing in review in Peine, Germany ca. May 27, 1945. In the original print, the USA Number of the M4A3(76)HVSS can be read, and it indicates that this unit was accepted at Chrysler in December 1944. No doubt the crew would have welcomed the actual canvas mantlet cover, as they appear to have been weather conscious. Note that an extended sleeve to protect the telescopic sight was retrofitted. This tank appears to have been rigged to carry sandbags on the front, as evidenced by the "fence" on the differential housing, along with a little "awning frame" around the bow machine gun. The late 1944 production M4A1(76)VVSS to the left, can be seen to have the M1A2 gun with factory installed muzzle brake, as well as the little cap over the smoke mortar. Note the absence of the canvas mantlet cover or even its fittings. Pressed Steel Car appears to have started receiving supplies of these around March 1945. The turret serial number can be read, and indicates it was the 1922nd turret produced by Union Steel. The highest serial number the authors have seen on a US turret in a WW II photo is about 2150.

HOME

Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads". It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork" .

Introduction - First trials

Click on the picture for larger size

____________________________________________________________

Early M4A1(76) Sherman tanks

Click on the picture for larger size

The M4A1(76) was the first model to enter production in January 1944. 156 of the first units were sent to the UK for familiarization. They evoked little interest from armored commanders whose troopers had been training for the Invasion for many months with M4 & M4A1(75)s. Confrontations with heavy German armor in Normandy aroused interest in the "orphan" M4A1(76)s sitting idle in England, and General Bradley ordered that they be shipped to France to take part in First Army's upcoming Operation Cobra. 120 were evenly distributed to the 2nd and 3rd Armored Divisions, & first entered combat in late July 1944.

Photos: Two Jan. 1944 production M4A1(76)s: a useful overhead view showing the general layout of the D82081 turret on "Gila Monster" (USA 3070533) as photographed at Aberdeen Proving Ground, MD on March 3, 1944 (above left); and USA 3070551 of the 3rd Armored Division in Chenee, Belgium, September 8, 1944.

An interesting anomaly that has been observed on the D82081 turrets used on the earliest M4A1(76)s is the absence of the rear ventilator. Unlike the Sherman, the T23 Medium Tank was designed with a hull ventilation system that did not require a separate turret ventilator. The specifications for adapting the turret to the Sherman series called for the addition of the ventilator. The manufacturing process requires good liaison between the designer & the builder, along with sufficient lead time to allow the manufacturer to obtain the parts required. In the rush to production, the ventilator appears to have "slipped through the cracks." The Union Steel Corp. was the turret supplier to Pressed Steel Car, the manufacturer of the M4A1(76). US turrets have their serial numbers cast in fairly large on each side, making it possible to "count heads" on this glitch. The ventilator appears to have been added to their turrets at around number 450. In the above photos, one can see how the locations of the various MG stowage fittings differed on the ventless turret compared with the vented.

Click on the picture for larger size

Another glitch likely related to the rush to production was mentioned in internal memos. It was remarked that in the first few months of M4A1(76) production, the split hatches didn't open past the vertical position, thereby interfering with the operation of the anti-aircraft machine gun, and making for an uncomfortable traveling position for the loader. As designed, the hatches were to open outward to 45 degrees. The manufacturer had corrected the problem, and it was noted that the problem might be repairable in the field. The above photo shows a 3rd Armored Division combat casualty near Bergerhausen, Germany, ca. March 1, 1945. This was likely one of the "UK orphan" M4A1(76)s, but in any case, the turret reflects the appearance of the early Union Steel - no ventilator, "unthreaded" M1A1 gun, and vertical hatches. If there ever was a field fix issued, this Sherman soldiered on without it.

Early M4A3(76) Sherman tanks

Click on the picture for larger size

The Chrysler Corporation began producing the M4A3(76) in March 1944. Many of their first units arrived almost simultaneously in France & Italy in August 1944. Some of the first M4A3(76)s (above left) await processing in La Cambe, France, ca. August 12, 1944. At right, members of A Company, 13th Tank Battalion, 1st Armored Division at gunnery practice with their new tanks, near Pisa, Italy circa August 19, 1944.

The French 2nd Armored Division received a small number of M4A3(76)s just prior to their dash to liberate Paris. They were probably the first to use this model in combat. Above, a French monument tank named Champagne, said to be an actual veteran of the Paris Campaign. The turrets installed on Chrysler Shermans were "up to spec" as regards the ventilator and the loader's split hatch. However, period photos, such as the one taken at La Cambe, show that some of the first Chryslers were "out of spec" when it came to the L-shape MG barrel stowage brackets on the turret rear. Note that on Champagne, one can see "weld scars" on the ventilator where the machine gun stowage pintle was once installed, but there is no evidence that this tank ever had the L-shaped brackets.

Champagne has an "unthreaded' M1A1 gun as on the early M4A1(76)s (left side photo above). Oldsmobile was the sole producer of 76mm guns, and it was noted that their first 385 units would be of this type. A muzzle brake was mandated for all future guns, and the ends of the barrels of subsequent units were threaded for a muzzle brake. The threads were protected by a collar, in anticipation of retrofitting muzzle brakes as they became available (right side photo above). 76 mm guns with the protective collars were labeled M1A1C, and period photos of early M4A3(76)s show that they were beginning to replace the "unthreaded" M1A1s as the tanks arrived in Europe in late Summer 1944.

An anomaly seen on many of the early Chrysler M4A3(76)s is the presence of what is informally referred to as "the extra lifting ring" in front the loader's hatch. This is a vestige of Chrysler's abortive T23 program. The T23 featured a boom for lifting the power pack, and the extra lifting ring served to support part of the boom's rigging. While the extra lifting ring did no harm on the Sherman (crews like to hang stuff on it), it was eliminated from subsequent turret molds. As best as can be determined, about 500 "XLR" turrets were mixed in with the first four month's M4A3(76) production at Chrysler. Chrysler was supplied with turrets made by American Steel Foundries & Continental Steel, and their casting logos are the only ones that have been seen on surviving "XLR" turrets. At left, the extra lifting ring as seen on the turret of an actual T23 Medium Tank (photo courtesy of Neil Baumgardner), & the same thing at right on Champagne.

Evolution of the T23 turret design

Although, the authors found no mention in Government documents, the examination of surviving examples makes it obvious that, at some point fairly early on, it was decided not to machine out the forward antenna socket. The above photo shows what is thought to be a US Army WW II combat casualty M4A3(76) on display in Clervaux, Luxembourg. Note the "ghost" of the former antenna socket, circled in red.

In an effort to simplify the T23's original D82081 design, the Ordnance Department substituted an oval loader's hatch for the split hatch. The "new" turret can be seen to have part number 7054366. The oval hatch was a little larger, and therefore more user friendly, than the one on late 75mm turrets. It was essentially the same size as the drivers' hatches. Because the "split ring" loader's hatch had an A.A. machine gun pintle built in, a pintle stand was provided and located in a rather awkward position between and slightly to the rear of the hatches. Period photos show that many crews relocated the pintle to suit their preference. An Ordnance Department Memo of June 1944, "expected" the new hatch would be on all M4A1(76)s built after August 1, & all M4A3(76)s after August 15. These expectations were usually somewhat optimistic; however, the authors' own "head count" seems to confirm that the goal was met with the M4A1s, whereas the transition appears to have occurred in October, 1944 with the M4A3s. The oval hatches start to show up overseas at the beginning of 1945, along with the factory installed muzzle brake.

Click on the picture for larger size

A canvas mantlet cover was designed, and Chrysler began to install the fittings for it around October, 1944. We can only conclude that they had a problem finding a contractor to provide the actual canvas cover, as these don't appear to have been factory installed until January 1945. Also in the Fall, a cap with retaining chain was installed over the smoke mortar aperture. M4A3(76)s with just the mantlet cover fittings begin to show up in Europe in early February, 1945. The earliest period photo (above) we know of that shows the actual canvas cover installed was taken March 31, and shows an Ordnance outfit in Germany preparing to process the tank for distribution.

Two photos that show the canvas mantlet cover mounted on the turret of a preserved M4A1(76).

Click on the picture for larger size

Fisher Body began to manufacture the M4A2(76) in May 1944. Not much is known about them, since they pretty much "disappeared" to Soviet Lend Lease. It is assumed the chronology of the turret changes closely mirrored Chrysler. Fisher also produced 525 M4A3(76)VVSS, starting in September 1944. Again, it is thought that the chronology of the turret changes closely followed Chrysler, and thus, the bulk of them would have been built with the later 7054366 turret. Above, a Soviet Lend Lease M4A2(76) on the Emms River Bridge in Leizen, Austria, early June, 1945. The turret can be seen to be a D82081 with split loader's hatch & "threaded" M1A1C gun.

Click on the picture for larger size

Our final photo shows a mix of Shermans of the 736th Tank Battalion passing in review in Peine, Germany ca. May 27, 1945. In the original print, the USA Number of the M4A3(76)HVSS can be read, and it indicates that this unit was accepted at Chrysler in December 1944. No doubt the crew would have welcomed the actual canvas mantlet cover, as they appear to have been weather conscious. Note that an extended sleeve to protect the telescopic sight was retrofitted. This tank appears to have been rigged to carry sandbags on the front, as evidenced by the "fence" on the differential housing, along with a little "awning frame" around the bow machine gun. The late 1944 production M4A1(76)VVSS to the left, can be seen to have the M1A2 gun with factory installed muzzle brake, as well as the little cap over the smoke mortar. Note the absence of the canvas mantlet cover or even its fittings. Pressed Steel Car appears to have started receiving supplies of these around March 1945. The turret serial number can be read, and indicates it was the 1922nd turret produced by Union Steel. The highest serial number the authors have seen on a US turret in a WW II photo is about 2150.

HOME