The

French received 274 M4A4s as Lend Lease. In addition, a small number, perhaps less than 50, former

British/Commonwealth M4A4s (Sherman Vs) were passed on to them in early

1945. Based on our study of the M4A4Ts, we suspect that the French must

have collected up more from European tank dumps in the post war years.

At the French Military Archives in Paris, Pierre-Olivier came across an entry in

the records of the 2ème Régiment de Hussards dated 13 September 1949,

"Lieutenant JEANNEST Louis of the 4th squadron detached for 3 months to the joint

commission set up for acceptance operations of M4A4 medium tanks from

Belgium, Ref D.M. N° 1635 EMG.FAG/ARMET dated 1.9.1949". P-O interprets this to mean that a joint

commission was established to receive or buy (accept) M4A4s from

Belgium. At present, P-O has not come across any statement of the

numbers involved. In any case, in order to accommodate the massive

30-cylinder Chrysler Multibank engine, the M4A4 was made 11 inches

longer than the standard Sherman. The Multibank with its front mounted

radiator (position 1) was so large that there was no room for vertical

fuel tanks in the front corners of the engine compartment, such as were

present on Radial engined M4s and M4A1s. However, the elongated hull

enabled the sponson fuel tanks (positions 2) to be enlarged to hold 80

gallons each. Thus, the two fuel tanks of the M4A4 held 160 gallons,

versus the 175-gallon capacity of the four fuel tanks on M4s and M4A1

Shermans. There might have been room for them, but the examination of a

few M4A4T wrecks suggests that no vertical fuel tanks were added, so

that the Transformés retained the M4A4's 160-gallon capacity. We would

note that the fuel tanks of M4s, M4A1s and M4A4s suffered in common from

an excessive heat condition, which caused melted solder joints and

other fire hazards. This was remedied by the addition of a pair grouser

compartment covers with air inlet grills (3) that provided for greater

air flow to the fuel tanks.

The

French received 274 M4A4s as Lend Lease. In addition, a small number, perhaps less than 50, former

British/Commonwealth M4A4s (Sherman Vs) were passed on to them in early

1945. Based on our study of the M4A4Ts, we suspect that the French must

have collected up more from European tank dumps in the post war years.

At the French Military Archives in Paris, Pierre-Olivier came across an entry in

the records of the 2ème Régiment de Hussards dated 13 September 1949,

"Lieutenant JEANNEST Louis of the 4th squadron detached for 3 months to the joint

commission set up for acceptance operations of M4A4 medium tanks from

Belgium, Ref D.M. N° 1635 EMG.FAG/ARMET dated 1.9.1949". P-O interprets this to mean that a joint

commission was established to receive or buy (accept) M4A4s from

Belgium. At present, P-O has not come across any statement of the

numbers involved. In any case, in order to accommodate the massive

30-cylinder Chrysler Multibank engine, the M4A4 was made 11 inches

longer than the standard Sherman. The Multibank with its front mounted

radiator (position 1) was so large that there was no room for vertical

fuel tanks in the front corners of the engine compartment, such as were

present on Radial engined M4s and M4A1s. However, the elongated hull

enabled the sponson fuel tanks (positions 2) to be enlarged to hold 80

gallons each. Thus, the two fuel tanks of the M4A4 held 160 gallons,

versus the 175-gallon capacity of the four fuel tanks on M4s and M4A1

Shermans. There might have been room for them, but the examination of a

few M4A4T wrecks suggests that no vertical fuel tanks were added, so

that the Transformés retained the M4A4's 160-gallon capacity. We would

note that the fuel tanks of M4s, M4A1s and M4A4s suffered in common from

an excessive heat condition, which caused melted solder joints and

other fire hazards. This was remedied by the addition of a pair grouser

compartment covers with air inlet grills (3) that provided for greater

air flow to the fuel tanks.

Aside from the interior ID plate,

some of the M4A4Ts examined have been noted to have "Rebuild" plates.

These have been seen welded to the tank's exterior. In some cases, they

have been found in three places on the same

tank - affixed to the front and rear of the hull, as well as on the top

of the turret. Of course in many instances, the plates have long since

rusted away or have been removed. The photo on the left shows what is

typically printed on one of these plates. The

right side photo shows the "usual" location of the front plate as noted

on M4A4 Serial Number 22169, a monument Sherman on display in Avranches

in Normandy. The plate's first line reads "A R L," which indicates that

the tank was "transformed" at the French

Army Facility known as "Atelier de construction de Rueil." Evidence found on the ARL plates suggests that the Transformé Program took place in the early 1950s.

We would note that other non M4A4T French Shermans have

been observed with rebuild plates or stampings from other facilities,

including

"A B S," (Atelier de construction de Bourges) and

"ERGMEB" (Etablissement de Réserve Générale du

Matériel - Engins Blindés).

A translation

of the plate above:

A R L (Atelier de construction de Rueil)

Char D57

(Thought to be the Serial Number of this particular M4A4T)

DATE 9.12.52 (9 December

1952, the date the M4A4T rebuild was accepted)

It is thought that the French Army stamped the

Ordnance Serial Number on most or all of the AFVs used in service in the

post war years. This has been recorded from quite a few surviving

Shermans tanks, to the extent that we refer to it informally as "the

Serial Number inside a box." This stamping is not always exactly in the

same place. Anyone wishing to see it is advised to look around on the

front of the tank. While the SN stamping is not exclusive to the M4A4Ts,

it has been noted on almost all surviving examples.

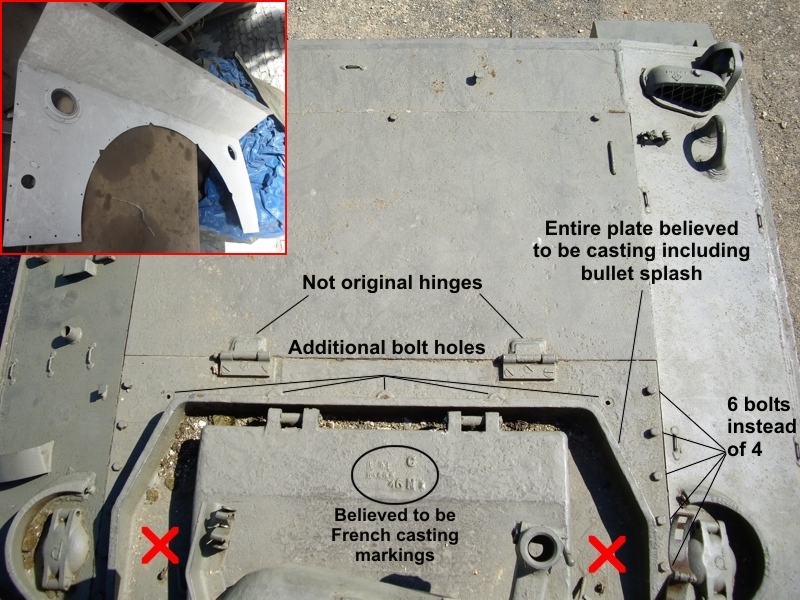

The photo on the left shows the typical M4A4 engine

deck configuration. The forward sections include an air intake grill

(1), and a cast armor blister (2) which protected the Multibank engine's

oversize radiator. The middle section of the deck (3) was hinged, and

could be lifted by means of a pair of handles in order to provide engine

access. The rear section (4) was not removable, but permanently welded

to the hull. The photo on the right shows the same view of an M4A4 after

the Transformé engine swap. As best we can tell, the conversion

retained the M4A4's middle engine deck plate (3), and simply replaced

the forward sections with the forward section of an M4/M4A1. The air

intake was protected by a large armored cover (5), and this in turn was

protected by a surrounding bullet splash (6).

One might assume that the

M4A4T's forward engine deck section was salvaged from surplus or

obsolete M4s or M4A1s. That might have been the case on some, although

we have not as yet encountered such an example. The twelve surviving

M4A4Ts that we have seen that still have this section, are installed

with what appear to be aftermarket components that seem to have been

fabricated by a French firm specifically for the Transformé

program. From

personal examination we would judge that the entire "French" plate

is a casting that includes the bullet splash surround. In

contrast, the standard M4 or M4A1 forward engine deck section was an

armor

plate with the bullet splash welded on to it. The "French casting"

features five additional bolt holes directly behind the bullet splash. These

are NOT present on the standard US engine deck section. On 11 out of 12

examples examined so far, the "French" bullet splash is indented in

order to accommodate three of the bolts. The examination of a few survivors

reveals that these additional bolts held a baffle plate (inset) to the

underside of the forward engine deck. The armored air intake covers have

casting marks not seen on any of the same US produced intake covers we have

encountered. Like the standard 1944 US produced version of this plate, there

are no fuel filler locations on either side of the air intake opening (marked

by Xs). We have also noted that there are six bolts along the sponson edges, as opposed to four on

the standard US radial deck. Finally the hinges, with their slotted bolt heads are aftermarket parts,

as they are not original to M4, M4A1 or M4A4 Shermans.

The

photos above show the casting marks on two of the armored air intake covers. We would speculate that the name of the foundry that

cast these pieces might be represented by the letter "C,” possibly CAIL

(« Société

française de constructions mécaniques (SFCM), » also known as « Anciens

Établissements Cail ») the firm whose name is seen on the hull casting of the

Somua S-35. “No" might be for

"numéro," and pertain to the serial number of the individual casting

– thought to be 3 on the left and 161 on the right. The part number or

"numéro de pièce" would be the same on all of the castings, and looks

to have been "64688." For comparison, the part number of US WW II

produced intake covers is D51304, and has been seen cast on the underside, as

in the inset. The dates that the French parts were cast appear to be 1 51

(January 1951) and 3 52 (March 1952), and provide something of a clue regarding

the chronology of the Transformé program.

The above shows comparison shots of the reproduction radial engine deck

of an M4A4T on the left, and an original radial engine deck of an M4(105) on

the right. On first inspection these decks are almost identical in appearance,

although the Transformé’s replacement deck does NOT

include the additional engine oil filler cap (1) seen on Second Generation

M4s& M4A1s. As noted above, the major identifier that the M4A4T’s deck is

not a salvaged radial engine deck are the three indents (2) seen here, which

allowed the fitting of the additional bolts. In some cases, the indentations are very subtle,

and don’t show up in photos, but have been noted during “hands on” examinations.

We can

also see the welds attaching the bullet splash rail to the original deck (3),

these welds not being required on the Transformé’s one piece casting. Another difference is that

there are two bolts securing the forward edge on both sides of the air intake

in the US configured deck (we’ve circled in red one of the bolts). These bolts are not

present on any of the Transformé replacement decks we have examined. Also note the difference in

location of the engine crank holes (4).

It is thought that the French received a number of

replacement Continental R-975 engines as "Spare Parts" for the

approximately 1500 radial engined M4(105)s and M4A1(76)s that they were

issued as Mutual Defense Assistance in the early 1950s. These crated

engine kits appear to have included a number of additional items

including new instrument panels, air cleaners with all the necessary

piping and fittings, and the Barber-Colman type of exhaust deflectors.

The air cleaners (1) and the centrally mounted exhaust pipes (2) were

adapted to fit the M4A4 hull. Although we have not encountered any

surviving examples that still have it present, it is evident that the

exhaust deflector was installed as indicated by the fittings (3) that

secured it in the "down" position, as well as the fitting (4) which

secured it in the "up" position in order to provide access to the engine

doors (5).

About a half dozen of the surviving M4A4Ts have been

recovered from Military Target Ranges. A few examples are very badly

damaged, and have been reduced to hulks, missing so much that a proper

ID is difficult. In the case shown above, the primary clue that this

was an M4A4T is the oblong engine crank hole (1) that was drilled or

ground into the top center of the M4A4’s upper rear hull plate. Only

Radial engine Shermans used a hand crank as part of the engine start up

procedure. On Radial airplanes, a crewman would spin the propeller a few

times so as to test for hydrostatic lock. On the radial Sherman, Step 1

of the start up procedure was, “Have engine turned over four complete

crankshaft revolutions by hand (about 50 turns of the hand crank).” This

would work to expel any excess fuel or oil that may have accumulated,

particularly in the combustion chambers of the cylinders closest to the

ground. A secondary M4A4T clue seen here is the fitting (2) that secured

the exhaust deflector in the "up" position. The two 80 gallon fuel

tanks of the M4A4 are missing from this hulk, but they sat on the

sponsons in the area indicated by the number 3.

Atelier

de construction de Rueil would have had to have provided a hand crank for each

M4A4T, either fabricated in house or salvaged from a surplus M4 or M4A1. The

photo above shows a restored example on display at Camp de Mourmelon in France.

The hand crank (1) seen here, along with the track wrench (2), do NOT reflect

the appearance of the same original equipment tools supplied in the US. It is

not known if the crank was made during the Transformé program, or fashioned in

later years for the display. We would note that the position of the hand crank

fittings corresponds to what has been observed on other M4A4Ts. Also of note

are the fittings with reflectors attached (3). These (or their weld scars) have

been observed on most or all surviving M4A4Ts, so it is thought that they were

added as part of the conversion process. This tank is Serial Number 4825. It

would have been accepted in August, 1942, and is at present the earliest

surviving M4A4 that we have recorded. It has the look of one of the 1610 M4A4s

remanufactured by Chrysler, and supplied to the British as Lend Lease in 1944. Despite

the fact that the French received 274 M4A4s as Lend Lease, a surprising number

of the surviving M4A4Ts are remanufactured, former British/Commonwealth

Shermans. We would assume that they were salvaged from post war Tank Dumps.

The commander's "split hatch" cupola was installed as

original equipment on all new production and remanufactured M4A4

Shermans. The study of surviving M4A4Ts suggests that it was replaced

with the "commander's vision cupola" (1) during the conversion process. The

transition to the improved cupola on new production Shermans was

completed in May, 1944. In addition, a Modification Work Order ((MWO

G104-W112) kit was released in September, 1944. It was to be retrofitted

to all "medium tanks of the M4 series located in overseas theaters of

operation or those scheduled for overseas shipment." These cupolas were

greatly superior to the old split hatches, and were in high demand in

combat zones. However, in the end, very few of the approximately 10000

kits produced were shipped overseas for field installation before the

end of WW II. About 1300 of the kits were retrofitted to Shermans

remanufactured in 1945. Thus, thousands of the kits would have been

available as "new old stock" after WW II, and it is thought that the

French received some as MDAP "Spare Parts" in the early 1950s. The kit

also included parts for an Anti-Aircraft Machine Gun Pintle Assembly

(2), and a vane sight (3 and inset) to replace the old blade sight (4).

Additionally, instructions were provided for relocating the commander’s

seat bracket, "to permit tank commander to look through vision blocks

while seated." One of the final instructions in the vision cupola

modification kit is "Install cal. .50 antiaircraft machine gun stowage

brackets (5) on back of turret in accordance with MWO G104-W108, if

vehicle is not so equipped." Thus, these two modifications were to be

installed together. It is thought that the French received some of the

MG stowage kits as well, since this mod is installed on many of the

turrets along with the commander's vision cupola.

From

start to finish, Chrysler M4A4s, including the 1610 units remanufactured from

December, 1943 though October, 1944, were built with a siren factory installed

on the left front fender as shown in the upper left. The siren most commonly

used on the M4A4 was the Federal Type 160 with the "V for victory"

grill (1). Power was supplied by conduit, and the coupling (2) is often all

that remains on many surviving Shermans. It is evident that the siren was

relocated with the M4A4T conversion, since surviving examples show the siren

mounted on a pad on the left front of the glacis plate just below the hull

lifting ring. The sirens are long since gone on most of the extant M4A4Ts, but

a mounting pad (3) remains. The presence of this pad on a surviving M4A4 is

almost invariably a clue of a Transformé conversion. A siren guard (4) was

fabricated, which on some hulls, is seen with wire mesh welded to its face. We

would note in passing that a few M4A4Ts and other French rebuilt Shermans have

a siren with stars around the faceplate (5).

The

stars around the faceplate are not typical of any of the various US

produced sirens supplied to Sherman manufacturers. This siren was made

in France, probably during the late 1940s or early 1950s, by Cicca

(Compagnie Industrielle et Commerciale du Cycle et de

l’Automobile), an auto equipment and accessories manufacturer

based in Neuilly-sur-Seine, near Paris.

Non standard mudguards (or traces of them)

are seen on the rear of many of the M4A4Ts (1), so it is thought that they

were added as part of the Transformé conversion. This M4A4 is

Serial Number 21752, indicating that it was accepted in July,

1943. The “no pistol port turret” was introduced in

production at Chrysler in July, so the turret, if not the original, is

appropriate. This tank is on display as a monument in

Chavannes-le-Grand, France, and honors “Foch” an early 1943

production M4A4 of the 1er Régiment de Chasseurs d'Afrique,

5ème Division Blindée, that was knocked out there on

November 23, 1944.

The

French received large numbers of Armored Fighting Vehicles from the US as

Military Assistance in the early years of the 1950s. Almost 3000 Medium Tanks

were supplied. Aside from the close to 1500 Shermans mentioned earlier, 544 M26

Pershings and 854 "M46, M47, M48 Series" Pattons were reported to

have been shipped as of January 31, 1954. Given that, it is somewhat surprising

that the French would have needed to do the Transformé conversions at all, much

less obtain more M4A4s from British/Commonwealth post war surplus. Considering

that M4A4Ts represent a good number of the surviving M4A4s in France, we are

somewhat frustrated in not having been able to find any period photos of them

in French service. This leads us to suspect that they may have been intended

for “off the books” export to Israel in the tense years before the outbreak of

the Second Arab-Israeli war in October, 1956. It is obvious that the Israelis

procured a number of ex British and French M4A4s, and a few sources state that

some were Transformes. We can only observe that a small number of period

photos, such as the above, taken in September, 1954 during an IDF Training

Exercise in the Negev Desert, show what appear to be M4A4Ts with the

“indents” characteristic of a French made forward engine deck section. This tank can also be seen with the

exhaust deflector fitting (1). The surviving M4A4Ts in France (that have turrets) are

equipped with the commander's vision cupola (2), but none that we have examined

have retrofitted loader’s hatches (3) as seen on this example. So perhaps that

and the VVSS track holders (4) were added by the Israelis? We would observe in passing that, while Foch from the

preceding caption has a “no pistol port turret,” the turret on this

example has a welded up pistol port (5). The decision to eliminate the

pistol port in mid 1943 was universally

unpopular, and it was reinstated in production in late 1943, coincident

with the introduction of the loader’s hatch. A few surviving IDF Shermans actually have turrets

that were painstakingly retrofitted with pistol ports, such as the M50

turret shown in the inset.

“First

Generation” Shermans with 75mm guns were still in combat use during the 1956

Sinai Campaign. It is thought that a number of these would have been M4A4Ts

with retrofitted loader’s hatches such as seen on the example in the previous

caption. None of these appear to have been preserved by the Israelis, possibly

because some or all were ultimately upgraded to the “legendary” M50

configuration. In

that regard, some French made M4A4T engine deck components appear to have been

recycled for reuse when Israeli Shermans were retrofitted with Cummins Diesel

Engines. On the top left is shown the French type casting marks on an armored

air intake cover half of an M4A4 based M50. On the bottom left are the “French

indentations” on the bullet splash halves on another M4A4 based M50. On the

right, we see both the indentations (arrow) and the French casting marks (circled in red) on an M4A1(76)

based M51. Of course, an M4A1 would have been built with the appropriate

forward engine deck components, but this example illustrates how original parts

were not necessarily reinstalled on their “mother” vehicles. Note that the

intake cover halves on the M50s on the left used only the original hinges, so

each half is attached with a single hinge. On the M51’s deck, the original

hinges can be seen to have been cut off, and two new hinges/fittings were added

to each half, perhaps for greater stability. Photos and info courtesy of Tom Gannon.

HOME