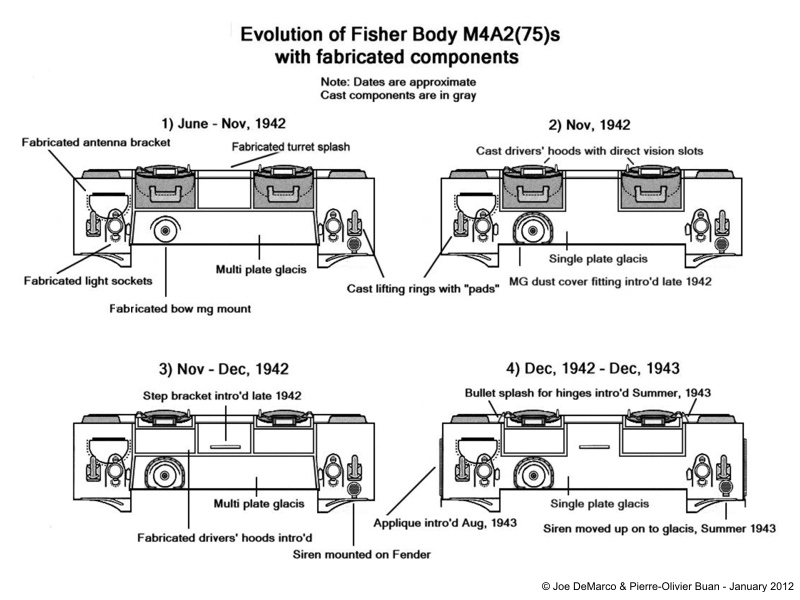

Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads". It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

First of all, you have to

identify the tank as being an M4A2(75) with small hatches. Please visit

this

page to do so.

Fisher Body produced 4614

M4A2(75) with "Dry Stowage" from April, 1942 through May, 1944. The

vast majority of them were of the so called "small hatch" type

discussed here. So far, the authors have found no official records that

provide exact production figures. It is thought that the transition to

the large hatch version with 47° glacis (not presented here)

took place in November, 1943. Our best guess of the production figures

would be 3614 small hatch and 1000 large hatch.

Nearly

all M4A2(75)s were provided as Lend Lease to the British Commonwealth,

the USSR and France. In addition, the US Marine Corps was supplied with

493 units.

Production Order T-3049

: 350 tanks manufactured (April - August 1942)

Production Order T-3195 : 2000 tanks manufactured (August 1942 - March 1943)

Production Order T-3318 : 275 tanks manufactured (March - May 1943)

Production Order T-3608 : about 986 "small hatch" tanks and 714 "large hatch" tanks manufactured (April 1943 - February 1944)

Production Order T-3195 : 2000 tanks manufactured (August 1942 - March 1943)

Production Order T-3318 : 275 tanks manufactured (March - May 1943)

Production Order T-3608 : about 986 "small hatch" tanks and 714 "large hatch" tanks manufactured (April 1943 - February 1944)

The rapid expansion of M3 Medium Tank production required more power plants than the limited supply of Radial tank engines could provide. Consequently, the Ordnance Department cast about for other possibilities. In August, 1941, General Motors was contracted to perform an experimental installation using M3 Lee Serial Number 28, which was pulled off the line at Chrysler and shipped a short distance to GM’s Detroit Diesel Plant. The configuration combined two "off the shelf" GM 6-71 diesel truck engines that were “coupled together by means of a transfer case delivering the doubled power to a single driver shaft.” Together the engines developed about 400 horsepower. SN 28 was evaluated at Aberdeen Proving Ground in Maryland, and in October, 1941, the twin diesel engine was designated the "GM Model 6046," and authorized for production as an alternate power plant for the Medium Tank. Above shows SN 28 at APG in November, 1941. The upper rear hull plate (1) was reconfigured by being elongated and mounted on an angle in order to accommodate and protect the rear mounted radiators. The engine access doors in the lower rear plate of the original M3 design were eliminated, and instead a pair of mufflers were mounted across the plate. Note that a sheet metal exhaust deflector (2) was installed on the pilot. The engine was serviced through a rather large pair of doors on the engine deck. This configuration was carried over to the Sherman design as the M4A2.

Above shows a GM Model 6046 twin diesel on display at the Tank Museum at Bovington. Note the transfer case indicated by the arrow. The size of the twin engine configuration necessitated a number of changes to the layouts of both the engine and fighting compartments. For instance, the addition of the transfer case made the power pack longer than the engine compartment. Consequently, the firewall was altered to permit the transfer case to protrude into the fighting compartment. From the start the US Army had determined that it would employ gasoline powered Shermans in its armored units, so production of the diesel was primarily intended to satisfy the requirements of the Lend Lease Program. Photo courtesy of the late Massimo Foti, a fine photographer, and friend to Sherman Minutia.

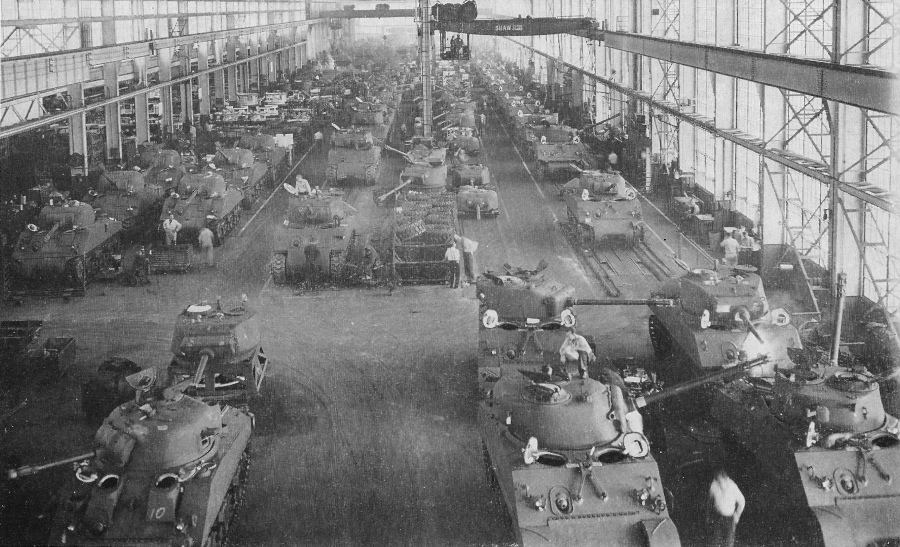

In August, 1940 the US Government financed construction of a dedicated tank plant in Warren, a small township outside of Detroit, Michigan. The "Detroit Tank Arsenal" was operated by the Chrysler Corporation, and was set up for the production of 1000 medium weight tanks per month. The plant produced 3352 M3 Medium series tanks from July, 1941 through August, 1942. In July, 1942, DTA began production of the M4A4 model of the Sherman Tank. Another massive and dedicated tank plant with a 1000 medium tank per month capacity was authorized by the War Department in November, 1941. The 452,000 square foot Grand Blanc Tank Arsenal was operated by the new corporate entity, the "Fisher Tank Division" of General Motors. The contract also provided funding for additional facilities at an existing automobile plant in Flint, Michigan. The photo above was part of an informational series on the conversion of auto plants for war production, and shows "workmen who once built Chevrolets" welding on the Fisher pilot model of the M4A2. David Jackson's fine website "The American Automobile Industry in World War Two" explains that, "Prototype work was done... at Fisher Body #1 4.5 miles north [of the Tank Arsenal] on Saginaw Street. The first tank came off the prototype line April [1942] along with three others and in May sixteen more M4A2s came off the Flint 1 prototype line, allowing Fisher Body to deliver tanks two months before scheduled, and before the Grand Blanc plant was finished in July."

The photo above shows the pilot M4A2, nearing completion at the Fisher Body Flint No. 1 plant. Throughout production Fisher appears to have used something akin to duct tape to seal up gun barrels and other voids for shipping. Note how the fixed and coaxial MG holes have "disappeared." Contrary to the caption of the previous photo, the workmen here did not build Chevrolets; rather they stamped out and constructed body parts for the Buick automobile assembly plant located nearby. The Fisher Tank Division was tasked with aiding in the design and production of a Tank Destroyer, and the hull of the T35, the first iteration of what became the "3 inch Gun Motor Carriage, M10," can be seen as the second "tank" in line. Note the "missing" bow machine gun, and the protective plate on the 3-piece differential housing. The addition of the plate appears to have been in anticipation of the superior 1-piece differential housing that had been designed and was just entering the Sherman production pipeline. Like the Fisher M4A2 pilot, the T35 was shipped to APG immediately after it was completed in April 1942.

The Fisher pilot M4A2, Serial Number 2305, USA 3014311 was the first model of welded hull Sherman produced, and after completion, was immediately shipped to Aberdeen Proving Ground for evaluation. The view above, dated April 15, 1942, shows the "method of blocking" for shipment by rail. The purpose of the U-shaped fittings (1) affixed to the front and rear bogies, and seen in a number of photos of early combat Shermans, is evident here. In some cases it was noted that these were tied down too tightly on the railroad car, which overly stressed the volute springs. The rear most turret splash section (2) can be seen to have been assembled by welding, and portends the use of a number of fabricated as opposed to cast components in the construction of Fisher built M4A2s. What we informally call the "bent rod" hull lifting ring (3) was used on early production Shermans, but was soon replaced by a casting with a rectangular base by most of the builders, including Fisher. The rear most engine deck panel was secured with 11 bolts (4) on early production M4A2s, but, for user convenience, this was reduced to 6 bolts shortly thereafter. SN 2305 is thought to be the only welded hull Sherman that was constructed with a step (5) in the sponson armor. Note that 2305 can be seen with a standard D50878 turret with gunner's periscope. As best we can determine, only a few of the earliest M4A1s produced by Lima Locomotive and Pressed Steel Car were built with turrets with rotor sights.

Here we show in more detail the odd step (arrow) on 3014311, the Fisher M4A2 pilot. To the best of our knowledge this peculiar feature was limited to just the one welded hull pilot. Perhaps the step was unintentional, caused by an error in the engineering drawing which created a step when the 2 dimensional drawing was translated into the 3 dimensional hull? As can be seen it would have been quite complex to build this intricate shape, requiring additional labor and materials, for no practical benefit. In fact the step would have created a shot trap and as such a potential vulnerability in combat. Regardless of the cause, it appears that it was rectified immediately because this step did not appear on subsequent Fisher hulls.

Here

we have a snapshot that we "won" on Ebay in 2022 showing USA 3014312.

"APACHE" would have been the first production Fisher M4A2, and we would

judge that it does NOT have the "odd step" seen on the pilot.

"Melichercik by M4 Tank (General Motors)" is all that is written

on the back. "AFS" is painted inside the star on the turret which

would suggest that the location was the Armored Force School at Ft.

Knox, Kentucky. Most likely "APACHE" was with the Demonstration

Regiment's A Company like "ASP" and "ATILLA" which we shall discuss

going forward. The foliage would indicate summertime 1942 but perhaps a

bit later than some of the other AFS photos, since we believe that this

tank would have been built with flat block rubber tracks, and that the

rubber chevrons seen here mounted backwards were replacements. The

inside of the commander's hatch appears to be (re?)painted olive drab

rather than the white seen in photos of some other early Fishers. As

with the pilot, the Registration Number seems to be in a darker color,

probably black. The May 1942 photos of ASP USA 3014316 and ATILLA

3014317 show a much lighter color (inset). The evidence suggests that

Fisher begin using blue drab for the RN very early on and continued

with it throughout production. A close look at the bow gunner's

hatch shows the handle mounted towards the rear and on an angle.

"APACHE" can be seen with a 1-piece differential housing which is

"flat" at the top. Some Lees can be seen in the background with at

least one being a cast hull M3A1.

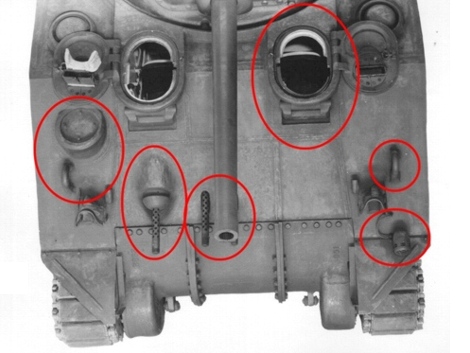

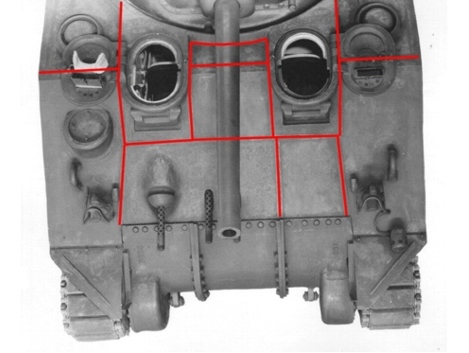

The two photos above show several items that are specific to very early Fisher built, small hatch M4A2s. On the left-side photo circled in red, from left to right, the cast antenna bracket and the crude "bent rod" lifting ring, the bow and fixed machine gun "plate," the cast drivers' hoods with direct vision slots, the other "bent rod" lifting ring, and the siren affixed to the mudguard. The right-side photo shows the construction of the front glacis with the red lines indicating the weld joints. Note that the "plate" that includes the bow and twin fixed machine guns was actually a casting, whereas the other flat sections of the glacis were armor plates. We think of this as a "7 section glacis pattern." On March 5, 1942, even before the first M4A2s rolled off the assembly lines, the Military Characteristics of the M4 series were revised to eliminate the two fixed machine guns. However, similar to some of the early Lima and PSC M4A1s, a few of the first few Fisher M4A2s were built with the fixed MGs installed or with the open holes. On the other hand, Pullman Standard also had its first M4A2 accepted in April, and photos of their first and succeeding units show neither the fixed MGs nor open holes.

It is thought that SN 2305 was the only M4A2, or welded hull Sherman for that matter, that was constructed with the "step," and the drivers' hatch handles welded on towards the rear and on top of the hatch "bumps." Succeeding units appear to have been built to a later revision of the design, where the upper sponson plates reflect the "usual" welded hull configuration. In a previous photo, the hull of the pilot T35, USA 4027647, can be seen as the second unit on the line at the Fisher Body Flint No. 1 plant. Consequently, we thought we might discuss it a little, since it was obviously based on an early Fisher M4A2 hull, but with an open top turret mounting a powerful 3 inch anti-aircraft gun. In this top view, note the "normal" way that the sponson plates are joined in front of the fuel cap bullet splash (1). The handles (2) of the drivers' hatches have been "relocated" to what became the standard position. Counting heads suggests that Fisher mounted the grouser cover plates (3) on top of the armor from the beginning of M4A2 production in April, 1942 to the end in May, 1945. We mention this because counting heads suggests that Pullman installed these cover plates flush with the armor surface, which provides a minor way to differentiate between the two producers' M4A2s in some photos. The rearmost engine deck plates of early M4A2s were "indented" (4) for reasons we have yet to discover. This was obviously unnecessary, since the indents appear to have been eliminated in July, 1942 at Fisher, coincident with the reduction in the number of bolts securing the plate from 11 to 6.

Fisher also completed the T35E1 pilot, USA 4027648, in April, 1942 and shipped it to APG. The Tank Destroyer Board wanted to use the lower hull, suspension, engine and power train of the M4A2, but as can be seen above, the upper hull was completely redesigned. The height, compared to the Sherman was lowered by 14 inches. In order to reduce weight and gain speed, the side and rear armor was reduced to a thickness of 1 inch, but mounted on an angle to improve ballistics. The glacis plate was the same as the M4A2's - 2 inches thick. While the T35E1's front plate can be seen in another photo from this series to have been composed of 3 sections, the idea of the design was to use a single plate for the glacis. Most significantly the glacis plate was "clean." The Sherman's protruding drivers' hoods and antenna bracket were eliminated, and the T35E1 provided a hatch in the roof of the hull, although only for the driver. This was essentially the "front end" concept submitted by Fisher for the Second Generation redesign of the Sherman about a year later. The fittings on the rear engine deck suggest that it was the intention that the tow cable would be coiled there. There may have been some debate about this, as the cable fittings can be seen on the rear decks of a few early Fisher and Pullman M4A2s. This would have added considerable weight to a removeable deck plate, and ultimately, the cable was mounted along the length of the hull on the left side as seen on the M4A2 pilot. In any case, a number of changes were made to the T35E1 design, particularly regarding the turret, but in June 1942, the Ordnance Committee approved standardization of "3-Inch Gun Motor Carriage M10." Fisher began M10 production a few months later in September, 1942.

Returning to the M4A2, here we see the fourth one completed by Fisher, S/N 2308. Buick, another division of General Motors, began making power trains in early 1942. From the outset, they constructed their units with the recently designed one-piece (E4186) differential cover, a great improvement over the three-piece differential of the M3 Medium. (The differential housings of many surviving Shermans are seen with "BU" among the casting marks, which we take to signify Buick.) S/N 2308 was used to test one of the first Buick power trains. Counting heads suggests that Fisher completed the transition to the 1-piece differential by June, 1942. The M3 type bogie units as seen on 2308 were seriously overtaxed by the Sherman, and sufficient supplies of M4 bogies became available so that Fisher was able to complete the transition to them by September, 1942. Note that while this tank has the tow cable mounted in the standard location, it was built with additional tow cable fittings on the rear deck. This example lacks the standard rear tow cable fitting that was was provided on the pilot model; instead the cable appears to be secured to the rear lifting ring by a shackle. An odd feature of 2308 is the white painted hatch interiors. No doubt they would have been repainted in Olive Drab, if the tank had ever been sent overseas. As it was, 2308/USA 3014314 was an asset of the Armored Force Board at Ft. Knox at least until February, 1945 when it was requested that it be removed from the Motor Pool to make room for more current test vehicles.

We

have recorded some textual listings for a few of the early Fisher M4A2s

that were shipped to Ft. Knox, Kentucky for evaluation by the

Demonstration Regiment of the Armored Force School. These include SNs

2307, 2308, 2311, 2314 and 2315. Here we have a somewhat washed out

color photo of what we assume to be SN 2308, since it has a 1-piece

diff, and some fuel has spilled down the side revealing the numbers

"314," which we take to equate to USA 3014314. Unfortunately, many of

the Signal Corps color photos have generic captions that provide

absolutely no "who, what, where, when." For instance, the caption of

this photo is "Picture of M-4 Sherman Tank." It would appear that a

number of 8 X 10 color transparencies were turned into the Pentagon

without captions, and released by the Bureau of Public Relations post

war.

One of our favorite color photos, showing some of the Demonstration Regiment's Shermans, Lees and Stuarts on a nice Summer day, no doubt in 1942. The tank with the one piece differential housing (arrow) is probably SN 2308. The lead Sherman can be seen with the "bump" (1) on the glacis casting, and one of the fixed machine guns installed, while the other hole is taped up. At first we thought this unit might be the fourth Pullman M4A2, SN 908, since photos show it had the "bump." However, that one was sent to APG for Acceptance Test in the Summer of 1942. And besides, the fixed MG holes were closed on SN 908 and it had a 1-piece differential housing. The USA Number of the Demonstration Regiment M4A2 can be seen painted on, and we were able to manipulate the photo where it was possible to discern that it began with "30143," possibly 3014321 (inset), which is listed in a text document as SN 2315 of B Company of the Demonstration Regt., "10/27/42, engine failure." Indeed, this is the only example of the "bump" on a Fisher built Sherman that we are aware of. Should readers know of any other photos, we would be pleased to see them.

Above shows interior and exterior views of the "bump" on a surviving Sherman, the first ALCO M4A2. It can be seen that this particular glacis casting was made to hold the twin fixed machine guns that were part of the original M4 design. The fixed MGs had been eliminated in March, 1942, before production of welded hull Shermans had begun, and one can see on this example that the holes were simply sealed up by welding. At first we thought that the use of the glacis casting with the bump was short lived, and limited to a few early M4A2s, along with the two Ford M4A3 pilots. We would note that in the few period photos showing the "bump" on M4A2s, as well as on the two known surviving examples, the tanks have direct vision. However, the bump has also been observed in a pair of photos of early 1943 production M4s thought to have been made by ALCO, and with the later type of drivers' hoods. We can only guess that the employment of these castings in the assembly of a 1943 production welded hull Sherman was a case of using obsolete, but acceptable parts that were on hand. At any rate, “the bump” provides us with an interesting and ongoing little Sherman mystery. (Photos courtesy of the APG Restoration Staff).

The photo above is part of a series that show tanks A8, "ASP," and A9 "ATILLA" of the Demonstration Regiment. From examining the other photos, we find that ASP was USA 3014316 and ATILLA was 3014317. These would have been accepted in May, 1942 and would have been the 6th and 7th M4A2s produced by Fisher. ASP can be seen with both fixed MGs installed, and appears to have the same "7 section glacis pattern" as on the pilot SN 2305. This is the pattern most commonly seen on the early Fisher M4A2s. On the other hand, ATILLA seems to show an 8 section glacis pattern, with a small bow MG casting, and a separate plate for the fixed MGs. These tanks have not yet been installed with the gunner's blade sight that became standard a month or so later. Note how the front fenders do not follow the contours of the 3-piece diffs, since they were made for the 1-piece jobs.

This interesting overhead view of ASP shows the configuration of the tow cable installed in the short lived rear engine deck position. M4A2s had 7 fuel/oil/water filler points as seen here. Because of the size of the twin diesel engines, there were no vertical fuel tanks in the engine compartment. Filler point 1 was for diesel fuel stored in the horizontal tanks. These were supplemented by a pair of reserve fuel tanks mounted on the engine compartment floor just below the horizontal tanks. The fuel capacity of the M4A2 was 148 gallons, compared to the M4/M4A1's 172 gallons. Point 2 provided for lubricating oil, and point 3 for water to the radiators. Of course these were mirrored on the right side, but they are in heavy shadow in this view. Point 4 was for the auxiliary generator (Little Joe), the same gasoline powered model as used on the radials. None are seen on this example, but pressed metal labels were affixed near each of the fuel filler covers to help the crews avoid contaminating the tanks with the wrong solutions. We confess that we have not been able to determine when these labels were first factory installed. For what it is worth, the first ALCO M4A2 was accepted in September, 1942 and can be seen with the "official labels," as can "Holy Roller" a Fisher built M4A2 that was also accepted in September. Little chains secured the fuel caps' removable hinge pins. It can be seen that the chain at filler point 1 is not connected to its hinge or "locking pin."

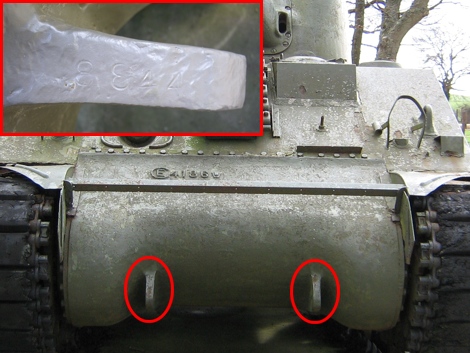

When we were informed recently that the tank shown above has Serial Number 2310 stamped on the rear towing lugs (left inset) and inside the dataplate frame, it became, for us at least, the oldest known surviving M4A2. Not only that, but Serial Number 2310 is an exact mathematical match to USA 3014316, the Registration Number of "ASP", "DR-A8" as seen in the photos of the two previous captions. A total of 525 M4A2(75)s that had been used by training units in the US were collected up and remanufactured from April through November 1944, and SN 2310 strikes us as one of them. We believe that the M3 bogies seen in the 1942 photos would not have been considered acceptable for a remanufactured Sherman and would have been replaced if they had not been earlier. Many remanufactured Shermans are noted with 3-piece differential housings such as "ASP" had originally, so that would not necessarily require replacement, but it obviously was at some point. We would note that there is a plate (right inset) screwed on to the front indicating that SN 2310 had been rebuilt by the "Etablissement de Réserve Générale du Matériel - Engins Blindés" in Gien on 30 March 1949. The turrets of early Fisher M4A2s such as "ASP", don't appear to have had any casting marks visible on their exterior surfaces. In the case of SN 2310, "D50878, (G in a shield) E" is visible inside on the "ceiling." From a very small sample, we believe that the earliest turrets produced by General Steel-Eddystone were cast in this configuration. In any case, if this turret with the "high" lifting rings is not original to SN 2310, it is certainly appropriate. With the paint worn away, we get an idea of the welded together construction of the glacis, including the filled in fixed machine gun holes. The "bent rod" hull lifting ring also shows to good effect.

We admit that we don't have any confirming photos of Fisher M4A2s with known good Serial or Registration Numbers past the twelfth one, but we would "project" that the first 49, built from April to June, 1942, SNs 2305 through 2353, with RNs in the 30143XX range, would have been constructed mostly with fronts composed of 7 section glacis patterns. Their antenna brackets, bow MG "plates," and front and side turret splash guard sections would "still" have been castings. Some may have had 1-piece differential housings, but we suspect all would have been built with M3 type bogies. A couple of these, SNs 2320 and 2349 were reported to be among the first 26 M4A2s received as Lend Lease by the Soviet Union. These are stated to have arrived "at a northern port of entry" in November, 1942. SN 2341, USA 3014349 is listed with the 81st Armored Regiment in a Maintenance Report from Camp Young, California dated September 18, 1942. And finally, we have SN 2318, USA 3014324 noted in a Disposition Report from Oceanside, California, dated September 4, 1945. We take Oceanside to be Camp Pendleton, where the US Marine Corps was seeking to dispose of this obsolete Sherman, probably one of the first M4A2s they received. At any rate, in an effort to conserve some of the nation's limited casting capacity, Fisher designed and began to substitute what are described as "fabricated" components for some of the original castings with which it began production. Their 110th M4A2 hull, which would have been accepted in July, 1942 had it been completed as a tank, was submitted to APG for a Ballistics Test during that month. It is mentioned that the hull's armor plate was supplied by Republic Steel Corporation. In this view, we can see the sharp angles of the fabricated turret splash sections (1). These appear to have been used exclusively by Fisher Tank, and are a sort of trademark of their small hatch M4A2s. One would think that the bullet splash (2) protecting the armored filler caps would have been fabricated, but the examination of surviving examples shows that these remained castings. Going the other way, the fabricated "bent rod" hull lifting rings of the early models were replaced by the castings shown here (3). For convenience, we refer to these as "padded" hull lifting rings.

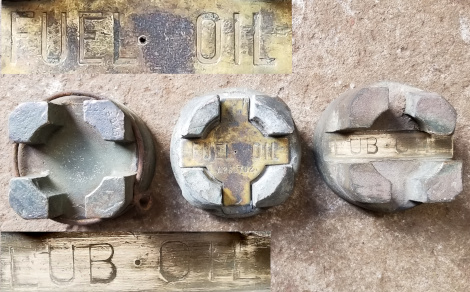

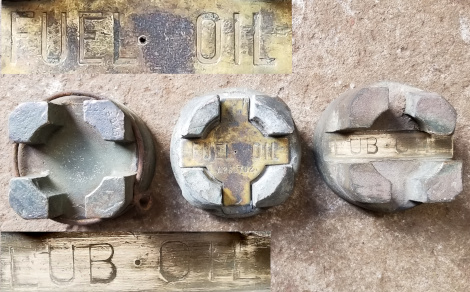

The above photos show an example of what we believe is an original pressed metal label as seen on a surviving M4A2. This is, of course, the "Gasoline" label for the auxiliary generator. The label itself measures about 1 1/8 inches in width, and 4 1/4 inches in length. The label appears to have been welded onto to a slightly larger pad which was welded on to the hull. We haven't as yet been able to measure one, but would judge that the curved ones (Diesel Fuel Oil, Lubricating Oil) are the same width, and span about 8 inches at their widest.

The armored filler caps protected a screw on cap over the filler necks of the various fuel, oil and water tanks. Pierre-Olivier photographed the examples shown on the left above from a surviving M4A2 diesel. They have a sort of "castellated" appearance, and two have the labels "FUEL OIL" and "LUB OIL." This type of inner cap appears to have carried over from the M3 Medium series. "FUEL OIL," which has been noted on the armored filler caps of a few M3 series diesels, is somewhat confusing, and the M4A2's exterior pressed metal label was changed to "DIESEL FUEL OIL," although it strikes us that "DIESEL FUEL" would have been sufficient. Our ability to count heads on these caps is extremely limited. Our best guess is that they were replaced in production in the Summer of 1943 with the "Fuel Tank Filler Neck, Filter and Cap" as shown in the illustration in the middle, and in the Korean War scene on the right. The new configuration was considered an important safety upgrade, and a Field Service Modification Work Order was released so that the new caps and filler necks could be retrofitted to Shermans in Tank Depots or in the field. Indeed, this was labeled an "Urgent" modification to be installed on all US Army Shermans in the UK before D-Day. As of Nov. 1, 1943, the Ordnance Department reported that "stock on hand" was 5897 kits.

Fisher M4A2 Serial Number 2420/USA 3020927 was produced in July, 1942 and was shipped to APG where it underwent an Acceptance Test in early August. The tank was widely photographed on the test tracks there as shown above. The Report notes that the M34 Gun Mount was manufactured by the Fisher Tank Division and was serial number 69. The gun was produced by another GM divison, Oldsmobile, which went on to manufacture most of the Sherman's 75 and 76 mm guns. Of interest is that the power train is listed not as Buick, but as Caterpillar #2C-216. Note the flatness of the differential housing with countersunk bolts running across the top. It is thought that the E4186 diffs designed and produced for Buick had a protective "lip" in front of the bolt strip. It is around this time that Fisher M4A2s begin to take on a rather consistent appearance characterized by the use of fabricated components. On this example, the glacis pattern has been reduced to 6 sections, with the fabricated bow machine gun socket (1) welded into a single plate. Note the distinctly sharp lines of the fabricated antenna bracket (2) and the turret splash sections (3). In the rear, one can see the original design of the sheet metal exhaust deflector with open sides (4). SN 2420 "still" has the "indented" rear engine deck plate, secured by 11 bolts (5). While photos of early Fisher M4A2s show the Federal Type 160 siren with the "V for victory" grill, by July it would appear that Fisher began to receive regular supplies of the larger Mars Signal Light Company siren (6). Period photos suggest that the Mars sirens predominate from then on, but the Federals continue to appear on some Fisher M4A2s. A gunner's blade sight (7) can be seen on SN 2420. The M4A2 was apparently designed without an external handle on the commander's cupola, and it is "still" lacking on 2420. However "counting heads" suggests the handle was introduced in July, welded on to the hatch half without the periscope (8).

Looking very much like SN 2420 of the previous caption, the M4A2 seen here is about to be installed with a differential housing/power train. In this case, the lip (arrow) would suggest a Buick made power train. We believe this photo was taken in July 1942 as production got underway at the new and gleaming Tank Arsenal in Grand Blanc. In this instance, a handle (1) is just visible on the hatch half of the commander's cupola. Throughout production, Fisher appears to have used both welded and pressed metal road wheels. The photos of SN 2420 showed that it had pressed metal wheels, but the unit seen here caught our eyes because it has some "unspoked" pressed metal wheels (2). We think of the unspoked wheels as the first version of the pressed metal road wheels which replaced welded spoke wheels on Chrysler Lees around March 1942. Chrysler soon replaced them with the standard spoked pressed metal wheels which they used on all of their Shermans until the end of VVSS production. In any case, the unspoked wheels are fairly rare and before seeing this photo, we had thought that they might have been confined to a few Chrysler Lees and the M4A4 pilot.

Counting heads suggests that in August 1942, in the interest of simplifying, Fisher lowered the number of bolts securing the rearmost engine deck plate from 11 to 6. The rearmost engine deck "indents" appear to have been eliminated with the bolt reduction.

This interior view shows how the "Bow Gun Front" was welded to the upper and lower pieces to form the bow MG socket.

At the same time as the introduction of the other fabrications, Fisher replaced the cast headlight socket with what was basically a pipe with an outside diameter of 2 3/4 inches and 5/8-inch-thick walls (left). This is described in a Fisher parts document as "Boss Outer Headlight - Rt." or "Boss Outer Headlight - Lt." although the Part Number for both is "A-245386" since they are identical. These are small fittings, but we can confirm that we have seen this Part Number stamped on at least one surviving example. We used the term "headlamp" in the previous caption since that is the way they are described in the Technical Manual illustrations. The Fisher doc uses "headlight", and we have followed suit in this caption. Take your pick. A plug fixture for the headlight can be seen inside the pipe, and, of course, the right photo shows one of the standard service headlights mounted. As best we can tell from the available evidence, the only other manufacturer that used these fabricated headlight sockets was Baldwin, and we can observe that they appear on 9 of the 12 surviving BLW M4s that we have examined. Fabricated headlight sockets were also standard on 47-degree hull Shermans, but they were "D-shaped" as opposed to round.

One of our favorite color photos, showing some of the Demonstration Regiment's Shermans, Lees and Stuarts on a nice Summer day, no doubt in 1942. The tank with the one piece differential housing (arrow) is probably SN 2308. The lead Sherman can be seen with the "bump" (1) on the glacis casting, and one of the fixed machine guns installed, while the other hole is taped up. At first we thought this unit might be the fourth Pullman M4A2, SN 908, since photos show it had the "bump." However, that one was sent to APG for Acceptance Test in the Summer of 1942. And besides, the fixed MG holes were closed on SN 908 and it had a 1-piece differential housing. The USA Number of the Demonstration Regiment M4A2 can be seen painted on, and we were able to manipulate the photo where it was possible to discern that it began with "30143," possibly 3014321 (inset), which is listed in a text document as SN 2315 of B Company of the Demonstration Regt., "10/27/42, engine failure." Indeed, this is the only example of the "bump" on a Fisher built Sherman that we are aware of. Should readers know of any other photos, we would be pleased to see them.

Above shows interior and exterior views of the "bump" on a surviving Sherman, the first ALCO M4A2. It can be seen that this particular glacis casting was made to hold the twin fixed machine guns that were part of the original M4 design. The fixed MGs had been eliminated in March, 1942, before production of welded hull Shermans had begun, and one can see on this example that the holes were simply sealed up by welding. At first we thought that the use of the glacis casting with the bump was short lived, and limited to a few early M4A2s, along with the two Ford M4A3 pilots. We would note that in the few period photos showing the "bump" on M4A2s, as well as on the two known surviving examples, the tanks have direct vision. However, the bump has also been observed in a pair of photos of early 1943 production M4s thought to have been made by ALCO, and with the later type of drivers' hoods. We can only guess that the employment of these castings in the assembly of a 1943 production welded hull Sherman was a case of using obsolete, but acceptable parts that were on hand. At any rate, “the bump” provides us with an interesting and ongoing little Sherman mystery. (Photos courtesy of the APG Restoration Staff).

The photo above is part of a series that show tanks A8, "ASP," and A9 "ATILLA" of the Demonstration Regiment. From examining the other photos, we find that ASP was USA 3014316 and ATILLA was 3014317. These would have been accepted in May, 1942 and would have been the 6th and 7th M4A2s produced by Fisher. ASP can be seen with both fixed MGs installed, and appears to have the same "7 section glacis pattern" as on the pilot SN 2305. This is the pattern most commonly seen on the early Fisher M4A2s. On the other hand, ATILLA seems to show an 8 section glacis pattern, with a small bow MG casting, and a separate plate for the fixed MGs. These tanks have not yet been installed with the gunner's blade sight that became standard a month or so later. Note how the front fenders do not follow the contours of the 3-piece diffs, since they were made for the 1-piece jobs.

This interesting overhead view of ASP shows the configuration of the tow cable installed in the short lived rear engine deck position. M4A2s had 7 fuel/oil/water filler points as seen here. Because of the size of the twin diesel engines, there were no vertical fuel tanks in the engine compartment. Filler point 1 was for diesel fuel stored in the horizontal tanks. These were supplemented by a pair of reserve fuel tanks mounted on the engine compartment floor just below the horizontal tanks. The fuel capacity of the M4A2 was 148 gallons, compared to the M4/M4A1's 172 gallons. Point 2 provided for lubricating oil, and point 3 for water to the radiators. Of course these were mirrored on the right side, but they are in heavy shadow in this view. Point 4 was for the auxiliary generator (Little Joe), the same gasoline powered model as used on the radials. None are seen on this example, but pressed metal labels were affixed near each of the fuel filler covers to help the crews avoid contaminating the tanks with the wrong solutions. We confess that we have not been able to determine when these labels were first factory installed. For what it is worth, the first ALCO M4A2 was accepted in September, 1942 and can be seen with the "official labels," as can "Holy Roller" a Fisher built M4A2 that was also accepted in September. Little chains secured the fuel caps' removable hinge pins. It can be seen that the chain at filler point 1 is not connected to its hinge or "locking pin."

When we were informed recently that the tank shown above has Serial Number 2310 stamped on the rear towing lugs (left inset) and inside the dataplate frame, it became, for us at least, the oldest known surviving M4A2. Not only that, but Serial Number 2310 is an exact mathematical match to USA 3014316, the Registration Number of "ASP", "DR-A8" as seen in the photos of the two previous captions. A total of 525 M4A2(75)s that had been used by training units in the US were collected up and remanufactured from April through November 1944, and SN 2310 strikes us as one of them. We believe that the M3 bogies seen in the 1942 photos would not have been considered acceptable for a remanufactured Sherman and would have been replaced if they had not been earlier. Many remanufactured Shermans are noted with 3-piece differential housings such as "ASP" had originally, so that would not necessarily require replacement, but it obviously was at some point. We would note that there is a plate (right inset) screwed on to the front indicating that SN 2310 had been rebuilt by the "Etablissement de Réserve Générale du Matériel - Engins Blindés" in Gien on 30 March 1949. The turrets of early Fisher M4A2s such as "ASP", don't appear to have had any casting marks visible on their exterior surfaces. In the case of SN 2310, "D50878, (G in a shield) E" is visible inside on the "ceiling." From a very small sample, we believe that the earliest turrets produced by General Steel-Eddystone were cast in this configuration. In any case, if this turret with the "high" lifting rings is not original to SN 2310, it is certainly appropriate. With the paint worn away, we get an idea of the welded together construction of the glacis, including the filled in fixed machine gun holes. The "bent rod" hull lifting ring also shows to good effect.

We admit that we don't have any confirming photos of Fisher M4A2s with known good Serial or Registration Numbers past the twelfth one, but we would "project" that the first 49, built from April to June, 1942, SNs 2305 through 2353, with RNs in the 30143XX range, would have been constructed mostly with fronts composed of 7 section glacis patterns. Their antenna brackets, bow MG "plates," and front and side turret splash guard sections would "still" have been castings. Some may have had 1-piece differential housings, but we suspect all would have been built with M3 type bogies. A couple of these, SNs 2320 and 2349 were reported to be among the first 26 M4A2s received as Lend Lease by the Soviet Union. These are stated to have arrived "at a northern port of entry" in November, 1942. SN 2341, USA 3014349 is listed with the 81st Armored Regiment in a Maintenance Report from Camp Young, California dated September 18, 1942. And finally, we have SN 2318, USA 3014324 noted in a Disposition Report from Oceanside, California, dated September 4, 1945. We take Oceanside to be Camp Pendleton, where the US Marine Corps was seeking to dispose of this obsolete Sherman, probably one of the first M4A2s they received. At any rate, in an effort to conserve some of the nation's limited casting capacity, Fisher designed and began to substitute what are described as "fabricated" components for some of the original castings with which it began production. Their 110th M4A2 hull, which would have been accepted in July, 1942 had it been completed as a tank, was submitted to APG for a Ballistics Test during that month. It is mentioned that the hull's armor plate was supplied by Republic Steel Corporation. In this view, we can see the sharp angles of the fabricated turret splash sections (1). These appear to have been used exclusively by Fisher Tank, and are a sort of trademark of their small hatch M4A2s. One would think that the bullet splash (2) protecting the armored filler caps would have been fabricated, but the examination of surviving examples shows that these remained castings. Going the other way, the fabricated "bent rod" hull lifting rings of the early models were replaced by the castings shown here (3). For convenience, we refer to these as "padded" hull lifting rings.

Here

we show the bullet splash (arrow) protecting the armored filler cap on

the tank's right side. The Part Number of the casting can be seen on the

top edge of the piece as D51016A. The splash on the left is a "mirror

image" of this with Part Number D51016B. These are described as "Gas Cap

Guard[s]" in a Fisher parts list, and have been observed on other

surviving Fisher Shermans with PNs D52519 A and B. We would note that we

have encountered quite a few examples of fabricated bullet splash "Gas

Cap Guards" on Second Generation Fishers only. What we informally call

"armored filler caps" are referred to as "Cast Cover Caps" in the Fisher

list. These are about 6 1/2 inches in diameter and are seen on

surviving M3 and M4 series tanks to have Part Number C84811 (although it

would appear that Fisher's primary supplier cast the Part Number

"hidden away" on the inside of the piece as shown in the inset). On our

example, a couple of the removable locking pins have survived the years.

Chains, now long gone, secured the pins. The chain was attached to a

little U-bolt (1) welded into the armor, and then to a looped wire

fitting (2) at the point where the locking pin bends. With the adoption

of the diesel engine, pressed metal labels were affixed near each of the

armored filler caps to help the crews avoid contaminating the tanks

with the wrong solutions. Most of the pressed

metal fuel/oil/water labels have rusted away on this example, but

the curved one inside the Gas Cap Guard remains somewhat, and once read

"DIESEL FUEL OIL." There was a straight "WATER" label at position 3, and

a curved "LUBRICATING OIL" label at position 4.

The above photos show an example of what we believe is an original pressed metal label as seen on a surviving M4A2. This is, of course, the "Gasoline" label for the auxiliary generator. The label itself measures about 1 1/8 inches in width, and 4 1/4 inches in length. The label appears to have been welded onto to a slightly larger pad which was welded on to the hull. We haven't as yet been able to measure one, but would judge that the curved ones (Diesel Fuel Oil, Lubricating Oil) are the same width, and span about 8 inches at their widest.

The armored filler caps protected a screw on cap over the filler necks of the various fuel, oil and water tanks. Pierre-Olivier photographed the examples shown on the left above from a surviving M4A2 diesel. They have a sort of "castellated" appearance, and two have the labels "FUEL OIL" and "LUB OIL." This type of inner cap appears to have carried over from the M3 Medium series. "FUEL OIL," which has been noted on the armored filler caps of a few M3 series diesels, is somewhat confusing, and the M4A2's exterior pressed metal label was changed to "DIESEL FUEL OIL," although it strikes us that "DIESEL FUEL" would have been sufficient. Our ability to count heads on these caps is extremely limited. Our best guess is that they were replaced in production in the Summer of 1943 with the "Fuel Tank Filler Neck, Filter and Cap" as shown in the illustration in the middle, and in the Korean War scene on the right. The new configuration was considered an important safety upgrade, and a Field Service Modification Work Order was released so that the new caps and filler necks could be retrofitted to Shermans in Tank Depots or in the field. Indeed, this was labeled an "Urgent" modification to be installed on all US Army Shermans in the UK before D-Day. As of Nov. 1, 1943, the Ordnance Department reported that "stock on hand" was 5897 kits.

Fisher M4A2 Serial Number 2420/USA 3020927 was produced in July, 1942 and was shipped to APG where it underwent an Acceptance Test in early August. The tank was widely photographed on the test tracks there as shown above. The Report notes that the M34 Gun Mount was manufactured by the Fisher Tank Division and was serial number 69. The gun was produced by another GM divison, Oldsmobile, which went on to manufacture most of the Sherman's 75 and 76 mm guns. Of interest is that the power train is listed not as Buick, but as Caterpillar #2C-216. Note the flatness of the differential housing with countersunk bolts running across the top. It is thought that the E4186 diffs designed and produced for Buick had a protective "lip" in front of the bolt strip. It is around this time that Fisher M4A2s begin to take on a rather consistent appearance characterized by the use of fabricated components. On this example, the glacis pattern has been reduced to 6 sections, with the fabricated bow machine gun socket (1) welded into a single plate. Note the distinctly sharp lines of the fabricated antenna bracket (2) and the turret splash sections (3). In the rear, one can see the original design of the sheet metal exhaust deflector with open sides (4). SN 2420 "still" has the "indented" rear engine deck plate, secured by 11 bolts (5). While photos of early Fisher M4A2s show the Federal Type 160 siren with the "V for victory" grill, by July it would appear that Fisher began to receive regular supplies of the larger Mars Signal Light Company siren (6). Period photos suggest that the Mars sirens predominate from then on, but the Federals continue to appear on some Fisher M4A2s. A gunner's blade sight (7) can be seen on SN 2420. The M4A2 was apparently designed without an external handle on the commander's cupola, and it is "still" lacking on 2420. However "counting heads" suggests the handle was introduced in July, welded on to the hatch half without the periscope (8).

Looking very much like SN 2420 of the previous caption, the M4A2 seen here is about to be installed with a differential housing/power train. In this case, the lip (arrow) would suggest a Buick made power train. We believe this photo was taken in July 1942 as production got underway at the new and gleaming Tank Arsenal in Grand Blanc. In this instance, a handle (1) is just visible on the hatch half of the commander's cupola. Throughout production, Fisher appears to have used both welded and pressed metal road wheels. The photos of SN 2420 showed that it had pressed metal wheels, but the unit seen here caught our eyes because it has some "unspoked" pressed metal wheels (2). We think of the unspoked wheels as the first version of the pressed metal road wheels which replaced welded spoke wheels on Chrysler Lees around March 1942. Chrysler soon replaced them with the standard spoked pressed metal wheels which they used on all of their Shermans until the end of VVSS production. In any case, the unspoked wheels are fairly rare and before seeing this photo, we had thought that they might have been confined to a few Chrysler Lees and the M4A4 pilot.

Counting heads suggests that in August 1942, in the interest of simplifying, Fisher lowered the number of bolts securing the rearmost engine deck plate from 11 to 6. The rearmost engine deck "indents" appear to have been eliminated with the bolt reduction.

The

left side view shows the fabricated antenna bracket that replaced the

casting used on the first 50 or so Fisher M4A2s. Note the sharpness and

the distinctive "D" shape. This is described in a Fisher document as

"Bracket Radio, Part Number C-99433" and we have seen that PN stamped

on the bracket of the historic M4A2 "Holy Roller" on display in London

in Ontario Province, Canada. Only a small percentage of Shermans were

outfitted as command tanks, which required some sort of holder for the

antenna of the high-powered radio installed in the right front sponson.

Even so, every small hatch model was equipped with either a cast or

fabricated antenna bracket. In the view from the top on the right, it

can be seen that the bracket was about 14 inches wide, and that the

formed armor was a little less than 2 inches thick. We would assume

that the blank off, or "Plate Radio Bracket, Part Number B-206494" was

the same as used on the various types of cast antenna brackets.

Pierre-Olivier measured some surviving Fishers and found that the

height of the bracket in the front varied about an inch, between 5 3/4

to 6 3/4 inches, "depending on the width and thickness of the

weld attaching it to the glacis." The fabricated bracket was not

exclusive to Fisher M4A2s. It has been noted on some Pullman M4A2s

produced in late 1942/early 1943, as well as nearly the entire

production of Baldwin M4s.

Two views of the

fabricated bow MG socket. This was composed of 3 sections, the "Bow Gun

- Upper," (1), the "Bow Gun Lower" (2) and the "Bow Gun Front"

(3). Pierre-Olivier measured the circular "Bow Gun Front" and

found it to have a diameter of 10 1/4 inches (inset). The bow gun

assembly was welded into an opening cut in the lower glacis plate that

is about 11 5/8 inches at its widest point. As production ramped up in

the Spring of 1942, the automakers, GM, Ford and Chrysler, set up many

of their facilities to produce various major components such as power

trains, gun mounts and bogie units, along with many minor components.

These were supplied to the "railroad" builders as extra capacity became

available. We can only assume that Baldwin Locomotive sourced

fabricated antenna, MG and head light sockets from Fisher Tank, or that

at the least, Fisher provided templates for these items. A few period

photos and surviving examples show that Pullman used

fabricated antenna, and MG sockets on some of its M4A2s built in

late 1942/early 1943.

This interior view shows how the "Bow Gun Front" was welded to the upper and lower pieces to form the bow MG socket.

Fisher

started production with a pair of castings (1) that were welded on to

the glacis to mount the headlamps. These casting were about 4 1/2 inches

in diameter, and standard on most small hatch, welded hull

Shermans. The Sherman was equipped with 2 service headlamps and one

driver's blackout headlamp. Each of these had a blackout marker lamp

mounted on top. The driver's blackout lamp was "hooded," and emitted "a

thin flat beam of light that cannot be seen from high above, yet

provides enough illumination to permit the driver to avoid most

obstacles." When not in use, the headlamps were store inside, and the

sockets were sealed with a plug. At

first the headlamp plug holders (2) were oriented parallel to the

glacis as seen above. Towards the end of 1942, most Sherman

manufacturers reoriented the headlamp plug holders to a vertical

position, presumably to keep the plugs from falling out during travel.

Counting heads suggests that Fisher reoriented them somewhat later, in

the Summer of 1943.

At the same time as the introduction of the other fabrications, Fisher replaced the cast headlight socket with what was basically a pipe with an outside diameter of 2 3/4 inches and 5/8-inch-thick walls (left). This is described in a Fisher parts document as "Boss Outer Headlight - Rt." or "Boss Outer Headlight - Lt." although the Part Number for both is "A-245386" since they are identical. These are small fittings, but we can confirm that we have seen this Part Number stamped on at least one surviving example. We used the term "headlamp" in the previous caption since that is the way they are described in the Technical Manual illustrations. The Fisher doc uses "headlight", and we have followed suit in this caption. Take your pick. A plug fixture for the headlight can be seen inside the pipe, and, of course, the right photo shows one of the standard service headlights mounted. As best we can tell from the available evidence, the only other manufacturer that used these fabricated headlight sockets was Baldwin, and we can observe that they appear on 9 of the 12 surviving BLW M4s that we have examined. Fabricated headlight sockets were also standard on 47-degree hull Shermans, but they were "D-shaped" as opposed to round.

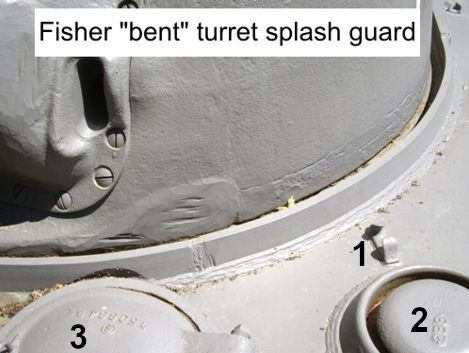

The welded hull Sherman was designed with the idea that the bullet splash guard sections around the turret would be castings, and indeed this was the case to the end of production in 1945 with every builder but Fisher. The photo on the left shows a section of the cast turret splash. As with most castings, the section can be seen with a nomenclature part number cast into it (circled in red and inset). In the Summer of 1942, Fisher replaced the turret splash castings with sections fabricated from armor cut and bent to shape where needed as shown on the right. Some other castings commonly used on Shermans include the tow cable clamp (1), ventilator (2) and small driver's hatch (3).

France

has the largest number of surviving Fisher M4A2s, and a few are actual

French Army combat veteran tanks on display as monuments or privately

owned. Pierre-Olivier has been visiting these as he has the time, with

the idea of taking measurements of the various fabricated components.

What he has observed suggests that the width of each fabricated turret

splash section started at 1 1/2 inches as shown on the left on Serial

Number 2495, produced in August 1942. However, he has encountered other

examples where the curved sections were only 3/4 inch wide, while the

straight sections remained at 1 1/2 inches as can be seen on SN 8873, a

January 1943 production unit thought to be a WW II veteran of the 2eme

Division Blindée. From P-O's notes, we would theorize that this change

occurred in late 1942, most likely coincident with the introduction of

the fabricated drivers' hatches and continued throughout the rest of

Fisher's production of the small hatch M4A2.

The photos above on the left show "straight" turret splash rear sections joined to the side sections. We assume that this was the "original" configuration, since it is observed on what are at present the two earliest known surviving Fisher M4A2s - Serial Numbers 2495 and 7486, both August, 1942 production. After that, starting with SN 7606 (September, 1942), surviving examples are seen with angled or bent splash sections as shown in the middle photos. This is the configuration observed on Fisher small hatch M4A2s up to the end of production in November, 1943. In fact, the use of fabricated, angled left and right turret splash sections was carried over to the Second Generation series of welded hull Shermans. For comparison, the photos on the right show the typical configuration of the cast sections used on the M4A2. Note the fire extinguisher pull housing (1), and how it is itself protected by a surround. Also seen here are some of the "official" fuel/oil/water pressed metal labels (2) used on M4A2s. Note the asymmetrical bolt pattern of the rear "mushroom" ventilator (3) typical of all welded hull Shermans, except Pressed Steel Car M4s. Oddly, this ventilator required a symmetrical bolt pattern on cast hull Shermans. One would think that a universal 5 hole casting could have been produced, but we have only seen ventilators with either symmetrical or asymmetrical bolt patterns.

The bullet splash guard in front of the engine deck doors was fabricated on the earliest M4A2s, including the Pilot. It is thought that in January, 1943, Fisher completed the transition to the cast piece that was used from the start by the other M4A2 manufacturers. Counting heads evidence is limited, but it would be our guess that most or all of Fisher's direct vision M4A2s and a few of its earliest welded hood units would have been built with the fabricated rear splash. The cast piece has been seen with Part Number C 99378 on a few surviving examples. We call it a "bullet splash," but it is described in a Fisher parts list as "Engine Compt. [Compartment] - Front Cover Casting." The piece is about 3 inches high, is removable, and was formed to accommodate 9 bolts, but we don't see any evidence that Fisher, as opposed to Pullman and ALCO, ever reamed out and used all 9 bolt slots. Like the fabricated part, at least at first, it was secured with 6 bolts as shown in the middle photo. The 6 bolt configuration appears to have been used by Fisher until around the Summer of 1943 when the number of bolts was reduced to 5. The 5 bolt configuration is what is seen on the many surviving M4A2(76)s, so would we assume it was used from the Summer of 1943 to the end of production in May, 1945.

In March, 1942 Fisher Tank ordered a "Radio Bracket B 50112" along with Front and Rear "Hoisting Eyes," Part Numbers C-95196 and C-95206, from the Ford Motor Company for an estimated cost of $73. These were described as "rough castings." It is thought that these were ordered as possible templates, but as we know, Fisher ultimately produced a fabricated Radio Bracket. On the other hand, the hoisting eyes were what we term "padded" hull lifting rings because they had rectangular bases as seen above. These begin to appear on Fisher M4A2s around the Summer of 1942. Looking at surviving examples, they do not seem to have been exact copies of the hoisting eyes provided by Ford, since they appear to have smaller bases, not to mention different part numbers - C-99457 (front) and C-99456 (rear). In any case, padded hull lifting rings were used by most of the other manufacturers of welded hull Shermans, although they transitioned to the most common or "standard" type of cast lifting rings (without the rectangular base) in early 1943. For some reason, Fisher does not appear to have transitioned to the use of the standard lifting rings until November, 1943 when the company began production of large hatch M4A2(75)s. And even then, some period photos and surviving examples show a "mix" with the standards on the front and padded ones on the rear.

As with most of the early manufacturers, Fisher started M4A2 production with the lifting rings on the turret mounted in the "high" position. This was quickly discontinued, and the low position became the de facto standard for the D50878 turret by the Summer of 1942. Pullman, which also began M4A2 production in April, 1942, appears to have switched to the low position by its third tank, which was accepted in May. The other M4A2 manufacturers, ALCO, Baldwin, and Federal Machine, didn't start production until the Fall/Winter of 1942, and the evidence suggests that all of their units were built with the low turret lifting rings. For whatever reason, Fisher continued to produce its M4A2s with the high turret lifting rings at least until February, 1943. Thus we would posit that all of their direct vision M4A2s would have had the "highs." The lifting rings were welded on to the Fishers whereas some turrets were made with the rings cast in. A couple of period photos such as the above show Fisher M4A2s with the high lifting rings, but with the stubs of the cast in rings, as if the lows were not acceptable and had been broken off. We would assume a memo was distributed to the manufacturers when the low position became preferred, but perhaps Fisher didn't get it? In any case, the photo shows USA 3063462 a December, 1942 Fisher parading through a town in Ohio in the Winter or early Spring of 1943. The Lima Tank Depot completely replaced the Toledo Tank Depot around this time, and it is thought that this series may show the transfer of AFVs from Toledo down to Lima, Ohio. Just visible on the front M4 bogie is the original half round type of track skid.

President Franklin Roosevelt rather casually called for the "Arsenal of Democracy" to make 50,000 tanks in 1942. The manufacturers scrambled to obtain the many resources and the heavy machinery necessary for for the task, but were limited by low materiel priority ratings and worker shortages, among other obstacles. Ultimately, during the 3 1/2 years of US involvement in WW II, American Industry "only" produced about 50,000 Shermans. Here we see an operation devised by Fisher engineers "whereby two machines can work on one turret simultaneously. As a means of utilizing every moment of time, the fixture holding the turret is set on a turntable so that another turret is fixed in position on one side of the table while the other is being milled. The table then revolves and work begins on the second while the first is removed and another put into position." Looking at the way the turrets are held in place, we would wonder if this procedure might have been the cause of the broken off cast in lifting rings seen in a few photos?

The

Sherman’s combat debut came with the British at the Second Battle

of El Alamein, which commenced on October 24, 1942. The story is well

known, but to recap...On June 21, Prime Minister Winston Churchill was

at the White House when he got the news of the surrender of Tobruk.

President Franklin Roosevelt asked if there was anything he could do to

help, and without hesitation, Churchill replied, "Give us as many

Sherman tanks as you can spare, and ship them to the Middle East as

quickly as possible." Soon after, Roosevelt ordered the dispatch of 300

Shermans and 100 M7 Priests. This would have been pretty much the

entire production of Shermans up to that point. The tanks were

collected up from the factories, as well as from US units that had just

begun training with them. The "5185 Opportunity" convoy sailed on July

15, 1942 with 302 Shermans and 100 Priests. The Shermans break down to

212 M4A1s and 90 M4A2s. The S.S. Fairport with 51 M4A1s and 32 Priests

on board was sunk by a U-Boat the next day. The Seatrain Texas sailed

unescorted two weeks later with replacements of 52 M4A1s and 25

Priests. The voyage took two months, and the Shermans began to arrive

in Egypt in September, 1942. Apart from these, an earlier

“regular” Lend Lease shipment of 15 M4A2s “which had

been intended to come well ahead...actually only preceded [the

emergency shipment] by a few days. The IWM photos above are dated

September, 9th. On July 15, when the convoy sailed, the only M4A2s that

were in production were made by either Fisher or Pullman. This

tank can be seen as T-74271. In another photo from this series, the USA

Number is partially visible as “305313X,” indicating that

it was made by Pullman. Note the “low” position of the

turret lifting rings. As mentioned previously Fisher

continued with the “high” lifting rings into early

1943. From that we “interpolate” that any of the

105 M4A2s in theater at the time, and seen with “high”

lifting rings would have been Fishers, and any with the

“lows” would have been Pullmans. Available period

photos suggest that Pullman M4A2s were far more numerous in

the emergency shipment, but some Fishers were sent. In a

Defect Report from Cairo dated 17 September 1942, US Army Col. E.S.

Gruver reported the Registration Numbers of 4 Fishers - USA 3020878,

3020884, 3020886 and 3020894, all of which would have been accepted in

July, 1942. The British War Department Numbers of the first 105

M4A2s all appear to have been in the T-742XX and T-743XX

range, but unlike the US Serial and Registration Numbers, these

tell us nothing about the builder or month of production of a

Sherman. IWM E16599 and E16603.

Since more than twice as many M4A1s were sent with the special shipment, they got most of the photographic “publicity.” For instance, the crews and M4A1s of C Squadron, 9th Queen’s Royal Lancers, 2nd Armoured Brigade, 1st Armoured Division were extensively photographed "in action" on October 16, 1942. It might be said that this series has become iconic, as any account of the Second Battle of El Alamein, will generally include one or more of these photos. However, the M4A2s also fought in the campaign from the start. The various “Tank State” documents record a total of 318 Shermans in the Middle East at the beginning of the battle. Unfortunately, these and the unit diaries don’t break down petrol versus diesel Shermans, so we have tried to seek out clues where possible. For instance, on September 4th, 1942, Eighth Army Headquarters directed that the 1st and 8th Armoured Divisions, along with the 9th Armoured Brigade, would receive the “Swallows.” As they were processed for issue in September, the 1st AD and 9th AB were assigned 94 and 46 petrol Shermans respectively. The first 64 diesels processed were ordered to the 8th AD, along with 30 petrols, which would be “replaced by Diesels as and when available.” From this we interpolate that, leading up to the start of the battle, the 8th AD, and more specifically, the 24th Armoured Brigade, was chosen to receive all of the available diesels. Due to manpower and materiel shortages, the 8th AD was essentially disbanded before the start of the battle, and the 24th Armoured Brigade, made up of the 41st, 45th and 47th Royal Tank Regiments, was transferred to the 10th Armoured Division on October 12th. IWM E 18377.

The WD Numbers reported for the battle in their respective War Diaries suggest that enough M4A2s to fully equip two Squadrons were issued to both the 41st and 47th Battalions of the Royal Tank Regiment, while the 45th RTR appears to have been issued M4A1s. Each of the Battalions began the battle with 3 Squadrons (A, B and C), two with Shermans, and one with Crusaders and each Squadron would have been composed of 14 tanks, assuming full availability. Unfortunately, the Shermans are not listed in the diary as “petrol” or “diesel,” but we interpolate from our counting heads research that the WD numbers in the T-74213 to T-74317 range were M4A2s. From this we take it that the 41st and 47th RTRs began the battle with only diesel Shermans. The WD Numbers listed in the diary for the Shermans of the 24th Armoured Brigade Headquarters (T-74233, T-74250, T-74266 and T-74287) indicate M4A2s, and we believe that Dover shown above, was one of these. The day before the battle, the units of the Brigade moved into their starting positions, “and tanks [were] immediately camouflaged as lorries,” as evidenced by the sunshield in place. Dover is in the process of being “teed up” with supplies, and we would observe that this tank has the additional cable clamps on the rear engine deck, and they appear to be preventing the various crates from lying flat. The dual muffler and exhaust system is partly visible here. We would have expected to see the sheet metal exhaust deflector mounted in front of (and obscuring) the mufflers, but it is notably absent in this and the few other rear shots of the Alamein M4A2s. The “71 on a square” painted on the rear sand shield identifies "Dover" as belonging to an Armoured Brigade HQ (BHQ), while another Sherman in this photo series (“Ports’th,” IWM E 18460) shows the formation marking confirming the brigade as the 24th Armoured Brigade. IWM E 18463.

The

first phase of El Alamein offensive was codenamed “Operation

Lightfoot.” In brief, the plan was for the infantry in the northern

sector of the line to attack and overwhelm the Axis’ forward positions.

Sappers would then clear two corridors through the minefields permitting

the armor to break through. “No battle plan ever survives first contact

with the enemy,” and the leading armor units, including the 8th and

24th Armoured Brigades, found that the gaps in the minefields had not

been cleared. Thus their progress was stalled, and limited to

“bridgeheads” where they faced extremely strong defenses. British

armored units took a tremendous pounding, but thanks in part to the 75

mm guns of the many M3 and M4 Mediums deployed, they gave nearly as good

as they got in a battle of attrition that the Axis forces simply could

not withstand. The

War Diaries of the 41st, 45th and 47th Battalions of the Royal Tank

Regiment state that they suffered their first tank casualties on October

25, 1942, the day after they were committed. An “Account of Operations

19th to the 29th October 1942,” written by Lt. Colonel J B Whitehead,

Commanding Officer of the 41st RTR reports, “Just before sunset about

forty German Mark III and IV tanks attacked across the flank of 41 RTR.

These were hotly engaged and several were soon in flames. Throughout the

day our tanks were subjected to heavy artillery shelling from 105mm

guns, which were numerous on our front and our first tank, 'Cocky', was

knocked-out.” The

well known photo above shows Cocky KO'd beyond recovery during the

Battle of Honey Hill in mid December, 1942. Although the tank still had

the large name across the rear, seen on a number of the M4A2s of the

24th Armoured Brigade, at that time she was serving with the Royal Scots Greys, 4th Armoured Brigade. The

WD Number can be read as T-74307, and that number is reported in a

November 1942 24th AB Tank Casualty State as with the 41 RTR, "Damaged

in battle, recovered and evacuated." Thus

it would appear that Cocky was repaired and passed on to the Greys

after the 24th AB was disbanded at the end of October, 1942. We would

assume that Cocky was one of the few Fisher built M4A2s that fought at

Alamein by virtue of the "high" turret lifting rings that can be seen in

the photo. IWM E 20514.

The 24th Armoured Brigade reportedly started the battle with 93 "Swallows." Counting heads suggests that a little more than 60 of them in the 41st and 47th RTRs, along with 24th AB Headquarters were M4A2s or Sherman IIIs. The Brigade was "used up" after 5 days in combat. Towards the end, the 41st RTR "could muster only eight," the 45th nine, and the 47th five running Shermans. The Brigade was withdrawn from the front "for a rest and refit" on October 29th. In fact, this was the unit's first and last battle. On the 30th, it's remaining Shermans and Crusaders were "handed over to Queen's Bays, 9 Lancers, and 10 Hussars" of the 2nd Armoured Brigade, 1st Armoured Division. The photos above were taken on November 10th by US Army Major Paul Wickens as part of a Military Intelligence Report "illustrating battle damage encurred (sic) by American tanks during the recent Alamein Offensive." Wickens examined about a dozen M4A1s as well as 2 M4A2s. "Many...were found about 9 miles South of the Rahman Mosque in the exact positions in which they were knocked out." Others, such as the M4A2 on the left had been removed to the "Rahman Collecting Point." The Major was an Ordnance officer, and noted that the "3 50 mm hits on turret" were not penetrations, whereas the hit on the left front sponson was. We see no obvious clues that could identify the unit, or if this was a Pullman or Fisher. It can be seen to have a 1-piece differential housing. Wickens made no comments about the M4A2 seen on the right, which appears to have been photo'd where it was KO'd. We would guess that this example was built by Fisher, as the turret splash appears to have the sharp angle (arrow) typical of the fabrications used by them. The pressed metal road wheels (1) are not commonly seen on the Alamein Shermans. The WD Number is not entirely readable, but appears to be in the T-7430X range. We don't believe that the units of the 24th Armoured Brigade ever got as far as the Rahman track, although these two may have been former 24th AB M4A2s, perhaps provided to one of the units of the 2nd Armoured Brigade as replacements?

The IWM photo above is captioned "A tank crew during a moment of relaxation in a tank battle," and is dated "29.10.42" [Oct. 29, 1942]. Sometimes the wording of the official captions can be misleading, and sometimes the dates are incorrect. John Taylor Firth, author of a history of the 47th Royal Tank Regiment, has concluded that this photo "was actually taken around the 21st October," that is, 3 days before the start of the Second Battle of El Alamein. The cartoon figure of "Capt. Reilly-Ffoul" no doubt caught the photographer's eye. An article, "From Oldham to Alamein," by Ian Hudson, that appeared in the Autumn 2020 issue of "Tracklink" identifies the crew as members of Five Troop, B Squadron, 47th RTR, and the tank as "Blighty." The piece is essentially a tribute to the young man seen in the lower right - Trooper Frederick Keates, the "wireless operator and gun loader." The 3 Shermans of Five Troop were reportedly KO'd as they advanced south of Kidney Ridge on October 27, 1942. A round penetrated the turret, killing young Fred, and wounding the Commander, Lt. Bob Hiseman (with arms akimbo in the photo), and the gunner Trooper Mackay (standing above Fred). Note the trailing return roller arm just visible on the center bogie. "Blighty" is proof that at least one of the "Alamein" M4A2s was equipped with M4 bogies. Indeed, Ian Hudson's article includes a snapshot of Blighty taken a month after the battle at the location where it was KO'd. The tank can be seen as T-74285, and has direct vision and a 1-piece differential housing, as well as the fabricated antenna bracket and turret splash typical of Fisher M4A2s. IWM E 18696.

After

their victory at El Alamein, the 8th Army pursued the retreating Afrika

Korps into Libya. The photo above shows "RIO" at a former Axis workshop

in Benghazi in late January, 1943. The "big name across the back"

suggests that RIO started the campaign as the Regimental Intelligence Officer's

tank of the Regimental Headquarters of the 41st RTR, 24th Armoured

Brigade. The tank was passed onto to another unit when the 24th AB was

disbanded, and continued to serve into 1943 until it required "3rd Line"

maintenance. RIO can be seen with in theater applied sand shields, and

"high" turret lifting rings. The British

expressed disappointment that no further shipments of Shermans would be

available to the Middle East until the end of 1942. A Tank State

document for early January, 1943 has it that there were 136

"M4A1/M4A2...Serviceable with 8th Army." The doc may provide a clue

about the next shipment to the M.E when it records that an additional 65

had "arrived since 6 Jan," and that 105 were in transit. There is also

the note that 1237 "M4A1/M4A2" and 185 M4A4 had been allocated to the

M.E. up to 31.12.42. However, 241 of the "M4A1/M4A2" had been diverted,

and would go the British 1st Army (6th Armoured Division) which had

landed in Northwest Africa as part of Operation Torch, and was then in

Tunisia. In fact, after the "special shipment" which included 264 M4A1s,

all of the British Lend Lease allocations in 1942 were of M4A2s (1111)

or M4A4s (939) with the exception of one M4A3 sent to the UK for

evaluation. Thus we would conclude that all further allocations in the

"M4A1/M4A2" category would have been M4A2s. The British found the M4A2

to be greatly superior to the M4A1, noting that it had more power and

got better fuel mileage. Indeed there were no further allocations

of 75mm Radial Shermans (M4 and M4A1) to the British until July 1943.

These came in lieu of M4A2s, as available stocks went to the Soviets.

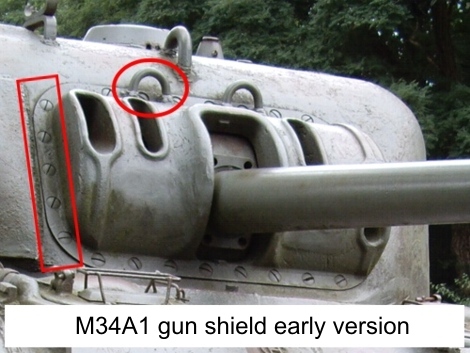

We have seen that a few of the "emergency shipment" Shermans had advanced features such as 1-piece differential housings and M4 bogies. However, there is no evidence to date that any had the later, non direct vision drivers' hoods. Direct vision was found to be a ballistic weak point, and the Ordnance Department ordered it eliminated from welded hull Shermans on August 13, 1942. Of course, some lead time was needed to implement the change, which in all cases but Fisher, involved the introduction of elongated castings with auxiliary periscopes replacing DV. Fisher Tank designed fabricated drivers' hoods as shown above, and current evidence suggests that they were exclusive to Fisher M4A2s.At present, our best guess is that Fisher began the transition to the fabricated drivers' hoods in November 1942. Although we have encountered a few surviving examples of fabricated "large" or Second Generation drivers' hatches, to date we have not come across any fabricated small hatches, so we would assume that all of the the drivers' hatches used by Fisher were the standard D50884 A and B castings as seen in these photos.

Fisher and most of the other manufacturers used what are informally referred to as "narrow" drivers' hoods on their small hatch Shermans. Whether cast or fabricated, the hoods were about 18 1/2 inches wide, and the photo on the left shows how they were welded into the glacis. Only Ford & Chrysler used "wide" drivers' hood castings on their M4A3s and M4A4s respectively. The castings included not only the drivers' hoods but inside armor sections which met in the center (arrow) and formed part of the glacis as shown on the right.