M4A3(75)W Shermans

Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads". It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

Introduction

The decision to continue production of 75mm Sherman tanks in 1944 and 1945

While the Sherman's 75mm main gun may have been "state of the art" in 1941 and 1942, it was outmoded as an anti-tank weapon by 1943. Unfortunately, the military bureaucracy became mired in controversy over the proper role of tanks, and ultimately failed to develop an effective replacement when it designed the 76mm gun and its original ammunition. In any case, most of the US Army heads involved with the Tank Program wanted to discontinue production of 75mm Shermans at the end of 1943. However, this was a decision made by committee, and some members hedged somewhat by noting “that the complete elimination of the 75m/m gun from the Medium Tank M4 Series would cause considerable difficulty should any portion of the Medium Tanks M4 be required in the future to be equipped with this same gun due to the change-over of the facilities involved.” It was noted that the British & US Marines still had requirements for the 75mm Sherman in 1944 and on. They considered the 75mm's High Explosive round to be markedly superior to that of the 76mm gun. Moreover, the British requested more 75mm Shermans with M34A1 gun mounts and Oil Gear Traverse Mechanisms, which they needed for their ongoing Firefly conversion program. In the event, the 75mm Sherman, in the form of the M4A3(75)W continued in production until March, 1945.

Hulls used for 75mm Wet Stowage Shermans were of the "ultimate" design, i.e. welded, 47 degree, with large hatches. Not many M4A3(75)W's have survived. Above is Serial Number 49578, produced in May 1944 and on display in Middletown, Pennsylvania. Note the sharp nosed differential housing (part Number E8543), which became standard on US built Shermans after September 1943.

Some of the first M4A3(75)Ws were shipped to Europe in the weeks and months following the Normandy Invasion on June 6, 1944. In the first 83 days of the Campaign, Medium Tank losses in the US Army were higher than expected, averaging 11 per day. The majority of these were repairable, but the ability of the Army logisticians to support the build up was severely strained. Included among the replacement tanks shipped were a good number of the various types of M4A3s - 75mm, 76mm, 105mm and M4A3E2 Assault Tanks [Jumbos]. It was the goal of US planners to place the Ford engined Shermans with their updated Second Generation features into the hands of combat troops as quickly as possible. Thus, an effort was made to identify the M4A3s with the idea of allocating them where possible on something of a proportional basis. As of September 17, 1944, it was reported that 92 M4A3(75)s were discharging or had been discharged at Utah Beach, along with another 53 at Omaha. A further 140 were "In UK Waters" awaiting berthing spaces on the Continent. The photo above shows some of the first M4A3(75)Ws to arrive in the ETO (along with a few M5A1 Light Tanks) in a storage lot in Normandy in July or August, 1944. These tanks appear to have been processed and made ready for issue.

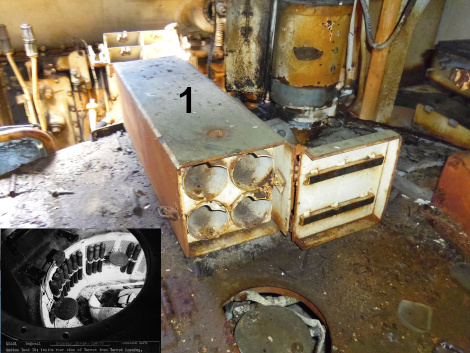

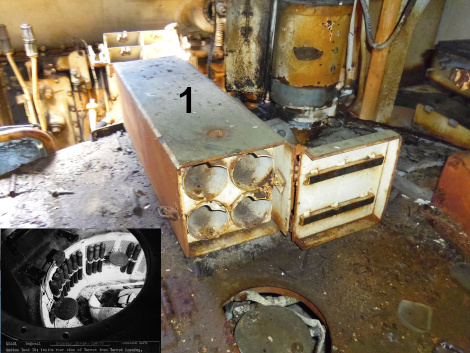

Fisher built M4A3(75)s were designated as having "Wet Stowage." Earlier Ford built M4A3s were retroactively labeled as "Dry Stowage." Dry Stowage Shermans had most of the ammunition racks mounted in more vulnerable positions up on the tank's interior sponson shelves. The Wet Stowage arrangement repositioned the racks to the floor in ten ten round, vertically oriented bins (above). Four "ready rounds" were also stored in the turret basket. Photo courtesy of Michael Green.

Each 10 round ammo rack had 3 sealed chambers that were filled with a liquid "quenching solution." It was thought that if an ammo rack was penetrated, the "quenching solution" would be dispersed, and at least slow the progress of an ammunition fire in order to give the crew a few more seconds to escape. For the tests, the first solution tried was plain water. The second was water mixed with ethylene glycol to prevent freezing. This was "suspected of being inflammable" and a third solution "ethyl sodium potassium phosphate" known as "Ammudamp" was substituted. Above, the liquid containers on the left are shown removed from the ammo rack on the right. Photos courtesy of Michael Green.

The turret basket of the M4A3(75)Wet is shown above. A four round ready rack (1) can be seen mounted on the "floor." This was completely enclosed in 1/4 inch of armor with access to the rounds by means of an armored door. The original Sherman design featured 12 unprotected rounds clipped to the wall of the turret basket (inset). For the sake of safety, 8 ready rounds were sacrificed over the objections of many commanders and crews. Ultimately, it was found that the wet stowage "quenching solution" had little to no effect, and the chambers were ordered drained and plugged post war. However, "The work on watered ammunition racks...led to two important recommendations: provide strong enough doors and sidewalls around the ammunition rack to confine the explosion and fire to the ammunition compartment and provide an outlet from this compartment for pressure and flames to be directed to the exterior of the vehicle." This led to the incorporation of vented type armored ammunition containers in future tank designs. Hatches can be seen in the loader's half of the turret basket floor. These gave him access to the 100 main gun rounds stored directly below. In some cases, it was necessary to rotate the turret in order for the loader to retrieve the rounds. Left side photo courtesy of Chris Hughes.

M4A3(75)W's were equipped with D78461 turrets, an improvement over the D50878 turrets used at the outset of Sherman production. The most important safety feature of the new turret was the inclusion of a loader's hatch. The turret bustle was raised a few inches in order to clear the protuberances of the large hatches. Thus, the informal term "high bustle." See this page for more information about the evolution of Sherman 75mm turrets. Left side photo courtesy of Chris Hughes.

The D78461 turrets of the M4A3(75)W's featured a protective housing for the gunner's periscope. Next to it can be seen the commander's vane sight, which replaced the "blade" sight used on earlier Shermans. Photo courtesy of Chris Hughes.

The 2 inch smoke mortar was standard on the M4A3(75)W. The mortar hole in the turret was level with the armor at first, but later production units can be seen with a protruding sleeve and a weatherproofing cap.

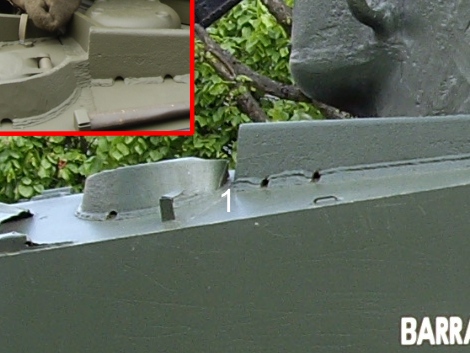

Two US Army Tank Battalions were equipped with M4A3(75)Ws prior to the Okinawa Campaign. The 193rd Tank Battalion appears to have been the rare case of a unit composed entirely of M4A3 based Shermans including 6 M4A3(105) Assault Guns. On the other hand, the AGs of the 711th TB were M4(105)s with HVSS going by the Registration Numbers listed in their tank casualty reports. The 193rd's first combat assignment on Okinawa was at Kakuza Ridge on 19 April when Company A, a platoon of B and all 6 of the Battalion's Assault Guns were ordered to attack the strongpoint in support of the 105th Infantry Regiment of the 27th Infantry Division. The 105th became pinned down and the tanks, operating without infantry support were mauled by the Japanese. "Of the thirty tanks that had maneuvered around the left end of Kakuza Ridge in the morning, only eight returned in the afternoon. The loss of twenty-two tanks on 19 April in the Kakazu area was the greatest suffered by American armor on Okinawa in a single engagement." Losses in the 193rd continued to mount, until on 1st May, "Tenth Army ordered all serviceable medium tanks turned over to other combat units as follows: 711th Tank Battalion - eleven (11) tanks, 706th Tank Battalion - nine (9) tanks, 763rd Tank Battalion fourteen (14) tanks." Losses had been heavy in all of the Army's Tank Battalions, and because of shipping shortages and poor planning, no replacement tanks were available. Thus, the 193rd's Medium Tanks became replacements. The photo above is dated 27 April and shows "Chuck-A-Luck," "C-13," Speed Number 55 preparing to advance "near Kakuza Ridge." (C was not involved in the debacle of April 19.) This tank has features that were typical of and exclusive to the 193rd's M4A3(75)Ws. Unit records mention that, "Additional armor plate (1), one inch in thickness was welded on each sponson of medium tanks." Unlike the 6th USMC Tank Battalion, the 193rd apparently had sufficient armor to obtain almost complete coverage of the sides. Like the 6th Tanks, the add on plates appear to have been mounted spaced off, but only by maybe half an inch. There is no mention of the installation of grouser racks (2) on the differential housing, but photographs suggest that these were universally fitted. This seems like a good idea, since, unlike other Shermans, Second Generation M4A3s did not have holes for grouser storage on their rear sponsons. One wonders where the standard 26 grousers were stored in these tanks? The fittings numbered "3" were "a device known as a “Back-scratcher” ...installed on 16 tanks and assault guns. This device consisted of four (4) electrically detonated anti-personnel mines mounted around the turret. These mines could be detonated by push button from the interior of the turret. The purpose of this device was to discourage enemy “tank hunters” from attacking the tank at close quarters." Backscratchers were reported to have been used by the 193rd a few times in combat on Okinawa, but the effect "was hard to determine." In any case, M4A3(75)Ws with these features are seen in photos of some of the other Army Tank Battalions on Okinawa, indicating that they were received as replacements.

It was intended to equip the turrets with the commander's all round vision cupola, but priority for these cupolas was given to the new 76mm Shermans coming on line at the same time. Until the supply caught up with the demand, "turret hatch D69993 with equilabrator" was used. This was an improved version of the original split hatch commander's cupola, in that it had integral springs on the hinges, and other features that provided greater safety and ease for the crew. The new hatch "still" had a pintle for the .50 Cal. AA MG as on the earlier version. It had been noted from the start that this was an awkward and even dangerous position in which to stow the machine gun when travelling.

A new travelling position for the AA MG was furnished by mounting a pintle (item 1) and clamp (item 2) on the turret bustle (above, left). When the machine gun was disassembled, barrel stowage was provided by two clamps (items 3 & 4) on the turret roof (above, right).

With the transition to the commander's all round vision cupola in August, 1944, a hinged MG pintle (item 1) and barrel clamp (item 2) were added to the turret roof. For a short time, the initial MG stowage travelling configuration was retained, as evidenced by the barrel clamps (items 3 & 4) in the photo on the left. In September 1944, the barrel clamps on the roof were replaced by a pair of L shaped brackets affixed to the turret bustle (items 1, above right).

The above shows M4A3(75)W's of CCA 14th Armored Division in Cirey, France November 23, 1944. The commander's vision cupola begins to appear in overseas photos about this time. These tanks are in the "first" MG stowage configuration without the L shaped brackets on the turret bustle. The fully assembled machine gun can be seen stowed in its canvas cover.

An interesting production variation took place starting in October, 1944. In order to save foundry capacity, Fisher Body agreed to equip 300 of its M4A3(75)s with earlier D50878 turrets recycled from the retriever conversion program. Baldwin Locomotive Works was one of the donors, and above can be seen some of the turrets left over from their M32B1 conversions.

The old turrets were updated to the standard of late 1944 D78461 turrets. Oval loader's hatches were retrofitted (left). The "thin spot" armor patch was added, if necessary. This particular D50878 turret was cast by Union Steel, and has their serial number 871, indicating 1942 production. Its original M34 gun mount was replaced with the late type of M34A1 mount, and the original commander's split hatch was replaced with an all round vision cupola.

In order to clear the protuberances of the large hatches, some material was removed from the lower outside edges of the D50878 "low bustle" turret. It is subtle, but note the upturned line at the bottom of the bustle in the left side photo. Readers often ask about the difference, so we have included a photo of a high bustle D78461 turret (right) for comparison.

The photo above is from the 13th Armored Division's History. "Always Available" can be seen to be USA 30115499, indicating October 1944 production, the month when the recycled turrets were introduced. Note how the low bustle nearly touches the tank's turret splash guard. Most or all of the recycled turrets appear to have been in the "late" configuration with the all round vision cupola (as evidenced by the MG pintle), the L shaped MG brackets and the extended smoke mortar sleeve with cap and chain.

Contrary to Chrysler, Fisher appears to have mounted the cable clamp in the forward or "standard" position from the start of the production of M4A3 hulls.

Small changes were incorporated by Fisher during the course of production. M4A3(75)W's manufactured from startup on into May 1944 had what the authors think of as the "early" glacis pattern. This pattern featured inboard hull lifting rings and "long" bullet splashes in front of the drivers' auxiliary periscopes (circled in red). The top edge of the glacis plate was neatly beveled.

The rear view mirrors were introduced on Fisher M4A3(75)s in May 1944, just before the glacis pattern was altered. The fitting for the mirror is circled. Note that the late type of hull lifting ring casting seen here was standard on these tanks.

Fisher transitioned to the "mid" glacis pattern in May 1944. The bullet splashes were shortened, and perhaps as a labor saving measure, the top edge of the glacis plate was no longer beveled, but simply square cut.

The "late" or "final" glacis pattern was introduced around August 1944. It was identical to the mid pattern except that the hull lifting rings were repositioned "outboard" to the edge of the glacis. Photo courtesy of Paul and Lorén Hannah.

75mm Shermans were equipped with a shorter gun travel lock than the ones used on 105mm and 76mm units. Many surviving Shermans have been upgraded with a single piece locking arm, but the less stable WW II configuration consisted of two "fingers." Both photos courtesy of Paul and Lorén Hannah.

Based on user feedback, a sheet metal cover to protect the ventilator between the drivers' hatches was introduced in August, 1944. The authors have not found any evidence of modification kits for the covers during WW II, but have noted that some surviving Shermans that obviously didn't have this item factory installed, had it added later during postwar upgrades. The U bolt that can be see on the uncovered example above held the padlocks for the drivers' hatches. Right side photo courtesy of http://www.toadmanstankpictures.com/

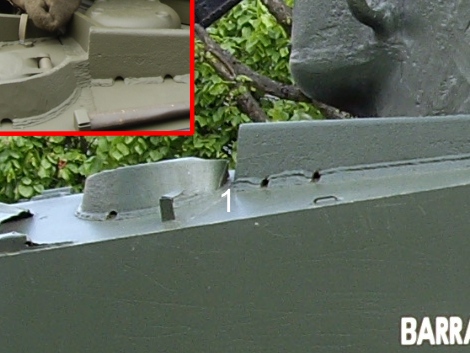

Many of the earliest M4A3(75)Ws were made with two small weep holes in the rear of the turret splash. It was found that the small holes could become clogged with debris, causing water to back up and foul the gasoline supply of the auxiliary generator. It was thought that a single, large hole would alleviate the problem. This transition appears to have been made around July, 1944. Note the gap between the turret splash and the fuel cap bullet splash (1). The "gap" appears to be typical of all Fisher built large hatch Shermans, as well as Chrysler M4A3(76)s. On the other hand, the gap can be seen to have been filled in by welding (inset) on Chrylser M4(105)s and M4A3(105)s until about mid 1944. Right side photo courtesy of Paul and Lorén Hannah.

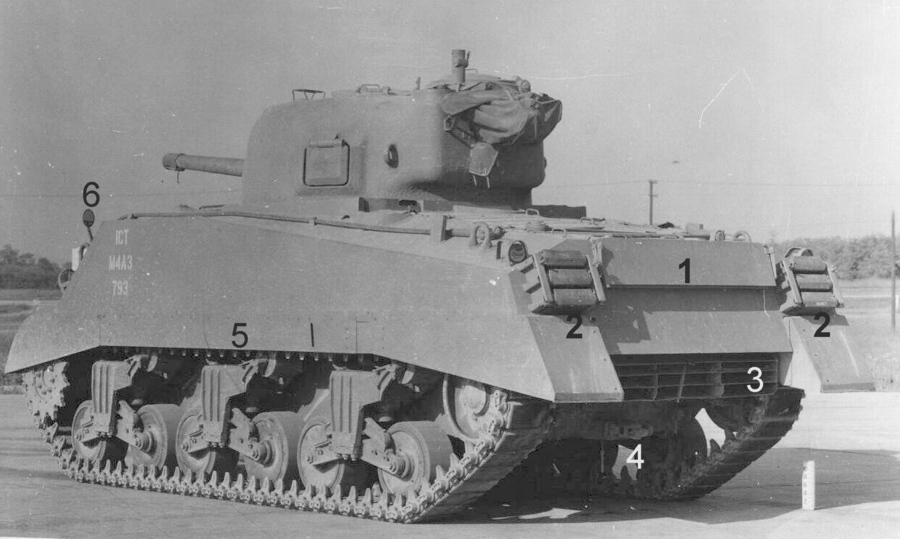

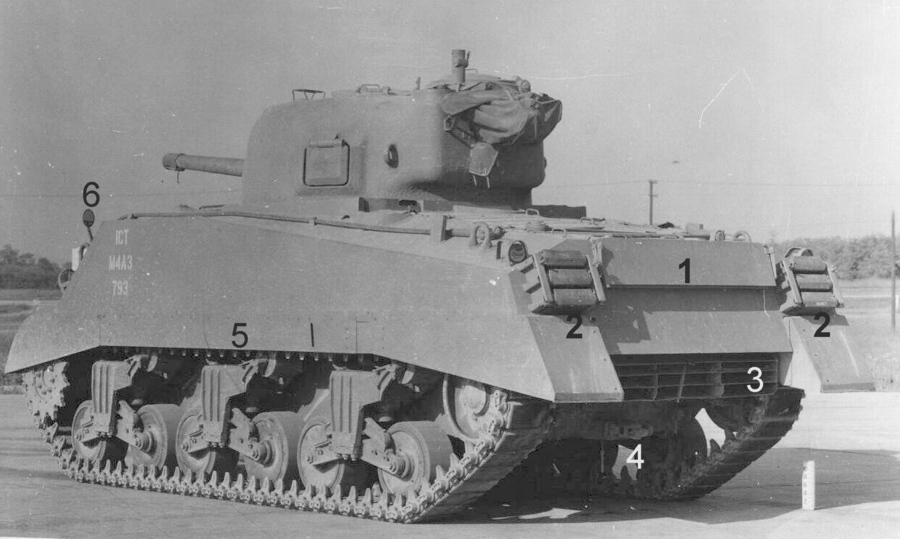

The blanket roll rack (item 1) was standard on these tanks, although the fittings for the cleaning rods were not added until the end of 1944. M4A3(75)W's with VVSS were fitted with a pair of spare track holders (items 2). The sheet metal exhaust deflector (item 3) was replaced by an armored deflector in 1945, too late to see much if any service on the M4A3(75)W during WW II. The towing pintle (item 4) was another standard fitting. Sand shields (item 5) were factory installed, although most crews removed them in service. The rear view mirror (item 6) can be seen installed on this August 1944 production tank.

Early production M4A3(75)W's had one-piece rear most engine deck plates (item 1). Differing from some other types of Shermans, the lift handles were welded onto the engine deck (item 2). Shermans had a total of four main fuel tanks. Unlike Ford built M4A3s, Fishers had only a single filler point for the two fuel tanks located on either side of the hull (items 3). The filler in the middle of the forward engine deck plate was for the engine coolant expansion tank and was protected by a bullet splash guard (item 4). A small exhaust pipe for the auxiliary generator (item 5) was extended to the rear of the tank in order to prevent asphyxiation of the crew. This particular M4A3(75)W strikes us as a possible US Army WW 2 combat veteran Sherman. It was once on display at the 1st Armored Division Museum in Baumholder, Germany. We had originally recorded its serial number there as 49047 (April 1944) because that is what is stamped on both of the rear towing lugs. The tank was returned to the US and is now on display at the National Mounted Warrior Museum at Fort Cavazos (ex-Ft. Hood), Texas. A correspondent was able to enter the tank and photograph the serial number "48740" stamped inside the dataplate frame (inset). That would indicate March 1944 acceptance, and would make it the oldest known surviving M4A3(75) W. So, which is it - 48740 or 49047? Shermans built by Fisher have been noted to have the serial number stamped on both edges of the differential housing. In this case, we can't confirm the serial number since the original sharp nosed E8543 diff was replaced with an earlier one-piece diff at some point. Further adding to the confusion, Pierre-Olivier noticed that "3081331" was stamped into the right side of the upper rear hull plate. The corresponding serial number for that Registration Number would be 48734, while the corresponding RN to SN 48740 would be 3081337. We suspect that in this instance, whoever stamped the RN on the tank mistook the "7" for a "1." The SN stamped on the rear towing lugs is generally reliable, but we have encountered a few cases where one or both of the original lugs were replaced probably because they had broken off in service, and we would guess that is what happened here.

Here we have one of the Shermans on display at the American Military Museum in South El Monte, California. Cary Erickson reported the serial number as 48960 which would indicate March 1944 acceptance, overall, the 345th M4A3(75)W produced by Fisher. At the time this tank still had its original USA Registration Number, 3081557, painted on. We believe this unit may be about "ground zero" for the start of the transition to when the rear most engine deck plate was divided into two pieces to make it easier for crew members to lift. The large, grated engine deck doors were heavy, and door bumpers (item 1) were added to the "ultimate" M4A3 series. The standard tool stowage arrangement can be seen here. Only the track adjusting wrench is missing. Photo courtesy of Chris Hughes.

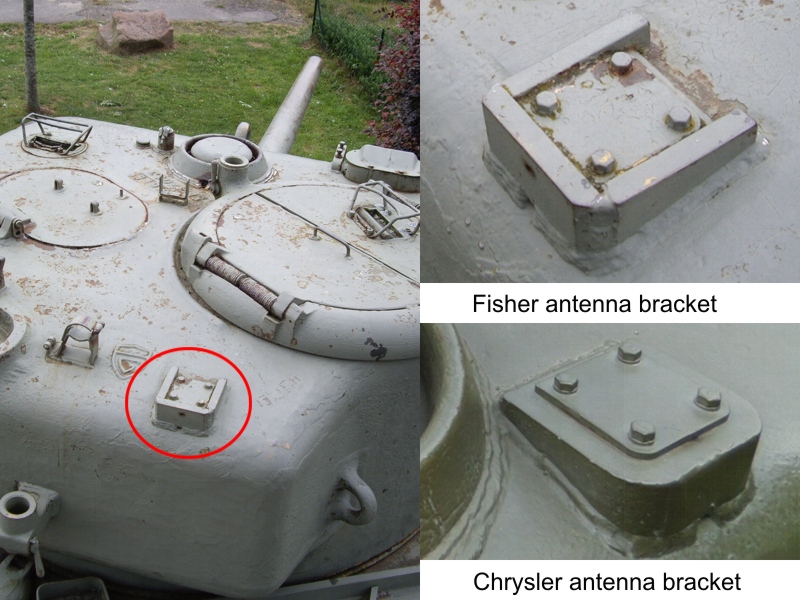

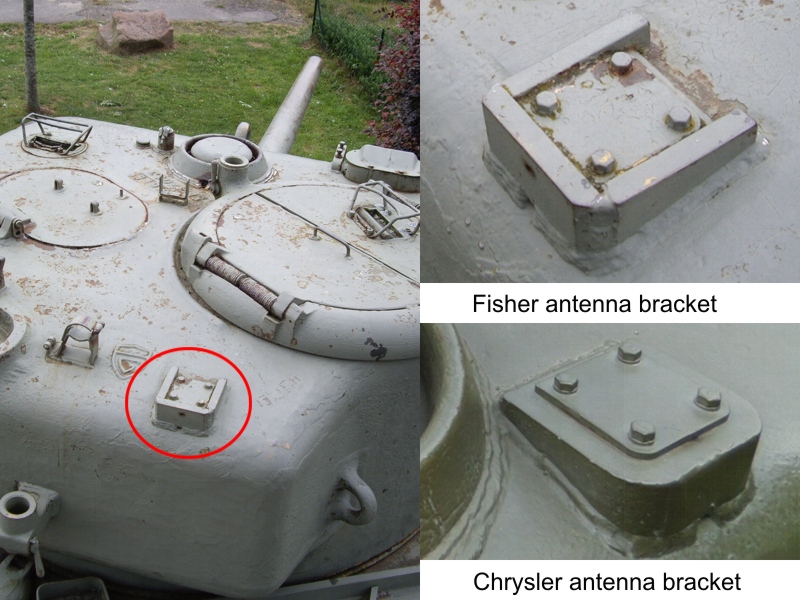

The turret antenna bracket on Fisher 75mm Shermans was fabricated from 3 pieces of plate, whereas it was a solid chunk of steel on the D78461 turrets used by Chrysler on its M4 Composites & 105 Shermans.

Another difference noted is that all surviving Fisher built large hatch Shermans we’ve examined have a series of weld beads mostly horizontal, but some vertical, that were applied to fill in the differential housing bolt strip overcut. We consider this a Fisher recognition feature, since all examples of Chryslers seen used a half round piece welded in to fill in the overcut.

The above photo shows "Sad Sack" USA 3081752 testing detachable grousers at Aberdeen Proving Ground September 1944. The late type bogie units with "upswept" return roller arms (items 1) were standard on the M4A3(75)W VVSS. The "plain" drive sprockets (item 2) were standard as well.

Idler wheels were primarily pressed spoked (left), but a few examples have been seen with "unspoked" idlers (right).

Fisher seems to have used just about every type of road wheel on its M4A3(75)W's with VVSS. The earliest production units were equipped with either the welded spoke (A) or pressed spoke wheels (B). The welded spoke with "small holes" (C) and the solid, concave wheels (D) were introduced in Summer 1944, and appear to have been prevalent by Fall 1944.

Fisher Body did not provide figures for the number of HVSS Shermans it manufactured. However, Ordnance documents state that on January 1, 1945 all Sherman production incorporated HVSS. 651 M4A3(75)W's were produced in 1945, and thus, we might conclude that at all of them had HVSS. We don't know of any confirmed surviving examples, and period photos are extremely rare. Registration Numbers listings for the US Firefly Program indicate that at least 8 were converted in April and May, 1945 (inset). The M4A3(75)W HVSS seen above was photographed on the streets of Exeter in 1945. While there is no visible USA Number to cross reference, it seems highly likely that this tank was in the UK for Firefly conversion. As yet, no photos of M4A3(75)W HVSS based Fireflies have turned up. Photo supplied courtesy of Peter D Thomas, copyright Ken Jackson, www.exeterbooks.com

The transitional nature of the introduction of changes suggests that a few Fisher M4A3(75)s made before January 1, 1945 were equipped with HVSS. At least one December 1944 example, USA 30115711, was photographed. "Hardboiled" is thought to have served with the 16th Armored Division which entered Pilsen, Czechoslovakia on May 6, 1945. It is another M4A3(75)W that was factory built with an earlier D50878 low bustle turret recycled from the retriever program. Photo courtesy of the Archival Collection, Patton Memorial Museum, Pilzen.

Surviving Shermans are displayed as monuments throughout the world. One of the most poignant memorials is Serial Number 49709, USA 3082306. "Bourg la Reine" was part of the 3rd Squadron, 12th Cuirassiers Regiment, 2nd French Armored Division, and was destroyed on the western outskirts of Phalsbourg, France on November 21, 1944. The first hit killed the driver. A second shell hit the turret ring, putting the tank out of action. The tank was hit repeatedly as the crew bailed out. The crew was rescued by a medical Half-Track, which was also targeted, causing more casualties among its crew. Bourg la Reine "was saved according to General Leclerc's desire and erected into a monument by the town of Phalsbourg in the grateful homage to the liberators."

Bourg La Reine was photographed a few days after it was destroyed. Its original French Matricule (Registration) Number can be seen as 96012 (left). About a week later, the tank was photographed again, by which time it had been salvaged for useable parts by supporting maintenance units following in the wake of the combat troops. The French did not officially receive any M4A3(75)W's as Lend Lease. However, they were provided with many different types of Shermans from US reserves in order to make up for losses. This tank was manufactured in May 1944, and so has such early features as the commander's split hatch, first type of smoke mortar aperture and "open" ventilator between the drivers' hatches. It was probably one of the last units to be built with the early glacis pattern.

Perhaps the most famous surviving Sherman in the

world is Serial Number 48935, USA 3081532 on display in McAuliffe Square in

Bastogne, Belgium. It was a battlefield recovery, enshrined on the Square in

1948. Not much was known of the tank's history, until the late 1990s, when some

excellent research by local historians revealed that it served

with B Company of the 41st Tank Battalion, 11th Armored Division and was

nicknamed "Barracuda." It was destroyed on December 30, 1944 in a meadow near

Renuamont. The left side photo was taken in June, 1954, while the right is

recent, & reflects the growth of Bastogne as a WWII tourist destination.

Fisher built Shermans have the tank's Ordnance Serial Number stamped into the rear towing lugs (left), as well as on both edges of the differential housing. The diff stamping is preceded by an "S" for "serial number." Barracuda's can be seen above - S48935.

In many cases the dataplate on the hull wall to the left of the driver is missing from surviving Shermans, but the evidence suggests that Fisher Body stamped the Serial Number inside the dataplate frame. This is the stamping on SN 49709, the historic "Bourg la Reine" on display as a monument in Phalsbourg, France.

In the postwar years, it was the intention of the US Army to equip its forces with M26s or M4A3(76)HVSS's. Since there were not enough of either type, a conversion program was initiated. The 585 M4A3(75)W HVSS Shermans in the US inventory were converted by taking 76mm turrets, ammo stowage bins, the "taller" gun travel locks, etc. from less desirable types like M4A1(76) or M4A2(76) Shermans. Several of these conversions are on display in the US. Above is Serial Number 65944 in Carlisle, Pa. This tank would have been accepted as an M4A3(75)W with HVSS in February 1945. Aside from the serial number, one tell tale sign of a 75mm to 76mm turret conversion is that the build number has an "A" prefix, as mentioned earlier.

The authors would gladly receive serial & sequence number reports from any readers who encounter a surviving Fisher built Sherman.

HOME

Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads". It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

Fisher Body was the sole manufacturer of 75mm M4A3

Shermans with large hatches and wet stowage. It produced 3071 M4A3(75)W's from

February 1944 to March 1945.

Production Order T-9724 : 1711 M4A3(75)W with VVSS

manufactured: Serial Number 48615 / USA 3081212 through S/N 50325 / USA 3082922

Production Order T-11315/1 : approx. 709 M4A3(75)W

with VVSS and 113 with HVSS manufactured: Serial Number 62038 / USA 30115060 through S/N

62859 / USA 30115881

Production Order T-11315/2 : 538 M4A3(75)W with

HVSS manufactured: Serial Number 65714 / USA 30125036 through S/N 66251 / USA

30125573

Introduction

The decision to continue production of 75mm Sherman tanks in 1944 and 1945

While the Sherman's 75mm main gun may have been "state of the art" in 1941 and 1942, it was outmoded as an anti-tank weapon by 1943. Unfortunately, the military bureaucracy became mired in controversy over the proper role of tanks, and ultimately failed to develop an effective replacement when it designed the 76mm gun and its original ammunition. In any case, most of the US Army heads involved with the Tank Program wanted to discontinue production of 75mm Shermans at the end of 1943. However, this was a decision made by committee, and some members hedged somewhat by noting “that the complete elimination of the 75m/m gun from the Medium Tank M4 Series would cause considerable difficulty should any portion of the Medium Tanks M4 be required in the future to be equipped with this same gun due to the change-over of the facilities involved.” It was noted that the British & US Marines still had requirements for the 75mm Sherman in 1944 and on. They considered the 75mm's High Explosive round to be markedly superior to that of the 76mm gun. Moreover, the British requested more 75mm Shermans with M34A1 gun mounts and Oil Gear Traverse Mechanisms, which they needed for their ongoing Firefly conversion program. In the event, the 75mm Sherman, in the form of the M4A3(75)W continued in production until March, 1945.

Hulls used for 75mm Wet Stowage Shermans were of the "ultimate" design, i.e. welded, 47 degree, with large hatches. Not many M4A3(75)W's have survived. Above is Serial Number 49578, produced in May 1944 and on display in Middletown, Pennsylvania. Note the sharp nosed differential housing (part Number E8543), which became standard on US built Shermans after September 1943.

Some of the first M4A3(75)Ws were shipped to Europe in the weeks and months following the Normandy Invasion on June 6, 1944. In the first 83 days of the Campaign, Medium Tank losses in the US Army were higher than expected, averaging 11 per day. The majority of these were repairable, but the ability of the Army logisticians to support the build up was severely strained. Included among the replacement tanks shipped were a good number of the various types of M4A3s - 75mm, 76mm, 105mm and M4A3E2 Assault Tanks [Jumbos]. It was the goal of US planners to place the Ford engined Shermans with their updated Second Generation features into the hands of combat troops as quickly as possible. Thus, an effort was made to identify the M4A3s with the idea of allocating them where possible on something of a proportional basis. As of September 17, 1944, it was reported that 92 M4A3(75)s were discharging or had been discharged at Utah Beach, along with another 53 at Omaha. A further 140 were "In UK Waters" awaiting berthing spaces on the Continent. The photo above shows some of the first M4A3(75)Ws to arrive in the ETO (along with a few M5A1 Light Tanks) in a storage lot in Normandy in July or August, 1944. These tanks appear to have been processed and made ready for issue.

Ironically,

the French 2nd Armored Division appears to have been one of the first

"US" combat units to be issued the new M4A3(75)Ws. Initially equipped

with 165 diesel M4A2(75)s, the Division landed in Normandy in early

August, 1944. Losses were heavy from the start, and in mid August, the

Division, which had not been provided with a reserve pool of M4A2s,

began to draw replacements from US Third Army stocks of gasoline powered

Shermans. Included among them were about 20 M4A3(75)Ws. The

photo above was taken in Paris, near the Palais-Bourbon on August 25,

1944, and shows an interesting pair of replacement Shermans. The

lead tank, "Cherbourg," is a Baldwin built M4 with Continental Radial

engine. Behind is "Saint-Vaast," one of the new M4A3(75)Ws with Ford V8

engine. These tanks were in service with the 2nd Squadron, 12th Regiment

of Cuirassiers. "Cherbourg"

was put out of action perhaps minutes after this photo was taken,

during the attack on the Palais-Bourbon. "Saint-Vaast"

was reported destroyed north of Paris in Le Bourget on August 27, 1944.

Photo courtesy of Arax Djololian, Musée Carnavalet.

Fisher built M4A3(75)s were designated as having "Wet Stowage." Earlier Ford built M4A3s were retroactively labeled as "Dry Stowage." Dry Stowage Shermans had most of the ammunition racks mounted in more vulnerable positions up on the tank's interior sponson shelves. The Wet Stowage arrangement repositioned the racks to the floor in ten ten round, vertically oriented bins (above). Four "ready rounds" were also stored in the turret basket. Photo courtesy of Michael Green.

Each 10 round ammo rack had 3 sealed chambers that were filled with a liquid "quenching solution." It was thought that if an ammo rack was penetrated, the "quenching solution" would be dispersed, and at least slow the progress of an ammunition fire in order to give the crew a few more seconds to escape. For the tests, the first solution tried was plain water. The second was water mixed with ethylene glycol to prevent freezing. This was "suspected of being inflammable" and a third solution "ethyl sodium potassium phosphate" known as "Ammudamp" was substituted. Above, the liquid containers on the left are shown removed from the ammo rack on the right. Photos courtesy of Michael Green.

The turret basket of the M4A3(75)Wet is shown above. A four round ready rack (1) can be seen mounted on the "floor." This was completely enclosed in 1/4 inch of armor with access to the rounds by means of an armored door. The original Sherman design featured 12 unprotected rounds clipped to the wall of the turret basket (inset). For the sake of safety, 8 ready rounds were sacrificed over the objections of many commanders and crews. Ultimately, it was found that the wet stowage "quenching solution" had little to no effect, and the chambers were ordered drained and plugged post war. However, "The work on watered ammunition racks...led to two important recommendations: provide strong enough doors and sidewalls around the ammunition rack to confine the explosion and fire to the ammunition compartment and provide an outlet from this compartment for pressure and flames to be directed to the exterior of the vehicle." This led to the incorporation of vented type armored ammunition containers in future tank designs. Hatches can be seen in the loader's half of the turret basket floor. These gave him access to the 100 main gun rounds stored directly below. In some cases, it was necessary to rotate the turret in order for the loader to retrieve the rounds. Left side photo courtesy of Chris Hughes.

M4A3(75)W's were equipped with D78461 turrets, an improvement over the D50878 turrets used at the outset of Sherman production. The most important safety feature of the new turret was the inclusion of a loader's hatch. The turret bustle was raised a few inches in order to clear the protuberances of the large hatches. Thus, the informal term "high bustle." See this page for more information about the evolution of Sherman 75mm turrets. Left side photo courtesy of Chris Hughes.

The D78461 turrets of the M4A3(75)W's featured a protective housing for the gunner's periscope. Next to it can be seen the commander's vane sight, which replaced the "blade" sight used on earlier Shermans. Photo courtesy of Chris Hughes.

The 2 inch smoke mortar was standard on the M4A3(75)W. The mortar hole in the turret was level with the armor at first, but later production units can be seen with a protruding sleeve and a weatherproofing cap.

The

bulldozer blade was one of more useful contraptions adapted for use on

the Sherman and was in high demand in all theaters. The Tank Recovery

Vehicle, an example of which can be seen directly behind the dozer, was

another successful adaptation. This scene was photographed in the

vicinity of "Merbeck" [sic...Meerbeck], Germany, 2nd March 1945. The

caption describes the dozer as clearing a "German tank trap" made of

logs. It was observed that it took the enemy many hours to build these

barriers, but only a few minutes were needed to clear them. From the

standpoint of research, particularly in the case of this dozer, the

tactical markings are very helpfully seen painted up high on the rotor

shield as opposed to the usual places such as the front plate or

differential housing. Period photos suggest that this was the practice

of both the 18th and 36th Tank Battalions of the 8th Armored Division,

presumably intended to keep the markings from being obscured by mud and

dust. In any case, the markings are easy to read and indicate the 17th

vehicle of C Company, 36th Tank Battalion, 8th Armored Division. For a

little context, the 8th AD arrived on the Continent in early January

1945 and had its combat debut a few weeks later during the Third Army's drive to eliminate the Moselle-Saar salient. The

features of this tank, particularly, the commander's all round vision

cupola (1) and the sheet metal cover over the ventilator (2), suggest it

was produced in August 1944 or later. In this case, the crew has opted

to install the vision cupola in a nonstandard orientation with the hatch

opening more towards the rear. The cap and retaining chain (3) over the

smoke mortar sleeve was a later addition as well.

As yet, we

haven't found evidence that any small or large hatch M4A3(75)s were

shipped to the Mediterranean Theater of Operations. M4A3(75)s did equip a

few of the Army and Marine Tank Battalions in the Pacific Theater. The

first combat use of the M4A3(75)W in the PTO appears to have come on 9

January 1945 when the 716th Tank Battalion made an assault landing on

Lingayen Gulf on the island of Luzon in the Philippines. Although the

Coast Guard photo above is dated 23 January, we think it was filmed on

the 9th, since the 716th TB was fighting miles inland in the area of

Palacpac on the 23rd. The M4A3(75)W in the foreground may be "Classy

Peg" made famous by the Tamiya plastic model kit introduced in the

1980s. The large wolf's head insignia appears to have been painted on

the Shermans of C Company, so it is likely that the scene took place on

White Beach 2 where C Company is reported to have landed. The two tanks

seen here are equipped with the wading trunks typical of the US produced

deep water fording kits. The 716th's records refer to their tanks only

generically as "medium" or "light" tanks" but from the available period

photos, it would appear that the medium companies of the716th TB were

equipped entirely with M4A3(75)Ws. Additionally, the photos show them

with the earlier split hatch commander's cupolas suggesting that they

were produced before August 1944. Indeed, the records mention that the

"all vision cupola"..."would have been extremely useful had they been

available." Other wanted items were extended end connectors, "M-32 B3"

tank recovery vehicles, infantry phones and 75mm canister ammunition.

The very specific nomenclature, "M-32 B3" for the desired retriever is

interesting. That was of course, the model converted from the M4A3

Sherman. A random document we found among the 716th's records refers to

repairs made in early May 1945 on some "tanks" of the 1st Platoon of Co.

A. Their Registration Numbers are listed as 3081226, 3081297, 3081259

and 3081370. For what it is worth, these would have been accepted in

February or March 1944, the first two months of M4A3(75)W production at

Fisher Body.

After

a month of intense fighting in Northern Luzon, the companies of the

716th were relieved and assigned to various Task Forces which were

ordered to destroy the enemy garrisons holed up on several islands in

the Southern Philippines. The photo above shows some of the M4A3(75)Ws

of Company C in support of the 185th Infantry Regiment of the 40th

Infantry Division during an attack against the town of Molo on the

Island of Panay, 19 March 1945. The records mention that the Assault

Gun Platoon fought alongside C Co. on Panay. One might think that

the medium tanks of the 716th would have been all Second

Generation M4A3s, since it was the goal of the Army to equip its

units with such tanks to the extent that production would permit.

However, at least one photo shows an M4(105) with its telltale air

scoops over the grouser compartments. Note that the Shermans are

seen here with only one radio antenna. Command tanks required 2

antennas, and as such, they were specifically targeted by the

Japanese. As a consequence, many Army and Marine Tank Battalions

outfitted all of their Shermans with a second, bogus antenna in order

to confuse the enemy. The caption of this Signal Corps photo

states that the photographer, T/5 Howard Klawitter was wounded while

filming this action.

For the Iwo Jima Campaign (19 February – 26 March 1945), the 3rd USMC Tank Battalion still employed diesel M4A2(75)s, while the 4th and 5th TBs were reequipped with M4A3(75)W Shermans, including 4 in each battalion in which a "Mark 1 flame thrower" fired through a dummy gun tube, replaced the tank's 75mm main gun. These were basically the same as the 54 M4 Composite based POA-CWS-H1 flamethrower Shermans used by the Army's 713th Tank Battalion on Okinawa. In both cases, they were lauded as the most effective weapons on the battlefield. This undated USMC photo offers a portrait of the crew of "CO-ED" one of the flamethrower M4A3s of the 4th Tank Battalion. From left to right are Cpl. B. Skoll (driver), Pvt. J.W. Lukac (asst. driver), Cpl. E. L. Randall (gunner), Cpl. J. E. Shutt (loader), and Sgt. R. A. Grotenhuis (tank commander). The crew appears to be having a respite away from the fighting and has piled sandbags around the front and sides of their tank presumably so that they can take cover under it. The 4th Tank Battalion employed a number of measures to add further protection to the 55 or so Shermans with which they were equipped. According to their "After Action" records, "Forty-one (41) tanks had spare track blocks spot welded around the turret and carried in brackets on the front slope plate." Approximately 37 of their Shermans were fitted with wide wooden planks or plywood bolted to the sides in a standoff fashion. In some cases, the "air space" was filed in with "a 1-2-3 mixture of concrete." "On fifty-four (54) tanks 1 1/2 inch wire mesh was welded to the top of all hatches." The mesh cages as seen on "CO-ED" served to prevent enemy tank hunters from placing charges directly on areas considered to be weak spots in the armor such as the hatches and periscopes. The wire mesh seen here has a very distinctive look, and its addition appears to have been exclusive to the 4th Tank Battalion, whereas the 5th Tank Battalion implemented similar concepts to protect the hatches and other openings, but used different designs and materials. Photographs suggest that both the 4th and 5th TBs came ashore with T54E1 steel chevron tracks installed with extended end connectors. Apparently, the M4A2s of the 3rd TB were not equipped with EECs before the campaign.

For the Iwo Jima Campaign (19 February – 26 March 1945), the 3rd USMC Tank Battalion still employed diesel M4A2(75)s, while the 4th and 5th TBs were reequipped with M4A3(75)W Shermans, including 4 in each battalion in which a "Mark 1 flame thrower" fired through a dummy gun tube, replaced the tank's 75mm main gun. These were basically the same as the 54 M4 Composite based POA-CWS-H1 flamethrower Shermans used by the Army's 713th Tank Battalion on Okinawa. In both cases, they were lauded as the most effective weapons on the battlefield. This undated USMC photo offers a portrait of the crew of "CO-ED" one of the flamethrower M4A3s of the 4th Tank Battalion. From left to right are Cpl. B. Skoll (driver), Pvt. J.W. Lukac (asst. driver), Cpl. E. L. Randall (gunner), Cpl. J. E. Shutt (loader), and Sgt. R. A. Grotenhuis (tank commander). The crew appears to be having a respite away from the fighting and has piled sandbags around the front and sides of their tank presumably so that they can take cover under it. The 4th Tank Battalion employed a number of measures to add further protection to the 55 or so Shermans with which they were equipped. According to their "After Action" records, "Forty-one (41) tanks had spare track blocks spot welded around the turret and carried in brackets on the front slope plate." Approximately 37 of their Shermans were fitted with wide wooden planks or plywood bolted to the sides in a standoff fashion. In some cases, the "air space" was filed in with "a 1-2-3 mixture of concrete." "On fifty-four (54) tanks 1 1/2 inch wire mesh was welded to the top of all hatches." The mesh cages as seen on "CO-ED" served to prevent enemy tank hunters from placing charges directly on areas considered to be weak spots in the armor such as the hatches and periscopes. The wire mesh seen here has a very distinctive look, and its addition appears to have been exclusive to the 4th Tank Battalion, whereas the 5th Tank Battalion implemented similar concepts to protect the hatches and other openings, but used different designs and materials. Photographs suggest that both the 4th and 5th TBs came ashore with T54E1 steel chevron tracks installed with extended end connectors. Apparently, the M4A2s of the 3rd TB were not equipped with EECs before the campaign.

We could not find a caption to the photo above, but the markings

seen on these two M4A3(75)Ws appear to be painted on in white. If so,

evidence suggests that white indicates B Company, while the diamond

indicates the 3rd Platoon. Thus, we have the second and third tanks of

the 3rd Platoon, B Company, 6th USMC Tank Battalion. 6th Tanks was, of

course, organic to the recently formed 6th Marine Division. The Division

acquitted itself with honor during its combat debut on Okinawa, hellish

scene of "the last battle" of WW II. The skeletal structure in the

photo resembles an airplane hangar, which we would theorize would put

the time and place as late May 1945 at Machinato Airfield or early June

at Naha Airfield, both of which were in the vicinity of Naha, the

largest city on the island. The 6th TB records note that "sections of

face hardened armor 1 and 1 1/2 inches thick were welded to the

sponsons. This extra armor was spaced from the tank about 1 inch. As

sufficient blocks of this armor were not available to cover the entire

sponson only a portion of each sponson opposite the driver and assistant

driver (1) and opposite the large gasoline tanks (2) were so

protected." In any case, the odd "little squares" of armor are seen only

in photos of 6th TB Shermans. After their experiences in earlier

campaigns, Marine tankers made extensive use of "track armor." In the

case of the 6th TB, "Sections of steel track blocks were spot-welded

around the turret and on the front slope plate with the track guides

towards the armor face." Supplies of steel tracks must have been

plentiful, as many 6th TB Shermans are seen with track armor on the

sides as well, such as shown here. Another protective measure noted on

6th TB tanks was "railroad iron or steel wire pickets (3)...spot welded

to the bogie support brackets in three rows." An observer's report has

it that this was effective in preventing Japanese tank hunters from

placing satchel charges, "which are about the size of a K ration case,"

on the sides of the lower hull. These Shermans appear to be missing a

few of the railroad irons. This side view affords us a comparison of the

high bustle turret on Diamond 2 versus the low bustle turret on Diamond

3. We will discuss Fisher's use of recycled turrets later in this piece

but would observe here that they were introduced in production in

October 1944. Note that Diamond 3 can be seen with welded spoke with

"small holes" road wheels (4) while Diamond 2 has the solid, concave

wheels (5). With thanks to Romain Cansiere for his insights on USMC

tactical markings.

Two US Army Tank Battalions were equipped with M4A3(75)Ws prior to the Okinawa Campaign. The 193rd Tank Battalion appears to have been the rare case of a unit composed entirely of M4A3 based Shermans including 6 M4A3(105) Assault Guns. On the other hand, the AGs of the 711th TB were M4(105)s with HVSS going by the Registration Numbers listed in their tank casualty reports. The 193rd's first combat assignment on Okinawa was at Kakuza Ridge on 19 April when Company A, a platoon of B and all 6 of the Battalion's Assault Guns were ordered to attack the strongpoint in support of the 105th Infantry Regiment of the 27th Infantry Division. The 105th became pinned down and the tanks, operating without infantry support were mauled by the Japanese. "Of the thirty tanks that had maneuvered around the left end of Kakuza Ridge in the morning, only eight returned in the afternoon. The loss of twenty-two tanks on 19 April in the Kakazu area was the greatest suffered by American armor on Okinawa in a single engagement." Losses in the 193rd continued to mount, until on 1st May, "Tenth Army ordered all serviceable medium tanks turned over to other combat units as follows: 711th Tank Battalion - eleven (11) tanks, 706th Tank Battalion - nine (9) tanks, 763rd Tank Battalion fourteen (14) tanks." Losses had been heavy in all of the Army's Tank Battalions, and because of shipping shortages and poor planning, no replacement tanks were available. Thus, the 193rd's Medium Tanks became replacements. The photo above is dated 27 April and shows "Chuck-A-Luck," "C-13," Speed Number 55 preparing to advance "near Kakuza Ridge." (C was not involved in the debacle of April 19.) This tank has features that were typical of and exclusive to the 193rd's M4A3(75)Ws. Unit records mention that, "Additional armor plate (1), one inch in thickness was welded on each sponson of medium tanks." Unlike the 6th USMC Tank Battalion, the 193rd apparently had sufficient armor to obtain almost complete coverage of the sides. Like the 6th Tanks, the add on plates appear to have been mounted spaced off, but only by maybe half an inch. There is no mention of the installation of grouser racks (2) on the differential housing, but photographs suggest that these were universally fitted. This seems like a good idea, since, unlike other Shermans, Second Generation M4A3s did not have holes for grouser storage on their rear sponsons. One wonders where the standard 26 grousers were stored in these tanks? The fittings numbered "3" were "a device known as a “Back-scratcher” ...installed on 16 tanks and assault guns. This device consisted of four (4) electrically detonated anti-personnel mines mounted around the turret. These mines could be detonated by push button from the interior of the turret. The purpose of this device was to discourage enemy “tank hunters” from attacking the tank at close quarters." Backscratchers were reported to have been used by the 193rd a few times in combat on Okinawa, but the effect "was hard to determine." In any case, M4A3(75)Ws with these features are seen in photos of some of the other Army Tank Battalions on Okinawa, indicating that they were received as replacements.

It was intended to equip the turrets with the commander's all round vision cupola, but priority for these cupolas was given to the new 76mm Shermans coming on line at the same time. Until the supply caught up with the demand, "turret hatch D69993 with equilabrator" was used. This was an improved version of the original split hatch commander's cupola, in that it had integral springs on the hinges, and other features that provided greater safety and ease for the crew. The new hatch "still" had a pintle for the .50 Cal. AA MG as on the earlier version. It had been noted from the start that this was an awkward and even dangerous position in which to stow the machine gun when travelling.

A new travelling position for the AA MG was furnished by mounting a pintle (item 1) and clamp (item 2) on the turret bustle (above, left). When the machine gun was disassembled, barrel stowage was provided by two clamps (items 3 & 4) on the turret roof (above, right).

With the transition to the commander's all round vision cupola in August, 1944, a hinged MG pintle (item 1) and barrel clamp (item 2) were added to the turret roof. For a short time, the initial MG stowage travelling configuration was retained, as evidenced by the barrel clamps (items 3 & 4) in the photo on the left. In September 1944, the barrel clamps on the roof were replaced by a pair of L shaped brackets affixed to the turret bustle (items 1, above right).

The above shows M4A3(75)W's of CCA 14th Armored Division in Cirey, France November 23, 1944. The commander's vision cupola begins to appear in overseas photos about this time. These tanks are in the "first" MG stowage configuration without the L shaped brackets on the turret bustle. The fully assembled machine gun can be seen stowed in its canvas cover.

An interesting production variation took place starting in October, 1944. In order to save foundry capacity, Fisher Body agreed to equip 300 of its M4A3(75)s with earlier D50878 turrets recycled from the retriever conversion program. Baldwin Locomotive Works was one of the donors, and above can be seen some of the turrets left over from their M32B1 conversions.

The old turrets were updated to the standard of late 1944 D78461 turrets. Oval loader's hatches were retrofitted (left). The "thin spot" armor patch was added, if necessary. This particular D50878 turret was cast by Union Steel, and has their serial number 871, indicating 1942 production. Its original M34 gun mount was replaced with the late type of M34A1 mount, and the original commander's split hatch was replaced with an all round vision cupola.

In order to clear the protuberances of the large hatches, some material was removed from the lower outside edges of the D50878 "low bustle" turret. It is subtle, but note the upturned line at the bottom of the bustle in the left side photo. Readers often ask about the difference, so we have included a photo of a high bustle D78461 turret (right) for comparison.

The photo above is from the 13th Armored Division's History. "Always Available" can be seen to be USA 30115499, indicating October 1944 production, the month when the recycled turrets were introduced. Note how the low bustle nearly touches the tank's turret splash guard. Most or all of the recycled turrets appear to have been in the "late" configuration with the all round vision cupola (as evidenced by the MG pintle), the L shaped MG brackets and the extended smoke mortar sleeve with cap and chain.

Contrary to Chrysler, Fisher appears to have mounted the cable clamp in the forward or "standard" position from the start of the production of M4A3 hulls.

Small changes were incorporated by Fisher during the course of production. M4A3(75)W's manufactured from startup on into May 1944 had what the authors think of as the "early" glacis pattern. This pattern featured inboard hull lifting rings and "long" bullet splashes in front of the drivers' auxiliary periscopes (circled in red). The top edge of the glacis plate was neatly beveled.

The rear view mirrors were introduced on Fisher M4A3(75)s in May 1944, just before the glacis pattern was altered. The fitting for the mirror is circled. Note that the late type of hull lifting ring casting seen here was standard on these tanks.

Fisher transitioned to the "mid" glacis pattern in May 1944. The bullet splashes were shortened, and perhaps as a labor saving measure, the top edge of the glacis plate was no longer beveled, but simply square cut.

The "late" or "final" glacis pattern was introduced around August 1944. It was identical to the mid pattern except that the hull lifting rings were repositioned "outboard" to the edge of the glacis. Photo courtesy of Paul and Lorén Hannah.

75mm Shermans were equipped with a shorter gun travel lock than the ones used on 105mm and 76mm units. Many surviving Shermans have been upgraded with a single piece locking arm, but the less stable WW II configuration consisted of two "fingers." Both photos courtesy of Paul and Lorén Hannah.

Based on user feedback, a sheet metal cover to protect the ventilator between the drivers' hatches was introduced in August, 1944. The authors have not found any evidence of modification kits for the covers during WW II, but have noted that some surviving Shermans that obviously didn't have this item factory installed, had it added later during postwar upgrades. The U bolt that can be see on the uncovered example above held the padlocks for the drivers' hatches. Right side photo courtesy of http://www.toadmanstankpictures.com/

Many of the earliest M4A3(75)Ws were made with two small weep holes in the rear of the turret splash. It was found that the small holes could become clogged with debris, causing water to back up and foul the gasoline supply of the auxiliary generator. It was thought that a single, large hole would alleviate the problem. This transition appears to have been made around July, 1944. Note the gap between the turret splash and the fuel cap bullet splash (1). The "gap" appears to be typical of all Fisher built large hatch Shermans, as well as Chrysler M4A3(76)s. On the other hand, the gap can be seen to have been filled in by welding (inset) on Chrylser M4(105)s and M4A3(105)s until about mid 1944. Right side photo courtesy of Paul and Lorén Hannah.

The blanket roll rack (item 1) was standard on these tanks, although the fittings for the cleaning rods were not added until the end of 1944. M4A3(75)W's with VVSS were fitted with a pair of spare track holders (items 2). The sheet metal exhaust deflector (item 3) was replaced by an armored deflector in 1945, too late to see much if any service on the M4A3(75)W during WW II. The towing pintle (item 4) was another standard fitting. Sand shields (item 5) were factory installed, although most crews removed them in service. The rear view mirror (item 6) can be seen installed on this August 1944 production tank.

Early production M4A3(75)W's had one-piece rear most engine deck plates (item 1). Differing from some other types of Shermans, the lift handles were welded onto the engine deck (item 2). Shermans had a total of four main fuel tanks. Unlike Ford built M4A3s, Fishers had only a single filler point for the two fuel tanks located on either side of the hull (items 3). The filler in the middle of the forward engine deck plate was for the engine coolant expansion tank and was protected by a bullet splash guard (item 4). A small exhaust pipe for the auxiliary generator (item 5) was extended to the rear of the tank in order to prevent asphyxiation of the crew. This particular M4A3(75)W strikes us as a possible US Army WW 2 combat veteran Sherman. It was once on display at the 1st Armored Division Museum in Baumholder, Germany. We had originally recorded its serial number there as 49047 (April 1944) because that is what is stamped on both of the rear towing lugs. The tank was returned to the US and is now on display at the National Mounted Warrior Museum at Fort Cavazos (ex-Ft. Hood), Texas. A correspondent was able to enter the tank and photograph the serial number "48740" stamped inside the dataplate frame (inset). That would indicate March 1944 acceptance, and would make it the oldest known surviving M4A3(75) W. So, which is it - 48740 or 49047? Shermans built by Fisher have been noted to have the serial number stamped on both edges of the differential housing. In this case, we can't confirm the serial number since the original sharp nosed E8543 diff was replaced with an earlier one-piece diff at some point. Further adding to the confusion, Pierre-Olivier noticed that "3081331" was stamped into the right side of the upper rear hull plate. The corresponding serial number for that Registration Number would be 48734, while the corresponding RN to SN 48740 would be 3081337. We suspect that in this instance, whoever stamped the RN on the tank mistook the "7" for a "1." The SN stamped on the rear towing lugs is generally reliable, but we have encountered a few cases where one or both of the original lugs were replaced probably because they had broken off in service, and we would guess that is what happened here.

Here we have one of the Shermans on display at the American Military Museum in South El Monte, California. Cary Erickson reported the serial number as 48960 which would indicate March 1944 acceptance, overall, the 345th M4A3(75)W produced by Fisher. At the time this tank still had its original USA Registration Number, 3081557, painted on. We believe this unit may be about "ground zero" for the start of the transition to when the rear most engine deck plate was divided into two pieces to make it easier for crew members to lift. The large, grated engine deck doors were heavy, and door bumpers (item 1) were added to the "ultimate" M4A3 series. The standard tool stowage arrangement can be seen here. Only the track adjusting wrench is missing. Photo courtesy of Chris Hughes.

The turret antenna bracket on Fisher 75mm Shermans was fabricated from 3 pieces of plate, whereas it was a solid chunk of steel on the D78461 turrets used by Chrysler on its M4 Composites & 105 Shermans.

Another difference noted is that all surviving Fisher built large hatch Shermans we’ve examined have a series of weld beads mostly horizontal, but some vertical, that were applied to fill in the differential housing bolt strip overcut. We consider this a Fisher recognition feature, since all examples of Chryslers seen used a half round piece welded in to fill in the overcut.

The above photo shows "Sad Sack" USA 3081752 testing detachable grousers at Aberdeen Proving Ground September 1944. The late type bogie units with "upswept" return roller arms (items 1) were standard on the M4A3(75)W VVSS. The "plain" drive sprockets (item 2) were standard as well.

Idler wheels were primarily pressed spoked (left), but a few examples have been seen with "unspoked" idlers (right).

Fisher seems to have used just about every type of road wheel on its M4A3(75)W's with VVSS. The earliest production units were equipped with either the welded spoke (A) or pressed spoke wheels (B). The welded spoke with "small holes" (C) and the solid, concave wheels (D) were introduced in Summer 1944, and appear to have been prevalent by Fall 1944.

Fisher Body did not provide figures for the number of HVSS Shermans it manufactured. However, Ordnance documents state that on January 1, 1945 all Sherman production incorporated HVSS. 651 M4A3(75)W's were produced in 1945, and thus, we might conclude that at all of them had HVSS. We don't know of any confirmed surviving examples, and period photos are extremely rare. Registration Numbers listings for the US Firefly Program indicate that at least 8 were converted in April and May, 1945 (inset). The M4A3(75)W HVSS seen above was photographed on the streets of Exeter in 1945. While there is no visible USA Number to cross reference, it seems highly likely that this tank was in the UK for Firefly conversion. As yet, no photos of M4A3(75)W HVSS based Fireflies have turned up. Photo supplied courtesy of Peter D Thomas, copyright Ken Jackson, www.exeterbooks.com

Due to their late date of manufacture, and average four to

five month (factory acceptance to combat issue) shipping times, very few M4A3(75)W with HVSS were

shipped overseas during WW II. In fact, 585 were listed in the US Inventory in

August, 1948. The foremost tank in the photo above is equipped with HVSS as

evidenced by the extended fender support (item 1). Curiously, it lacks the

"usual" type of gunner's periscope housing as seen on the second tank (item 2).

The third and a few others have what appear to be larger housings (item 3),

possibly necessary to accommodate an improved gunner's periscope. These tanks

were photographed at a staging area near Marseilles on June 19, 1945. They had

been processed and sealed for direct shipment to the Pacific, in the event they

were needed for the Invasion of Japan.

Very much like the preceding photo, this one

shows approximately forty M4A3(75)W HVSS at an Ordnance Depot in Manila, August

1, 1945. Again, larger than usual periscope housings can be seen on a number of

these (item 1). Many of the high bustle turrets have a "bulge" in the casting to

better accommodate the commander's vision cupola (item 2). Many can be seen to

have the "thin spot" armor patch, indicating they are recycled, low bustle

turrets, as explained on this page (items 3 & 3a). Note the late armored exhaust

deflector halves laying on the front of a couple of the tanks (item 4). The

2 inch smoke mortar was ordered eliminated in January, 1945, and the foremost

Shermans in this and the preceding photo appear to have had a "patch" welded

over the mortar hole (item 5).

The transitional nature of the introduction of changes suggests that a few Fisher M4A3(75)s made before January 1, 1945 were equipped with HVSS. At least one December 1944 example, USA 30115711, was photographed. "Hardboiled" is thought to have served with the 16th Armored Division which entered Pilsen, Czechoslovakia on May 6, 1945. It is another M4A3(75)W that was factory built with an earlier D50878 low bustle turret recycled from the retriever program. Photo courtesy of the Archival Collection, Patton Memorial Museum, Pilzen.

Surviving Shermans are displayed as monuments throughout the world. One of the most poignant memorials is Serial Number 49709, USA 3082306. "Bourg la Reine" was part of the 3rd Squadron, 12th Cuirassiers Regiment, 2nd French Armored Division, and was destroyed on the western outskirts of Phalsbourg, France on November 21, 1944. The first hit killed the driver. A second shell hit the turret ring, putting the tank out of action. The tank was hit repeatedly as the crew bailed out. The crew was rescued by a medical Half-Track, which was also targeted, causing more casualties among its crew. Bourg la Reine "was saved according to General Leclerc's desire and erected into a monument by the town of Phalsbourg in the grateful homage to the liberators."

Bourg La Reine was photographed a few days after it was destroyed. Its original French Matricule (Registration) Number can be seen as 96012 (left). About a week later, the tank was photographed again, by which time it had been salvaged for useable parts by supporting maintenance units following in the wake of the combat troops. The French did not officially receive any M4A3(75)W's as Lend Lease. However, they were provided with many different types of Shermans from US reserves in order to make up for losses. This tank was manufactured in May 1944, and so has such early features as the commander's split hatch, first type of smoke mortar aperture and "open" ventilator between the drivers' hatches. It was probably one of the last units to be built with the early glacis pattern.

Fisher built Shermans have the tank's Ordnance Serial Number stamped into the rear towing lugs (left), as well as on both edges of the differential housing. The diff stamping is preceded by an "S" for "serial number." Barracuda's can be seen above - S48935.

In many cases the dataplate on the hull wall to the left of the driver is missing from surviving Shermans, but the evidence suggests that Fisher Body stamped the Serial Number inside the dataplate frame. This is the stamping on SN 49709, the historic "Bourg la Reine" on display as a monument in Phalsbourg, France.

Fisher built Shermans have been seen to have a loose build sequence

number stamped on the left front (driver's side). On Second Generation

Fishers, these numbers have letter prefixes. The "A" seen stamped in

front of 399 indicates it was built as an M4A3(75)W. This was recorded

from Serial Number 49008 a French combat casualty Sherman on display as a

monument in Strasbourg. While the number stamped here is 399, it would

actually have been the 393rd M4A3(75) made by Fisher (accepted in March

1944). Thus, our characterization of the build sequence number as

"loose." This number can be useful in the event the tank's serial number

can't be found. Other letters noted are "E" for M4A3E2 (Jumbo), "M" for

M4A3(76) and "W" for M4A2(76). In cases where there is not a lot of

paint build-up, the same "side number" has been observed stamped on the

rear most engine deck door hinges of some Fisher Shermans and M10s as

shown on the right. Of course, there have been instances where the

numbers on the engine deck door hinges do not match the "side number",

and we assume that, in those cases, the engine deck doors may have been

replaced.

In the postwar years, it was the intention of the US Army to equip its forces with M26s or M4A3(76)HVSS's. Since there were not enough of either type, a conversion program was initiated. The 585 M4A3(75)W HVSS Shermans in the US inventory were converted by taking 76mm turrets, ammo stowage bins, the "taller" gun travel locks, etc. from less desirable types like M4A1(76) or M4A2(76) Shermans. Several of these conversions are on display in the US. Above is Serial Number 65944 in Carlisle, Pa. This tank would have been accepted as an M4A3(75)W with HVSS in February 1945. Aside from the serial number, one tell tale sign of a 75mm to 76mm turret conversion is that the build number has an "A" prefix, as mentioned earlier.

The authors would gladly receive serial & sequence number reports from any readers who encounter a surviving Fisher built Sherman.

HOME