M4A3E2

"Jumbo" Shermans

Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

Dedicated to the late Don Moriarty who helped restore Cobra King, and graciously gave us a digital "backstage pass."

"This tank has a chance." General R.G. Grow, CG of the 6th AD.

The idea of producing a more heavily armored Sherman originated with the

British. During a meeting at the US War Department on February 21, 1942, Michael

Dewar and other members of the British Tank Mission "stated that a tentative

suggestion had been made to London that the Infantry Tank Mark III (Valentine)

and the Infantry Tank Mark IV (Churchill) should be discontinued in the British

Programme and their place taken by a heavier edition of the US M4. The armour

thickness of this tank should be front 3 1/2 " basis, sides 3"." Note that this

meeting took place about a week before the first production Sherman was

accepted. Tank Doctrine in the US at the time was such that no requirement

existed for a heavier Medium Tank, and thus, the British proposition that it be

produced by them. We suspect that the "heavier edition M4" as envisioned by the

British, would have been based on the cast hull M4A1 as it was stated that "the

original plan was to thicken up castings generally." Subsequent events suggest

that had this program been adopted in 1942, the impact might have been

significant.

Although British production of the "heavier edition M4" never came about, the US Ordnance Department was compelled to reconsider the idea in late 1943 as a result of discussions with the D-Day planners in the UK. The “12th Army Group Report of Operations” published in July, 1945, explains the matter... “Early in January 1944, a theater requirement was submitted for 250 heavy assault tanks for operational purposes, it then being assumed that the tank in question would be of the T26E1 type (M26). When it appeared that the production of this tank would not make it available for early use on the Continent, the War Department inquired, on or about 15 April 1944, whether our operational requirement was such as to make it desirable that they fill our requirement with a specially up-armored M4 series tank. The reply was that the extra heavy tank was required for assault purposes. It was hoped that the tank would be available on or shortly after D-Day.” The Ordnance Department appears to have put the wheels in motion on the "extra heavy" Sherman project starting on December 17, 1943, when it directed the General Motors Proving Ground to operate an M4A3 with a test weight of 82,600 pounds. After 500 miles over a standard endurance course, it was found that "no abnormal failures were encountered...It, therefore, appears feasible to convert a Medium Tank into an Assault Tank with a weight of 82,600 lbs. if only limited operation is to be encountered." Above, the Ford built M4A3 test tank with additional "ballast" as photographed on January 18, 1944 before commencement of the 500 mile endurance test. Note the use of the recently developed extended end connectors, which reduced the ground pressure to 14.2 pounds per square inch.

Plans for the "Assault Tank" were drawn up, and on March 2, the Ordnance Technical Committee recommended "that the M4A3 Tank with heavier armor...be designated Medium Tank M4A3E2." Note that the M4A3 alone is specified, no doubt because its 500 hp Ford V8 engine was the most powerful of the Sherman series. With perfect hindsight, we know that production of, say, 1000 M4A3E2s could have been delivered to the fighting fronts "in time," and would have been welcomed by the troops. However, the Ordnance Committee recommended a limited procurement of 250 M4A3E2s [the specific ETO assault tank requirement] for overseas shipment, plus 4 pilots for tests. The files of General Gladeon Barnes, the Ordnance Department's Chief of Research and Engineering, have these notes for 2 March 1944, "We need it [M4A3E2], because we have been held up on the heavier tanks, and this is a stop gap. This M4 tank has the armor of the heavy tank and is very much overloaded. General Barnes is going to try to see that no more of these are built." In any case, on 23 March, limited procurement of 254 units was approved. It is to be noted that, from the start, the Corps of Engineers objected to any changes that made the original Sherman design longer, wider or heavier. So, of course, they "non-concurred" with the Committee regarding the M4A3E2.

Fisher Body was the primary contractor. The government had certain standards, which were verified by tests during each step of the production process. In late March, Fisher and its subcontractors were notified that "In order to expedite delivery of M4A3E-2 Assault Tanks, certain requirements of applicable specifications will be waived for a total of 254 vehicles." That is, the government "trusted" that the producers would meet specs without the confirmation of the usual time consuming ballistic and radiographic tests. In fact, such tests were conducted on a few tanks and components even as production was in full swing. Bear in mind that the "E" in M4A3E2 stands for "Experimental." Had it been determined that the design was not acceptable for combat, the contractors would have been paid nonetheless for the production of 254 experimental units which would have remained in the US. The 40 M6 Heavy Tank series, and the 250 T23 Medium Tanks are examples of designs that were produced in some quantity, and at some cost, but which failed to be approved for combat use. In any case, 250 M4A3E2s were released for overseas shipment in late May 1944, and their performance exceeded expectations. The “12th Army Group Report of Operations” sums it up like so: “These tanks...were amazingly successful in operation, taking punishment not possible with the standard M4 series tanks. In spite of the increased weight no extra suspension troubles occurred and the campaign ended with many of these tanks still in operation.”

The M4A3E2 was converted using the M4A3(75)W hull that Fisher had been producing since February, 1944. The M4A3(75)W upper hull had 2.5 inches of armor plate on the front, 1.5 inches on the sides and rear and .75 inches on the top. The lower hull had 1.5 inch sides and rear, and a .5 inch floor. Using the same technique as would be employed for the M4A3E2, another .5 inch plate was welded on to the front of the belly plate to provide the drivers with additional protection from mines.

To convert to M4A3E2, 1.5 inch armor plates were welded to the front and sides of the upper hull. The upper rear hull and hull top were left unchanged at 1.5 inches and .75 inches respectively. The lower hull was left unchanged as well. In order to insure a strong bond, the side armor was installed in two sections. A two inch gap running down the middle of the hull was neatly filled in by welding. Photo courtesy of the AMVCC - http://www.armytrucks.org/

While refurbishing the historic M4A3E2 "Cobra King," Don Moriarty found the part number "D-52644" stamped into the front plate. This is the same part number noted on the standard Sherman 2.5 inch glacis plate. We can only speculate that the thickness of the part was reduced by an inch, since the official front armor basis of the M4A3E2 is given as 4 not 5 inches. Photo courtesy of Don Moriarty.

Pressed Steel Car was subcontracted to assemble and finish the turrets and gun mounts. The turret "is based on the 76mm turret and the internal layout is similar. However, a full basket is employed. Vision cupola and loader's hatch are provided...Turret thickness of 6 inches is maintained on the front, sides and rear; thickness at the rear reduces to 2 1/2 inches below the bulge." Two sections of .75 inch armor plate were welded on to the turret casting to provide the "roof." The M4A3E2 was the only "second generation" Sherman turret design that didn't include a pistol port. Restorers might be interested to know that a Pressed Steel Car plate was found on the interior turret wall of a surviving M4A3E2.

The turret casting was part number 7067400 as seen above. Using period photos and surviving examples to "count heads," leads us to believe that two companies cast the turrets - Union Steel and Ordnance Steel Foundry. Union Steel castings have the turret serial numbers cast in fairly large on both sides, and it is often possible to read them in period photos. The highest Serial Number recorded from a Union Steel turret is 203, which indicates they made at least that many. OSF turrets have the serial numbers cast in on the front part of the roof, so it has not been possible to record any from historic photos. Two known surviving examples are SER 12 and SER 38. This would indicate that OSF cast at least 38 of the 254, or slightly more, of the M4A3E2 turrets that were ordered. Photo courtesy of Don Moriarty.

The castings differ a bit in that Union Steel turrets are seen to have a rounded or "soft" lower edge (above, left ), whereas Ordnance Steel Foundry turrets are seen to have a "hard" edge.

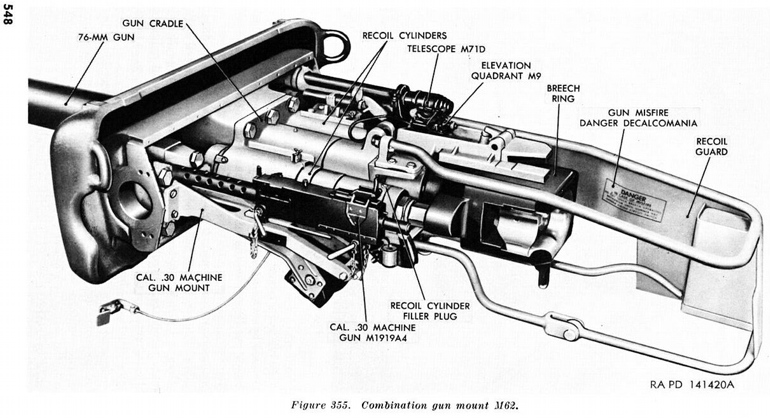

“Sherman” author Richard Hunnicutt writes of the M4A3E2...“It was originally intended to mount the 76mm gun, but the 75 was preferred for infantry support so the latter weapon was installed in all 254 tanks.” Even though it was decided to arm the M4A3E2 with the 75mm gun, it was installed in an up-armored 76mm type turret, using a modified version of the 76mm's M62 Gun Mount (upper image). Five inches of rolled plate were welded on to the M62's original 2 inch cast gun shield resulting in a fairly massive mantlet that protected 70 per cent of the turret's front surface. On May 25 1944, "For purposes of identification, the combination 75mm-Cal. .30 Mount used in Medium Tank M4A3E2 is designated: "Combination Gun Mount, T110."

Although they were not part of the original design of the Sherman, from about mid 1943 until the end of production, the Ordnance Department required the factory installation of sand shields. They were NOT popular with the troops. "Experience in this theater indicates that sand shields on tanks are superfluous, and are quickly taken off or knocked off by troops. Recommend that War Department be advised and tanks be shipped without sand shields." Perhaps there was some kind of political patronage / jobs issue involved with their continued use? In any case, the M4A3E2 required the installation of small fender extensions in order to permit the sand shields to clear the extended end connectors.

The M4A3E2 had the same timeline as the M4A3(75)W regarding the introduction of minor changes. While some early M4A3(75)'s were built with a one piece rear most engine deck, by May when M4A3E2 production commenced, the two piece deck was standard. Also present from the start was the smoke mortar with weather proofing cap. Only the first month's production featured the early glacis pattern with the "long" bullet splashes in front of the drivers' auxiliary periscopes. The transition from two small weep holes to a single large one in the rear of the turret splash, appears to have occurred about midway through production in June. Left side picture courtesy of "Joe D."

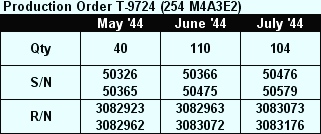

The first 40 M4A3E2s rolled off the line at Fisher Body in May 1944. 110 were accepted in June and the final 104 in July. The first unit, Serial Number 50326, USA 3082923, Union Steel Turret 2, arrived at Chrysler's Tank Laboratory in Highland Park, Michigan on May 19, where it was brought "up to the latest production releases," fully stowed, measured, weighed and extensively photographed (complete with "Photoshopped" terrain). The unit lacked a couple of standard features - the bow mg dust cover and sand shields, although the report stated that the sand shields were received and installed later.

On June 8, 50326 was shipped to the Tank Arsenal Proving Ground for endurance trials. "400 miles of test operation resulted in one broken spring." However, it was noted that low mileage failures had "also been experienced on standard weight vehicles." It was obvious that the weight of the M4A3E2 overtaxed the standard Sherman Vertical Volute Spring Suspension system, particularly in the front. The photo above shows "TOM," Serial Number 50360, USA 3082957, Union Steel Turret 15, on the Test Course at Aberdeen Proving Ground, June 26, 1944. Weights were added to each side to simulate a fully loaded tank with crew. One can see the greater compression of the springs on the front and middle bogies. Note how the front bogie arms are nearly horizontal. While this was not considered a fatal flaw, the following warning was issued, "One thing that users must realize is that, in rough cross-country operation, the front volute springs will fail if permitted to 'bottom' violently." As a matter of minutia, we believe that the turret of SN 50360 has survived and is the same turret (SN 15) as the one shown earlier in our Union Steel vs. OSF turret comparison caption.

Click on the photo for larger size

After the endurance test at Chrysler, 50326, USA 3082923, was shipped to Aberdeen Proving Ground for ballistic tests. It was tested to destruction there in September 1944. The test was "for information only" as the M4A3E2 had been released for overseas shipment months earlier. There is some interest in trying to identify the other 3 M4A3E2s that remained in the US, since the 250 shipped to the ETO can all be considered WW II "combat veterans." The vast majority of surviving Shermans survived because they were used as training vehicles and did not leave the US during WW II. The situation is quite the opposite regarding the seven or so surviving M4A3E2s.

On February 10, 1945, USA 3082940 was stated to be in the Armored Board Motor Park at Ft Knox. The date would indicate that this M4A3E2 could NOT have been one of the units sent overseas. Unlike the other test facilities, the Armored Board was rather "inconsiderate" to future researchers. Only rarely did they list their test tanks by serial and/or registration number. In any case, we believe that AB Test Operation #420 (above) was S/N 50343, USA 3082940, US Turret 8. It was no longer required by the AB in Feb. 1945, and was clogging up the Motor Park, so a request was submitted to Army Ground Forces for its removal. Whatever disposition was made, the tank "reappeared" as the T33 (Flamethrower) Pilot #1, delivered to APG in September 1947.

Click on the photos for larger size

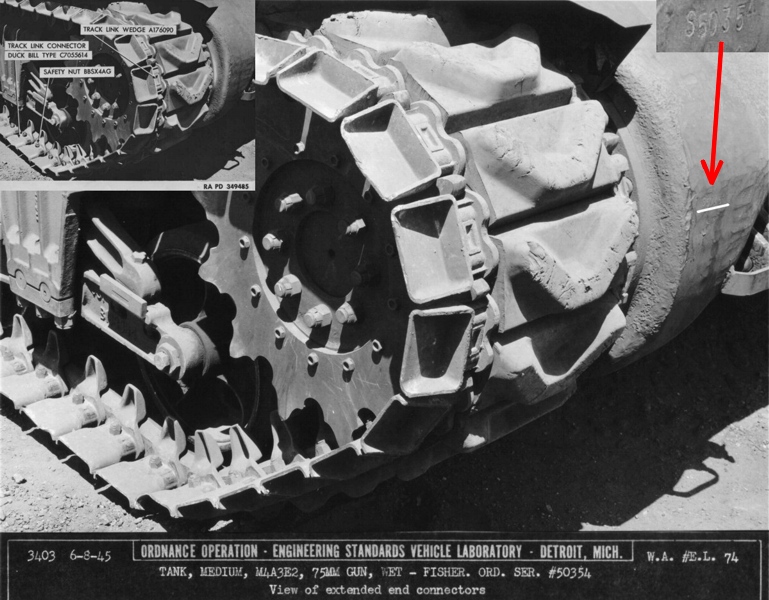

It was standard practice to store one or two examples of special types for future reference and/or historical purposes (at the APG Ordnance Museum). We suspect that S/N 50354, US Turret 5 was retained at Tank Automotive Command in Detroit, and that "TOM" S/N 50360 (shown earlier), was retained at APG. In the photo captions above, note that the tank has been misidentified as a "76-MM." These photos are dated July and August 1944, and the front stencil reads "Prepared by L.T.D. (Lima Tank Depot) 7/1/44."

Click on the photo for larger size

The photo above shows 50354 again, but is dated nearly a year later - June 8 1945. Note that this photo of 50354 correctly identifies it as "75 MM." A 1945 date supports our theory that this tank was stored at TACOM "for future reference." The photo provides a good view of the extended end connectors that were factory installed on every M4A3E2. It was used to illustrate the revised Extended End Connector Modification Work Order dated July 1945 (inset). It is also the only period photo we have seen in which a stamped on serial number can be read. Many years ago, after seeing this photo for the first time, we began to look for this same stamping on surviving Shermans. This led to the realization that, starting around July 1943, Fisher Body stamped the serial number, preceded by an "S," on both edges of the differential housings of its Shermans.

During WW II, it took on average from 4 to 5 months to get a new tank from the factory into the hands of the fighting troops. The M4A3E2s began to arrive at the New York Port of Embarkation around mid August. 208 had been shipped out by September 8th. The initial shipments began to arrive at Cherbourg (above) around September 22. Some time was required for the acquisition of berthing spaces, for unloading, processing for combat, and final delivery to selected units. The pace seems to have been somewhat leisurely for such a high priority project. This may have been due in part to the strained logistical situation that existed in the ETO at the time.

On October 24th, ETOUSA allocated the M4A3E2s: 105, 90 and 60 were to go to the First, Third and Ninth Armies respectively. That this is 5 more than were available reflects the "fog of war" typical of the Army bureaucracy. The document above provides a disposition as of December 3 1944. Note that by this late date, only about half of the total number of M4A3E2s were reported to be in the hands of troops. 10 had already been lost in combat, 25 were enroute to the various Armies, 28 were enroute to depots for combat processing and 46 were still aboard ships offshore. The 12 units "not accounted for" were explained away as receptions or battle losses not yet confirmed.

It has been difficult to track the distribution of M4A3E2s to individual units, since their records often list their holdings generically, as "Medium Tank, 75mm gun." Evidence suggests the Armies began to receive and distribute the first tanks in early October. Author Richard Anderson has reported that "By 14 October, 36 had been received by the First Army. They were issued 15 each to the 743rd and 745th Tank Battalions and 6 to the 746th Tank Battalion." The USAAF photo above is thought to show an M4A3E2 of the 745th Tank Battalion in Aachen Germany in October 1944. The tank appears to be relatively new, with shipping stencils and chalk markings still visible. Note that the turret has the "hard" edge associated with OSF castings. This is one of a very few "combat shots" that shows even a section of the sand shields installed.

The original intent appears to have been to distribute the M4A3E2s to independent Tank Battalions, since they supported the Infantry Divisions that were generally tasked with assaulting prepared positions. However, according to Gen. Gay, Patton's Chief of Staff, "Everyone wants the M4A3E2." Armored Divisions wanted to employ them as "point" tanks, because "of the repeated hits they have turned off." The first 40 received by the Third Army were reported to have been issued as shown above. Note that the 10th Armored Division was included in the allocation.

It is thought that the 4th and 6th Armored Divisions received the Third Army's next allotment in early November. Above, a hapless 6th AD M4A3E2 is shown serving as a "telephone pole." According to the 15th Tank Battalion's History, on November 22, the lead tank of Company B stumbled in the darkness "into a deep crater in the road" leading to Saint-Jean-Rohrbach, France. As noted previously, the M4A3E2 was not provided with headlamps, could they have helped? In any case, the next day, engineers erecting a Bailey Bridge at the site set off a charge which knocked the tank on its side. We've reproduced the photo's caption (inset) simply because the writer used the word "Jumbo" to describe the tank.

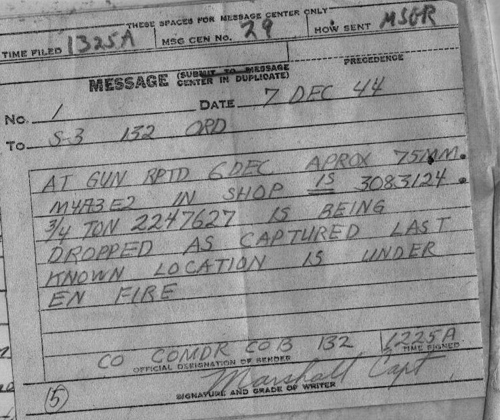

The records of the 746th Tank Battalion for October 1944 state that "Fifteen new heavily armored tanks (M4A3E2) were placed into operation during the period." Company B is reported to have drawn four on October 12. Thus far, the first loss of an M4A3E2 that we can document was listed by the 746th when they reported their tank losses for the month of October (above, left). We keep a list of the M4A3E2 USA Numbers that can be read in period photos, or that are written in WW II documents such as casualty or repair reports. Above right is a "Morning Report" of the 132nd Ordnance Maintenance Battalion, 10th Armored Division stating that M4A3E2 USA 3083124 was in Company B's shop on December 7 1944.

In the records of the 743rd Tank Battalion for October 11th, it is noted that a platoon (5 tanks) of A Company "was equipped with new Ford (47 ton) tanks at Herzogenrath." These appear to have been the first E2s received by the 743rd, and they were "put in line" the next day. A Roster for A Co. lists: Tank 1, E2 3083034; Tank 5, E2 3083089; Tank 10, E2 3083000; Tank 11, E2 3083131 and Tank 15, E2 3083102. All but one of the Jumbos were commanded by officers, which suggests many served as command tanks. The other Shermans listed were 1943 production M4s, and a single M4(105) (Tank 3). Tank 15 survived the war, and is featured in several photos in William Folkestad's "The View From The Turret." It appears to be a case of a painted on "typo" in the USA Registration Number - 3038102 instead of 3083102.

While the M4A3E2s had some of the heaviest armor of any tank at the time, they were not impervious to enemy guns. C Company lost the first of the 743rd's "new assault type" tanks (Tank 5) to panzerfaust fire on November 16 near Worselen Germany. C Co. lost 2 more on November 22 while supporting an infantry attack on Lohn, Germany. They became the subject of a G2 Report "Effect of German Projectiles on US Tanks." The first, commanded by Lt. Thornell, was knocked out at 0850 by anti-tank fire. One crew member was killed and two were wounded. The photo above shows the condition of this tank when it was photographed a few days later. For their report, the G2 people chalked hit numbers on the two tanks. While several rounds were turned away, hit 9 actually penetrated the gun mantlet's telescope aperture.

At 0900, Lt. Disbrow's E2 was disabled by a "friendly" mine, and the crew evacuated to safety. The attack was called off not long after, and the tank was left a "lame duck." It is frequently noted that the enemy continued to pour fire on lame ducks in order to render them unrecoverable. "Both of these tanks, which were built with more armor than earlier Shermans, burned later when they were enveloped by direct fire from enemy tanks." Regarding the photo above, it was stated that only round 3 penetrated. Round 3 hit exactly where the USA Number was painted on. A close examination of the original print revealed the last 3 digits to be "114." Within the range of USA Numbers assigned to Jumbos, the only possibility for this one would be 3083114. This would have been from the last month of production, and the tank has a relatively high Union Steel turret serial number at 167, and such later features as the "small holes" welded spoke wheels and the single, large weep hole in the turret splash.

Sand bag debris can be seen on the glacis plates of both tanks in the G2 Report photos. The records of the 743rd mention that they "sandbagged" or "re-sandbagged" their tanks during lulls. This was not the smartest idea with the M4A3E2, as it would have further taxed the already over burdened suspension. On the right, the appearance of the 743rd's sand bag job, topped off with camouflage netting. This was probably a B Company E2, as they assisted elements of the 120 Infantry Regiment / 30th Infantry Division in taking Altdorf Germany in a night attack on November 28th.

As noted earlier, only about half of the 250 M4A3E2s were reported to have been issued to combat units by December 3. Even so, the tank had proven its value, and users were requesting not only the remainder, but further production. An AFV & W Report dated December 7, was composed of a number of quotes, including the following by General R.G. Grow, CG of the 6th AD, "Get me more M4A3E2s. Our efforts are canalized (reference to impassability of rain soaked terrain), this tank has a chance. We want more of them." Above, Tank Commander and Bronze Star recipient Sam Moore of the 736th Tank Battalion poses with a newly issued Jumbo with OSF turret.

Click on the photo for larger size

The M4A3E2's final drive ratio was increased from the standard 2.84:1 to 3.36:1, which decreased the top speed to 22 MPH. Coupled with the overtaxed suspension, this led some to consider the tank a slow cumbersome vehicle, subject to frequent breakdown. However, Cobra King, USA 3083084, US Turret 138 was able to complete the hazardous winter trek to become "First in Bastogne" on December 26. A roster of C Company / 37th Tank Battalion, most likely prepared for reporters on the occasion, lists another Jumbo, USA 3083058 with the note "needs new clutch." Was it forced to drop out of the relief column? A few days later, on December 30, the 37th TB noted that they had 41 operative Medium Tanks, including 7 M4A3E2s. On that day they received 5 of the new M4A3(76)HVSS Shermans as replacements.

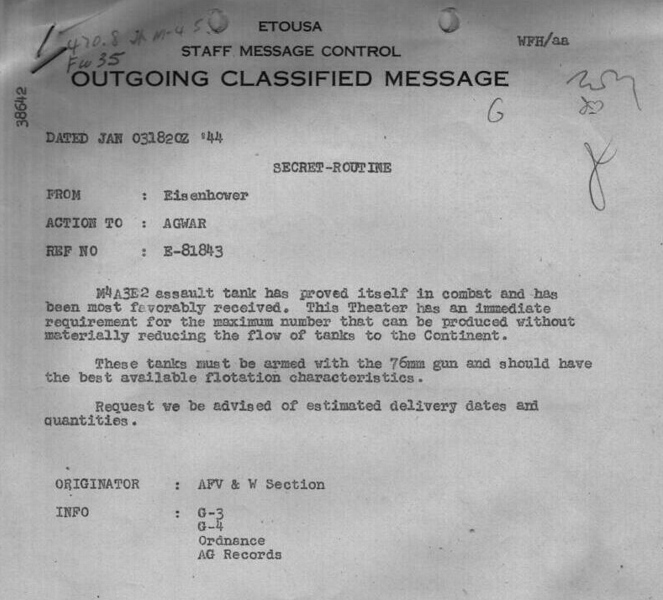

On January 31 1945 "Eisenhower" sent the message reproduced above to AGWAR (Adjustant General, War Dept.). The ETO was basically asking for new M4A3E2s with 76mm guns and HVSS. "Without materially reducing the flow of tanks to the Continent" was the great "Catch 22" in all such requests for better tanks, guns and ammunition. Considerable lead time was necessary in order for US Ordnance and Industry to juggle priorities to fulfill these requirements. In turn, this "juggling act" would have interrupted the flow of existing production. Note that there is a typo in the date of the document. Had this requirement actually been submitted on January 31 1944, an improved M4A3E2 might have been available by late 1944.

Starting in February, 1945, about 100 M4A3E2s were retrofitted in theater with 76mm guns. This was a fairly simply upgrade, because the E2's gun mount was nearly identical to the 76mm's. Above is shown an upgunned Jumbo, tactical number “E-2,” the second tank of E Company, 2nd Battalion, 32nd Armored Regiment, 3rd Armored Division in Cologne on March 6, 1945. “Then and now” photo analysis by Dierk Lurbke has determined that this iconic WW II Sherman scene was shot at the intersection of Venloerstraße and Spichernstraße. Some units of the 3rd AD painted the USA Number on the front and rear of their tanks. It was censored in the photo, possibly to prevent the enemy from using the information to “count heads.” However, a motion picture crew also filmed this scene, and individual frame captures (inset) reveal that the Registration Number was USA 3083173, one of the last E2s made. Note that it has the sheet metal cover (item 1) over the ventilator between the drivers' hatches. It is thought that perhaps the last 75 units had the cover factory installed. This tank also has the solid type road wheels that Fisher introduced into production around July 1944.

A small number of the upgunned M4A3E2s have been noted to have had the heavy gun collar removed. This is described in an APG Test Report as a "counterweight." So, perhaps it was removed as unnecessary to the balance of the longer and heavier 76mm gun? A few period photos show the counterweight removed on 6th Armored Division Jumbos, such as the examples seen in the grayscale photos above. The lower left photo is of the historic combat veteran “Cobra King” showing just the outer collar removed. The tank was retrofitted with a 76mm at some point, and the restorers at Ft Knox exchanged the 75 gun and mantlet from their other M4A3E2 (USA 3083026), so that Cobra King would reflect its appearance as of 26 December 1944. The authors are pleased that “CK” was chosen to be the “representative” Sherman tank on display at the National Museum of the United States Army at Ft. Belvoir, Virginia. Photos courtesy of Joe Burgess, upper right; Garry Redmon, lower left; and Chris Ballance, lower right.

Steven Newhouse recently sent us the snapshot on the left, which shows his Grandfather, Sgt. Elfridge Newhouse (smoking cigar) posing with his M4A3E2, “China Clipper,” USA 3083035. Steven knows that Sgt. Newhouse served with the 6th Armored Division, but he has no further documentation about his Grandfather’s lower unit affiliation. We were able to cross reference the snapshot with a screen capture from some Signal Corps footage taken in Oberdorla, Germany on April 4th, 1945. No doubt this also shows China Clipper, and it can be seen to have been up-gunned with a 76mm. (Note the missing gun collar/counter weight in the snapshot.) From what we have been able to ascertain from available records, C Company of the 69th Tank Battalion was part of Combat Team 44 which went through Oberdorla on that day. We would point out that the photo at the top left of the previous caption shows another(?) up-gunned M4A3E2 of C/69th TB in 1947. Left side photo courtesy of Steven Newhouse.

"Necessity is the mother of invention," and with no prospect of further deliveries of Jumbos, in February 1945, the Third Army embarked on a program to "up-armor" its M4A3(76)s. These might be considered to be "field expedient M4A3E2s." The numerous Battle of the Bulge tank wrecks, both Allied and Axis, were used as sources for the additional armor. Above are several examples. Looking from left to right, note the increase in the areas protected.

There aren't many genuine WW II combat veteran Shermans in the US. The Chrylser M4A3(76)HVSS on display at Rock Island Arsenal certainly appears to be one, although the Museum doesn't seem to have any documentation about its history. "4th Armored Divison General Sherman Tank Knocked Out During the Battle of the Bulge Dec. 16 1944 - Jan.23 1945" is painted on the (4 inch?) slabs of (German?) armor welded on the the hull sides. Battle of the Bulge casualty seems doubtful in that the up-armoring process didn't commence until February. The glacis armor was taken directly from another Sherman (inset), complete with hull lifting rings as well as headlamp and gun travel lock fittings. If this tank could talk, it would probably have stories of 3 or more WW II battle losses.

At about the same time as the M4A3E2 was under development, the Ordnance Department considered the idea of an auxiliary armor set that would have been produced as a kit to be applied in the field or (one presumes) at Tank Depots before overseas shipment. The Chrysler Engineering photo above is dated February 24, 1944, and shows the wooden mock up of the concept. Note that the protection is concentrated on the front of the hull and turret, and unlike the M4A3E2, no provision was made for additional armor on the sides. Of interest in the photo is that this kit has “eliminated” the cast antenna “pot” that projected from the right side of the glacis on 1st Generation welded hull Shermans. This bracket strikes us as unnecessary to the original design, since it was only needed for command tanks carrying long range radios in the right sponson. It seems like it could have been replaced with a 50 cent metal antenna bracket? The evident weakness of the drivers’ hatches (1) projecting from the glacis plate was addressed by the 2nd Generation Sherman project. The “added armor” concept obviously had merit, but we have not as yet found an explanation as to why this project was terminated at the end of February, 1944. The long lead time needed to mass produce such kits, along with the anticipated availability of the the T20 series "Heavy Tank" probably factored in. Note how the armor added to protect the differential housing (2) extends beyond the front of the tank. Richard Hunnicutt stated that an earlier beefed up differential housing project was rejected for that reason. Another factor in the rejection of the auxiliary armor set might have been the Engineer Board's consistent objections to any changes that made the Sherman longer, wider or heavier than the original design.

Meanwhile, the M4A3E2 soldiered on. The Sherman above can be identified as a Jumbo by the lack of pistol port. It is "out of spec" in that it is not equipped with extended end connectors. It appears to have been retrofitted with flat block rubber tracks, possibly as a result of wear or damage to the originals. The caption identifies it as with the 750th Tank Battalion supporting Task Force R of the 104th Infantry Division in Halle, Germany, April 14 1945. A movie still (inset) reveals that this E2 was upgunned with a 76mm.

Above, a column of CCA / 11th Armored Division fords the Muhl River near Neufelden Austria on May 4 1945. The Jumbo in the middle distance appears to lack EECs, and the right track is installed backwards. The combat history of the M4A3E2 seems to have ended on VE Day, May 8th, 1945. Rich Anderson has estimated that about 61 were lost in action. Late model AFVs such as the M26 and M4A3(76)HVSS were wanted for the planned invasion of Japan, and it was requested that many of those in Europe be shipped back to the US. Shermans with VVSS were not wanted as they were considered obsolete. However, it was suggested that the remaining M4A3E2s "be offered to active theater." Operation Olympic plans contemplated extensive use of the M26, so it is improbable that the E2s were formally requested. In any case, some Jumbos were shipped back to the States. Records indicate that, in August 1948, there were 96 in US Depots - NRFI (Not Ready for Issue).

Click on the photos for larger size

Flamethrower equipped Shermans were used to good effect in the final campaigns in The Pacific. However, users requested that future models be armed with a large caliber main gun along with the flamethrower. They also requested "that maximum practical armor protection be provided." Thus, in May 1945, development work commenced on the "Flamethrower Tank, T33." The M4A3E2, retrofitted with a new turret as well as HVSS, was selected for the conversion. Twenty units were authorized for procurement. Left open was the possibility of further production, if necessary. Ultimately, at the surrender of Japan, the program was cut to 3 pilot models. The T33s weren't actually delivered until September 1947 (USA 3082940) and January 1948 (3083011,3083021). In 1953, two of the T33s (3082940, 3083021) were converted to "Self Propelled Flamethrower, T68" as seen on the right.

The Korean War caused a reassessment of the status of the many obsolescent WW II era AFVs sitting in storage throughout the US. In January 1951, the Bowen-McLaughlin-York Co. was given a contract to remanufacture 1493 M4A3(75)s and M4A3E2s. It is thought that less than 100 E2s would have been available for the program. Several of the surviving Jumbos show evidence of having been rebuilt by BMY. 50429 still has a Bowen & McLaughlin dataplate (above left, courtesy Don Moriarty), and 50331, 50344 and 50415 have fittings for the type of hinged "comb" device (item 1, above right, courtesy Jim Goetz) typical of BMY.

Click on the photo for larger size

HOME

Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

Dedicated to the late Don Moriarty who helped restore Cobra King, and graciously gave us a digital "backstage pass."

The Fisher Body Division of General

Motors Corporation was the sole manufacturer of M4A3E2 Jumbos. It produced

254 units between May and July 1944.

Production Order T-9724: 254 M4A3E2: Serial Number 50326 / USA 3082923 through S/N 50579 / USA 3083176

"This tank has a chance." General R.G. Grow, CG of the 6th AD.

Although British production of the "heavier edition M4" never came about, the US Ordnance Department was compelled to reconsider the idea in late 1943 as a result of discussions with the D-Day planners in the UK. The “12th Army Group Report of Operations” published in July, 1945, explains the matter... “Early in January 1944, a theater requirement was submitted for 250 heavy assault tanks for operational purposes, it then being assumed that the tank in question would be of the T26E1 type (M26). When it appeared that the production of this tank would not make it available for early use on the Continent, the War Department inquired, on or about 15 April 1944, whether our operational requirement was such as to make it desirable that they fill our requirement with a specially up-armored M4 series tank. The reply was that the extra heavy tank was required for assault purposes. It was hoped that the tank would be available on or shortly after D-Day.” The Ordnance Department appears to have put the wheels in motion on the "extra heavy" Sherman project starting on December 17, 1943, when it directed the General Motors Proving Ground to operate an M4A3 with a test weight of 82,600 pounds. After 500 miles over a standard endurance course, it was found that "no abnormal failures were encountered...It, therefore, appears feasible to convert a Medium Tank into an Assault Tank with a weight of 82,600 lbs. if only limited operation is to be encountered." Above, the Ford built M4A3 test tank with additional "ballast" as photographed on January 18, 1944 before commencement of the 500 mile endurance test. Note the use of the recently developed extended end connectors, which reduced the ground pressure to 14.2 pounds per square inch.

Plans for the "Assault Tank" were drawn up, and on March 2, the Ordnance Technical Committee recommended "that the M4A3 Tank with heavier armor...be designated Medium Tank M4A3E2." Note that the M4A3 alone is specified, no doubt because its 500 hp Ford V8 engine was the most powerful of the Sherman series. With perfect hindsight, we know that production of, say, 1000 M4A3E2s could have been delivered to the fighting fronts "in time," and would have been welcomed by the troops. However, the Ordnance Committee recommended a limited procurement of 250 M4A3E2s [the specific ETO assault tank requirement] for overseas shipment, plus 4 pilots for tests. The files of General Gladeon Barnes, the Ordnance Department's Chief of Research and Engineering, have these notes for 2 March 1944, "We need it [M4A3E2], because we have been held up on the heavier tanks, and this is a stop gap. This M4 tank has the armor of the heavy tank and is very much overloaded. General Barnes is going to try to see that no more of these are built." In any case, on 23 March, limited procurement of 254 units was approved. It is to be noted that, from the start, the Corps of Engineers objected to any changes that made the original Sherman design longer, wider or heavier. So, of course, they "non-concurred" with the Committee regarding the M4A3E2.

Fisher Body was the primary contractor. The government had certain standards, which were verified by tests during each step of the production process. In late March, Fisher and its subcontractors were notified that "In order to expedite delivery of M4A3E-2 Assault Tanks, certain requirements of applicable specifications will be waived for a total of 254 vehicles." That is, the government "trusted" that the producers would meet specs without the confirmation of the usual time consuming ballistic and radiographic tests. In fact, such tests were conducted on a few tanks and components even as production was in full swing. Bear in mind that the "E" in M4A3E2 stands for "Experimental." Had it been determined that the design was not acceptable for combat, the contractors would have been paid nonetheless for the production of 254 experimental units which would have remained in the US. The 40 M6 Heavy Tank series, and the 250 T23 Medium Tanks are examples of designs that were produced in some quantity, and at some cost, but which failed to be approved for combat use. In any case, 250 M4A3E2s were released for overseas shipment in late May 1944, and their performance exceeded expectations. The “12th Army Group Report of Operations” sums it up like so: “These tanks...were amazingly successful in operation, taking punishment not possible with the standard M4 series tanks. In spite of the increased weight no extra suspension troubles occurred and the campaign ended with many of these tanks still in operation.”

The M4A3E2 was converted using the M4A3(75)W hull that Fisher had been producing since February, 1944. The M4A3(75)W upper hull had 2.5 inches of armor plate on the front, 1.5 inches on the sides and rear and .75 inches on the top. The lower hull had 1.5 inch sides and rear, and a .5 inch floor. Using the same technique as would be employed for the M4A3E2, another .5 inch plate was welded on to the front of the belly plate to provide the drivers with additional protection from mines.

To convert to M4A3E2, 1.5 inch armor plates were welded to the front and sides of the upper hull. The upper rear hull and hull top were left unchanged at 1.5 inches and .75 inches respectively. The lower hull was left unchanged as well. In order to insure a strong bond, the side armor was installed in two sections. A two inch gap running down the middle of the hull was neatly filled in by welding. Photo courtesy of the AMVCC - http://www.armytrucks.org/

The 1.5 inch glacis plate featured a keyhole shaped

aperture for the bow machine gun. The standard bow mg dust cover set up was

provided. The 75mm, or "short" gun travel lock was used, but was raised about 3

inches off the glacis by spacers. Hull lifting rings were mounted in the

"inboard" position. The M4A3E2 appears to

have used the same wiring harness as the M4A3(75)W as there are

conduit fittings for the headlamps and siren inside a few surviving

examples. These items were omitted from the M4A3E2 design, possibly for

ballistic reasons. One would think there might have been a few complaints from

the field about the lack of headlamps, but we did not come across any in our

research. Left side photo courtesy of Mike Green.

While refurbishing the historic M4A3E2 "Cobra King," Don Moriarty found the part number "D-52644" stamped into the front plate. This is the same part number noted on the standard Sherman 2.5 inch glacis plate. We can only speculate that the thickness of the part was reduced by an inch, since the official front armor basis of the M4A3E2 is given as 4 not 5 inches. Photo courtesy of Don Moriarty.

Pressed Steel Car was subcontracted to assemble and finish the turrets and gun mounts. The turret "is based on the 76mm turret and the internal layout is similar. However, a full basket is employed. Vision cupola and loader's hatch are provided...Turret thickness of 6 inches is maintained on the front, sides and rear; thickness at the rear reduces to 2 1/2 inches below the bulge." Two sections of .75 inch armor plate were welded on to the turret casting to provide the "roof." The M4A3E2 was the only "second generation" Sherman turret design that didn't include a pistol port. Restorers might be interested to know that a Pressed Steel Car plate was found on the interior turret wall of a surviving M4A3E2.

The turret casting was part number 7067400 as seen above. Using period photos and surviving examples to "count heads," leads us to believe that two companies cast the turrets - Union Steel and Ordnance Steel Foundry. Union Steel castings have the turret serial numbers cast in fairly large on both sides, and it is often possible to read them in period photos. The highest Serial Number recorded from a Union Steel turret is 203, which indicates they made at least that many. OSF turrets have the serial numbers cast in on the front part of the roof, so it has not been possible to record any from historic photos. Two known surviving examples are SER 12 and SER 38. This would indicate that OSF cast at least 38 of the 254, or slightly more, of the M4A3E2 turrets that were ordered. Photo courtesy of Don Moriarty.

The castings differ a bit in that Union Steel turrets are seen to have a rounded or "soft" lower edge (above, left ), whereas Ordnance Steel Foundry turrets are seen to have a "hard" edge.

“Sherman” author Richard Hunnicutt writes of the M4A3E2...“It was originally intended to mount the 76mm gun, but the 75 was preferred for infantry support so the latter weapon was installed in all 254 tanks.” Even though it was decided to arm the M4A3E2 with the 75mm gun, it was installed in an up-armored 76mm type turret, using a modified version of the 76mm's M62 Gun Mount (upper image). Five inches of rolled plate were welded on to the M62's original 2 inch cast gun shield resulting in a fairly massive mantlet that protected 70 per cent of the turret's front surface. On May 25 1944, "For purposes of identification, the combination 75mm-Cal. .30 Mount used in Medium Tank M4A3E2 is designated: "Combination Gun Mount, T110."

A

new final drive housing was cast for the M4A3E2. It was 3000 pounds

heavier than the standard Sherman E8543 casting. Armor thickness varied

from 4 inches to a maximum of 5.5 inches at the nose. The part number of

the housing is 7067389, and the few examples examined all carry the

caster's logo of Union Steel. Purchase Orders for an item such as this

generally included provision for a certain number of spares. While it is

not known if that was the case for the M4A3E2 differential housing, the

one shown here is serial number 256, suggesting that Union Steel cast

at least two more than total M4A3E2 production required. As a matter of

interest, we would note that this final

drive housing is on M4A3E2 SN 50331 on display at the Collings

Foundation. This tank would have been accepted in May 1944, overall, the

6th Jumbo produced. As we shall explain going forward, Fisher

Body stamped the serial number, preceded by an "S," on both edges of

the differential housings of its Shermans. This particular example has

S50533 stamped on, indicating it is a replacement, that originally came

from an "E2" accepted in July 1944. Left side photo courtesy of Mike Green, right side courtesy of Chris Hughes.

Although they were not part of the original design of the Sherman, from about mid 1943 until the end of production, the Ordnance Department required the factory installation of sand shields. They were NOT popular with the troops. "Experience in this theater indicates that sand shields on tanks are superfluous, and are quickly taken off or knocked off by troops. Recommend that War Department be advised and tanks be shipped without sand shields." Perhaps there was some kind of political patronage / jobs issue involved with their continued use? In any case, the M4A3E2 required the installation of small fender extensions in order to permit the sand shields to clear the extended end connectors.

The M4A3E2 had the same timeline as the M4A3(75)W regarding the introduction of minor changes. While some early M4A3(75)'s were built with a one piece rear most engine deck, by May when M4A3E2 production commenced, the two piece deck was standard. Also present from the start was the smoke mortar with weather proofing cap. Only the first month's production featured the early glacis pattern with the "long" bullet splashes in front of the drivers' auxiliary periscopes. The transition from two small weep holes to a single large one in the rear of the turret splash, appears to have occurred about midway through production in June. Left side picture courtesy of "Joe D."

The first 40 M4A3E2s rolled off the line at Fisher Body in May 1944. 110 were accepted in June and the final 104 in July. The first unit, Serial Number 50326, USA 3082923, Union Steel Turret 2, arrived at Chrysler's Tank Laboratory in Highland Park, Michigan on May 19, where it was brought "up to the latest production releases," fully stowed, measured, weighed and extensively photographed (complete with "Photoshopped" terrain). The unit lacked a couple of standard features - the bow mg dust cover and sand shields, although the report stated that the sand shields were received and installed later.

On June 8, 50326 was shipped to the Tank Arsenal Proving Ground for endurance trials. "400 miles of test operation resulted in one broken spring." However, it was noted that low mileage failures had "also been experienced on standard weight vehicles." It was obvious that the weight of the M4A3E2 overtaxed the standard Sherman Vertical Volute Spring Suspension system, particularly in the front. The photo above shows "TOM," Serial Number 50360, USA 3082957, Union Steel Turret 15, on the Test Course at Aberdeen Proving Ground, June 26, 1944. Weights were added to each side to simulate a fully loaded tank with crew. One can see the greater compression of the springs on the front and middle bogies. Note how the front bogie arms are nearly horizontal. While this was not considered a fatal flaw, the following warning was issued, "One thing that users must realize is that, in rough cross-country operation, the front volute springs will fail if permitted to 'bottom' violently." As a matter of minutia, we believe that the turret of SN 50360 has survived and is the same turret (SN 15) as the one shown earlier in our Union Steel vs. OSF turret comparison caption.

Click on the photo for larger size

After the endurance test at Chrysler, 50326, USA 3082923, was shipped to Aberdeen Proving Ground for ballistic tests. It was tested to destruction there in September 1944. The test was "for information only" as the M4A3E2 had been released for overseas shipment months earlier. There is some interest in trying to identify the other 3 M4A3E2s that remained in the US, since the 250 shipped to the ETO can all be considered WW II "combat veterans." The vast majority of surviving Shermans survived because they were used as training vehicles and did not leave the US during WW II. The situation is quite the opposite regarding the seven or so surviving M4A3E2s.

On February 10, 1945, USA 3082940 was stated to be in the Armored Board Motor Park at Ft Knox. The date would indicate that this M4A3E2 could NOT have been one of the units sent overseas. Unlike the other test facilities, the Armored Board was rather "inconsiderate" to future researchers. Only rarely did they list their test tanks by serial and/or registration number. In any case, we believe that AB Test Operation #420 (above) was S/N 50343, USA 3082940, US Turret 8. It was no longer required by the AB in Feb. 1945, and was clogging up the Motor Park, so a request was submitted to Army Ground Forces for its removal. Whatever disposition was made, the tank "reappeared" as the T33 (Flamethrower) Pilot #1, delivered to APG in September 1947.

Click on the photos for larger size

It was standard practice to store one or two examples of special types for future reference and/or historical purposes (at the APG Ordnance Museum). We suspect that S/N 50354, US Turret 5 was retained at Tank Automotive Command in Detroit, and that "TOM" S/N 50360 (shown earlier), was retained at APG. In the photo captions above, note that the tank has been misidentified as a "76-MM." These photos are dated July and August 1944, and the front stencil reads "Prepared by L.T.D. (Lima Tank Depot) 7/1/44."

Click on the photo for larger size

The photo above shows 50354 again, but is dated nearly a year later - June 8 1945. Note that this photo of 50354 correctly identifies it as "75 MM." A 1945 date supports our theory that this tank was stored at TACOM "for future reference." The photo provides a good view of the extended end connectors that were factory installed on every M4A3E2. It was used to illustrate the revised Extended End Connector Modification Work Order dated July 1945 (inset). It is also the only period photo we have seen in which a stamped on serial number can be read. Many years ago, after seeing this photo for the first time, we began to look for this same stamping on surviving Shermans. This led to the realization that, starting around July 1943, Fisher Body stamped the serial number, preceded by an "S," on both edges of the differential housings of its Shermans.

During WW II, it took on average from 4 to 5 months to get a new tank from the factory into the hands of the fighting troops. The M4A3E2s began to arrive at the New York Port of Embarkation around mid August. 208 had been shipped out by September 8th. The initial shipments began to arrive at Cherbourg (above) around September 22. Some time was required for the acquisition of berthing spaces, for unloading, processing for combat, and final delivery to selected units. The pace seems to have been somewhat leisurely for such a high priority project. This may have been due in part to the strained logistical situation that existed in the ETO at the time.

On October 24th, ETOUSA allocated the M4A3E2s: 105, 90 and 60 were to go to the First, Third and Ninth Armies respectively. That this is 5 more than were available reflects the "fog of war" typical of the Army bureaucracy. The document above provides a disposition as of December 3 1944. Note that by this late date, only about half of the total number of M4A3E2s were reported to be in the hands of troops. 10 had already been lost in combat, 25 were enroute to the various Armies, 28 were enroute to depots for combat processing and 46 were still aboard ships offshore. The 12 units "not accounted for" were explained away as receptions or battle losses not yet confirmed.

It has been difficult to track the distribution of M4A3E2s to individual units, since their records often list their holdings generically, as "Medium Tank, 75mm gun." Evidence suggests the Armies began to receive and distribute the first tanks in early October. Author Richard Anderson has reported that "By 14 October, 36 had been received by the First Army. They were issued 15 each to the 743rd and 745th Tank Battalions and 6 to the 746th Tank Battalion." The USAAF photo above is thought to show an M4A3E2 of the 745th Tank Battalion in Aachen Germany in October 1944. The tank appears to be relatively new, with shipping stencils and chalk markings still visible. Note that the turret has the "hard" edge associated with OSF castings. This is one of a very few "combat shots" that shows even a section of the sand shields installed.

The original intent appears to have been to distribute the M4A3E2s to independent Tank Battalions, since they supported the Infantry Divisions that were generally tasked with assaulting prepared positions. However, according to Gen. Gay, Patton's Chief of Staff, "Everyone wants the M4A3E2." Armored Divisions wanted to employ them as "point" tanks, because "of the repeated hits they have turned off." The first 40 received by the Third Army were reported to have been issued as shown above. Note that the 10th Armored Division was included in the allocation.

It is thought that the 4th and 6th Armored Divisions received the Third Army's next allotment in early November. Above, a hapless 6th AD M4A3E2 is shown serving as a "telephone pole." According to the 15th Tank Battalion's History, on November 22, the lead tank of Company B stumbled in the darkness "into a deep crater in the road" leading to Saint-Jean-Rohrbach, France. As noted previously, the M4A3E2 was not provided with headlamps, could they have helped? In any case, the next day, engineers erecting a Bailey Bridge at the site set off a charge which knocked the tank on its side. We've reproduced the photo's caption (inset) simply because the writer used the word "Jumbo" to describe the tank.

The records of the 746th Tank Battalion for October 1944 state that "Fifteen new heavily armored tanks (M4A3E2) were placed into operation during the period." Company B is reported to have drawn four on October 12. Thus far, the first loss of an M4A3E2 that we can document was listed by the 746th when they reported their tank losses for the month of October (above, left). We keep a list of the M4A3E2 USA Numbers that can be read in period photos, or that are written in WW II documents such as casualty or repair reports. Above right is a "Morning Report" of the 132nd Ordnance Maintenance Battalion, 10th Armored Division stating that M4A3E2 USA 3083124 was in Company B's shop on December 7 1944.

In the records of the 743rd Tank Battalion for October 11th, it is noted that a platoon (5 tanks) of A Company "was equipped with new Ford (47 ton) tanks at Herzogenrath." These appear to have been the first E2s received by the 743rd, and they were "put in line" the next day. A Roster for A Co. lists: Tank 1, E2 3083034; Tank 5, E2 3083089; Tank 10, E2 3083000; Tank 11, E2 3083131 and Tank 15, E2 3083102. All but one of the Jumbos were commanded by officers, which suggests many served as command tanks. The other Shermans listed were 1943 production M4s, and a single M4(105) (Tank 3). Tank 15 survived the war, and is featured in several photos in William Folkestad's "The View From The Turret." It appears to be a case of a painted on "typo" in the USA Registration Number - 3038102 instead of 3083102.

While the M4A3E2s had some of the heaviest armor of any tank at the time, they were not impervious to enemy guns. C Company lost the first of the 743rd's "new assault type" tanks (Tank 5) to panzerfaust fire on November 16 near Worselen Germany. C Co. lost 2 more on November 22 while supporting an infantry attack on Lohn, Germany. They became the subject of a G2 Report "Effect of German Projectiles on US Tanks." The first, commanded by Lt. Thornell, was knocked out at 0850 by anti-tank fire. One crew member was killed and two were wounded. The photo above shows the condition of this tank when it was photographed a few days later. For their report, the G2 people chalked hit numbers on the two tanks. While several rounds were turned away, hit 9 actually penetrated the gun mantlet's telescope aperture.

At 0900, Lt. Disbrow's E2 was disabled by a "friendly" mine, and the crew evacuated to safety. The attack was called off not long after, and the tank was left a "lame duck." It is frequently noted that the enemy continued to pour fire on lame ducks in order to render them unrecoverable. "Both of these tanks, which were built with more armor than earlier Shermans, burned later when they were enveloped by direct fire from enemy tanks." Regarding the photo above, it was stated that only round 3 penetrated. Round 3 hit exactly where the USA Number was painted on. A close examination of the original print revealed the last 3 digits to be "114." Within the range of USA Numbers assigned to Jumbos, the only possibility for this one would be 3083114. This would have been from the last month of production, and the tank has a relatively high Union Steel turret serial number at 167, and such later features as the "small holes" welded spoke wheels and the single, large weep hole in the turret splash.

Sand bag debris can be seen on the glacis plates of both tanks in the G2 Report photos. The records of the 743rd mention that they "sandbagged" or "re-sandbagged" their tanks during lulls. This was not the smartest idea with the M4A3E2, as it would have further taxed the already over burdened suspension. On the right, the appearance of the 743rd's sand bag job, topped off with camouflage netting. This was probably a B Company E2, as they assisted elements of the 120 Infantry Regiment / 30th Infantry Division in taking Altdorf Germany in a night attack on November 28th.

As noted earlier, only about half of the 250 M4A3E2s were reported to have been issued to combat units by December 3. Even so, the tank had proven its value, and users were requesting not only the remainder, but further production. An AFV & W Report dated December 7, was composed of a number of quotes, including the following by General R.G. Grow, CG of the 6th AD, "Get me more M4A3E2s. Our efforts are canalized (reference to impassability of rain soaked terrain), this tank has a chance. We want more of them." Above, Tank Commander and Bronze Star recipient Sam Moore of the 736th Tank Battalion poses with a newly issued Jumbo with OSF turret.

Click on the photo for larger size

The M4A3E2's final drive ratio was increased from the standard 2.84:1 to 3.36:1, which decreased the top speed to 22 MPH. Coupled with the overtaxed suspension, this led some to consider the tank a slow cumbersome vehicle, subject to frequent breakdown. However, Cobra King, USA 3083084, US Turret 138 was able to complete the hazardous winter trek to become "First in Bastogne" on December 26. A roster of C Company / 37th Tank Battalion, most likely prepared for reporters on the occasion, lists another Jumbo, USA 3083058 with the note "needs new clutch." Was it forced to drop out of the relief column? A few days later, on December 30, the 37th TB noted that they had 41 operative Medium Tanks, including 7 M4A3E2s. On that day they received 5 of the new M4A3(76)HVSS Shermans as replacements.

On January 31 1945 "Eisenhower" sent the message reproduced above to AGWAR (Adjustant General, War Dept.). The ETO was basically asking for new M4A3E2s with 76mm guns and HVSS. "Without materially reducing the flow of tanks to the Continent" was the great "Catch 22" in all such requests for better tanks, guns and ammunition. Considerable lead time was necessary in order for US Ordnance and Industry to juggle priorities to fulfill these requirements. In turn, this "juggling act" would have interrupted the flow of existing production. Note that there is a typo in the date of the document. Had this requirement actually been submitted on January 31 1944, an improved M4A3E2 might have been available by late 1944.

Starting in February, 1945, about 100 M4A3E2s were retrofitted in theater with 76mm guns. This was a fairly simply upgrade, because the E2's gun mount was nearly identical to the 76mm's. Above is shown an upgunned Jumbo, tactical number “E-2,” the second tank of E Company, 2nd Battalion, 32nd Armored Regiment, 3rd Armored Division in Cologne on March 6, 1945. “Then and now” photo analysis by Dierk Lurbke has determined that this iconic WW II Sherman scene was shot at the intersection of Venloerstraße and Spichernstraße. Some units of the 3rd AD painted the USA Number on the front and rear of their tanks. It was censored in the photo, possibly to prevent the enemy from using the information to “count heads.” However, a motion picture crew also filmed this scene, and individual frame captures (inset) reveal that the Registration Number was USA 3083173, one of the last E2s made. Note that it has the sheet metal cover (item 1) over the ventilator between the drivers' hatches. It is thought that perhaps the last 75 units had the cover factory installed. This tank also has the solid type road wheels that Fisher introduced into production around July 1944.

A small number of the upgunned M4A3E2s have been noted to have had the heavy gun collar removed. This is described in an APG Test Report as a "counterweight." So, perhaps it was removed as unnecessary to the balance of the longer and heavier 76mm gun? A few period photos show the counterweight removed on 6th Armored Division Jumbos, such as the examples seen in the grayscale photos above. The lower left photo is of the historic combat veteran “Cobra King” showing just the outer collar removed. The tank was retrofitted with a 76mm at some point, and the restorers at Ft Knox exchanged the 75 gun and mantlet from their other M4A3E2 (USA 3083026), so that Cobra King would reflect its appearance as of 26 December 1944. The authors are pleased that “CK” was chosen to be the “representative” Sherman tank on display at the National Museum of the United States Army at Ft. Belvoir, Virginia. Photos courtesy of Joe Burgess, upper right; Garry Redmon, lower left; and Chris Ballance, lower right.

Steven Newhouse recently sent us the snapshot on the left, which shows his Grandfather, Sgt. Elfridge Newhouse (smoking cigar) posing with his M4A3E2, “China Clipper,” USA 3083035. Steven knows that Sgt. Newhouse served with the 6th Armored Division, but he has no further documentation about his Grandfather’s lower unit affiliation. We were able to cross reference the snapshot with a screen capture from some Signal Corps footage taken in Oberdorla, Germany on April 4th, 1945. No doubt this also shows China Clipper, and it can be seen to have been up-gunned with a 76mm. (Note the missing gun collar/counter weight in the snapshot.) From what we have been able to ascertain from available records, C Company of the 69th Tank Battalion was part of Combat Team 44 which went through Oberdorla on that day. We would point out that the photo at the top left of the previous caption shows another(?) up-gunned M4A3E2 of C/69th TB in 1947. Left side photo courtesy of Steven Newhouse.

"Necessity is the mother of invention," and with no prospect of further deliveries of Jumbos, in February 1945, the Third Army embarked on a program to "up-armor" its M4A3(76)s. These might be considered to be "field expedient M4A3E2s." The numerous Battle of the Bulge tank wrecks, both Allied and Axis, were used as sources for the additional armor. Above are several examples. Looking from left to right, note the increase in the areas protected.

There aren't many genuine WW II combat veteran Shermans in the US. The Chrylser M4A3(76)HVSS on display at Rock Island Arsenal certainly appears to be one, although the Museum doesn't seem to have any documentation about its history. "4th Armored Divison General Sherman Tank Knocked Out During the Battle of the Bulge Dec. 16 1944 - Jan.23 1945" is painted on the (4 inch?) slabs of (German?) armor welded on the the hull sides. Battle of the Bulge casualty seems doubtful in that the up-armoring process didn't commence until February. The glacis armor was taken directly from another Sherman (inset), complete with hull lifting rings as well as headlamp and gun travel lock fittings. If this tank could talk, it would probably have stories of 3 or more WW II battle losses.

At about the same time as the M4A3E2 was under development, the Ordnance Department considered the idea of an auxiliary armor set that would have been produced as a kit to be applied in the field or (one presumes) at Tank Depots before overseas shipment. The Chrysler Engineering photo above is dated February 24, 1944, and shows the wooden mock up of the concept. Note that the protection is concentrated on the front of the hull and turret, and unlike the M4A3E2, no provision was made for additional armor on the sides. Of interest in the photo is that this kit has “eliminated” the cast antenna “pot” that projected from the right side of the glacis on 1st Generation welded hull Shermans. This bracket strikes us as unnecessary to the original design, since it was only needed for command tanks carrying long range radios in the right sponson. It seems like it could have been replaced with a 50 cent metal antenna bracket? The evident weakness of the drivers’ hatches (1) projecting from the glacis plate was addressed by the 2nd Generation Sherman project. The “added armor” concept obviously had merit, but we have not as yet found an explanation as to why this project was terminated at the end of February, 1944. The long lead time needed to mass produce such kits, along with the anticipated availability of the the T20 series "Heavy Tank" probably factored in. Note how the armor added to protect the differential housing (2) extends beyond the front of the tank. Richard Hunnicutt stated that an earlier beefed up differential housing project was rejected for that reason. Another factor in the rejection of the auxiliary armor set might have been the Engineer Board's consistent objections to any changes that made the Sherman longer, wider or heavier than the original design.

Meanwhile, the M4A3E2 soldiered on. The Sherman above can be identified as a Jumbo by the lack of pistol port. It is "out of spec" in that it is not equipped with extended end connectors. It appears to have been retrofitted with flat block rubber tracks, possibly as a result of wear or damage to the originals. The caption identifies it as with the 750th Tank Battalion supporting Task Force R of the 104th Infantry Division in Halle, Germany, April 14 1945. A movie still (inset) reveals that this E2 was upgunned with a 76mm.

Above, a column of CCA / 11th Armored Division fords the Muhl River near Neufelden Austria on May 4 1945. The Jumbo in the middle distance appears to lack EECs, and the right track is installed backwards. The combat history of the M4A3E2 seems to have ended on VE Day, May 8th, 1945. Rich Anderson has estimated that about 61 were lost in action. Late model AFVs such as the M26 and M4A3(76)HVSS were wanted for the planned invasion of Japan, and it was requested that many of those in Europe be shipped back to the US. Shermans with VVSS were not wanted as they were considered obsolete. However, it was suggested that the remaining M4A3E2s "be offered to active theater." Operation Olympic plans contemplated extensive use of the M26, so it is improbable that the E2s were formally requested. In any case, some Jumbos were shipped back to the States. Records indicate that, in August 1948, there were 96 in US Depots - NRFI (Not Ready for Issue).

Click on the photos for larger size

Flamethrower equipped Shermans were used to good effect in the final campaigns in The Pacific. However, users requested that future models be armed with a large caliber main gun along with the flamethrower. They also requested "that maximum practical armor protection be provided." Thus, in May 1945, development work commenced on the "Flamethrower Tank, T33." The M4A3E2, retrofitted with a new turret as well as HVSS, was selected for the conversion. Twenty units were authorized for procurement. Left open was the possibility of further production, if necessary. Ultimately, at the surrender of Japan, the program was cut to 3 pilot models. The T33s weren't actually delivered until September 1947 (USA 3082940) and January 1948 (3083011,3083021). In 1953, two of the T33s (3082940, 3083021) were converted to "Self Propelled Flamethrower, T68" as seen on the right.

The Korean War caused a reassessment of the status of the many obsolescent WW II era AFVs sitting in storage throughout the US. In January 1951, the Bowen-McLaughlin-York Co. was given a contract to remanufacture 1493 M4A3(75)s and M4A3E2s. It is thought that less than 100 E2s would have been available for the program. Several of the surviving Jumbos show evidence of having been rebuilt by BMY. 50429 still has a Bowen & McLaughlin dataplate (above left, courtesy Don Moriarty), and 50331, 50344 and 50415 have fittings for the type of hinged "comb" device (item 1, above right, courtesy Jim Goetz) typical of BMY.

Click on the photo for larger size

In general,

1950s remanufactured Shermans were given a thorough overhaul of their

mechanical and electrical systems, so that they were ready for issue. If

present, the spare track holders on the upper rear hull plate were

removed, and an infantry phone was installed on the right rear in some cases. On

BMY remanufactures, 3 spare track blocks were fitted to the turret

sides. The studs that held these can be seen in the above photo on both

Jumbo turrets. The smoke mortar had been eliminated in early 1945, and

these were removed, and

the holes were welded shut. The spotlight was also eliminated, but the

few surviving Jumbos still have the fittings, possibly because the E2

did not have head lights. Wet stowage was eliminated by sealing up the

liquid containers in the ammo racks. If not present, the sheet metal

cover was installed over the vent between the drivers' hatches. Gun

travel locks were retrofitted with the later one-piece locking

arm. It is doubtful that BMY was contracted to, or able to retrofit

extended end connectors to the E2s where they were missing, simply

because supplies were no longer available. After remanufacture, some of

the M4A3(75)s and M4A3E2s were issued as training tanks. The photo above

shows members of the 194th Tank Battalion of the Minnesota National

Guard in 1955. Present are 2 Jumbos, 3 Ford built M4A3s and an M47.

(Courtesy MNG Archives, via Tom Chial).

The

Sherman was finally declared obsolete in 1957. Most were scrapped, but

some were presented to towns and veteran's organizations for use as

monuments. Some were used by the military as range targets. Indeed, the 2

Minnesota National Guard Jumbos shown in the previous photo were

spotted on a range at Camp Ripley in 1977 by Guardsman Tom Chial. Tom

recorded their Registration Numbers as 3082941 and 3083052. Recognizing

the rarity of the M4A3E2, he brought them to the attention of base

command. He reported that 3082941 was not too badly damaged and

suggested that it would make a "presentable static display" for the

(then) proposed Minnesota National Guard Museum at Camp Ripley. It was

placed on display there in 1986. In Tom's photo on the left, note that

"152" can be seen cast in on the turret and that there is some sort of

deflector plate attached to the front left side of the hull. These

features are also observed in the 1955 photo of the previous caption.

Photos courtesy of Tom Chial.

Fisher

built Shermans have the Tank's Ordnance Serial Number stamped into the

rear towing lugs as shown in the photo on the left. If the dataplate

mounted on the hull wall to the left of the driver's seat is missing,

the SN of Fisher Shermans can be found stamped inside the dataplate

frame, although in some cases, a little paint removal may be required.

Right side photo courtesy of Don Moriarty.

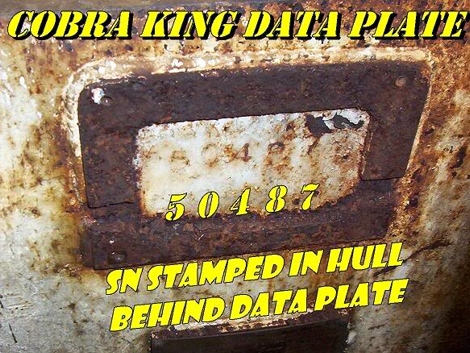

The

examination of surviving examples reveals that Fisher built Shermans

have a loose build sequence number stamped on the left front (driver's

side) of the hull. These numbers have been observed to have letter prefixes or suffixes. "Counting heads" suggests that the various letters noted amount to "A" for M4A3(75)W, "E" for M4A3E2, "M" for M4A3(76) and "W"

for M4A2(76). The photo on the left shows "E9" on SN 50344 at Camp

Ripley. In fact, this would actually have been the 19th M4A3E2 built,

which explains our characterization of the build sequence number as

"loose." Second Generation Fisher

built Shermans are also noted to have the tank's Ordnance Serial Number

stamped on both edges of the differential housing. The diff stamping is

preceded by an "S" for "Serial Number." Cobra King's can be seen in the

right-side photo above as "S50487", indicating that CK has retained her

original differential housing. That is not always the case. For

instance, SN 50344 at Camp Ripley has "S50455" stamped on its diff.

housing. That corresponds to USA 3083052, which just so happens to be

the Registration Number of the other M4A3E2 that Tom Chial photographed

on the range at Camp Ripley in 1977. (Left side photo courtesy of Dan Reed, right side photo courtesy of Don Moriarty).

HOME