Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

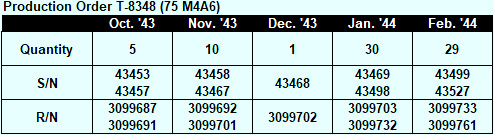

The Chrysler Corporation was the sole manufacturer of the M4A6, and produced 75 units from October, 1943 to February, 1944.

Production Order T-8348: 75 units: Serial Number 43453/USA 3099687 through S/N 43527/USA 3099761

The US Medium Tank was designed around a modified 9-cylinder Wright

R-975 Whirlwind radial aircraft engine that was widely used by the Army

Air Corps and had a proven record of reliability. As the US military

commenced its massive build up in the early 1940s, materials priority

appears to have been given to the Navy and Air Corps. Recognizing that

there would be a critical shortage of aircraft engines, the Army turned

to the automotive industry for alternate tank power plant designs. In

July 1941, just as M3 Medium production was getting underway, the

Ordnance Department asked the Chrysler Corporation if it could design an

alternate medium tank engine "in a hurry." The expedient that emerged

used the "off the shelf" 6-cylinder engine from Chrysler's "Royal" line

of automobiles and combined five of them into a "star" configuration.

The Army found Chrysler's unconventional "stop gap" design acceptable,

and in December 1941, the Ordnance Department contracted for the

installation of 109 "experimental multiple engine power plants" in the

Medium Tank, M3. This configuration was given the nomenclature "M3A4"

and approved for production later that same month. The 109 M3A4s were

manufactured from June through August 1942. This was not a simple engine

swap. The massive "Chrysler Multibank" required an 11-inch elongation

of the existing hull. Despite numerous teething problems and the

complexity of the 30-cylinder Multibank engine, the Government committed

its flagship Detroit Tank Arsenal to the Multibank's continued

production and in early January 1942 Chrysler was contracted to build

the third T6 (Sherman) pilot. It would be a welded hull model, elongated

for the Multibank, and given the nomenclature "M4A4." For a sense of

the chronology, we would observe that the M3A4s were immediately

replaced in production by the M4A4s, with the first 2 accepted in July,

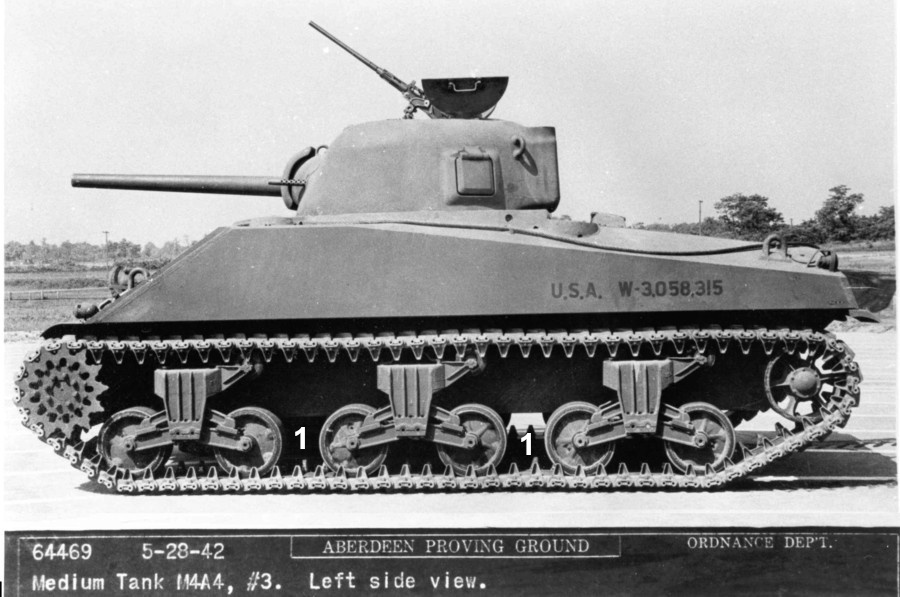

followed by 167 in August 1942. The pilot M4A4, Serial Number 3, USA

3058315 is shown above. It was completed on 9 May 1942 and delivered to

Aberdeen Proving Ground later that month. In a side view such as this,

the 10-inch gap (1) between the road wheels is a good recognition

feature of the elongated M4A4 hull. On the "as designed" Sherman hull,

the gap is about 3 inches. This applied to all of the other models - M4,

M4A1, M4A2 and M4A3.

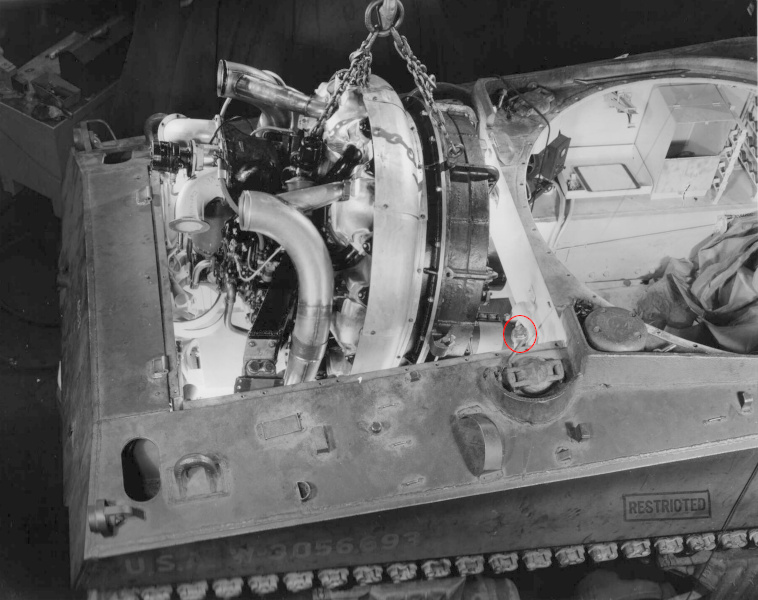

In 1941 the Ordnance Department also approached the other members the "Big Three" automakers, General Motors and Ford for design ideas for alternate tank engines. GM developed a twin diesel power plant and Ford a V8 gasoline engine and these went into Sherman production in April and June 1942 respectively. In July 1941, the Caterpillar Tractor Company of Peoria, Illinois was asked if it could produce a diesel-powered engine based on the ubiquitous 9-cylinder Wright R-1820 Cyclone radial, another proven aircraft engine that was in high demand by the Army Air Corps. Caterpillar was and still is a manufacturer of "track-type tractors" and by the 1930s, had a great deal of experience in the relatively new field of diesel engine technology. Caterpillar developed a prototype radial in early 1942, which was "multi-fuel", as requested by Ordnance, and could run on diesel and various grades of gasoline and even crude oil. Presumably, the "multi-fuel" radial was the ideal of a universal tank engine in the minds of some at the Ordnance Department. In any case, the government appears to have jumped in with both feet, and on 12 February 1942, Illinois Senator Scott Lucas announced "that the War department planned to build a 25-million-dollar ordnance plant near Decatur to make engines for tanks. It will be called the Victory Ordnance plant." Ground was broken in May, and the government contracted with a new subsidiary, the Caterpillar Military Engine Company, to run the plant, which would eventually have the capacity to produce 1,000 engines per month. By November 1942, as Sherman production was in full swing with the Chrysler, GM, Ford and the original Wright/Continental engines, progress at Caterpillar was such that the Ordnance Committee recommended that engines be installed in 20 M4 series tanks that would carry the experimental designation "M4E1." The photo shows the pilot installation in an August 1942 production M4A4, Serial Number 4883, USA 3056693. The Chrysler Multibank engine was removed before the tank was shipped down to the Caterpillar plant in late 1942. As can be seen, the engine which is called the "RD-1820" in the test report, was as large as the Multibank and therefore would only fit into the elongated hull of the M4A4. Note the filler pipe (circled) for the addition of engine oil. A digest of the report dated January 1944, describes the conversion process with "minor changes and stowage item relocations, including both those necessitated by the engine installation and those requested by Ordnance." It is worth mentioning here that in an evaluation report dated 16 December 1942, the Armored Force Board recommended that "The Chrysler Multibank engine be considered unsatisfactory as a power plant for medium tanks and its production discontinued at the earliest possible date." So, it would seem that the Caterpillar RD-1820 may have been under consideration as a replacement for the Chrysler Multibank. In any case, the tank, which was now M4E1 Serial Number 1, was reportedly only run for 60 miles before being shipped to the Ford Motor Company "to be prepared for winterization testing." (Diesel engines of the time had "issues" with cold winter temperatures.) It is thought that the vehicle was then shipped to Fort Knox for engine endurance tests where it was designated "AFB #701-A." Interested readers may wish to have a look at "TM9-1756A, Ordnance Engine Model RD-1820 (Caterpillar)" which provides a great deal of detail about the engine, although it does not seem to have a single photo of it installed in a Sherman.

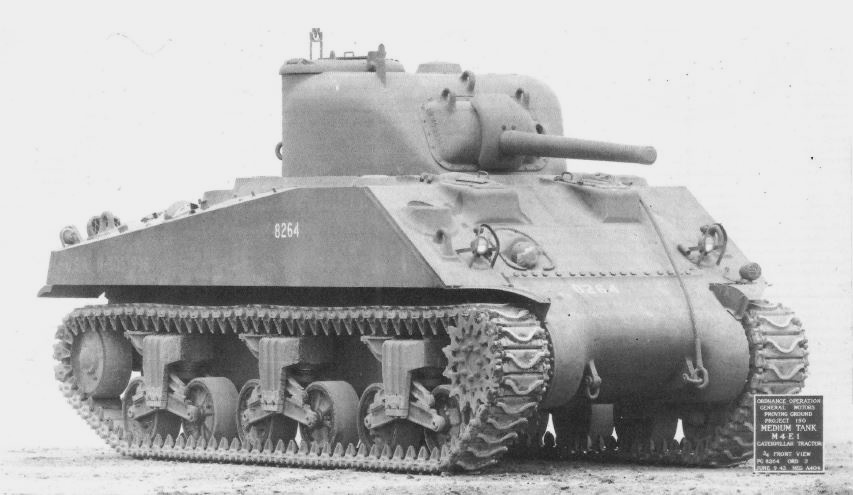

"Sherman" author Richard Hunnicutt has it that "The second tank [M4E1] was shipped to Fort Knox in January 1943 followed in May by number 4." According to the Ordnance records we found, "M4-E1 tank No. 4; W-3057623; Chrysler serial No. 5813" was accepted after a 26-mile test run. It was then shipped to Aberdeen, Maryland. The M4A4 Serial Number would indicate that Number 4 was built at Chrysler in October 1942. In early May 1943, after dynamometer testing and a 38-mile test drive at Caterpillar, "M4-E1 tank No. 3; W-3057896; Chrysler serial No. 6086" was accepted and shipped to the General Motors Proving Ground in Milford, Michigan. Caterpillar manufactured transmissions and final drives for the Sherman program, and it is stated that "an experimental power train of Caterpillar 2C-2402 design was installed in this tank." The photo above shows SN 3 at GMPG on or about 9 June 1943, with the CAT 1-piece differential housing that replaced the original Chrysler 3-piece diff. The tank can be seen to have been assigned GMPG Number 8264. Note the elongated drivers' hoods. M4A4 SN 6086 would have been accepted at Chrysler in November 1942, the month that the company transitioned to the later drivers' hood castings according to our "counting heads" method. A digest of the GMPG report dated 3 January 1944 states that "The vehicle was operated a total of 958 miles over various terrain" and sums up, "In general, the performance of the M4E1 was similar to that of the M4A2 Tanks tested at the General Motors Proving Ground, and superior to the M4A1 and M4A3 vehicles. No failures were charged to the engine and transmission." We would observe that the various test reports are often dated months after the findings would have been of any practical use, but there is evidence that the test data was passed on to interested members of the Ordnance Department in real time.

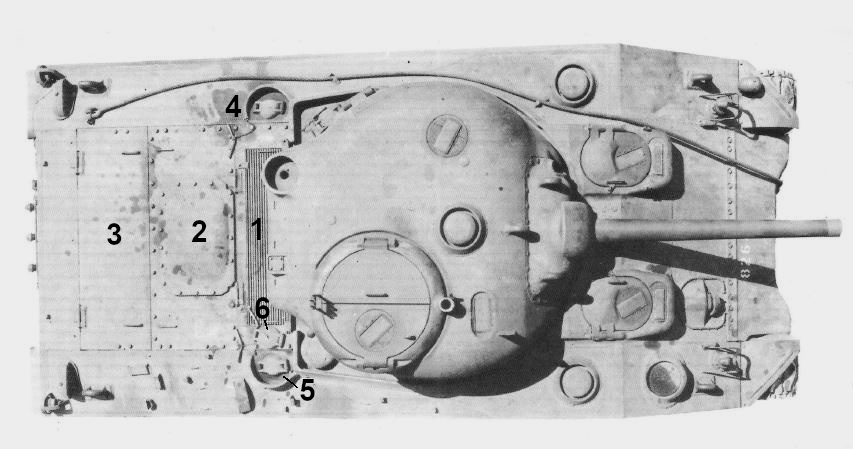

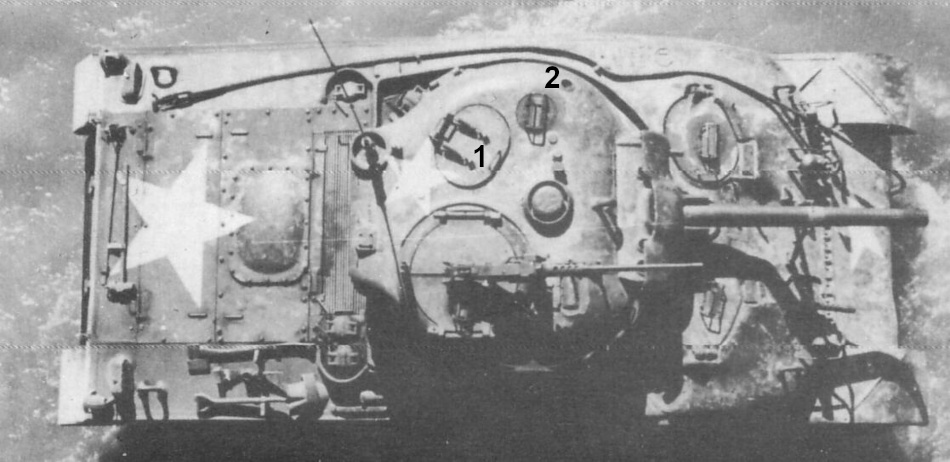

This overhead view of M4E1 Number 3 shows the changes made to the engine deck configuration. The air intake grill (1) appears to be identical to the M4A4's. The cast armor bulge (2) that protected that part of the radial engine that projected above the engine compartment appears to be about twice as wide from front to back as the one used on the M4A4. Consequently, the rear removable engine deck panel (3) was made smaller than the M4A4's and hinged at the back. The M4E1 used the same 80 gallon fuel tanks mounted along the left and right sponsons as the M4A4. Filler caps (4 and 5) serviced the fuel tanks, and a new filler (6) was included on the right side only for the addition of engine oil. One of the modifications recommended by GMPG was that "hold-open latches on hatch covers be provided." Positive hatch lock mechanisms with equilibrator springs were reported to have been introduced on Chrysler M4A4s in late April 1943, but as mentioned in the previous caption, M4E1 Number 3 would have been built as an M4A4 in November 1942.

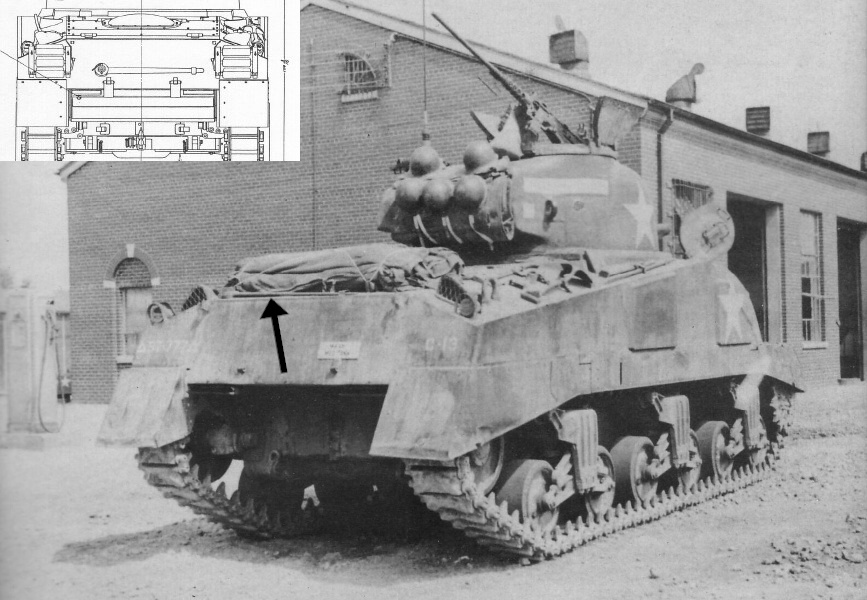

Using various Ordnance documents to track the movement and timeline of the 20 "Chrysler Tanks without engines", we found that a total of 18 M4A4s were shipped in late December 1942. They were delivered to Caterpillar's main plant in Peoria, not the "Victory Ordnance Plant" in Decatur. A local newspaper article of the day has it that the new facility did not produce its first engines until August 1943. As a matter of record, the M4A4 Serial Numbers were listed in a shipping document. Here they are, and we have added their dispositions in brackets: 6086, M4E1 No.3 [GMPG 8264]; 5813, M4E1 No.4 [to APG]; 17454, M4E1 No.5 [AFB #704]; 17445, M4E1 No.6 [AFB #703]; 17466, M4E1 No.7 [AFB #706]; 17455, M4E1 No.8 [AFB #705], 17451, M4E1 No.9 [AFB #707], 17440, M4E1 No.10 [to APG]; 17465, M4E1 No.11 [AFB #711]; 17444, M4E1 No.12 [AFB #712]; 17443, M4E1 No.13 [AFB #713]; 17446, M4E1 No.14 [AFB #714]; 17441, M4E1 No.15 [AFB #716]; 17447, M4E1 No.16 [AFB #719]; 17448, M4E1 No.17 [AFB #718-A]; 17450, M4E1 No.18 [to APG]; 17442, M4E1 No.19 [to APG]. This gives us a total of 19 M4E1 Serial Numbers, not 20 as per the Ordnance Committee Memorandum. In a shipping document, M4A4 SN 17462, USA W-3017768 is referred to as "the extra tank returned by Caterpillar Tractor Company to the Chrysler Tank Arsenal...on 24 June 1943." So, perhaps there were only 19 M4E1 conversions? It is assumed that M4A4 SN 4883, USA 3056693, M4E1 No.1, the pilot installation that became AFB #701-A, was shipped to Caterpillar in November 1942. In the endurance tests at Ft. Knox, the engine (Serial Number 4C1501) of M4E1 No.1, AFB #701-A, is listed as "rebuilt." This leaves us with one tank unaccounted for, M4E1 No. 2. Perhaps it remained at Caterpillar as a template model? All of the M4A4s with 174XX Serial Numbers would have been December 1942 production. The shipping document notes that all of the Serial Numbers listed were "reported as M4A4 acceptances in 1942. There does not seem to be any reason, therefore, why they should affect the 1943 program." We interpret this to mean that these tanks were accepted as completed M4A4s at Chrysler with no deduction in the official production figures. They were then accepted again as M4E1s at Caterpillar. It would appear that after M4E1 Numbers 1 and 2, the remainder of the engines were not completed or accepted until April or May 1943. For instance, M4E1s Numbers 5, 6, 7 and 8 "were shipped to Lima Tank Depot for the installation of Radio Equipment and OVM Tools on...May 13, 1943 and May 14, 1943. As soon as they are fitted, they will be re-consigned to Fort Knox, Kentucky." There are not very many photos of the M4E1s, and there is no way to identify the tank shown above as one except for the "718-A" painted on the side which cross references to M4E1 No.17, M4A4 SN 17448. The tank was photographed at Ft. Knox "after its 40 foot fall into Otter Creek on 26 October 1943." Production of the M4A6 began in the month of October but it would seem that the Armored Force Board and APG were still running endurance tests of the M4E1s into late 1943. Note that the tank is mis-labeled "M4F1" in the information panel. We take it that the "A" suffix indicates an engine change or rebuild.

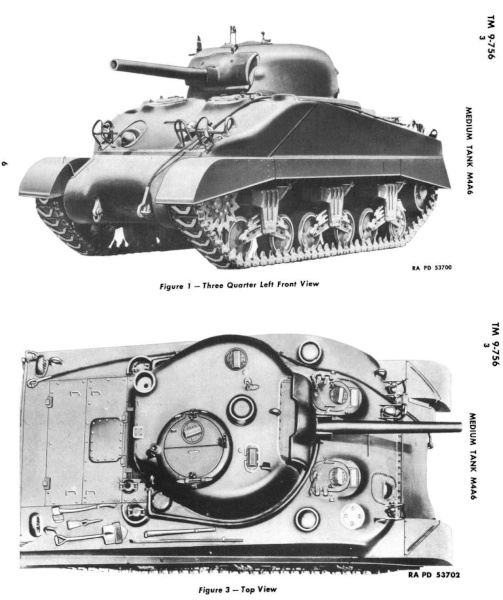

As a matter of minutia, we thought we'd show some photos (or perhaps drawings?) from the M4A6 Technical Manual which is dated 21 December 1943. Apparently, the publishers could not immediately locate a few walk-around photos of a real M4A6 and used images of a prototype M4 Composite with small hatches. Note the short spacing between the road wheels compared to the railcar photo of the previous caption. In the overhead shot, it can be seen that the M4A6 armored bulge or "blister" on the engine deck was crudely "Photoshopped" in. The armored cover cap for engine oil looks pretty good, though. In any case, the images more or less provide an idea of the appearance of a small hatch composite. It is thought that all of the production Composite hull Shermans would have been built with the sharp-nosed, one-piece differential housing (Part Number E8543) not the earlier E4186 diff seen here. Throughout the M4A4 program, Chrysler used three-piece differential housings. At the outset of the M4 program, Chrysler Power Trains were reconfigured to the late one-piece diff housings. "Chrysler will finish M4A4 on 3 pc. Will start M4, M4A6, M4 (105 How) with single piece." In addition, starting in September 1943, the Ordnance Department mandated the use of the E8543 one-piece final drive in all domestic Sherman production. The prototype lacks the "Quick Fix" applique plates, and the gun travel lock. Counting heads suggests that all of the Composite hull Shermans were built with those items factory installed.

Another "milestone" photo taken at the Detroit Tank Arsenal shows a left rear view of the "First Chrysler Built M-4 A-6 Tank Shipped Oct. 28th, 1943." The Registration Number is painted on very small, probably in blue drab, but can be read as "USA 3099687". According to our research, the corresponding Serial Number would have been 43453. However, we admit that we have not recorded a single example of an M4A6 with known good Serial and Registration Numbers together but are trusting that the ranges provided in the Ordnance Department Records Section documents are accurate in this case. For want of a better term, we refer to item 1 as the "little plate". From "counting heads", we interpolate that these plates were factory installed exclusively on M4A4s starting around mid-April 1943. Consequently, they are not present in the few photos of M4E1s since they were accepted as M4A4s in 1942. We have not come across any official documentation, but it is assumed that the little plates were added to protect the drain holes on each side at the rear of the turret splash castings. They are seen in all of the few photos of M4A6s suggesting that they were installed on most or more likely all of them. The little plates have not been observed in photos or on surviving examples of M4 Composites. The exhaust deflector (2) appears to be very similar to the one used on the M4A4. Here it is in the "up" position. The exhaust pipes (3) are similar to those on M4s and M4A1s, but perhaps a bit wider at the outlet and more exposed. The return roller arms (4) are the final "upturned" type. Again, these are seen in all of the few photos of M4A6s. While the M4 and M4A6 Composites had many 2nd Generation Sherman features, they "still" had much of the 75mm ammunition mounted "up high" on the sponson shelves as on the original Sherman design. The applique plates (5) were an expedient intended to protect the sponson mounted ammunition bins. The bins were repositioned to safer positions on the hull floor in most 2nd Generation Shermans. USA 3099687 can be seen with a Continental-Wheeling D50878 low bustle turret without pistol port (6). There aren't enough photos of M4A6s with known Serial or Registration Numbers to permit counting heads, but our study of Chrysler M4 Composites indicates that those transitioned to the high bustle D78461 turret which incorporated a loader's hatch starting in November 1943. Note the lack of recognition stars on this unit.

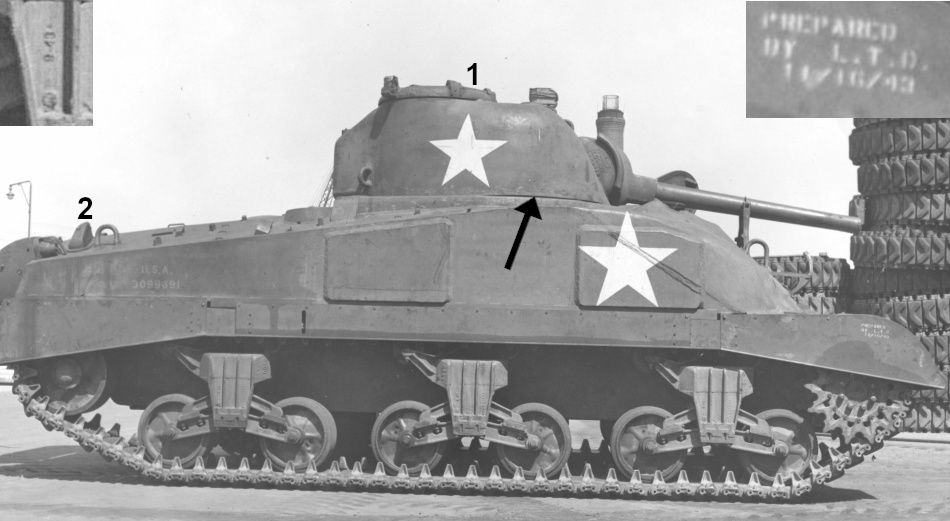

We apologize for all of the familiar M4A6 photos from the Hunnicutt collection, but frankly, we have not come across many others. This one shows a left side view of USA 3099691, which we take to have been the 5th production M4A6, the last one accepted in October 1943. Anything with a date is valuable to our research, and one of Chrysler’s prime suppliers of bogie bracket castings was the National Malleable and Steel Castings Company, whose logo was an “N in a circle”. They included production dates on their bogie castings. In general, original component parts will predate the acceptance of the tank by a month or more. So, for instance, the forward bogie seen here appears to be dated "8-43" or "9-43" [Aug. or Sep. 1943, inset]". Speaking of dates, the stencil on the front sand shield section reads, "Prepared by L.T.D. 11/16/43 [Nov. 16, 1943, inset]". We would guess that this series of photos was taken at the Lima Tank Depot on or about that date. LTD in Ohio was the closest Tank Depot to the Detroit Tank Arsenal in Warren Michigan (about 150 miles) and we suspect that they processed most or all of the M4A6s and gave them the "star treatment" shown here. Again, we have a low bustle turret and here we have tried to show what we call for want of a better term, "the cast-in thickened cheek" (arrow). Two areas on the inside right front of the original turret casting had been thinned to allow for the proper operation of the traversing mechanism. As the first Shermans entered combat, troops began to report that the enemy aimed for these "thin spots." In April 1943, the D50878 turret was revised to eliminate the pistol port, which was considered a ballistic weak point, as well as "increase thickness of turret in area of the traversing mechanism." The revised "No Pistol Port" turret castings began to enter the production pipeline on Chrysler M4A4s around June 1943, and they are noted on a few M4A6s such as 3099687 and 3099691. The commander's split hatch on this example can be seen as the improved type ("turret hatch D69993 with equilibrator"). These had integral springs on the hinges (1), as opposed to the catches on the earlier type of hatch locks. Again, our study of Chrysler M4 Composites suggests that the equilibrator hatches entered the production lines in November, around the same time as the transition to the high bustle D78461 turrets began. Like the M4, M4A1 and M4A4, the M4A6 used a pair of "air scoops" (2) to assist in the dissipation of heat inside the engine compartment. Two castings were made, one for each side. The "proper" installation of these shows the high side of the casting mounted toward the outer edge of the tank, so this unit has them mounted backwards. However, the mix up does not seem to have affected their function. In some cases, they are seen turned around with the open end toward the rear.

This photo of USA 3099691 provides a left rear view and shows the armored bulge or "blister" on the engine deck to good effect. LTD appears to have painted a huge white star on the engine deck and the top point of it overlapped the blister. Like the M4A4, the M4A6 required an armored blister on the belly plate as well as shown in the inset. The lower rear hull is in heavy shadow, but we would interpolate that M4A6s like Chrysler M4 Composites were built without trailer towing pintles. Periscope guards appear to have been factory installed to protect all of the periscopes except the gunner's.

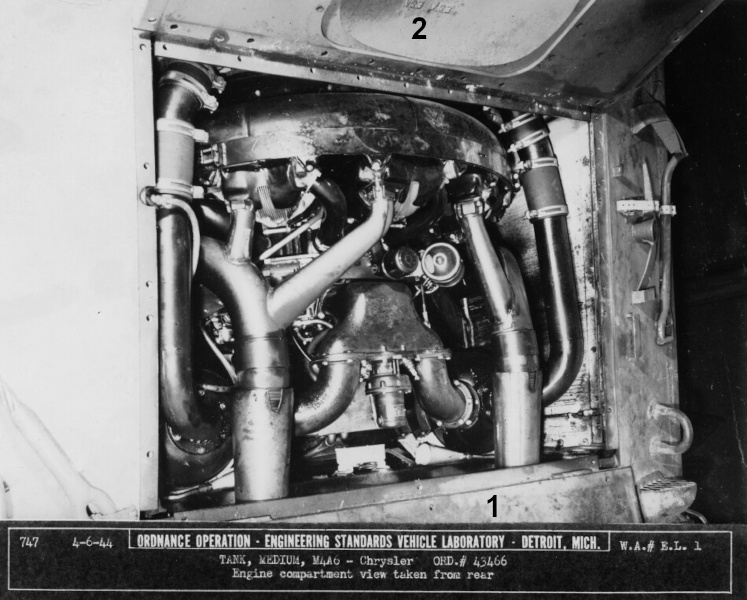

Here

we see the massive RD-1820 Radial crammed into the engine compartment.

This photo is dated 6 April 1944, a month or so after the M4A6

Production Order was terminated in February at 75 units. It was taken at

the Engineering Standards Vehicle Laboratory in Detroit. The

information panel identifies this particular M4A6 as "Ord. # 43466",

indicating November 1943 acceptance. By our reckoning, the corresponding

Registration Number would be USA 3099700. The rear engine deck panel

(1) was hinged to open to the rear. The inside surface of the armored

blister casting (2) on the forward panel can be seen to have "ESA" cast

into it twice. We assume that this was a particular company's casting

logo, but at present, we have not been able to identify the firm.

The Armored Board at Ft. Knox conducted trials in which "Thirteen Medium Tanks M4A6 with the different test engines [RD 1820, RD 1820-X, RD 1820-N and RD 1820-XN] were operated continuously over the endurance, cross-country courses until the engines failed." The engines with the "dash" designators incorporated various improvements. Ultimately, it was found that "the RD 1820-N and RD 1820-XN engines were the only ones considered satisfactory, although some modifications were recommended." This report is dated 28 September 1944, 7 months after the M4A6 program had been terminated. The Board's conclusion from the "Resume" of the report was quite laudatory, "Medium Tank M4A6 exhibited better performance, economy and cruising range than any other standard tanks of the M4 series." However, it was noted that "An appreciably higher rate of failure was experienced with the one-piece power train assembly than with the older type three-piece power trains." This strikes us as odd, since, as best we can determine, all of the M4A6s would have been built with power trains using the late E8543 differential housings. It is possible that the Armored Board was comparing the M4A6 failure rate to that of the M4E1s tested at Ft. Knox in 1943. These would have been shipped with Chrysler three-piece power trains. We recorded the Registration Numbers of the M4A6s that were used at least in the first part of the Armored Board Test from some Ordnance Department files. These were 3099698, AFB #721; 3099737, AFB #722; 3099736, AFB #723; 3099758, AFB #724; 3099702, AFB #725; 3099708, AFB #726; 3099704, AFB #727; 3099718, and AFB #728. These eight were reportedly installed with RD1820 engines. Five M4A6s were installed with RD 1820-X engines. Three of them, "Tanks No. 721, 722 and 725 were redesignated No. 733, 735 and 734, respectively, when equipped with RD1820-X engines following early failures of RD1820 engines." The other two equipped with RD1820-X engines are listed as 3099761, AFB #731 and 3099699, AFB #732. It is stated that the original RD1820 engine of 3099699 had failed at the time of receipt. We would observe that the Registration Numbers listed are for M4A6s accepted in November and December 1943 plus January and February 1944, so they encompass all but the first month of M4A6 production. In fact, we believe USA 3099761, AFB #731, would have been the absolutely last M4A6 officially accepted, which leads us to suspect that these trials were mostly conducted after the M4A6 contract had been terminated. We would guess that the second part of the trials involved "the RD 1820-N and RD 1820-XN engines...the only ones considered satisfactory." The "Resume" or digest notes that "This 115-page report includes 29 photographs of the M4A6s and their components" but the only ones we have encountered to date are from the Hunnicutt files showing USA 3099699, AFB #732. This unit, which would have been accepted in November 1943, can be seen with a stencil that reads "Prepared by L.T.D. 1/XX/44". Note the LTD stars and the "new" high bustle turret with oval loader's hatch.

Here we have a right front view of AFB #732. The information panel has it that this unit was installed with "Ordnance Engine RD1820", but that is likely just a generic description, since its original RD1820 engine (SN 200020) reportedly failed at the time of receipt "due to hydrostatic lock resulting from a compression release linkage failure and was not considered a test engine." It was only after the tank was installed with an RD1820-X engine (SN 200097) that the Test Number AFB #732 was assigned. For some reason, the information panels of the Armored Force Board photos rarely include dates, but judging by the bare trees in the background, these photos were taken in the Winter or early Spring of 1944. In this series of photos AFB #732 is seen with rubber chevron tracks, but we came across a report that lists this unit along with AFB #731, 3099761 and AFB #727, 3099704 as used in trials of T-74 steel tracks in April 1944. If any readers know of any photos of M4A6s with AFB Numbers aside from 732, we would be happy to hear from you. General Motors Proving Ground had a facility in Phoenix, Arizona, and in general one or two new model AFVs were sent there "to determine the effects of desert heat and dust." According to the digest of the GMPG Report dated 24 October 1944, M4A6 Serial Number 43479 (Jan. 1944) did not do well, "The first test engine failed at the first mile. The second test engine failed at 176 miles, terminating the project." For what it is worth, this M4A6 likely would have had the GMPG Number "8508" painted on the front, sides and rear.

This view of AFB #732 was probably taken from a bridge over Otter Creek. The Armored Force Board used the bridge on occasion to take such overhead photos of vehicles parked underneath. The "Maximum fording depth (at slowest forward speed)" is given as 36 inches. We assume that this means "as delivered" without any additional waterproofing sealant on the belly plate or lower hull. The provision of a hatch for the loader was an important safety feature that was added to the design of the Sherman starting in late 1943 and was standard on all Second-Generation models. In November 1943, Chrysler transitioned to the new high bustle D78461 turret that added a loader's hatch and reintroduced the pistol port. The photo affords a view of the oval loader's hatch (1) and the opening (2) for the 2-inch smoke mortar. Note the large recognition star on the rear deck and another painted on the top of the turret.

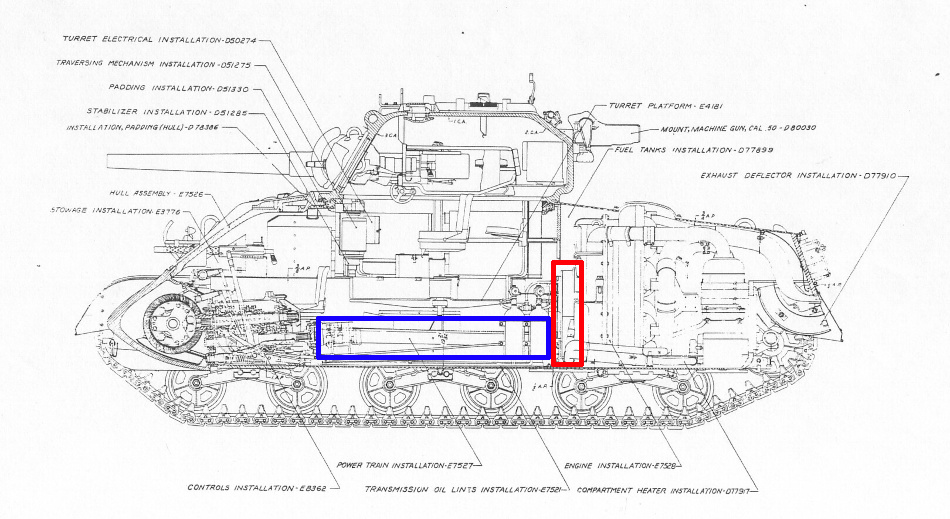

Years ago, the now defunct Ordnance Museum at APG sold large sized scale plans of various AFVs, including the M4A6. This side view shows how the RD 1820 engine was mounted straight up and down inside the engine compartment; that is, not tilted forward as on the Wright/Continental R975 Radial. To make it work in a tank, the engine was installed with a transfer case (highlighted in red) that permitted the propeller shaft (highlighted in blue) to be positioned further down in the tank, providing a little more room in the fighting compartment. Some of the APG drawings are a bit odd as they feature an incongruous mix of early and late features. For instance, the low bustle turret seen here has an M34 Gun Mount with an armored shield over the coaxial machine gun. The M34 would have been replaced at Chrysler by the M34A1 Gun Mount at least 6 months before the first M4A6 rolled off the line. The drawing also shows some later features that don't seem to have been factory installed on any M4A6s, such as the machine gun stowage on the turret bustle and spare track holders on the upper rear hull plate.

In July 1941, when Caterpillar was first approached to develop a diesel-powered tank engine based on the Wright R-1820 radial aircraft engine, the Ordnance Department was very anxious about the supply of tank power plants. However, in the next two and a half years the situation clarified, and the needs of the Army Supply Program had been downsized. By February 1944, only three of the original ten companies that had manufactured Shermans remained: Chrysler, Fisher Body and Pressed Steel Car. One of the "prime directives" of the 2nd Generation Sherman program was "Standardize Power Plants" and the Caterpillar Military Engine Company ran straight into that buzzsaw since it had been decided that the Army's needs could be met by the Ford V8, the Continental Radial and the GM Twin Diesel engines. The termination of a Production Order was pretty brutal for all parties concerned: the primary contractor, the subcontractors, the workers and Uncle Sam. The government appears to have invested over $31 million dollars in a new engine plant and a production contract. (This would be equivalent to $608 million in 2025 according to "US Inflation Calculator".) T. R. Farley, executive vice president of the Caterpillar Military Engine Company put it this way, "In spite of the fact that we have been informed from high sources that our RD-1820 radial diesel engine is the outstanding power unit for General Sherman tanks, we have been directed by the War Department that in view the more urgent need for tractors, the radial diesel engine program be brought to an early close so as to make available added manufacturing facilities for tractors." Reading between the lines of the few available documents, we are not convinced that the RD-1820 was really "the outstanding power unit for General Sherman tanks" when production was terminated. In any case, taxpayers could take some consolation from the fact that the Decatur plant was repurposed. As for Chrysler, "Cancellation of 700 M4A6 occurred on Production Order T-8348, and vehicles were reordered as M4A3." Indeed, we have collected enough data to state with near certainty that the 700 Serial and Registration Numbers assigned to the terminated M4A6s were simply reassigned to Chrysler's first M4A3(76) Production Order T-9872 for 700 units - SN 43528/USA 3099762 through SN 44227/USA 30100461. The M4A6 termination does not seem to have created a great deal of disruption at the Detroit Tank Arsenal since the last M4A6 rolled off the line in February 1944 and the first M4A3(76) was accepted in March.

The "Unit Identification Symbols" (popularly known as "bumper codes") on the M4A6 in the photo above can be seen as "∆ST 777∆ C-13". We take this to mean Armor of the "School Troop", 777th Tank Battalion, C Company, Vehicle 13. This photo along with a few GI snapshots suggest that the 777th was issued some M4A6s during its time at Ft. Knox. Charles W. (Billy) Ray Jr. has done extensive research on the history of the 777th since his father, Technician Fourth Grade Charles W. Ray Sr., served with the unit. He reports that the battalion, which had been training at Camp Gordon, Georgia was moved by rail with its tanks and equipment to its new post at Fort Knox, arriving 14 October 1943. On that day, "The 777th Tank Battalion was assigned to the Armored Test Board [School Troops] ...The men of the 777th Tank Battalion would contribute to the development and field testing of new vehicles and equipment which was vitally needed for the war effort." Since 75 M4A6s were produced, there would have been a sufficient number to equip the three medium tank companies of the battalion with, say, 17 each plus a few more in the Headquarters Company. Whatever the number, these were of course left behind when the unit deployed to Europe in late 1944. C-13 can be seen with a high bustle turret. The exhaust deflector had been removed making it possible to see the rather wide exhaust pipe outlets, along with single rear towing lugs and no trailer pintle. This is a case where the air scoops can be seen to be turned around with the open end facing to the rear. The inset from one of the APG drawings shows the large offset hinges used to attach the exhaust deflector. We are a little skeptical about the presence of the double rear towing lugs, the 2nd Generation "short" trailer towing pintle and of course the spare track holders shown in the drawing. Also, the track wrench appears to have been mounted on the rearmost panel of the engine deck (arrow) throughout production, not on the upper rear hull plate as in the drawing.

Here we have a photo that is in the collection of snapshots of T/4 Charles W. Ray of the 777th Tank Battalion. His son, Billy, informed us that after its service at Fort Knox, the battalion was deployed to Europe, and "arrived in Liverpool on Dec 30, 1944, and was issued new tanks at Wimborne Minster in Jan 1945. Left Portland in Feb to Le Havre and entered the war on Feb 28 at Schleiden [Germany]." T/4 Ray served as the driver of an M4A3(105)HVSS Assault Gun named "Big Bertha". Judging by his photos, "Big Bertha" appears to have been one of the tanks issued to the 707th in the UK in January 1945. There were no notes on the back of the above snapshot, but the rounded front ends, elongated hulls and the "little plates" which are just visible on two of these would tend to identify them as M4A6s photographed at Ft. Knox during the time that the 777th TB was stationed there (14 October 1943 to 7 December 1944). Although the photo is somewhat fuzzy, to our eyes the first two tanks in the center have high bustle turrets while the third has a low bustle. Photo courtesy of Charles W. (Billy) Ray Jr.

The M4A6 was declared obsolete by Ordnance Committee Memorandum 30056 dated 17 January 1946. It was recommended "That one tank, Medium M4A6 be retained at Aberdeen Proving Ground for historical purposes" and "That all other tanks, Medium M4A6 be authorized for disassembly and disposal in accordance with War Department regulations". If an M4A6 was preserved at the Ordnance Museum at APG, we did not come across a record of it in the accession files. Unless one turns up on a US target range in the future, it would appear that no M4A6s have survived. A few post war snapshots floating around the Net show some GIs at Ft. Knox posing with at least two still intact M4A6s on display there, one with a low bustle turret and another with a high bustle. The back of one snapshot is dated October 1946. The US Army photo above shows the low bustle M4A6 that was once on display in front of Rose Hall, the Headquarters Building of the 3rd Armored Division. The angle and shadows in the image might make it difficult to distinguish this from an M4 Composite, but the "little plate" is present. For an idea of a possible timeline for the photo, the veteran 3rd AD, which had been inactivated in November 1945, was reactivated as a training formation at Ft. Knox in July 1947 and served there until 1956 when it deployed to Germany. The HQ was named in honor of Major General Maurice Rose, the 3rd AD's commander who was killed in action on 30 March 1945 near Paderborn, Germany.

The accession files at the old Ordnance Museum at APG included a photo taken in March 1947 of what is identified in the information panel as an "M4A6". Mr. Hunnicutt wrote that "one [M4E1] remained at Aberdeen Proving Ground for historical purposes." We assume it was MCV 123, but it was no longer in the collection years later, probably because it was scrapped during the Korean War along with many other one-of-a-kind AFVs. We would guess that item 1 was a chain that was used as an expedient to secure the hatch in the open position so as to avoid injury to the test drivers. We could not get a good read of the Registration Number of the M4E1 from the original print. It would appear that five M4E1s were tested at APG, Numbers 4, 8, 10, 18 and 19. We believe Number 4 would have had direct vision, so MCV 123 was likely one of the others.