Small and large hatch M4 Shermans

Composites (Hybrid)

Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

A "photo op" showing "The First [sic] Chrysler Built M4 Tank Shipped Aug 28th, 1943." This tank can be seen to be USA 30100471, so while it may have been the first one shipped, we believe 30100462 was the first one built. Many improvements and modifications were beginning to filter into the Sherman production lines by August, and a number of them can be seen on 30100471. Note the factory installation of applique armor, gun travel lock with the corresponding "late" siren position, late E8543 differential housing, and the recently introduced "no pistol port" turret. Some light-colored tape appears on the turret in the location of the 2-inch smoke mortar. Chrysler is reported to have begun factory installing this item on 15 October 1943. If accurate, the tape might suggest that the smoke mortar hole was machined out from the start in anticipation. Most Chrysler Composites were built with periscope guards and bogies with "upturned" return roller arms, whereas this early example lacks the guards and has straight return roller arms.

Here we have a small hatch M4 Composite (SN 44256, September 1943 acceptance) on display at the National Guard Armory in Trenton, Tennessee. It is one of only two known surviving examples. The other, SN 44255, is privately owned. The early front-end casting is similar in appearance to the small hatch M4A1 but includes a pair of ventilators by the drivers' hatches, such as were standard on welded hull M4s. The protrusion on the right front was used as an antenna bracket on the M4 and M4 Composite, whereas it housed a ventilator on the M4A1. 44256 was retrofitted with the E9 modification. The "no pistol port turret" is appropriate, but it is not original, as it was cast by Union Steel, which was not a supplier to Chrysler. No doubt the turret and E9 suspension along with the commander's vision cupola were added during a remanufacture in Spring 1945. The inset shows the casting marks in the middle of the glacis. While the part number is only partially visible as "E634X," period documents indicate that it was E6347. When appropriate, we try to "count heads" using such marks but there are only 2 survivors in this case. We can observe that both were cast by American Steel Foundries-Granite City (G in an octagon), and that their part serial numbers are B33 and B35. This suggests to us that ASF-G cast at least 35 E6347 front ends. Photo courtesy of Paul and Lorén Hannah.

At present, "counting heads" evidence suggests that only about 50 small hatch M4 Composites were produced. Consequently, there are very few period photos of them. Above shows the one with the highest Registration Number we can document - USA 30100510. This would have been accepted in September 1943, overall, the 49th M4 Composite produced at the Detroit Tank Arsenal. USA 30100510 was shipped to Aberdeen Proving Ground where it was installed with the Multiple Rocket Launcher T34, nicknamed "Calliope." The launcher was "capable of firing 60 4.5 inch rockets in a period of 30 seconds." The photo was taken in late 1943, and the front shot of this dramatic night scene was used on the cover page of APG's "Sketchbook," their WW II souvenir history, even though Aberdeen developed many things that were far more useful and effective than tank mounted rocket launchers. History shows that these were, shall we say, "not popular" with tankers who were ordered to mount them on their Shermans. In any case, this M4 can be seen to have a low bustle turret with the "thin spot" patch, with presumably a welded up pistol port on the other side. Most Composites were built with "upturned" return roller arms but here we see the earlier straight ones.

Above left, some of the crew of a small hatch Composite of the 499th Armored Field Artillery Battalion, 14th Armored Division pose armed to the teeth during the Tennessee Maneuvers in January 1944. Again, we see the applique armor patch on the turret. A few Composites, both small and large hatch, appear to have been produced with earlier D50878 turrets with the "patches" and welded up pistol ports. At right is a rare "combat shot" of a small hatch Composite, serving with the 40th Tank Battalion, 7th Armored Division in Niedersorpe, Germany, April 7, 1945. Note the "telltale" ventilators next to the drivers' hatches. Unfortunately, not much else can be seen due to the extensive use of camouflage, but this tank appears to have extended fenders, which suggests it was a remanufactured unit. Although 75mm Shermans were no longer "required" in the ETO, a number of remanufactured jobs were shipped there in 1945 on an emergency basis to make up for losses suffered during the Battle of the Bulge.

The 20th Armored Division was the last US armored division deployed to the ETO, arriving in France on 17 February, 1945. Previous armored divisions had been issued tanks when they arrived in theater, however the 20th were instructed to bring their vehicles with them from the States. Oddly, for this late stage of the war, the vast majority of their tanks were not the army’s preferred Ford GAA powered M4A3s, but rather Continental radial engined M4s & M4A1s, many of these being older variants that had been remanufactured. The two tanks seen here can be identified as small hatch Composites by the ventilator (1) located on the shoulders of the tank’s hull, and we point out to readers the distinctive twin drain holes in the ventilator (2). On the left we see Pedro of the 27th Tank Battalion, while on the right Cpl. Dale Ellis, the gunner of Petunia II, stands next to his tank of the 2nd Platoon, B Company, 27th Tank Battalion. The original Petunia is recorded as having been knocked out by a German mine and was presumably one of the 17 medium tanks lost by the 20th in its 8 days of combat. Most likely both of these tanks were made with D50878 turrets with the "patches" (3) and welded up pistol ports (4). Both have stowage modifications commonly seen in the 20th Armored Division, such as field installed turret bustle baskets, as well as extended fenders with the sand shields fitted upside-down, creating stowage for jerry cans and machine gun ammo. (Left side photo: author’s collection; right side photo courtesy of Gary Ellis).

One of the deficiencies of the original Sherman design was the hazardously small size of the drivers' hatches. In February 1943, larger hatch dimensions were submitted, but it was found that "increased size not possible of application to present hull design." Development work was begun to reconfigure the front of the Sherman to accommodate larger hatches. The new hatches were to be oval shaped and approximately 24 inches long and 19 inches wide. In comparison, the small drivers'' hatches of the original design were about 21 inches long and 16 inches wide. Chrysler's cast front concept was used, and in May, the new casting was attached to SN 30263, an April 1943 production Sherman pulled off the line at Pullman Standard. This project was part of the "ultimate" redesign of the Sherman, which also included the introduction of a new 76mm turret as can be seen above, although the turret shown here was characterized as "not according to print." By June, the Ordnance Department determined that the "Chrysler front end" was an acceptable solution and approved of making all subsequent welded hull Shermans as large hatch Composites. However, in that same month, Fisher Body submitted an alternate large hatch design that featured a single 2 1/2-inch glacis plate that was found to be ballistically superior. As a result, the cast front concept was abandoned except at Chrysler which had already made commitments and started production.

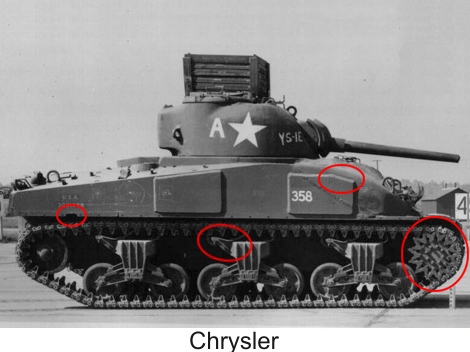

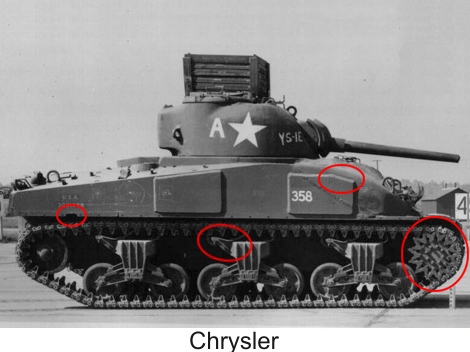

The M4 Composites that began to roll off the lines in September 1943 were the first "large hatch" Shermans of any type. Improvements were added as they became available. Most of them appear to have been equipped with the new "upturned" return roller arms (circled). In November, Chrysler transitioned to the new high bustle D78461 turret that added a loader's hatch and reintroduced the pistol port. This M4 is currently preserved in a private collection in the US. While the hand crank may be a reproduction, it is appropriate, since Chrysler appears to have introduced the simplified one-piece design. Photos courtesy of Mark Holloway.

Chrysler started M4A4 production using side armor plates that had nicely beveled top edges (left). In July, 1943, the company transitioned to the use of square cut side armor plates, a practice already employed by most of the other builders. It is thought that, from August, 1943 to the end of production in June, 1945, all Chrysler Shermans, including the M4 Composites, were built with square cut side armor plates. Our example on the right, shows the Firefly Composite in Klein-Willebroek, Belgium. Modelers might note that on M4 Composites and welded hull M4s, the air scoops (1) are seen to sit ON TOP of the sponson plate, whereas the holes on cast hull Shermans were machined out in such a way that the scoops were flush mounted (inset).

At the outset of production, Chrysler M4s were equipped with the "original design" exhaust deflector (above left, but not a Composite). This had been added to M4 and M4A1 models starting in the Spring of 1943. The Barber-Colman Increased Air Flow System became available in late 1943, and featured an improved exhaust deflector (1), along with "pyramid turning vanes" (inset) over the air intake on the engine deck. The "Freeze Date" on this item at Chrysler was Jan. 1, 1944, which, along with a few period photos, suggests that it was installed on some of the final Composites built in late 1943/early 1944.

It would appear that Chrysler was supplied exclusively with the "square" type of air cleaners. Surviving examples have been noted with an identification and instruction plate from the "Vortox Mfg. Co. Claremont, Ca. USA". The rear hull was constructed of armor plate with an angled transition piece joining to the the belly plate (outlined in red). Trailer towing pintles were standard on the Sherman series by the time Chrysler began M4 production, but they don't appear to have been factory installed on any of their Composites. Chrysler was directed to install the pintles on M4A4s starting in April 1943, but it was found that they bent up in service, making it impossible to open the engine access doors. Consequently, "It was immediately burnt off as many new tanks M4A4 as possible," and further installation was suspended. At the changeover to M4 production, it is likely that Chrysler had trouble finding a supplier for the pintles, so that the Government gave them a temporary "pass." In any case, in period photos showing only the rear, an M4 without a towing pintle is likely to be a Chrysler built Composite. The M4 Composite at the RAAC Museum, Puckapunyal, is shown in the photo on the right and is SN 59427, indicating December 1943 acceptance. We consider this tank to be a valuable reference as appears to have been shipped to Australia "as built" and only slightly modified during the course of its service. Note the fittings (circled) for the Barber-Colman exhaust deflector. For future reference, we would observe that it does not show evidence of ever having been installed with a blanket roll rack.

Midway through their M3 Lee program, Chrysler designed and introduced the pressed metal type of bogie wheel. They used them throughout production on their VVSS equipped Shermans. Their distinctive drive sprocket (right) was also employed throughout, including HVSS production.

The front contours of the large hatch M4A1(76) were very similar to the Composite's. However, the M4A1(76) was equipped with an additional mushroom type ventilator next to the bow gunner's hatch (left) whereas this area was blanked off on the Composites (right) and could serve as an antenna location for a command tank.

M4 Composites were, and still are, often mistaken for M4A1s, particularly in head on photos such as the one on the left above. If one can see it, the little "nubbin" (asterisked) in the center of the glacis is a sure indication of a Composite. Remanufactured tanks can be a challenge when trying to determine the "as built" appearance. It was noted that, 98% of the time, power trains did not require replacement, but our example had its original replaced with one featuring a three-piece differential housing. The tank was also retrofitted with the E9 track modification, the modified M34 gun mount with "wing piece," commanders' vision cupola and the late armored housing for the gunner's periscope.

This Signal Corps photo is dated 22 July 1944 with the location given as Saipan. The caption reads, "This tank crew used 2″ bomb throwers for protection to escape from enemy territory during the battle for the island. L to R: Pvt. Michael Wietman, Brooklyn; Pfc. Earl E. Holman, Nashville, Tenn.; Lt. Jack P. Lansford, Athens, Tenn.; and Cpl. John A. Armstrong, Long Beach, Calif." Cpl. Armstrong is seen holding the 2-inch smoke mortar that we assume he has removed from the turret. In his right hand is one of the finned smoke bombs. While the caption provides no unit identification, Lt. Lansford is listed in the records of the 762nd Tank Battalion as commander of the 1st Platoon of B Company. The company was equipped with M4 Composites and was the only Medium Tank Company of the 762nd that fought on Saipan. While not much else is visible, Lt. Lansford is standing inside the loader's hatch, so we might infer that it is a high bustle D78461 turret, introduced at Chrysler in November 1943. The "Speed Number" is only partially visible on the right front of the turret; we suspect Lt. Lansford's tank was "28." The smoke mortar, a standard feature on the M4 Composite, was not popular with US crews who found it to be "in the way" inside the cramped turret (inset). Most preferred to fire smoke from the 75mm gun. When Japanese infantry "swarmed" buttoned up Shermans, it was noted that they would try to drop grenades or other explosives down the smoke mortar barrel. The Marines reported that they fashioned wooden plugs to prevent this. As a result of the negative feedback, in January 1945, the Ordnance Department eliminated the smoke mortar from the Sherman design. In any case, if the smoke mortar was actually used in battle by Lt. Lansford's crew, it might have been on 7 July as B Company supported the 105th Infantry Regiment of the 27th ID when the Japanese broke through their lines in what is described as the "largest Banzai attack of the war." Over 4300 Japanese soldiers were reported killed during this "last gasp" attack.

Sand shields were mandated to be factory installed by the time Chrysler began production. This seems a waste, as most crews removed them. The little notch (item 1) seen on the sand shield attachment strip, might serve as a minor recognition feature, as it appears to have been exclusive to Chrysler's late production and remanufactured M4A4s, as well as their M4 Composites. Our example shows a POA-CWS-H1 Flamethrower Sherman of the 713th Tank Bn on Okinawa, June 1945. A Ronson flame gun replaced the main armament, and was "hidden" inside the 75mm gun tube. Note the overflow pipe emerging from the turret splash (item 2) - a Flamethrower Sherman recognition feature.

The engine decks were in the typical pre 1944 M4 / M4A1 configuration, where each of the four main fuel tanks had its own filler nozzle. However, the Composites' engine deck lift handles (circled in red) were oriented front to back rather than side to side. The pioneer tools on our example are mounted in their "initial" positions. "Tokyo or Bust" of the 44th Tank Battalion was photographed in action near Manila on March 10 1945.

M4 Composites were produced at the time when Shermans were most needed overseas for the massive counter offensives planned for Europe and the Pacific. The majority of them appear to have been sent to the US Army in the Pacific Theater of Operations. The US employed them in much smaller numbers in the European Theater. At present, we haven't been able to find any photos of their use in US service in the Mediterranean Theater. The Signal Corps photo above was reported to have been take during a training exercise in the British Isles on 26 April 1944. The caption identifies the tank commander as Sgt. George D. Vinyard of Poplar Bluff, Missouri, but does not name his unit. The tactical markings (1) were censored out except for "C[ompany]-10" (2). "Find a Grave" has it that SSgt. Vinyard died at age 26 on March 26, 1945. He is buried at Jefferson Barracks National Cemetery in St. Louis, Missouri, and "69 Tank Bn, 6 Armd Div, World War II" is engraved on his headstone. Rest in peace, SSgt. Vinyard. As for the tank, USA 30100929 would have been accepted in October 1943. It can be seen to have a "no pistol port" turret, and the "original design" exhaust deflector. The tools on the upper rear hull plate reflect the "initial" configuration. About a month later, the sledgehammer and wrench were relocated to the rearmost section of the engine deck. Note the absence of tool or fittings on the left rear sponson. From the standpoint of this piece, we would note that period photos suggest that the 6th Armored Division was equipped with a fair number of M4 Composites (as a subtype) after it arrived in the UK in February 1944.

This Signal Corps photo is dated 14 April 1945 and captioned, "With the (148th Inf. Regt., 37th Div., Monglo, Luzon, P.I.) Mine sweepers are shown moving ahead of the tanks to check for land mines, etc., along road to (Baguio)." [It is assumed that the units and locations were put in parentheses for possible censorship.] Monglo is a village less than 10 miles northwest of the City of Baguio, the headquarters of General Tomoyuki Yamashita's Fourteenth Area Army. The caption does not identify the tank's unit, but the "triangle inside a circle" symbol (circled) appears in some other SC photos where the unit is identified as the 775th Tank Battalion. The "Unit History" of the 775th that we have available is somewhat terse, but report that in April, B Company, "less the 1st platoon...were attached to the 37th Infantry Division to move on Baguio." The history states that on 24 April, "tanks and crews from this Battalion were the first American troops to enter BAGUIO." Regarding the tank, blanket roll racks (1) were standard equipment on the "ultimate design" Shermans. As yet, it can't be confirmed if the racks were ever factory installed on Composites. This modification was charged to Tank Depots starting in late December 1943, however, the modification kit also included parts for the AA Machine Gun stowage on the turret bustle, which is not present on this unit. It is thought that the sledgehammer and wrench were relocated to the rearmost section of the engine deck as seen here, with, or in anticipation of, the introduction of the blanket roll rack. Another item of interest is the "quick release towing shackle with handle" (2). These had been installed on the front from the outset, while the rear continued in the original Sherman configuration. The quick release required double towing lugs; the doubles show up on the rear of only a small number of period photos of Chrysler Composites, but on no surviving examples that we have encountered so far. Note that this tank can be seen with a fitting (3) on the engine access door that held the Barber-Colman type exhaust deflector. As mentioned previously, the "Freeze Date" [that is, "No tank without this item accepted after..."] at Chrysler is listed as 1/1/44. Available evidence suggests that it was installed on some of the final Composites built in late 1943/early 1944.

Meanwhile, to the east of Baguio, the 1st Platoon of B Company was attached to the 128th Infantry Regiment, 32nd Infantry Division in late March 1945. The combat team was ordered to push its way up a narrow path through the Caraballo Mountains known as the Villa Verde Trail. Salacsac Pass No. 2 was a particular chokepoint, and elements of the 32nd ID fought there nearly to exhaustion from 5 March through 17 April before the pass was cleared. The photo above is dated 3 April 1945, and captioned in part, "CO of (1st Plat, Co B, 775th Tank Bn), Lt. Jack Beltz personally guides one of his tanks around a sharp curve high in the (Villa Verde Trail, Luzon)." As mentioned, the "Unit History" of the 775th Tank Battalion is very terse. Its description of the activities of the 1st Platoon of B Company: "The platoon spent nearly two months in the mountain with their tanks accomplishing unbelievable tasks in climbing 60 degree slopes and building roads. This platoon fought along the Villa Verde Trail until junction was made with the 25th Division at Santa Fe [ca. 28 May 1945]." We haven't been able to determine the composition of the 1st Platoon, but, in general, at full strength a platoon consisted of 4 or 5 tanks. The mention of "building roads" would suggest that perhaps the 1st Platoon may have had a dozer Sherman. In any case, the full photo provides a dramatic view of the nature of the precipitous terrain, but we have cropped it in order to focus on the tank, which appears to have "B-3" (1) painted on the driver's side of the differential housing. A four-leaf clover type symbol (2) can be seen painted on the rear with the number "3" in the top left leaf. Although it's not totally clear, close examination of the photo suggests that the tank may be named "Battle Baby" (3). Photos of the 775's M4s consistently show them with a spare road wheel (4) mounted on the front, and 5 spare track links (5) mounted on each side of the turret.

This photo is also dated 3 April 1945 and shows the same M4 Composite judging by the identical arrangement of the crew's "stuff." The caption reads, "US tank climbs a hill which is stated to have a grade not less than 60 [degrees] on the (Villa Verde Trail, Luzon, PI). The tank was used to draw enemy fire and thus locate their positions. The hill was 4700 feet above sea level, the highest a tank has been in SWPA [Southwest Pacific Area]." We have not cropped the photo so that readers can see the incredible vista. Note the "triangle inside a circle" symbol painted on the differential housing on the bow gunner's side (inset). There appears to be a shotgun laying across the feet of the gun travel lock. In a post combat Q & A, it was noted that the 775th did not use the .50 caliber anti-aircraft machine gun provided with their Shermans. In fact, they removed them and put them in storage. This enabled the crews to carry more .30 caliber ammunition since they found the .30 caliber machine guns more useful due to their higher rate of fire. The second inset is another photo of the tank taken from above, "showing how far the tank would drop if it slipped off the trail. The tank did slip on the soft shoulder and had to be pulled back by another tank." So, we know that there were at least two tanks in the platoon. The overhead view shows that this M4 had a low bustle turret without a loader's hatch.

In 2023 Jim Goetz visited an M4 Composite that appears to have been a casualty of the Battle of the Villa Verde Trail. It sits at the Mangili Tindaan Historical Nature Park near Salacsac Pass No. 2 on a peak that the locals call "Tangke." Jim found the serial number 59284 stamped into the hull wall next to the dataplate frame (inset 1) as well as on the rear towing lugs, indicating that it was accepted in December 1943, and would have been assigned USA 3099450 according to our calculations. There is no evidence that the tank was penetrated, but there are indications that it burned. Jim interviewed the proprietor who showed him copies of the same Signal Corps photos that we have featured in the two previous captions. She seemed to be under the impression that "her" tank is B-3. However, SN 59284 has the later D78461 high bustle turret with loader's hatch and pistol port, whereas B-3 can be seen to have had a low bustle turret without a loader's hatch. The proprietor mentioned that the brother of a Japanese soldier visited the site in 2007. The soldier reportedly attacked the tank with a gasoline bomb, killing all five of the crew. It certainly seems possible that SN 59284 was destroyed by fire and left in place on top of the mountain after being stripped of useable parts. Unfortunately, the "Unit History" of the 775th TB does not go into any detail regarding their losses of men and tanks. The Medium Companies listed 11 men Killed in Action with 8 of those in B Company. Tank losses are reported as 4 totally destroyed, with 34 "damaged and returned to service." Whatever happened to SN 59284 certainly warrants a deeper dive into the history, if any readers would be in the position to assist. Regarding the tank, Jim could not discern any tactical markings on the differential housing that might aid in identifying the unit or tank number. We would judge that the "nubbin" (circled) once held a threaded rod for a spare road wheel, typically seen on the 775th's Shermans.

In order to focus on the tank, we have cropped this Signal Corps photo of "Brassierless Baby," another B Company, 775th TB M4. This Sherman was filmed on the outskirts of Baguio, 27 April 1945, so likely would have been part of B Company, "less the 1st platoon...attached to the 37th Infantry Division to move on Baguio." What caught our eye is that the gun travel lock (1) has been broken off in a manner similar to what is seen on SN 59284 in the previous photo. This made us wonder if they could be the same tank, but we had been able to examine the original Signal Corps print with a magnifying glass and got a partial read of the USA Registration Number of "303147X." As mentioned, SN 59284 would have been assigned USA 3099450 according to our calculations, so no match there. We hope to unearth more "who, what, where, when" details about the destruction of SN 59284, but suspect it had already been KO'd when the photo of "Brassierless Baby" was taken on 27 April 1945. "BB" can be seen with the "triangle inside a circle" symbol (2) as well as some sort of tactical symbol that we take to be a palm frond (3) with the number "4" painted on it. Also visible is the threaded rod (4) that held the spare road wheel. The crew have named the 75mm gun "Big Mike."

In this view of SN 59284, it can be seen that there is no rubber on the road wheels. The rubber often burned off the wheels during catastrophic tank fires. On the other hand, the rubber could have delaminated over the years or could have been salvaged like so many other items from this tank including the engine and engine decks. The number "775" (outlined) is faintly visible, although photos suggest that a "triangle inside a circle" was used to identify the battalion in lieu of "775 delta." Various weld scars including those from the "Upper Attaching Angle" (1) indicate that this tank had once been installed with the deep water fording modification. Also, evident are hinge bits and weld scars (2) suggesting that the vehicle once had a blanket roll rack. The "W inside a C" (3) casting mark on the turret bustle indicates that this D78461 turret was produced by Continental-Wheeling, one of Chrysler's major turret suppliers. Their turrets appear to have had the lifting rings mounted a few inches higher than observed on some other D78461 castings.

Jim visited another M4 Composite at the Philippine Military Academy in Baguio. He recorded the Serial Number 59440 from the rear tow lugs, indicating that it was accepted in December 1943, and would have been assigned USA 3031303. This tank was modified at some point by the addition of the "commander's vision cupola" (1). This Modification Work Order was released in September 1944, but it seems to have been greatly delayed, since it doesn't appear to have been available for field retrofit until very late in the war. The kit included a pedestal mount (2) for the .50 caliber anti-aircraft machine gun along with a traveling clip (inset) for the gun's barrel, although there is no weld scar evidence that the clip was ever installed on this example. Note the flush mounting of the smoke mortar barrel (3) typical of Chrysler M4 Composites and the fittings for the spot and signal light (4). These items were ordered to be removed in early 1945. We consider surviving Shermans that still have them intact, such as 59440, to be in "WW II configuration."

Most of the Shermans that took part in the Pacific Campaigns were waterproofed and installed with deep water fording stacks, since it was expected that they would have to wade ashore during the amphibious assaults on the various islands. In this view, one can see the vestiges of the sheet metal pieces that would have enclosed the lower rear hull in order to protect the air cleaners and engine access doors from water damage. The inset at the top left is from the "Preparation of Ordnance Materiel for Deep Water Fording" manual and shows the assembly of some of these parts. The Composite was built with a notched in upper rear hull plate. It can be seen how a rectangular "Upper Attaching Angle" was welded on (1) as part of the process. This piece covered over the indent so that the lower edge ran straight across. The inset at the top right shows the complete installation of the stacks on USA 3031428, built about 125 units after our subject. As soon as possible after landing, "De-waterproofing Stations" were established so that the tanks could have the wading gear and sealants removed permitting them to run cooler and fight more efficiently. Period photos show that in some cases, the "Upper Attaching Angle" was not removed so that the lower edge of the upper rear hull plate appears to run straight across like a Second Generation M4. Note that 59440 has the fittings (2) on the engine access doors that held the Barber-Colman type exhaust deflector. There are no visible weld scars that would indicate that this unit had ever been installed with a blanket roll rack. This D78461 turret was cast by Continental-Hubbard (H inside a C). Note the lower position of the turret lifting rings compared with the Continental-Wheeling turret on SN 59284.

"Another Dinah" USA 3099241 (above left) of the 763rd Tank Battalion was photographed on Okinawa in April 1945. By the Registration Number, this tank would have been about the 1026th Chrysler M4 and would have been accepted in November 1943. Our "counting heads" method suggests that this was about the introduction point of the high bustle D78461 turret, i.e., about 1000 units would have been made with "no pistol port" D50878 turrets. In general, the introduction of changes was "with obsolescence." As the new parts began to enter production, the manufacturer continued to use the old parts until the supply was exhausted. So, for instance, another A Co. 763rd M4, USA 3099276 (above right), built 35 units later, is installed with the earlier, low bustle turret. USA 3099276 can be seen as an example where the "Upper Attaching Angle" (1) was not removed when the tank was de-waterproofed, so that the lower edge of the upper rear hull plate appears to run straight across.

This well-known Marine Corps photo is undated and is captioned in part, "The Crews Were Saved - enemy anti-tank guns accounted for these two VS [sic...US] tanks burning near Yigo, Guam..." The Battle of Yigo was the last in the Guam Campaign. The 706th Tank Battalion's After Action Report states that Company C lost two tanks and suffered 6 casualties on 7 August 1944. Based on the same "blotch" patterns as seen in the previous photo, the Composite in the foreground is Cupid. The paint of "Speed Number" 751 on the turret (1) is burning away in the intense fire. A pair of track links (2) can be observed on the left front fender. The M4 in the background appears to be named "Champagne" (3) and "C-13" (4) can be made out on the right side of the upper rear hull plate. Like Cupid, Champagne has a no pistol port turret and pioneer tools in the "initial" configuration. Note the remains of wading stack fittings (5). We could not get a good read of Champagne's Registration Number, but based on her appearance, an educated guess would be USA 3099056. Like SN 59284 on the Villa Verde Trail, these tanks were left in place as sort of informal monuments. Cupid was photographed as late as 1954 but seems to have "disappeared" sometime after that. Champagne without turret was photographed as late as "circa 1965" and then it too was gone. We can only assume they were scrapped since neither is in the collection of Guam's Pacific War Museum.

The photo above was taken in late July 1945 at the Manila Supply Depot. It shows a few Composites along with some "new" remanufactured M4A1(75)s. "Bloodthirsty" appears to be a combat veteran Sherman of the 44th Tank Battalion. The Registration Number is USA 30100748, indicating September 1943 acceptance. We've pointed out the "cast in thickened cheek," typical of D50878 "no pistol port" turrets as well as the later D78461s. The commander's cupola has the positive hatch lock mechanisms that were added to Shermans starting in the Spring of 1943. These were replaced by "turret hatch D69993 with equilabrator," which can be seen on the M4 in the foreground. The improved hatches had integral springs on the hinges, and appear to have entered the production lines at Chrysler in November.

On the left, an M4 Sherman named "Hot Box" is shown as it "leaves LSM in unloading test into 6 feet of water off Los Negros Island." The water level seems to be more like 6 inches, so this appears to be a "dry" landing. Or, judging by the rearward focus of the men on the tank, we suspect it is actually backing into the LSM. The caption of the photo on the right specifically identifies "Hot Box" as "Co A, 44th Tank Bn." Period photos indicate that Company A's Shermans were decorated with a wolf's head cartoon (1). The single horizontal line seen here (2) is thought to have been a tactical marking that denoted the first platoon, while "Bloodthirsty" shown in the previous caption with 3 lines suggests it was in the third platoon of Company A. In the 44th TB, tank names obviously did not have to begin with the letter of the Company as was a common practice with US tank units. An LSM [Landing Ship Medium] could carry 5 medium tanks and a few tactical vehicles on its deck. The caption of the right-side photo is dated 8 October 1944 and it is thought that it shows the 5 M4 Composites that made up the 1st Platoon of Company A preparing to load aboard LSM 258 for Operation King II, the invasion of Leyte Island in the Philippines. Most of the Tank Battalions in the Pacific Theater of Operations had wading trunks installed on their tanks before an amphibious landing. However, photos of the Shermans of Companies A and B of the 44th do not show evidence of having been equipped with deep water fording kits. Probably the most that was done was that the belly plates and rear engine access doors were sealed for shallow wading of 2 or 3 feet. Of interest is that "Hot Box" is one of the few large hatch Composites observed with an earlier low bustle D50878 turret with the "thin spot" patch (3). Presumably, the pistol port was welded up, but of course it can't be seen in these photos. Company A landed at Leyte on "A" Day, 20 October 1944, and had its combat debut on "A plus 6." It supported elements of the 1st Cavalry, 24th Infantry and 32nd Infantry Divisions from 26 October through 15 December. Company A is reported to have "inflicted heavy casualties, including enemy infantry, armor and artillery. Their own casualties were five men wounded in action...one man killed in action (acting company commander), one tank destroyed by enemy action, and one tank destroyed by own forces to prevent falling into enemy hands." During WW II, LSM 258 is reported to have survived "dozens of kamikaze attacks and five major beachhead invasions."

Another view of the Manila Supply Depot which shows some of the remanufactured Shermans. Note the various later features such as all round vision cupolas, gunner’s armored periscope covers, commander's vane sights, and .50 cal MG stowage on the turret bustle, typical of remanufactured tanks. Despite the updates, these tanks were obsolete in the sense that they would not have been wanted for the planned Invasion of Japan, which required that all of the Shermans be M4A3 models with HVSS. We have included this photo since the third tank from the front is a rare small hatch Composite, as evidenced by the ventilator on the hull shoulder of the cast front end. Also of interest, is that the sixth tank in can be seen with a "hole" (arrow) in the drive sprocket, indicative of the E9 suspension modification.

The British/Commonwealth received over 2000 M4(75)s as Lend Lease. These were allocated to them from September 1943 through May 1944. While the US made no distinction between welded hull and composite hull M4s, the British did, and labeled them “Sherman I” and “Sherman I Hybrid” respectively. Only a few period photos show “Sherman I Hybrid” 75mm gun tanks in Commonwealth service in both the ETO and MTO. The Imperial War Museum photo above is dated 29 June 1944, and captioned "Troops dig in beside a Sherman tank nr. Rauray to consolidate the ground they have gained. Troops of 49th Div. Rauray between Tilly and Caen." It is thought that the Sherman would have served with one of the units of the 8th Armoured Brigade, who were in support of the 49th Infantry Division during the heavy fighting in the Caen sector at the time. The British War Department Number is T-263137, and the tank's turret can be seen as a low bustle D50878 with no pistol port, the most prevalent turret type used on the M4 Composite. Courtesy of the Imperial War Museum, Photo B6225.

Wartime photos of "Sherman Ic Hybrids," the British designation for Firefly conversions based on the M4 Composite, are far more common. The January to June 1945 “Half Yearly Report on the Progress of the Royal Armoured Corps” states that “3,260 [Fireflies were] ordered and 2,139 produced by 31st May 1945.” Thus, it would appear that total Firefly production amounted to 2139, since “No further conversions will be carried out as there is no requirement for this vehicle in the Far East.” The production documents refer to the conversions generically as “Sherman 17 pdr.” Unfortunately, there is no breakdown of the model types, such as Sherman I (M4), Sherman I Hybrid (M4 Composite) or Sherman V (M4A4). In period photos, M4 Composite and M4A4 based Fireflies seem to be represented in about roughly equal numbers, while all welded hull M4 based Fireflies appear less frequently. The M4A1 was not acceptable for Firefly conversion because the rounded contours of the cast hull could not accommodate the arrangement of the Firefly's interior stowage. Despite the cast front end, this was obviously not an issue with the Composites, and one of the converting firms mentioned that those with the D78461 turrets saved them a lot of time and effort since they already had loader's hatches. Above shows such a turret on a Sherman Ic Hybrid of the Sherwood Rangers, 8th Armoured Brigade photographed in Geldern, Germany, 6 March, 1945. Courtesy of the Imperial War Museum, Photo B 15230.

In October 1948, VVSS models of the M4, 75/105mm, and M4A1, 75mm were classified as "Limited Standard" with the note that they were "unsuitable for meeting U.S. requirements but satisfactory for meeting foreign-aid requirements." Even so, a few such types were sent from Japan to Korea in the early days of the Korean Conflict. The above shows USA 3099372, a December 1943 Chrysler M4 Composite photographed at Masan in September 1950. This tank, which we suspect served with the 89th Medium Tank Battalion shows a number of the stowage modifications typical of the Tokyo Ordnance Depot, such as the spare bogie wheel on the turret and spare drive sprockets and track links on the hull sides. The Tokyo OD may have refurbished the tank and fitted it with an M1 Dozer Blade, an item that was in high demand in Korea. It is thought that the few non M4A3 HVSS Shermans seen in photos during the Korean War, would have been replaced eventually, so 3099372 was most likely one of the last M4 Composites to serve with the US Army.

Since VVSS models of the M4 with 75mm were considered "satisfactory for meeting foreign-aid requirements," it stands to reason that a few M4 Composites were distributed to Allied countries as part of the Mutual Defense Assistance Program [MDAP]. Brazil was reported to have been shipped 22 "Tank, Medium, 75mm Gun, M4 Series" up to 31 January 1954. Period photos show that some of these were M4 Composites. The image above is dated 1957 and shows "Brazilian M4 Sherman tanks on maneuvers in Rio de Janeiro." The Brazilian MDAP M4s seen in this and other photos are characterized by certain upgrades, the most obvious of which was the commander's vision cupola (1). These particular tanks were also retrofitted with armored first aid boxes (2). The T-shaped towing shackles (3) appear to have been introduced in Sherman production in October 1944, well after Composite production had ended in January 1944. So, we would consider them to be retrofits. The lead tank is seen with extended end connectors (4). These had gone out of production in 1945 and would not have been available for universal installation to VVSS Shermans during the remanufacturing/reconditioning programs of the late 1940s/early 1950s. Thus, EECs appear somewhat randomly on such Shermans. We can't help but wonder if some of these tanks had not been shipped back from dumps in the Pacific after the end of World War II. Many of the Brazilian MDAP M4s are noted to have a rather large "comb" device (5) affixed to the differential housing below the bow machine gun.

More than one of the surviving Brazilian Composites has been noted to have had the USA Registration Number stamped into the right front of the E6289 casting as pointed out above. In this case, it is 3031184. We suspect this may have been done by the firm Brown and Root of Houston when they reconditioned and/or processed these tanks for MDAP issue. Our correspondent recorded the Serial Number from one of the rear towing lugs as "59321" (inset). Thus, this M4 on display at the Military Academy in Resende, Brazil, has what we rarely find on a surviving Sherman - one with a known good Serial and Registration Number together. By our reckoning, SN 59231/USA 3031184 would have been accepted in December 1943, and would have been the first unit built on Chrysler's final M4 Composite Production Order T-10888. (The Order was cut back to 398 M4s, and the rest of the Production Order was converted over to the manufacture of 853 MA3(76)s.) Just visible is the large "comb" device (circled) affixed to the differential housing below the bow machine gun. Photos and information courtesy of Colonel Renato Rocha.

Pierre-Olivier encountered another M4 Composite with the "big comb" (top inset) at a restoration facility in France. We take the presence of this particular type of comb to be an indication of a Sherman reconditioned and processed for MDAP shipment in the early 1950s. Another indication is the stamping of the USA Registration Number on the right front. In this instance, it is 3099392 (bottom inset) denoting December 1943 production. As mentioned, our guess is that this stamping (plus the "big comb") was done by Brown and Root. Some MDAP countries were supplied with "Bulldozer, Tank, Mounting" kits of various types. The fittings seen here appear to correspond to the M1 series dozer, widely used during WW II. The oddest thing about this M4 is that it was converted to 105 howitzer configuration. While this tank's original turret was very likely a high bustle D78461, it was obviously exchanged for another D78461 turret of much later production as evidenced by the “bump out” (1) added to better accommodate the commander's vision cupola and noted on turrets cast from November 1944 onward. The turret is missing the 105 gun mount, but it can be seen with a variation of the late style of 105 dust cover fittings (2). Present, but unseen here, is the additional ventilator on the turret "roof" exclusive to 105mm Shermans. Finally, this tank was retrofitted with a "tall" gun travel lock (3) used on 76mm and 105mm Shermans. Note the post war 1-piece clasp (4). The weld scars (5) from the tanks' original "short" 75mm gun travel lock are clearly visible.

With Shermans, we never know when or where we might come across some heretofore "hidden" object. Pierre-Olivier was able to look around inside USA 3099392, and it was the first time he/we had encountered a 105mm turret that had the power traverse mechanism “shoehorned in in the rear." From left to right is the "turret traversing hydraulic pump" (1), the "turret traversing electric motor" (2) and the "hydraulic oil reservoir" (3). The decision to omit power traverse on the 105 Sherman design was the subject of many complaints from the using arms. Had it been installed from the start, 105 mm Shermans may have been used more aggressively, and merited the name “assault gun.” The Ordnance Department agreed to add it, and power traverse was finally introduced into production around mid-March 1945, too late for use during WW II. It had to be “shoehorned in in the rear" as seen here, and we can’t help but think that the addition of these components only exacerbated the already cramped crew conditions inside the small turret. Other objects seen here include the radio shelf (4), part of the ducting for the rear ventilator (5), and the support for the commander’s seat (6).

Someone expended a great deal of effort converting this M4 to 105mm configuration, and the conversion appears to have been done with accuracy. That is to say that 105 ammunition bins were retrofitted to replace the original 75 mm bins, and to our eyes, they appear to have been installed "by the book." The 105 Shermans were the only Second-Generation models that did NOT include wet stowage for the 66 rounds carried. Also, unlike wet stowage Shermans, not all of the rounds were repositioned off of the sponsons, mainly to the floor of the hull (1). The size of the rounds more or less "forced" 21 of them to be stored in a pair of bins on the right-side sponson. The forward bin (2) held 9 rounds, while the rear bin (3) held 12. We would note that no provision was made for external appliqué plates to further protect the sponson stowed ammo as on other dry stowage Shermans. But, of course, as an M4 Composite, 3099392 was built with the applique plates factory installed. This tank was reported to have been acquired from Israel, and at first, we were thinking the modifications might have been done there, since they were quite adept at changing and upgrading Shermans to suit their needs.

On a subsequent visit, the staff showed P-O the dataplate from this tank. It is one of those generic plates noted on some post war remanufactured Shermans. The only thing stamped into the blank spaces was the Serial Number 59226, which is an exact mathematical match to the Registration Number 3099392 found stamped on the right front of the hull. There is nothing stamped to indicate the manufacturer or the production date and no inspector's initials. Of greatest interest is that the nomenclature "preprinted" across the top of the plate is "TANK, MEDIUM, M4 105 MM HOWITZER," which suggests that this Composite was purposefully converted to M4(105) in the US. That strikes us as odd since 105mm Shermans were over produced during WW II, and there were plenty of them available postwar for distribution as MDAP. For instance, there were 2695 Sherman 105s reported in the US inventory in 1948, including 776 M4(105)s. On the other hand, many uses were found for these tanks. Some, perhaps around 400, were distributed as straight 105mm Shermans. The hulls and turrets of others were used in the M4A1E6 and M4A3E4 conversion programs. Counting heads suggests that over 1000 M4A3(105)s were converted to M74 Tank Recovery Vehicles. It is just hard to imagine that this conversion needed to be done to satisfy an MDAP 105mm requirement, but there it is. France was by far the largest MDAP recipient of "Tank, Medium, 105mm How, M4 Series" at 230 units, so perhaps the Israelis got this odd duck from them? In any case, we are told that this tank will be restored back to a WW II era M4 Composite with 75mm gun.

It might be appropriate here to observe that the Second Generation M4(105) pilot tank was built using a Composite hull, even though it had been decided that production 105s would be assembled using the welded “Fisher Front End,” since it had been found to be superior to the cast “Chrysler Front End” seen here. The pilot has survived and is on display at historic Ft. Wayne in Detroit, Michigan. The serial number, recorded from the rear tow lugs is 44272. That is an exact mathematical match to USA 30100506 which has been noted in period documents and photos of the test tank. SN 44272 would have been accepted in September 1943, overall, the 45th M4 Composite made at the Detroit Tank Arsenal, and possibly one of the first assembled with the E6289 front casting with large drivers' hatches, a major feature of Second Generation Shermans. Photo courtesy of Lorén and Paul Hannah.

The only other type of Sherman built in the Composite configuration was the M4A6. This was powered by a radial diesel that was even more massive than the multibank engine of the M4A4. Consequently, the M4A6 was assembled by marrying the large hatch cast front to the M4A4's longer hull. Although the initial contract called for 775 units, it was cut back to only 75, as the Government determined instead to increase production of Shermans powered by the Ford V8 engine. M4A6 production ran from October 1943 to February 1944. Serial and Registration Numbers assigned appear to have been Serial Number 43453/USA 3099687 through S/N 43527/USA 3099761. To date, no surviving examples have come to light.

Chrysler built Shermans have been observed to have the Tank's Ordnance Serial Number stamped into both of the rear towing lugs. Should any readers have the opportunity to examine a surviving M4 Composite, we would greatly appreciate a report.

Some Chrysler built M4 Composites have been seen to have the Serial Number stamped in the driver's compartment, about 6 inches (15 centimeters) to the left of the dataplate or dataplate frame.

Along with the tank's serial number, we try to record the data about the large hatch front casting - Part Number E6289. The casting information can be seen on the top of the hull, just behind the driver's hatch. Most of the examples examined have caster's logos indicating that they were produced by the American Steel Foundries East Chicago, Indiana plant as shown on the left above. These have been seen to have part serial numbers with an "A" prefix. A few others have been noted with ASF-Granite City, Illinois logos, with "B" prefix serial numbers. The photos show the highest A and B prefix serial numbers we have recorded A1481 and B651. To our way of thinking, these numbers suggest that at least 2132 of the E6289 casting were produced. Chrysler manufactured around 1700 large hatch Composites, both M4s and M4A6s. So, we have over 400 extra castings. Although the historical documentation is pretty "emphatic" that only Chrysler made Composite hull Shermans, a few surviving examples have revealed to us that the American Locomotive Company (ALCO) produced some as well, most likely using front castings that became excess after Chrysler's M4 and M4A6 contracts were terminated. This was somewhat unexpected since the incorporation of larger hatches was not stated to have applied to the companies that were leaving the Sherman program by the end of 1943: ALCO, Baldwin, Federal Machine, Ford, Lima, Pacific Car, and Pullman. At present, the "discovery" of surviving non-Chrysler Composites has been limited to ALCO, but one never knows.

Years ago, we corresponded with a gentleman in South Africa concerning the M4 Composite Firefly (Hybrid Ic) on display at the Museum of Military History in Johannesburg. He sent us a Xerox copy image of the dataplate (inset, top left) which showed that the tank had been "M'F'D BY AMERICAN LOCOMOTIVE COMPANY." The Firefly had an ALCO not Chrysler Serial Number - 40319. We didn't know what to make of this ALCO M4 Composite at the time, and asked our correspondent to see if he could find the Serial Number on the rear towing lugs in order to confirm that it matched the SN on the dataplate. However, it wasn't until 2020 when Pierre-Olivier visited the Museum that the Serial Number on the left tow was "revealed" as 40319 (inset, bottom left) the same as on the dataplate. This tank appears to have been part of a "consent to retransfer" approved by the US Lend Lease Administrator on 3 January 1947. War materiel from U.K Military Holdings in Italy was permitted to be provided and shipped to South Africa. The original agreement included 98 Shermans of various types and 24 M10 Gun Motor Carriages. SN 40319 can be seen with T-263727 painted on. We suspect that that is the original British War Department Number, since it is listed as a "Sherman M4 (1C) on a "Nominal Roll of Tractors and Tanks, 1 Special Service Bn, Potchefstroom, South Africa, 31 March 1948" provided by author William Marshall.

During a Sherman spotting tour in South America in November 2013, our peripatetic friend Jim Goetz examined a pair of M4 Composites that have Serial Numbers that were assigned to the final Production Order of the American Locomotive Co. These tanks are former British Firefly conversions that were purchased by Argentina from Commonwealth tank dumps in Belgium in the late 1940s. The Argentinians re-engined and up gunned many of their Shermans and labeled them "Repotenciados." Jim was not permitted to photograph the Composite and welded hull M4 on display in Asuncion, Paraguay, since they may have still been in service at the time, but he was able to look at the Composite and noted that the Serial Number was 40351. Jim recorded the Serial Number from the left rear tow lug of the one in Olavarria, Argentina (pictured above) as 40313. These findings enabled us to build up a little weight of evidence that the ALCO M4 Composite was actually a "thing."

Jim examined other South American M4 Composite Repotenciados that had Chrysler Serial Numbers. It is to be noted that, on the few ALCO all welded hull M4s we have examined, the serial numbers are stamped "one on top of the other," and only on the left rear tow lug. That is what Jim found on the ALCO built Composites, such as seen with 40351 above left. On the other hand, Chrysler serial number stampings have been noted to be oriented "side by side," and present on both rear tow lugs. The Chrysler orientation can be seen on the right above, from the Repotenciado on display in Cordoba, Argentina. Also of note is that the two Composites with ALCO serial numbers were seen to have double rear towing lugs, whereas the Chryslers had only one.

During his visit to South Africa in 2020, Pierre-Olivier "discovered" two more ALCO M4 Composite Fireflies. The one shown above is SN 40381 on display in Bethlehem. One would think that the South Africans would have chosen unused or low mileage tanks for their post war home defense forces, but this example is installed with extended end connectors, perhaps suggesting that it had been issued to a combat unit before the end of the war in Italy. Note the early configuration E8543 sharp nosed differential housing with cast in steps. We suspect that the storage bins at the rear of the hull and turret may have been retrofitted in Italy as the tank was processed for issue.

It is our theory that some or all of the 300 ALCO M4s manufactured from October to December 1943 on their last Production Order were large hatch Composites. Serial Numbers assigned to this P.O. ran from 40305 to 40604. Here we have SN 40554 on display in Bloemfontein. Of the six surviving examples know at present, this one has the highest serial number, while the Repotenciado in Olavarria, Argentina has the lowest at SN 40313. Here we have focused on the lower rear hull since it is typical of the three in South Africa, showing round Vortox Air Cleaners (1), double rear tow lugs (2), door stops (3) and fittings for the US trailer towing pintle (4). These items are not commonly seen on Chrysler built Composites. The engine access doors of M4 and M4A1 Shermans included a flange which was welded to the right-side door. For some reason, this flange is not present on the 3 surviving ALCO built Fireflies in South Africa, and there are no traces of weld scars on the right doors. (The ones in South America can't be counted since they had engine upgrades which changed the original configuration of the lower rear hull.) In any case, it seems possible that ALCO may not have welded the flange to the door on some of its late production M4s, but we can only reference these and 3 welded hull M4s at present.

Another item observed on the few known ALCO Composites, but not on Chryslers, is the protective splash around the fire extinguisher housing (circled).

Fireflies were also issued to Commonwealth armored units in the Mediterranean Theater of Operations. No doubt some would have been lost to “wastage” or “attrition,” but the “15 Army Group AFV Holdings as at 25th June, 1945” states that there were 225 “Sherman 17 pdr” in Italy and Greece. Demobilization would have been underway, but 173 were still listed “With Formations” at that time. Period photos show that Commonwealth troops in Italy received a number of Fireflies converted from M4 Composites. The Polish 4th (Skorpion) Armoured Regiment is reported to have been issued a dozen M4 based Fireflies in early 1945. One of the tanks, a Sherman Ic Hybrid named POWAB, was knocked out on April 19, 1945 near Bologna. This M4 Composite has a number of ALCO features, such as the rounded applique plate on the right front (1) and the "plain" sprocket (2). Note the step bracket (3), which appears to have been omitted by Chrysler with the introduction of the gun travel lock. ALCO produced its last Sherman in December 1943, and it is thought that they ended production with the low bustle, no pistol port turret, along with suspension units with "straight" return roller arms (4). Chrysler Composites have a "notch" in the rear section of the sand shield strip (5), while ALCOs do not. Photos courtesy of the Polish National Archives.

Lance Sergeant Michal Krzywoszanski was a fitter attached to the Regiment's Light Aid Detachment. He took a few photos of POWAB as he and his crew salvaged useable parts from the tank. As mentioned previously, the towing pintle became a standard feature on Shermans by the middle of 1943, although they don't appear to have been installed by Chrysler. ALCO began adding them in April 1943, and one can see the pintle's faceplate (1) in the left side photo. In the right side image, note how the ventilator on the turret drains to the front (inset). This appears to be consistent with ALCO Shermans, whereas with Chryslers, it consistently drains to the rear. Photos courtesy of Chris Wroblewski.

This photo of POWAB highlights a few other features not typically seen on Chrysler Composites - the 3-piece engine crank (1), and the round air cleaners (2). One can also see that this M4 has double rear towing lugs (3). Photo courtesy of the Polish National Archives.

HOME

Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

The Chrysler Corporation

manufactured M4(75)s featuring cast front ends joined to welded rear hulls. The

US Army did not create a new designation in order to distinguish them from

completely welded hull M4s; officially, all of them were "Tank, Medium,

M4, 75mm, Dry." In period documents, such as unit rosters and even some

Ordnance Dept. Test Reports, these were frequently misidentified as M4A1s. For

convenience, we will use the popular term "M4 Composite." The British

designated them as "Sherman I Hybrid." Chrysler produced 1676 M4

Composites from August 1943 through January 1944.

Production Order T-7903 : 580 tanks manufactured : Serial Number 44228 / USA 30100462 through S/N 44807 / USA 30101041 (August-December 1943)

Prototypes were often made using existing Shermans. In this case, Chrysler removed the original welded front section and retrofitted their new casting. Note the the absence of appliqué armor and gun travel lock, as well as the old style commander's blade sight, and the earlier one piece differential housing.

Production Order T-7903 : 580 tanks manufactured : Serial Number 44228 / USA 30100462 through S/N 44807 / USA 30101041 (August-December 1943)

Production Order

T-7281: 698 tanks

manufactured:

Serial

Number 58623 / USA 3098789 through S/N 59320 / USA 3099486

(November 1943 -

January 1944)

Production Order T-10888 : 398 tanks manufactured : Serial Number 59321 / USA 3031184 through S/N 59718 /

USA 3031581 (December 1943 - January 1944)

In addition, evidence from surviving examples has

recently come to light which confirms that the American Locomotive Co. also

manufactured some M4s with Composite hulls. So far, the data suggests that

some or all of the tanks of the last ALCO Production Order were built

as large hatch Composites.

Production Order

T-4305: 300 tanks

manufactured:

Serial

Number 40305 / USA 3072902 through S/N 40604 / USA 3073201

(October -

December 1943)

The original Sherman design included both cast and welded upper hulls.

In the rush to increase production, it was noted that cast hulls could

be manufactured cheaper and faster than welded hulls, with "a large

saving of welding rod and labor." However, in October 1942, it was

concluded that while conversion to all cast hulls would be advantageous,

it was not feasible under the current industrial conditions. That is,

the number of US foundries capable of pouring such large castings was

limited. In that same month, the Ordnance Department in conjunction with

the Chrysler Corporation, began design work on a cast front end that

offered a partial solution to the higher cost of the all welded upper

hull, since the front is where a good deal of the welding man-hours were

spent. Also, the front casting as shown above, was a fraction of the

size of a complete cast hull, so could be produced by smaller capacity

foundries.

Prototypes were often made using existing Shermans. In this case, Chrysler removed the original welded front section and retrofitted their new casting. Note the the absence of appliqué armor and gun travel lock, as well as the old style commander's blade sight, and the earlier one piece differential housing.

A "photo op" showing "The First [sic] Chrysler Built M4 Tank Shipped Aug 28th, 1943." This tank can be seen to be USA 30100471, so while it may have been the first one shipped, we believe 30100462 was the first one built. Many improvements and modifications were beginning to filter into the Sherman production lines by August, and a number of them can be seen on 30100471. Note the factory installation of applique armor, gun travel lock with the corresponding "late" siren position, late E8543 differential housing, and the recently introduced "no pistol port" turret. Some light-colored tape appears on the turret in the location of the 2-inch smoke mortar. Chrysler is reported to have begun factory installing this item on 15 October 1943. If accurate, the tape might suggest that the smoke mortar hole was machined out from the start in anticipation. Most Chrysler Composites were built with periscope guards and bogies with "upturned" return roller arms, whereas this early example lacks the guards and has straight return roller arms.

Here we have a small hatch M4 Composite (SN 44256, September 1943 acceptance) on display at the National Guard Armory in Trenton, Tennessee. It is one of only two known surviving examples. The other, SN 44255, is privately owned. The early front-end casting is similar in appearance to the small hatch M4A1 but includes a pair of ventilators by the drivers' hatches, such as were standard on welded hull M4s. The protrusion on the right front was used as an antenna bracket on the M4 and M4 Composite, whereas it housed a ventilator on the M4A1. 44256 was retrofitted with the E9 modification. The "no pistol port turret" is appropriate, but it is not original, as it was cast by Union Steel, which was not a supplier to Chrysler. No doubt the turret and E9 suspension along with the commander's vision cupola were added during a remanufacture in Spring 1945. The inset shows the casting marks in the middle of the glacis. While the part number is only partially visible as "E634X," period documents indicate that it was E6347. When appropriate, we try to "count heads" using such marks but there are only 2 survivors in this case. We can observe that both were cast by American Steel Foundries-Granite City (G in an octagon), and that their part serial numbers are B33 and B35. This suggests to us that ASF-G cast at least 35 E6347 front ends. Photo courtesy of Paul and Lorén Hannah.

At present, "counting heads" evidence suggests that only about 50 small hatch M4 Composites were produced. Consequently, there are very few period photos of them. Above shows the one with the highest Registration Number we can document - USA 30100510. This would have been accepted in September 1943, overall, the 49th M4 Composite produced at the Detroit Tank Arsenal. USA 30100510 was shipped to Aberdeen Proving Ground where it was installed with the Multiple Rocket Launcher T34, nicknamed "Calliope." The launcher was "capable of firing 60 4.5 inch rockets in a period of 30 seconds." The photo was taken in late 1943, and the front shot of this dramatic night scene was used on the cover page of APG's "Sketchbook," their WW II souvenir history, even though Aberdeen developed many things that were far more useful and effective than tank mounted rocket launchers. History shows that these were, shall we say, "not popular" with tankers who were ordered to mount them on their Shermans. In any case, this M4 can be seen to have a low bustle turret with the "thin spot" patch, with presumably a welded up pistol port on the other side. Most Composites were built with "upturned" return roller arms but here we see the earlier straight ones.

Above left, some of the crew of a small hatch Composite of the 499th Armored Field Artillery Battalion, 14th Armored Division pose armed to the teeth during the Tennessee Maneuvers in January 1944. Again, we see the applique armor patch on the turret. A few Composites, both small and large hatch, appear to have been produced with earlier D50878 turrets with the "patches" and welded up pistol ports. At right is a rare "combat shot" of a small hatch Composite, serving with the 40th Tank Battalion, 7th Armored Division in Niedersorpe, Germany, April 7, 1945. Note the "telltale" ventilators next to the drivers' hatches. Unfortunately, not much else can be seen due to the extensive use of camouflage, but this tank appears to have extended fenders, which suggests it was a remanufactured unit. Although 75mm Shermans were no longer "required" in the ETO, a number of remanufactured jobs were shipped there in 1945 on an emergency basis to make up for losses suffered during the Battle of the Bulge.

The 20th Armored Division was the last US armored division deployed to the ETO, arriving in France on 17 February, 1945. Previous armored divisions had been issued tanks when they arrived in theater, however the 20th were instructed to bring their vehicles with them from the States. Oddly, for this late stage of the war, the vast majority of their tanks were not the army’s preferred Ford GAA powered M4A3s, but rather Continental radial engined M4s & M4A1s, many of these being older variants that had been remanufactured. The two tanks seen here can be identified as small hatch Composites by the ventilator (1) located on the shoulders of the tank’s hull, and we point out to readers the distinctive twin drain holes in the ventilator (2). On the left we see Pedro of the 27th Tank Battalion, while on the right Cpl. Dale Ellis, the gunner of Petunia II, stands next to his tank of the 2nd Platoon, B Company, 27th Tank Battalion. The original Petunia is recorded as having been knocked out by a German mine and was presumably one of the 17 medium tanks lost by the 20th in its 8 days of combat. Most likely both of these tanks were made with D50878 turrets with the "patches" (3) and welded up pistol ports (4). Both have stowage modifications commonly seen in the 20th Armored Division, such as field installed turret bustle baskets, as well as extended fenders with the sand shields fitted upside-down, creating stowage for jerry cans and machine gun ammo. (Left side photo: author’s collection; right side photo courtesy of Gary Ellis).

One of the deficiencies of the original Sherman design was the hazardously small size of the drivers' hatches. In February 1943, larger hatch dimensions were submitted, but it was found that "increased size not possible of application to present hull design." Development work was begun to reconfigure the front of the Sherman to accommodate larger hatches. The new hatches were to be oval shaped and approximately 24 inches long and 19 inches wide. In comparison, the small drivers'' hatches of the original design were about 21 inches long and 16 inches wide. Chrysler's cast front concept was used, and in May, the new casting was attached to SN 30263, an April 1943 production Sherman pulled off the line at Pullman Standard. This project was part of the "ultimate" redesign of the Sherman, which also included the introduction of a new 76mm turret as can be seen above, although the turret shown here was characterized as "not according to print." By June, the Ordnance Department determined that the "Chrysler front end" was an acceptable solution and approved of making all subsequent welded hull Shermans as large hatch Composites. However, in that same month, Fisher Body submitted an alternate large hatch design that featured a single 2 1/2-inch glacis plate that was found to be ballistically superior. As a result, the cast front concept was abandoned except at Chrysler which had already made commitments and started production.

The M4 Composites that began to roll off the lines in September 1943 were the first "large hatch" Shermans of any type. Improvements were added as they became available. Most of them appear to have been equipped with the new "upturned" return roller arms (circled). In November, Chrysler transitioned to the new high bustle D78461 turret that added a loader's hatch and reintroduced the pistol port. This M4 is currently preserved in a private collection in the US. While the hand crank may be a reproduction, it is appropriate, since Chrysler appears to have introduced the simplified one-piece design. Photos courtesy of Mark Holloway.

Chrysler started M4A4 production using side armor plates that had nicely beveled top edges (left). In July, 1943, the company transitioned to the use of square cut side armor plates, a practice already employed by most of the other builders. It is thought that, from August, 1943 to the end of production in June, 1945, all Chrysler Shermans, including the M4 Composites, were built with square cut side armor plates. Our example on the right, shows the Firefly Composite in Klein-Willebroek, Belgium. Modelers might note that on M4 Composites and welded hull M4s, the air scoops (1) are seen to sit ON TOP of the sponson plate, whereas the holes on cast hull Shermans were machined out in such a way that the scoops were flush mounted (inset).

At the outset of production, Chrysler M4s were equipped with the "original design" exhaust deflector (above left, but not a Composite). This had been added to M4 and M4A1 models starting in the Spring of 1943. The Barber-Colman Increased Air Flow System became available in late 1943, and featured an improved exhaust deflector (1), along with "pyramid turning vanes" (inset) over the air intake on the engine deck. The "Freeze Date" on this item at Chrysler was Jan. 1, 1944, which, along with a few period photos, suggests that it was installed on some of the final Composites built in late 1943/early 1944.

It would appear that Chrysler was supplied exclusively with the "square" type of air cleaners. Surviving examples have been noted with an identification and instruction plate from the "Vortox Mfg. Co. Claremont, Ca. USA". The rear hull was constructed of armor plate with an angled transition piece joining to the the belly plate (outlined in red). Trailer towing pintles were standard on the Sherman series by the time Chrysler began M4 production, but they don't appear to have been factory installed on any of their Composites. Chrysler was directed to install the pintles on M4A4s starting in April 1943, but it was found that they bent up in service, making it impossible to open the engine access doors. Consequently, "It was immediately burnt off as many new tanks M4A4 as possible," and further installation was suspended. At the changeover to M4 production, it is likely that Chrysler had trouble finding a supplier for the pintles, so that the Government gave them a temporary "pass." In any case, in period photos showing only the rear, an M4 without a towing pintle is likely to be a Chrysler built Composite. The M4 Composite at the RAAC Museum, Puckapunyal, is shown in the photo on the right and is SN 59427, indicating December 1943 acceptance. We consider this tank to be a valuable reference as appears to have been shipped to Australia "as built" and only slightly modified during the course of its service. Note the fittings (circled) for the Barber-Colman exhaust deflector. For future reference, we would observe that it does not show evidence of ever having been installed with a blanket roll rack.

Midway through their M3 Lee program, Chrysler designed and introduced the pressed metal type of bogie wheel. They used them throughout production on their VVSS equipped Shermans. Their distinctive drive sprocket (right) was also employed throughout, including HVSS production.

All large hatch Shermans

had a U-shaped ventilator between the drivers' hatches as shown in the

photo on the left. The little "bump" (1) just below has a hole in its

face which served as drainage for any water that built up inside the

ventilator's ducting. The eyebolt (2) held a pair of chains that secured

the drivers' hatch padlocks. Pierre-Olivier measured a ventilator on an

M4 Composite and found it to be about 11 1/4 inches from the point

where the casting rises to form the turret splash to the front. The

width was about 11 1/2 inches and the width of the opening was roughly

an inch and a half.

The front contours of the large hatch M4A1(76) were very similar to the Composite's. However, the M4A1(76) was equipped with an additional mushroom type ventilator next to the bow gunner's hatch (left) whereas this area was blanked off on the Composites (right) and could serve as an antenna location for a command tank.

M4 Composites were, and still are, often mistaken for M4A1s, particularly in head on photos such as the one on the left above. If one can see it, the little "nubbin" (asterisked) in the center of the glacis is a sure indication of a Composite. Remanufactured tanks can be a challenge when trying to determine the "as built" appearance. It was noted that, 98% of the time, power trains did not require replacement, but our example had its original replaced with one featuring a three-piece differential housing. The tank was also retrofitted with the E9 track modification, the modified M34 gun mount with "wing piece," commanders' vision cupola and the late armored housing for the gunner's periscope.

This Signal Corps photo is dated 22 July 1944 with the location given as Saipan. The caption reads, "This tank crew used 2″ bomb throwers for protection to escape from enemy territory during the battle for the island. L to R: Pvt. Michael Wietman, Brooklyn; Pfc. Earl E. Holman, Nashville, Tenn.; Lt. Jack P. Lansford, Athens, Tenn.; and Cpl. John A. Armstrong, Long Beach, Calif." Cpl. Armstrong is seen holding the 2-inch smoke mortar that we assume he has removed from the turret. In his right hand is one of the finned smoke bombs. While the caption provides no unit identification, Lt. Lansford is listed in the records of the 762nd Tank Battalion as commander of the 1st Platoon of B Company. The company was equipped with M4 Composites and was the only Medium Tank Company of the 762nd that fought on Saipan. While not much else is visible, Lt. Lansford is standing inside the loader's hatch, so we might infer that it is a high bustle D78461 turret, introduced at Chrysler in November 1943. The "Speed Number" is only partially visible on the right front of the turret; we suspect Lt. Lansford's tank was "28." The smoke mortar, a standard feature on the M4 Composite, was not popular with US crews who found it to be "in the way" inside the cramped turret (inset). Most preferred to fire smoke from the 75mm gun. When Japanese infantry "swarmed" buttoned up Shermans, it was noted that they would try to drop grenades or other explosives down the smoke mortar barrel. The Marines reported that they fashioned wooden plugs to prevent this. As a result of the negative feedback, in January 1945, the Ordnance Department eliminated the smoke mortar from the Sherman design. In any case, if the smoke mortar was actually used in battle by Lt. Lansford's crew, it might have been on 7 July as B Company supported the 105th Infantry Regiment of the 27th ID when the Japanese broke through their lines in what is described as the "largest Banzai attack of the war." Over 4300 Japanese soldiers were reported killed during this "last gasp" attack.