Go to M32 series page

We have seen WW II era photos of exactly 2 Tank Retrievers with E9 installed. Both were cast hull conversions done by Baldwin. The Aberdeen Proving Ground photo above is dated 22 June 1945, and lists the vehicle as Serial Number 2143, the highest Tank Retriever serial number we have recorded. USA 3060795 is the original tank Registration Number, indicating that this unit was accepted in December 1942 at Pacific Car & Foundry. The other photo was in the September 1945 issue of Baldwin's company produced magazine and was dated July 1945 and captioned something like "The last Tank Recovery Vehicle produced by Baldwin." Unfortunately, we were not permitted to reproduce the photo, but the vehicle looked exactly like "Miss Tex", complete with a late production retriever addition - the "automatic tow hook" (1). Over the years, a certain confusion has attended the issue of 1945 production TRVs. Note that while the vehicle has "M32B1" stenciled on, the APG information panel identifies "Miss Tex" as an "M32A1B1." Baldwin Locomotive is stated to have done 180 M32B1 (converted from M4A1s) and 37 M32A1B1 conversions. According to Ordnance Committee Memorandum 27196 dated 4 April 1945, the designator "A1" was assigned to the retrievers being built with a package of changes/modifications to the earlier M32 series design. These included E9 suspension, raised boom, remote control recovery hook, elimination of 81mm mortar and miscellaneous changes to stowage. TRVs with these features were to be standardized as M32A1, M32A1B1, M32A1B2 and M32A1B3. The use of HVSS was not considered at this time because it was not "available in sufficient quantities to permit application to tank recovery vehicles without jeopardizing the medium tank program." Going by the definition in OCM 27196, only 37 Tank Recovery Vehicles with the designation "A1" were actually produced during WW II - specifically 37 M32A1B1s according to the Summary Report of Acceptances. So, the "A1" inserted in the nomenclature indicates a retriever built with E9 suspension along with the other changes listed in the OCM. This goes against the commonly held notion that the "A1" designator applied to M32 series TRVs installed with HVSS. We would interpolate that "Miss Tex" was the first of the 37 M32A1B1s, and that they would have been assigned Serial Numbers 2143 through 2179. With thanks to Kurt Laughlin for providing a copy of OCM 27196.

The photos above show what may have been the only surviving example of an M32A1B1. It was photographed at Keep Them Rolling Association events in The Netherlands in 2009. This retriever can be seen with fittings for the boom raising sheave along with the automatic tow hook. It is thought that The Netherlands received 10 of the Baldwin built M32A1B1s along with at least 1 T14E1 as Military Assistance in the 1950s. This "Miss Tex" can be seen to have a riveted lower hull, indicating that it was originally produced as an M4A1 by Pressed Steel Car, whereas the real "Miss Tex" shown previously was based on an M4A1 made by Pacific Car and had a welded lower hull. Note the oxygen and acetylene cylinders installed with purpose made fittings such as seen on the real "Miss Tex." We were curious to know if this unit still had its dataplate and, if so, did it have the nomenclature "M32A1B1"? However, it was reported that it did not have a dataplate installed, and that the retriever has since been converted to M4A1(75) gun tank. Photos courtesy of Keep Them Rolling Association.

As mentioned earlier, the Marine Corps was provided with 20 M32B3s based on new production large hatch M4A3(75) Wet Stowage Shermans with Vertical Volute Spring Suspension (VVSS). Although it was the US Army's policy to employ used Shermans for its retriever conversion program, it was agreed that new tanks would be converted "in order to attain maximum interchangeability" with the M4A3(75) Wets issued to Marine Tank Battalions as part of their 1944 requirements. For their 1945 requirements, the Corps stated in August 1944 that it would need an additional 50 M32B3s based on new production M4A3 Shermans. At first, there was no mention of Horizontal Volute Spring Suspension, but by the time the Ordnance Department approved of the request, all new M4A3 production featured HVSS. This created something of an issue, "Since the 23 " track and horizontal volute spring suspension have not been tested to determine their suitability for carrying the loads normally imposed on Tank Recovery Vehicles." Consequently, a pilot vehicle, "converted from a standard Tank Recovery Vehicle M32B3" was retrofitted with HVSS. Changes to the boom lifting device and some stowage items were incorporated, and on January 25, 1945, the Ordnance Committee designated the pilot as "Vehicle, Tank Recovery, T14." After trials were completed, the T14 pilot was retained by the Ordnance Department at APG for historical reference, and the photo above shows it there in March of 1949. The USA Registration Number is chalked on, and can be read as 40154986, indicating that the T14 was converted from M32B3 Serial Number 412, which we have featured in a number of previous captions. There has been some confusion about the T14, which might be partly to blame on this photo. Note that "M32A1" is stenciled on the side, and that the vehicle is labeled "M32A1" in the information panel. We would remind readers that Serial Number 412 originally had a chute turret but was retrofitted with the door turret seen here when converted to T14.

Unfortunately, the T14 appears to have been scrapped in the 1950s, so is not available for study. Ordnance Committee Memorandum Item 26511, which designated the pilot as "Vehicle, Tank Recovery, T14," is dated January 25, 1945. The reference text states that, " A pilot vehicle is being built from an old vehicle..." From that, we would guess that M32B3 Serial Number 412 was converted to T14 in early 1945, most likely before the first M32A1B1, which was similar in concept, was completed. The photo above shows the T14 with its boom raised in the forward position. Again, we see the "boom raising sheave" (arrow) which replaced the lifting arm and drum of the original M32 series design. The original stabilizer plates were for the Vertical Volute Spring Suspension system. With the introduction of HVSS, these were rendered obsolete, and no longer carried on the left side of the glacis. Instead, according to author Richard Hunnicutt, "Adjustable rod type stabilizers were used to lock out the springs on the front and rear bogies during lifting operations."

The photo above was taken by the Chrysler Engineering Division in April 1945. Again, some confusion arises since the T14 is identified as an "M32B3" in the information panel. Chrysler designed new fittings for stowage of the snatch blocks on each side of the vehicle. These do NOT appear to have been adopted for the T14E1s. (We believe that the snatch blocks were stowed in the usual M32 series position on top of the chock blocks on the engine deck.) The "adjustable rod type stabilizers" mentioned by Mr. Hunnicutt are referred to as "lockout bars" by author David Doyle. The item circled in red and shown larger in the inset is one of the four "lockout bars" installed on the bogie units just below the shock absorbers "to lock out the springs on the front and rear bogies during lifting operations." The evidence suggests that the T14E1 was designed to use the standard M32 toolbox arrangement. However, the trial installation of the muffler/exhaust silencer on the T14 displaced the toolbox mounted transversely on the rear engine deck. Perhaps to compensate for this, the side mounted toolboxes on the T14 pilot were made noticeably longer than the boxes seen on the M32 series and the T14E1.

Above is an enlargement of the left side plan view of the T14. It is thought that the items circled in red were welded on to the front and rear bogie castings on both sides in order to hold the "adjustable rod type stabilizers" or "lockout bars". A close-up view of one of the fittings as seen on a surviving T14E1 is shown in the inset. It is our theory that the T14 was the only retriever that was retrofitted with HVSS during WW II, and that the T14E1s were the only WW II era models that were converted from Shermans originally built with HVSS. Furthermore, we would speculate that the T14 pilot and the T14E1s were the only retrievers that utilized the "lockout bars" with the special fittings welded to the bogies. The evidence seen on surviving examples suggests that post war M32 series retrievers that were retrofitted with HVSS used alternate stabilizer plates, which we will discuss going forward.

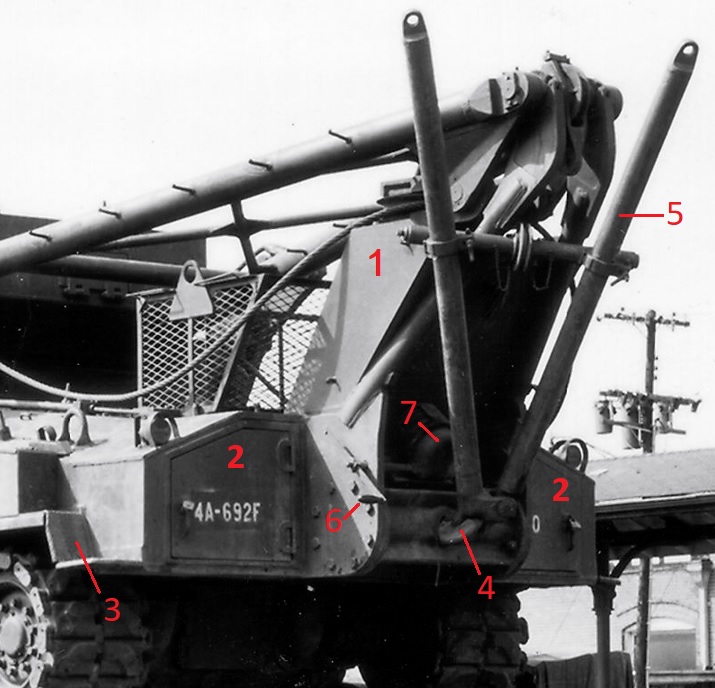

The first phase of the invasion of Japan was scheduled for November 1945. Plans called for 3 Marine Tank Battalions to be equipped with M4A3(75) and M4A3(105)s with HVSS, with T14E1s providing recovery and maintenance support. In the post war years, some M4A3(105)s and T14E1s were retained by the USMC, while the M4A3(75)s were replaced with M26s by the time of the Korean War. The T14E1s do not appear to have been assigned new retriever Registration Numbers, but simply retained their original M4A3 tank USA Numbers. However, the Marines used their own numbering system. The photo above shows T14E1, USMC Number 103210 at the Marine Corps base at Camp Pendleton, California in May 1949. Note the M4A3(105)HVSS in the background. The further away one gets from production, the more likely it is that changes will have been made to vehicles by base shops or depots or even simply by the preferences of crews. In this case, the only apparent spare road wheel stowage can be seen on the upper rear hull plate (1). Perhaps reflecting its limited utility, the automatic tow hook has been removed, although the extension assemblies (2) are "still" welded to the vehicle's A frame support sockets. The "Towing Hook Hanger Assembly" (3) also remains. The relocated pintle (4) appears to have been an exclusive feature of the T14 series. The T14E1s were ordered with "deep water fording equipment" as evidenced by the wading trunk in the previous photo. This was obviously removed from this unit but note the weld scars running across the rear hull plate just above the armored exhaust deflector (5). The spare HVSS tracks (6) are stowed in what we would consider the standard T14E1 configuration. It differs slightly from the standard configuration seen on, say, the M4A3(105)HVSS. Note that the fittings (7) for the spare VVSS tracks are "still" present on the rear of the turret. The evidence suggests that these were standard on the T14 series.

A "Special Action Report" detailing the activities of the 1st Marine Tank Battalion "in the WONSON-HAMHUNG-CHOSIN RESERVOIR Operation", stated that, in October 1950, the Battalion was equipped with 97 "track laying vehicles", including 70 M26s, 12 M4A3 Tank Dozers, 9 M4A3 Tanks w/POA Flame Throwers, 1 M4A3 Communication Tank, and 5 M32B3 Tank Recovery Vehicles. Again, we have some confusion about the TRV nomenclature, since, in the documents that we have examined, the Marines never use the term "T14E1" in their strength and repair reports, but consistently refer to their retrievers as "M32B3s". However, based on the documentation, we must conclude that a T14E1 Tank Recovery Vehicle can be distinguished from an M32B3 by its boom raising sheave (1), the vertical orientation of the external hinge brackets (2), the absence of lifting drum on the right drive sprocket (3), and the little fittings (circled) added to the front and rear HVSS suspension units for attaching the rod type stabilizer or lockout bar. There are several Korean War photos of the USMC's TRVs that show without doubt that they were T14E1s, at least at first. The image above is one of a series that shows a T14E1 performing repairs on a mine damaged M26 of B Company. No dates are provided in the captions, but the location is given as "near Yang-gu," which leads us to think that this scene took place shortly after June 13, 1951, when it was reported that Tanks B-22 and B-41 (seen in the background) suffered light damage as they passed over mines in a rice paddy. B22 can be seen with US Army Registration Number 30128393 indicating that it was built by Chrysler in May 1945. The T14E1 can be seen as USMC 103374. "Z11" is painted on the jerry can and is seen on the turret in another photo in the series (inset). We take the "Z" to indicate that this was the retriever of the Maintenance Section of HQ Company.

On paper, each of the 1st Marine Tank Battalion's letter companies (A through D) was equipped with a Tank Recovery Vehicle, along with 17 M26s and 3 M4A3 Dozers. The photo above is dated 10 November 1950 at Hamhung, which would indicate the Chosin Reservoir Campaign. B45 can be seen with the unmistakable features of a T14E1. The spare road wheel fittings are in the same locations as in the June 1945 Detroit Arsenal photo shown earlier. However, the crew (we would guess) has relocated 2 of the stowage boxes to the upper rear hull plate. The snatch block (1) and the hinged tow bar (2) are also in nonstandard positions on the side of the hull. Again, the automatic tow hook has been removed, but the "Towing Hook Hanger Assembly" (3) is still present. If one can see only the hanger in a period photo, it is a clue that that the retriever was installed with the auto tow hook modification. Just barely visible are the lockout bar fittings (circled) welded to the front and rear bogies. The available evidence suggests that the external hinge brackets on both sides of the T14E1s were no longer welded on on an angle but mounted vertically as seen here (4). This was no doubt due to the introduction of the boom raising sheave. However, we would note that the T14 pilot retained the original angled orientation of its external brackets. The "Special Action Report" has it that the 1st Marine Tank Battalion reported 15 M26s and 3 M4A3 w/Tank Dozers as total losses during the harrowing retreat from the Chosin Reservoir in late 1950. Eight other seriously damaged tanks and one "M32B3" (burnt out engine, clutch and broken drive train) were evacuated to Combat Support Group or the USMC 1st Ordnance Battalion. If the Ord. Battalion could not repair or replace such units from USMC reserves, they would have to draw on US Army stocks. Thus, the Marines received quite a few Army M26s to replace the 15 lost in the retreat from the Chosin. It is thought that the supply of what the Marines called "M32B3s" but what photos show as T14E1s was not unlimited. In their repair and service reports, the Maintenance Company of the 1st Ordnance Battalion lists mostly M32B3s, but an M32 or M32B1 pops up on occasion. We suspect that these might have been replacements received from the Army.

This interesting photo shows T14E1 "Speed Number" D46 apparently assisting in replacing the main rotor blade on one of the 15 Sikorsky HRS-1 helicopters of Marine Transport Helicopter Squadron, HMR-161. The Squadron arrived in Korea in September 1951, just in time to assist the First Marine Division's final major offensive of the Korean War, the Battle for the Punchbowl (31 August - 21 September 1951.) HMR-161 performed what was lauded as invaluable service, delivering supplies, evacuating wounded and successfully completing the first helicopter-borne assault landings of combat troops in the mountainous terrain of the battlefield. The Marines took all of their objectives during the costly and hard-fought battle but were ordered to consolidate and dig in as the truce talks resumed. The photo is dated December 1951 which, we believe, would put the location north of the Punchbowl along the Hays-Kansas Line, basically where the Demilitarized Zone is situated today in the eastern part of the Korean peninsula. Looking at D46, again one can see the rearrangement of the as built stowage; for instance, the bin on the right rear has been repositioned and the spare HVSS tracks have been moved or eliminated. A VVSS spare track holder is just visible on the rear of the "turret." Since the T14E1s were originally built to service the Marine's HVSS Shermans during the planned invasion of Japan, we can't help but wonder why these VVSS track holders were not replaced with something more useful.

The retriever on display at the National War and Resistance Museum (Oorlogsmuseum) in Overloon, The Netherlands is believed to be the only T14E1 that has survived more or less intact. The boom raising sheave and the side roadwheel stowage are missing, but overall this unit is in remarkable condition. We examined this retriever just before it was shipped to Europe, at which time it had the boom raising sheave installed. In order to mount the 81mm mortar, it was necessary to either disconnect the sheave from the turret and fold it down as shown in the inset, or to remove it completely. Author Richard Hunnicutt wrote, "although retained on the pilot [T14], the 81mm mortar was eliminated from the later production models." We have an admittedly small number of survivors and period photos to work with, but we would judge that all of the T14E1s were factory equipped with the mortar and the necessary fittings to mount it on the front of the vehicle. The T14E1s were converted from M4A3s made in 1945, and consequently had the "late" glacis pattern, which featured the "short" bullet splash sections (1) in front of the drivers' auxiliary periscopes, along with the hull lifting rings mounted in the "outboard" position, very close to the edge of the glacis plate. As best we can determine, the only other large hatch welded hull retrievers done during WW II were the 12 M4A2s and 20 M4A3s converted for the USMC. The new Shermans converted by Lima would have been produced in the first half of 1944, and would have featured the "early" or "mid" glacis patterns. These would have had the hull lifting rings mounted in the "inboard" position, several inches in from the edge of the glacis.

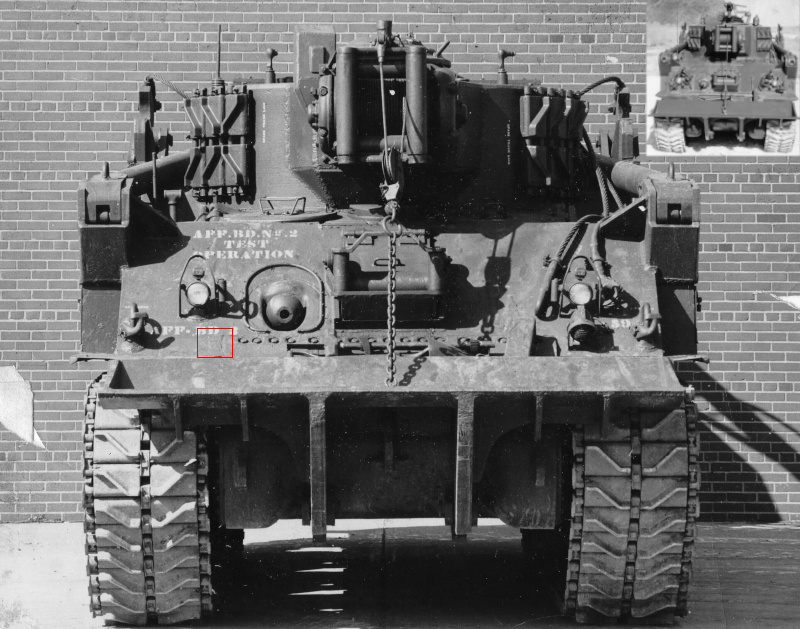

This right rear view shows some of the fittings for the automatic tow hook. The heavy duty tank recovery vehicle towing pintle (1) was not installed in the center of the lower rear hull as was standard on the M32 series. Instead, it was mounted in between the A frame support sockets. The towing pintle (2) seen welded to the center of the lower rear hull was standard on late production Shermans, and was probably retained on all of the T14E1s. Note the vertical orientation (3) of the right side external hinge bracket. The front and rear bogies have the "special fittings" welded on (we've circled one). We would assume that the T14E1s were equipped with "T14E1" dataplates that provided the serial number assigned, and perhaps an identification of the company that did the conversion - either Baldwin or International Harvester. Unfortunately, this unit no longer has a dataplate.

Here we have a "before" view of the Overloon T14E1 photographed at the Port of Baltimore in 2004. Note the weld scars (1) showing where the transverse mounted toolbox was fitted across the rear deck. The two longitudinally mounted toolboxes sat above the engine deck doors and were mounted on the small fixtures identified here. The innermost mountings (seen here at 2 and missing at 3) held a locking pin which could be removed, permitting the outermost mountings (4) to act as hinges, allowing these bins to be folded outwards to give access to the engine deck doors. However, access to the engine bay was still inhibited by the splash shields under the engine deck doors of Ford engined vehicles. This could explain why photographs often show the two longitudinally mounted toolboxes removed from their official locations and repositioned elsewhere. It should be noted that these mountings are seen on other M32 series TRVs, so they are not exclusive to the T14E1. Also of note are the two openings cut through the grating of the engine deck doors. These apparently provided access to what are, judging by their locations, the oil level gauge or “dipstick” (5) and the oil filler cap (6) on the Ford GAA engine. However, these access points have not been seen on other M32B3 based TRVs and with only one other T14E1 believed to have survived we have not been able to ascertain if they are peculiar to T14E1s or just this specific vehicle. Finally, note the weld scars (7) that remained after the removal of the spare VVSS tracks holders. It is thought that some crews removed these in order to mount something more useful in their place.

The authors are not aware of a surviving Technical Manual for the T14E1, but on retrievers equipped with the boom raising sheave, the two fittings seen here on the glacis and on the boom (circled) appear to have been installed to serve a similar purpose to the “lifting cable safety connection” covered in the M32 series Tech Manual - “to prevent boom from falling back on the vehicle if the lifting cable should break, or the load is released suddenly.” The inset shows the T14 pilot with what we believe is a “safety cable” connected to the fittings.

It is our theory that, except for the T14 pilot and the T14E1s, no other M32 series recovery vehicles were built with HVSS before the retriever conversion program was terminated in the third quarter of 1945. Most Ordnance contracts for major items included provision for replacement of damaged or worn-out parts. The T14E1 contract specified "spare parts, equipment and tools for twelve (12) months' maintenance of vehicle; and spare parts, equipment and tools for major overhaul and distribution." As these spares were depleted, AFVs could still be repaired through cannibalization of other vehicles. A small number of period photos suggest that a few T14E1s had their original booms replaced with M32 series booms with lifting arms that connected to lifting drums on the right sprocket. The photo above was taken in Korea in the mid 1950s and shows members of the 707th Ordnance Maintenance Battalion with what appears to be a T14E1 retrofitted with a standard M32 series boom (1). The main T14E1 clue is the fitting for the boom raising sheave (arrow). We believe that the cable clamps (circled) installed on the glacis were also exclusive to the T14E1s.

The fittings (circled) seen on the recovery vehicle on display at a military base in Cimahi, Indonesia suggest that it is also a case of a unit that started out as a T14E1, but had its original boom replaced with an M32 series boom, which required that the lifting drum be retrofitted to the right sprocket. Note as well, how the external boom bracket on the left is welded on in a vertical orientation. Assuming that this conversion job had been done "in the field," we were hoping that this unit might still have a "T14E1" dataplate inside, but our correspondent reported that there is no dataplate. The changes made to this retriever are very extensive, which leads us to think that it may have been a T14E1 remanufactured and refitted with an M32 series boom in the US before shipment as MDAP. Photo courtesy of Budi Nurtjahjo Djarot.

In late 1948, Bowen-McLaughlin-York was awarded a contract to rebuild 1300 M4A3(76)s. A specification of the order included the instructions, "Introduce an engineering conversion of the suspension system from Vertical Volute Spring Suspension to Horizontal Volute Spring Suspension by welding basic components to the chassis." In this way the Army was able to "produce" additional supplies of M4A3(76)HVSS Shermans, the model considered to be the best acceptable substitute to make up for the shortage of available M26s. Period photographs and a few surviving examples suggest that this process was applied to some M32 series Tank Recovery Vehicles. The photo above shows such a unit towing an M43 8-inch Howitzer Motor Carriage "along the fighting front in Korea" in May 1952. In the absence of much documentation, we will try to piece together what little we know about these particular conversions. Note that this unit is equipped with the original M32 series lifting arm (1). It is obvious from period photos and surviving examples that the T14E1's replacement of the original lifting arm and drum with the boom raising sheave was not absolutely necessary in order to accommodate the 23-inch HVSS suspension. Note the pair of new items stowed just above the "2."

The only hint we have come across concerning the production of M32 series retrievers retrofitted with HVSS comes from a dataplate found inside an example we once examined at the Ranges of Recovery Division at Aberdeen Proving Ground. In the photo above, it can be seen that the Serial Number of this unit is 273, indicating a Pressed Steel Car M32B3 conversion originally accepted in June 1944. The unit was "Rebuilt By R.I.A." [Rock Island Arsenal] in Illinois, and the year "1949" is stamped in the space at the bottom of the plate. Note that Rock Island labeled the retriever "M32B3-HVSS." In the absence of any other documentation, we will use that nomenclature to describe M32 series retrievers retrofitted with HVSS. Photo courtesy of Kurt Laughlin.

The photo above is thought to have been taken at APG in the 1970s and shows a rather battered "M32B3-HVSS." At the time, the Registration Number was still painted on the side and rear and is just visible as "USA 40154847." That is a mathematical match to Serial Number 273 on the dataplate of the retriever once at the Ranges of Recovery. Thus, we can deduce that when this M32B3 was rebuilt at Rock Island Arsenal, its original PSC Serial and Registration Numbers were retained. This unit appears to have been "used hard and put away wet" at APG. It can be seen that some of the HVSS suspension components are damaged or missing, and that the lifting arm has been broken off and what can be seen is the left-over remnants bent out of shape (arrow). The engine access door (1) demonstrates that it was not possible to open these hatches with the boom in the travelling position. This was corrected in the later M74 retrievers by splitting each hatch in half. It is thought that the items circled were "stabilizer plates," and that they were used in place of the "rod type stabilizers" that equipped the T14E1s. If any readers can explain how these would have been used "to lock out the springs on the front and rear bogies during lifting operations," we would be pleased to have a report. Photo courtesy of David Haugh.

Above shows USA 40155147 another "M32B3-HVSS" that was once on display at Aberdeen Proving Ground. The inset from a 1952 snapshot shows a stencil that identifies the “new” objects as “Stabilizer Plates.” We would note that on both USA 40154847 and USA 40155147, two of these plates are seen mounted on the right side of the vehicle, and there is no evidence that an additional pair were mounted on the left.

The above is a photo of part of the suspension of Serial Number 273. In this view it is possible to see that the bogie, idler wheel and return roller brackets were welded on to the hull. These components were bolted on to Shermans built with HVSS factory installed. Note how the bolts (arrows) appear to have been melted during the retrofit process. It is assumed that the "welding [of the] basic components to the chassis" during retrofit was done for strength, but it would have been much harder to replace the bogie assemblies and such in the event of damage. The inner road wheel is missing on SN 273 which provides us with a good view of one of the clearance notches (1). Each inner road wheel required a clearance notch on the lower edge of the hull side as shown. As built, these were neatly machined. It is thought that the notches were torch cut on HVSS retrofits, as their appearance is somewhat rougher than the machined notches.

The available photographic evidence suggests that the 1st Marine Tank Battalion deployed to Korea equipped with some of the T14E1s it had received in 1945. The US Army, on the other hand, was not able to standardize on a single type, such as the M32B3, but instead had to resort to using any and all available models, including retrievers with the original VVSS, as well as those with the HVSS upgrade. The Signal Corps gave good coverage to recovery operations during the Korean War, and while the majority of the TRVs seen in photos are M32B1s, M32B3s are also well represented. Above is the only SC photo we know of at present that shows a straight M32. Note the slight gap (arrow) between the internal boom pivot bracket and the antenna casting, typical of M32s, as opposed to M32B3s. Somewhat ironically, this retriever is seen being recovered by an M4A3(76)HVSS after having fallen into a ditch. The photo is dated August 9, 1950, which was just as the first Shermans began to arrive and enter combat in Korea.

The photo above is dated July 19, 1950, and shows an M24 of Company A, 79th Heavy Tank Battalion under tow by the unit's M32B1 retriever. In the late 1940s, the 4 US Infantry Divisions serving Occupation Duty in Japan, had had their attached Tank Battalions reduced to single companies consisting of approximately 24 M24 Light Tanks. The M24s were rushed to Korea where they suffered heavy losses attempting to slow the progress of the initial North Korean onslaught. The M32B1 shown here was most likely one of the first Sherman based vehicles to be deployed to Korea. Judging by the "low" position of the crow bars (1), we would guess that this unit was a Baldwin conversion. Note that the anvil (2) and the vise (3) are installed in the frame type holders on the front fenders. Of particular interest is the oxyacetylene tank (4) emplaced in a hole cut in the hull in the area of the right side grouser storage compartment.

Andy Zeigler saw the photo in the previous caption, and contacted us with the information that his grandfather, Sgt. Thomas L. Clymer was the commander of another 72nd Tank Battalion M32B1 named "Miss Carriage" as seen here in two of his snapshots. The tactical markings painted on the differential housing are "2 72 Δ" [2nd Infantry Division, 72nd Tank Battalion] and "H/S" followed by an indeterminate vehicle number (perhaps 15) on the driver's side. We interpret "H/S" to mean "Headquarters Company/Service Section." In any case, we are informed by Sgt. Clymer's relatives that he served with HQ Company in Korea from September 1950 through June 1952. It is thought that there would have been two retrievers in the HQ Company and one each in the three letter companies A through C. We believe these photos were taken in early 1952, at which time the 72nd would have been entirely equipped with M4A3(76)HVSS Shermans, with each of the letter companies having 22 at full strength. The 1952 history of the 72nd pays this tribute, "The hours of backbreaking labor performed by the men of the Battalion Maintenance section can never be fully described. A broken track here; a burned out engine there; a turned over tank on the other side of the hill, day and night there was always another vehicle to be fixed." "Miss Carriage" is another example that was not updated with the automatic tow hook modification. She differs from the M32B1 of the previous caption in having the final "door" type of turret port, thought to have replaced the earlier "chute" by the end of August 1944. Photos courtesy of Sgt. Clymer's daughter, Anita Ziegler and his grandson Andy.

The above shows an M32B1 which has become bogged while attempting to recover an Army M46 Patton tank on May 1, 1951. The M32 series TRVs had been designed to recover the 30 ton Sherman Medium Tank. During the Korean War, it was found that the M32s were just not powerful enough to handle the M26 and M46, both of which weighed over 40 tons. Reports from the field stated that, while they were capable of towing the newer tanks on level ground, they could not safely perform this task either up or down the inclines typical of the mountainous terrain of Korea. A number of armored units noted that the best vehicle for towing or recovering an M46 Patton Tank was another M46. Consequently, it was requested that a new Tank Recovery Vehicle be developed based on the Patton.

While the M32 series TRVs struggled with the M26s and M46s in Korea, the Ordnance Department was developing even heavier tanks to counter the perceived threat of a Soviet invasion of Western Europe. The M47 Patton wasn’t issued to the forces in Korea but was the USAREUR’s (United States Army Europe) first line of defense in West Germany when first deployed in 1952, closely followed by the M48 Patton in 1953. With the development of the M103 Heavy Tank with a weight nearly twice that of the WWII Sherman tanks, the writing was on the wall for the M32 series. By 1951, the Army had a replacement recovery vehicle on the drawing boards, the T51, which was based on the M103 Heavy Tank. However, the width of the original design was over 12 feet, which was considered unacceptable due to road and rail transport limitations. In the meantime, a new Sherman design was accepted. The M74 was based on the M4A3 chassis with HVSS, and production commenced in 1953. Even so, the M32 series soldiered on and there are photos showing them in US Army service as late as 1956. The above shows an M47 Patton being towed by an M32B1-HVSS of the 28th Infantry Division’s 110th Regiment through a German village in late 1953/early 1954. Both vehicles are fitted with rubber tracks (1) presumably to limit any damage to the German road network. This TRV is one of the few M32B1s we have seen based on a direct vision hull, the drivers' visors hidden here behind the appliqué plates (2). The extensions to the boom mounts (3) can be seen here, as can the loop for the bridle assembly (4), although no bridle is fitted. Colorful “candy stripes” (5) are seen painted on the front fenders. Also of note is that the front towing pintle is absent (6), suggesting that the transmission housing is most likely a replacement.

In May 2022, we were pleased to be contacted by Norman Nelson (Jr.), who was kind enough to share a photo of his father, Cpl. Norman Nelson (Sr.), posing with "his" retriever, the very same one shown in the previous caption. Cpl. Nelson was a track & wheel mechanic who served with the 110th Infantry Regiment in Neu Ulm, Germany in 1953 and '54. Again, we point out the colorful “candy” warning stripes on the vehicle’s boom. The configuration of the taillight guards and the “blocky” rear lifting rings provide evidence that this M32B1-HVSS was converted from an M4A1 made by Pacific Car and Foundry. It should be noted that in both photos most of the vehicle’s spare wheels holders are empty, although one spare Patton idler wheel and two spare Patton sprockets are seen stowed on the left-hand side of the hull in Norman’s photo above.

Here we can see that an adaptor was produced to adjust the 3-point lifting arm mechanism, permitting the cable attaching to the cable lifting drum to be moved further outboard, presumably to assist in clearing the wider HVSS suspension. This adaptor (1) has been noted on both M32B1s & M32B3s retrofitted with HVSS in postwar service and is indeed seen on Norman Nelson's M32B1-HVSS in addition to the extension to the height of the boom mount (2).

Part 4 : M74 Series

In 1944, Pressed Steel Car was commissioned to build a prototype tank retriever based on the M26 chassis, and designated "T12." The pilot was equipped with a telescoping boom in a fully rotating turret, similar in design to the original T2 and T7 Tank Recovery Vehicles. Two winches were mounted in the turret bustle, one for the boom and the other for drag line operations. Like the M31 and M32 series retrievers, the T12 would have had a crew of 6 men. It was estimated that, fully loaded, it would have weighed 90,000 pounds. That strikes us as a "lowball" estimate, considering that the M26 is listed as having had a combat weight of over 92,000 pounds. From the photos, it would appear that the T12 would have been built with extended end connectors factory installed like the M4A3E2 [Jumbo] Sherman. In the event, the T12 project was terminated with the end of WW II, and as we have shown, the US military continued to rely on Sherman based retrievers in the post war era.

From the beginning of the Korean War it had been recognized that the Sherman based M32 series, including the T14E1s, "are considered too light for retrieving tanks in excess of 40 tons [the M26 & M46].” Several Korean War unit records state that the best AFV for towing an M46 was another M46. Despite that, Sherman based retrievers continued in service, until they were replaced NOT by a Patton (M46, M47, M48) based retriever conversion, but by another model based on the M4A3 - the M74. Designed by Bowen-McLaughlin-York, the M74 was a vast improvement over the earlier M32 series of retrievers. It featured a powerful 90,000-pound capacity winch, a hydraulically operated boom, and a front spade (1) which could be dug in (2) to anchor and stabilize the vehicle during winching operations as shown above. Of course, the spade could also function as a bulldozer. In order to augment the towing power, the final drive ratio was increased from the standard Sherman 2.84:1 to 3.36:1. “The final drive ratios are from the old, heavier assault tanks...[M4A3E2 Jumbo] which are slower but more powerful, and let you tow a full track vehicle weighing up to 100,000 pounds.” Still, as the photo suggests, in some cases, the enormous weight of an M48 required two units to complete a recovery. This scene was filmed at Baumholder, Germany on 9 August 1956 and shows "Two M-74 V.T.R.s from the 66th Tk Bn, 2nd Armd Div, moving an M-48 90MM Gun Tank onto the North Trail."

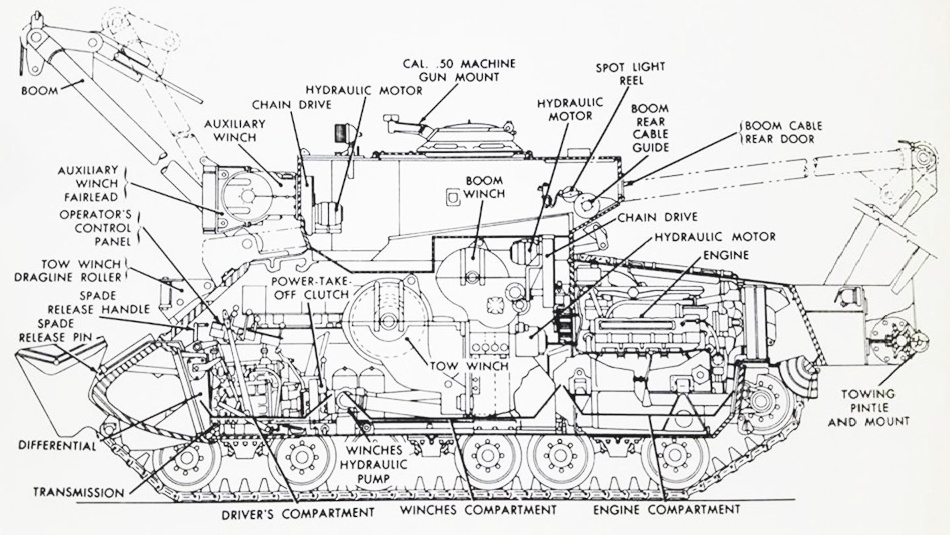

BMY’s design was a relatively low cost, around $60,000 per unit, evolution of the M32 series, utilizing the same basic layout but incorporating a number of engineering improvements. The single 60,000-pound all-purpose winch of the M32 was replaced by three special purpose winches: a 25,000-pound boom winch and a 90,000-pound tow winch, both mounted in the hull; and a 10,000-pound auxiliary winch mounted on the front of the turret. There was also a 2,000-pound utility hand winch at the rear. Similarly, the simple boom design of the M32 series was improved by incorporating hydraulic rams for raising and lowering, which permitted it to be used as a live boom. Unlike the M32 series, the M74 used only one type of "donor" Sherman - the M4A3 with HVSS.

Above shows the T74 pilot photographed at Army Field Forces Board No. 2 at Ft. Knox in the Summer of 1952. As mentioned above, we have observed from period photos that BMY M74s appear to have retained their original Sherman Registration Numbers, and all of those recorded so far, with the exception of the pilot model, which can be seen here as USA 30125569, have been from Chrysler built M4A3(105)HVSS's. Additionally, on surviving M74s where we have been able to read the Sherman Serial Number from the rear tow lugs, all of them have been of former M4A3(105)HVSS's. Consequently, the pilot may be somewhat unique in that its Registration Number provides the information that it was converted from a March 1945 Fisher built M4A3(75)W HVSS, in fact one of the last of that type made. The OCM references a Work Directive dated 13 March 1952 which "provided for the modification and conversion of two tanks, Medium M4A3, 105-mm How., HVSS to Vehicle, Tank Recovery, Interim Type." We can only guess that the pilot was converted using an M4A3(75)W HVSS simply because it was the nearest acceptable tank at hand at the time. "Assault Gun" 105mm Shermans were overbuilt during WW II, that is the supply far exceeded the final demand. Therefore, large numbers of M4A3(105)s with HVSS were still available in the US inventory when the M74 program commenced, and so these would have been the obvious choice to use as donors. Except for an all-purpose open basket type bin on the rear deck, the M74 didn’t include toolboxes on the engine deck as per the M32 series TRVs. Instead, the designers supplied an extensive range of tool and stowage boxes attached to the sides and rear of the vehicle. Note that the pilot can be seen with four stowage boxes on the side.

Surviving vehicles and period photographs show most M74s with three stowage boxes on each side of the hull. Indeed, these are described in the Technical Manual as "Front," "Center" and "Rear Side Stowage Boxes." However, walk around photos of the T74 pilot show it with four outward opening stowage boxes on each side of the hull. We suspect the number was reduced to three by the time the design was finalized and approved for production. A small number of period photographs and a few surviving M74s show examples with five or six side stowage boxes. The one seen here with 6 very "official" looking stowage boxes was reported to have been photographed at the Detroit Tank Arsenal in 1961. Perhaps there was some sort of upgrade program at the time? We recorded the USA Number as 30141152 from the color print at the Patton Museum Library at Ft. Knox. This unit would have been built as an M4A3(105)HVSS in June, 1945, the last month of Sherman production at Chrysler.

The 81mm mortar, a standard feature of the M32 series, was dropped from the M74 design, presumably because the auxiliary winch mounted on the front of the turret would not permit its installation. The M74 Technical Manual catalogues the armament carried as a .30 cal. bow machine gun, a .50 cal. machine gun affixed to a mount on the commander’s cupola, and a 3.5” rocket launcher, M2 [“Bazooka”]. Whereas the M32 series TRVs specified a crew of 6, in the M74 this was reduced to 4 men, consisting of vehicle commander, driver/winch operator, co-driver/rigger and a mechanic. The fully loaded (combat) weight is given as 93,750 pounds, about 32,000 pounds more than the original M32 series. The 500 HP Ford V8 was and still is considered an engineering marvel, but we can't help but think that the M74's weight would have tested it to the max. For future reference, note the hinged comb device (circled and inset). This (or traces of it) is seen on most surviving M74s as well as on other AFVs rebuilt by BMY.

The detachable A-frame of the M32 and T14E1 was replaced by a fixed superstructure (1) that extended out from the rear of the M74 hull. To either side were two large stowage boxes (2) and small steps (3) were incorporated into the rear fenders. The rear towing pintle (4) was mounted at a similar height to that seen on the T14E1, and the automatic tow hook was discontinued, being replaced with a tow-bar (5) which was stowed on the rear of the superstructure and was typically preconnected to the pintle. The tow-bar could be quickly lowered with the hand crank (6) of the 2,000 lb utility winch (7) and then the free ends would be attached to the towing lugs of the vehicle awaiting recovery.

M74s were converted from late model M4A3s with HVSS, many of which would have been built with the armored exhaust deflectors reported to have been introduced in production at Chrysler in January, 1945. The armored deflectors are rarely seen in WW II photos, simply because Shermans produced in 1945 were "too late" to be needed overseas. Ultimately, the surplus tanks remained in the US, and those that weren't issued to US training forces, were put in storage in the event of emergency. We would observe that in the Summer of 1948, there were nearly 2000 M4A3(105)HVSS in the US inventory. The photo above shows USA 30141181 which would have been built as an M4A3(105)HVSS by Chrysler in June, 1945, their last month of Sherman production. Without doubt this tank would have had the armored exhaust deflector factory installed. However, as an M74 conversion, 30141181 can be seen to have been retrofitted with the earlier style of sheet metal exhaust deflector (1). No doubt the sheet metal deflector was substituted due to the long overhang of the rear stowage boxes on the M74. The armored deflector was designed to swing outwards and upwards to give access to the door, and the long overhang would have prevented this operation. The earlier sheet metal deflector worked with the M74 design since it swung inwards and up under the rear deck. The photo in the inset is from the M74 Tech Manual, and shows the deflector in the "up under" position.

Ford engined Shermans and variants had "splash shields" (1) fitted under the engine deck doors as shown at the top left. However, as mentioned previously, and seen at the top right, the boom of the M32 series TRV prevented the engine deck doors from being opened or closed when the boom was in the stowed position. The solution utilized by the M74 designers was to cut each engine deck door in half and allow it to fold onto itself by using hinges (2) as seen in the photo at the bottom left. The innermost portions were folded outwards and held secure by spring mounted hooks (3). Also of note are the torsion bars/counterbalanced hinges (4) for the engine deck doors. The doors were extremely heavy, and the torsion bar hinges made it possible for one person to lift them with very little effort. These were standard fittings on the M74, and were retrofitted to many M4A3s during rebuild programs of the early 1950s. At the bottom right we can see the doors being held open by another spring mounted hook (5). The splash shield was also cut in half and we can only assume that the tubular supports (6) were added to ensure that the shields retained their structural integrity.

While the M32’s turret was bolted to the vehicle’s hull, the turret of the M74 was welded to the hull (1) as seen in the above photo. In fact much of the sponson roof was removed on both sides of the hull to accommodate the new turret superstructure. The M74 came equipped with an M19 periscope that the driver could use in place of the standard M13 periscope. This was part of an "infrared driving system" for night operations, consisting “of a light source, a periscope assembly, and a high voltage power pack." We have noted on M74s that the driver’s periscope guard (2) is noticeably different from the rest, presumably purpose made to accommodate the M19. The small fittings (3) on either side of the periscope are only seen the driver’s hatches of M74s, and it may be that their purpose was to hold some sort of weather cover for the periscope. Two fixed auxiliary periscopes were installed between the drivers' hatches on 2nd Generation Shermans, but on the M74 these were removed and the openings blanked off (4).

Here we see how a pair of mounts were fashioned to hold a cluster of lights, along with a horn on the right side. Each cluster was protected by a single brush guard. As mentioned above, the M74 utilized an active infrared driving system with a pair of IR illuminators described in the TM as “special purpose lights”. These consisted of one headlight on each side “with a deep-red filter lens mounted in the front cover of each light. These filter lenses absorb visible light and allow tthe [sic] passage of infrared rays...These projected infrared rays illuminate field objects and are, in turn, gathered by the periscope and converted therein to visible light for observation and night driving.” The fittings for the boom assembly "forced" the front hull lifting rings to be relocated down and in a bit from their original positions on the glacis.

Unlike the M32, the turret of the M74 was fully weather proofed, being enclosed with a commander’s cupola hatch (1), a smaller oval crew access hatch (2) and twin doors (3) in the foremost section of the roof for the boom cable, which replaced the chute and door arrangements seen on the front of the M32 & T14E1 turrets. Note that the commander’s cupola appears to be a modified version of the standard cupola seen on late model Shermans (inset), with an adaptor ring insert made for a .50 cal machine gun pintle mount. We suspect that BMY recycled the cupola, the oval hatch and the ventilator cover (4) from the donor tank during the conversion process. A large panel (5) described in the TM as a “cupola mounting plate” was bolted to the turret roof. Pierre-Olivier has measured this panel as 64 inches or 1.625 meters wide (side to side) and 52 inches or 1.320 meters long (front to back). This could, of course, be removed to allow access to the internal winches and other components in the event maintenance or replacement was required.

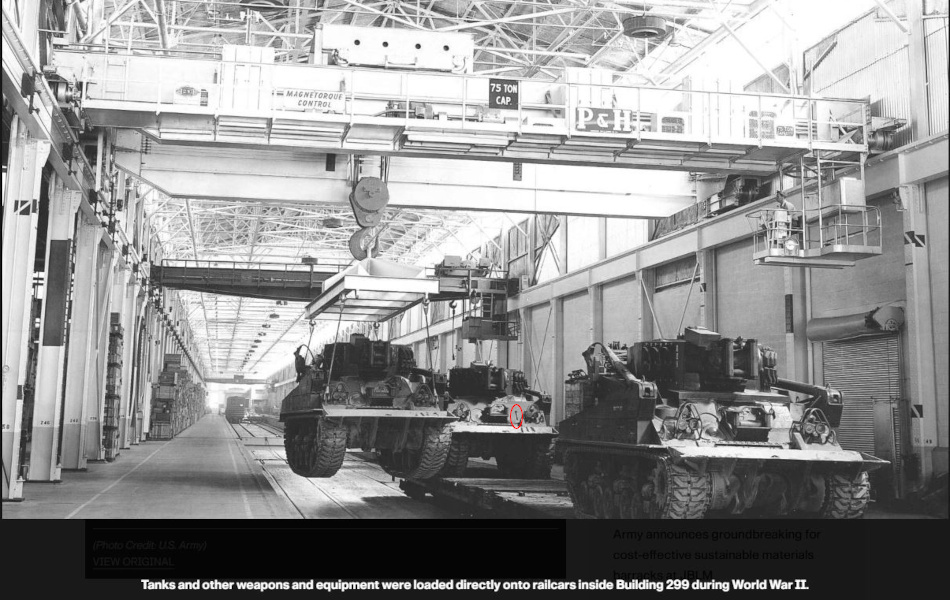

Here we have a US Army photo we happened upon while looking for something else on the Rock Island Arsenal website. It is captioned, "Tanks and other weapons and equipment were loaded directly onto railcars inside Building 299 during World War II." That is no doubt true, but this photo had to have been taken in the mid-1950s since it shows what we take to be two M74B1s converted from small hatch M32B3s at RIA. The middle unit with the 47-degree glacis can be seen with the hinged comb device (circled) typical of Bowen-McLaughlin-York M74s. Perhaps BMY provided a pattern model for RIA to use as reference for working up the M74B1? However, we would at least hold out the interesting possibility that it may have been an RIA M74B1 conversion using one of the 20 large hatch M32B3s done by Lima Locomotive.

HOME