Go to M31 TRV page

Production Order T-9273: 14 T5E2: Serial Numbers 1 through S/N 5 and S/N

97 through S/N 104. These vehicles retained their original Sherman RNs.

Production Order T-12508: 12 large hatch M32B2s: Serial Numbers 906 /

USA 3036487 through S/N 917 / USA 3036498 (RNs unconfirmed).

Production Order T-14813: 20 large hatch M32B3s. Serial Number 49459 /

USA 3082056, S/N 49485 / USA 3082082 and S/N 49498 / USA 3082095; Serial Number

49904 / USA 3082501 through S/N 49920 / USA 3082517 (SNs & RNs unconfirmed).

Pressed Steel Car manufactured 91 M32B1s from December, 1943 to March,

1944; 163 M32s, 475 M32B1s and 298 M32B3s from December, 1943 to December,

1944.

Production Order T-9553: 91 M32B1s from new production M4A1s: Serial

Numbers 6 / USA 40149307 through S/N 96 / USA 40149397.

Production Order T-10482: 845 units: 163 M32s, 384 M32B1s and 298 M32B3s. Serial Number 106 / USA 40154680 through S/N 905 / USA 40155479 (change

in the RN sequence within this range) ; Serial Number 1943 / USA 40191700

through S/N 1987 / USA 40191744.

Federal Machine and Welder converted 400 M32s and M32B1s from November,

1944 to May, 1945. (At present, no evidence of FMW M32s has been found.)

Production Order T-14407: 400 M32s and M32B1s. Serial Numbers 1343

through S/N 1742. These vehicles retained their original Sherman RNs.

Baldwin Locomotive Works converted 180 M32B1s from November, 1944 to March, 1945; 37 M32B1 with E9 suspension from May to ca. July, 1945; and 30 T14E1s from June to ca. July, 1945.

Production Order T-16140: 180

M32B1s. Serial Number 1763 through S/N 1942. These vehicles retained their

original Sherman RNs.

Production Order T-22383: 30 T14E1s. Serial Numbers unknown. These vehicles retained their original Sherman RNs.

International Harvester converted 50 T14E1s. Best evidence suggests that 15 were completed in March, and 35 in April, 1945.

Production Order T-19856: 50 T14E1s. Serial Number 3381 through S/N 3430. These vehicles retained their original Sherman RNs.

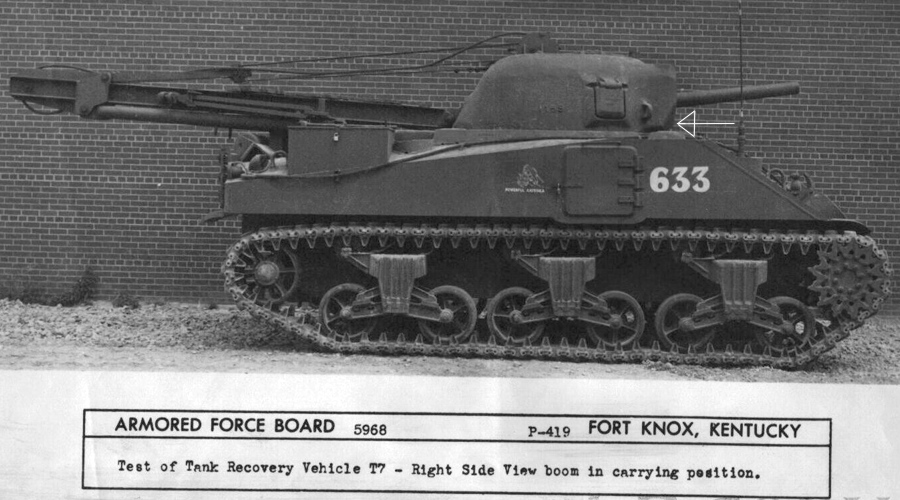

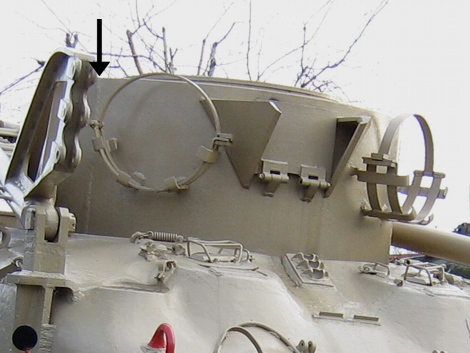

As production of the T2 series ramped up in early 1943, Lima Locomotive Works was directed to develop a new design for a retriever based on the M4 series, the Army's standard Medium Tank. At the same time, Baldwin Locomotive was tasked with producing a version of the T2 based on the Sherman. Above shows "Powerful Katrinka" as tested by the Armored Force Board at Ft. Knox in the Spring of 1943. Baldwin pulled an M4 off its production line, and installed the same boom in the turret in the same manner as on the T2. A roller mechanism for the winch cable was mounted on the roof of the turret. A dummy gun was mounted on the turret's bustle. It is thought that the bustle was cut off on the lower sides (arrow) to provide clearance for the drivers’ hatches to open and close when the turret and boom were in the traveling position as shown here. The T7 was installed with a working door on the right side only. Tests revealed that the rotating turret and boom of the T7 had the same issues as the T2; for instance, the boom could not be traversed "when on slopes." While the boom could lift an engine, it could not "handle medium tank turrets." On June 16 1943, the "Final Report of Tank Recovery Vehicle, T7" recommended that it "be considered as unsatisfactory and not be adopted for use by the Armored Force."

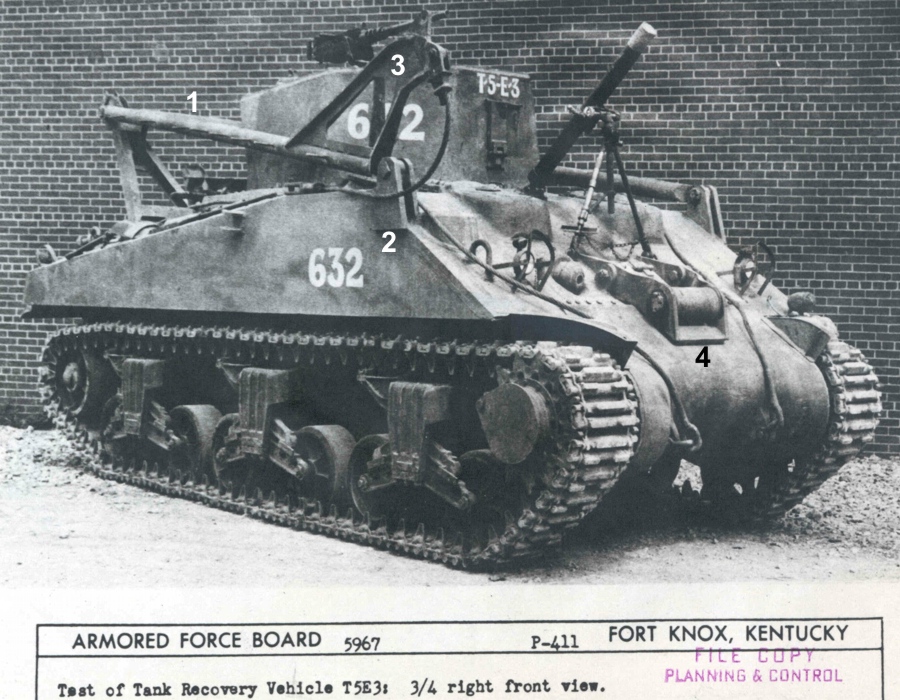

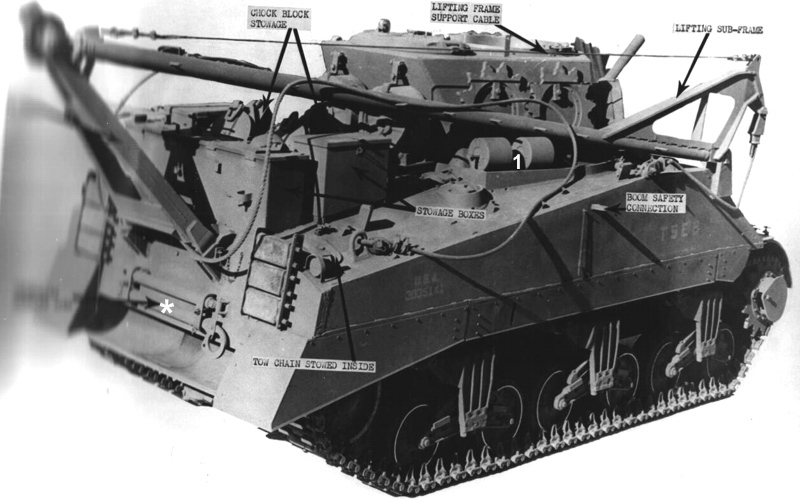

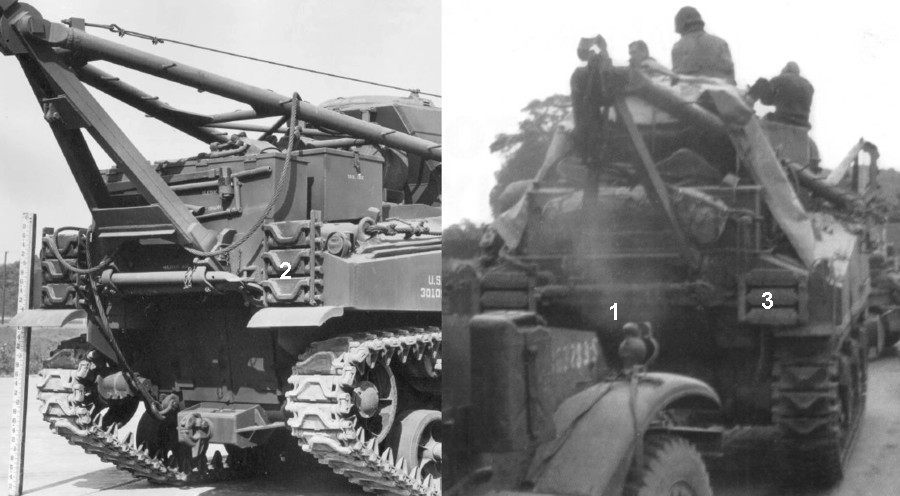

Lima Locomotive began work on the T5 series design in January 1943. Above shows the T5E3 (M4A3 based) pilot testing the lifting ability of the 60000 pound capacity winch and A-frame boom on an object marked as "7 TONS." This photo is undated, but 5 new production Shermans were released to Lima for the conversions, and the T5E3 was based on USA 3053972, an M4A3 that had been accepted at Ford Motor Company in March, 1943. For stability, a fixed turret arrangement was adopted for this and subsequent versions of US tank retrievers. The turrets of the pilots were fabricated from armor plates welded together. We suspect the first 5 T5E2s (M4A2 based) were the only production models equipped with turrets made of "welded, beveled plates." "Turret ports" were provided in the front and rear for lifting operations in either direction. The small slot with a hinged door (1) is only seen on the 5 T5 series pilots. The Armored Force Board found that the front and rear "under the hull" winching arrangement of the T2 and T7 was not entirely satisfactory, and the T5 series abandoned the rear winching capability. Instead a "Dragline Door" and "Cable Rollers" (2) were installed on the front center of the vehicle. During the design work, the fitting for the bow machine gun dust cover was removed in order to avoid any potential interference issues with the cable rollers and/or the fittings for the 81 mm mortar stand. In the end this was not a problem, and the dust cover was standard equipment on the T5 series.

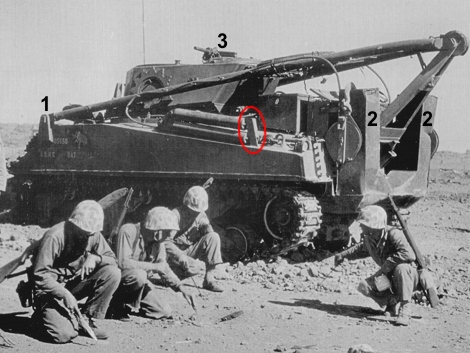

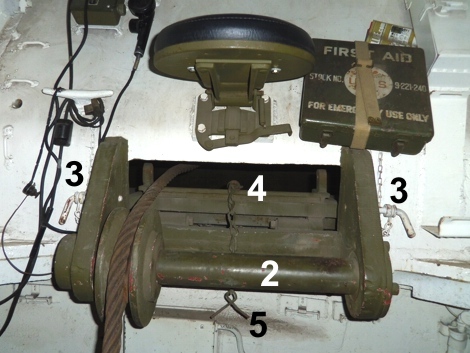

Both the T5E1 (M4A1 based) and T5E3 pilots were shipped to the Armored Force Board at Ft. Knox for evaluation. In June 1943, the AFB recommended the adoption of the T5 series for use by the Armored Force. During its tests, the Board found fault with some aspects of the T5E1 and T5E3 pilots, and proposed that a number of changes be made to the design. Above shows a "before" photo of the T5E3 taken during the initial trials. The original A-Frame boom struts were 4 1/2 inches in diameter (1). The brackets on which the boom pivoted were initially mounted to the hull in the vertical orientation seen here (2). The lifting arm (3) welded to the right boom strut originally had 2 connection points for attaching the lifting cable. The "as designed" cable roller assembly (4) was a rather simple affair which was substantially modified based on the findings of the Armored Force Board. The "standard" T5 series had heavy duty towing pintles installed on the front and rear, but both the T5E1 and T5E3 were shipped without the front pintle. The designers were still finalizing the details of the Recovery Vehicle stowage, when the pilots were shipped to the AFB.

Above provides an "after" view of the T5E3 taken at Lima Locomotive in October, 1943. A stronger A-frame with 5 9/16 inch diameter boom struts (1) was retrofitted. The lifting arm (2) was larger and more substantial than the original, and featured 3 connection points. In the photo, the cable is affixed to the center point, used for recoveries on level ground. The top and bottom connections were used for operations on upward and downward slopes, respectively. The external brackets (3) were welded to the hull on an angle, apparently so that the right side bracket would provide clearance for the enlarged lifting arm (inset). The redesigned cable roller assembly (4) featured a housing holding 2 side rollers, which prevented the cable from slipping off while winching off center loads. A towing pintle (5) was welded to the differential housing. Stabilizer plates (6) can be seen installed on the front and rear bogies. These limited the volute spring action when lifting loads over 10000 pounds. Note how a little "stop" (7) was welded on to the bogie arm. A stronger "lifting cable safety connection" (8) replaced the original. A block (9) and another fitting (10) were added to hold a banana shaped tow bar, although the bar is rarely seen in place in period photos. Even after modification, it can be seen that the T5E3 retained the original "plate" turret with small door. The turret stowage represents the "first" configuration, and included a pair of spare road wheels installed on the front sides, along with two more affixed to the rear. Two spare drive sprockets were installed on the each side of the turret as shown. On welded hull models, the siren was relocated from the left front fender to the glacis, and fittings were provided to hold a vise on one fender and an anvil on the other.

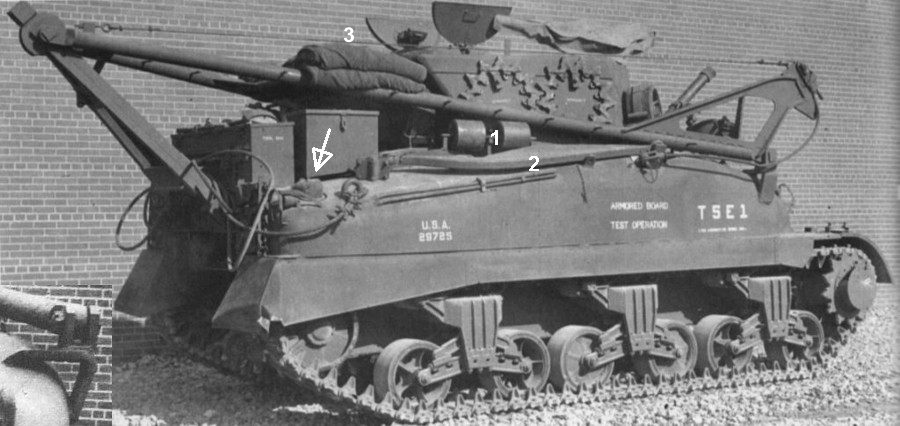

This view shows the T5E1 pilot after it was fully stowed. The tank's Serial Number was painted on instead of the USA Registration Number. M4A1 Serial Number 29725 was accepted at Lima in April 1943, and would have been assigned USA 3038255. Unlike the T5E3, this unit and the other pilots were not retrofitted with the heavy duty A-Frame that became standard on the M32 series. The cast hull pilot employed hinge brackets mounted on a platform that held the brackets out from the hull at the proper distance (inset). The hinge bracket assembly used on production cast hull conversions with the standard larger diameter A-Frame boom was much more substantial. A pair of spare return rollers (1) were carried on each side of the hull as shown. Note that the T5E1 pilot was outfitted with the seldom seen "banana bar." (2) The Technical Manual has it that a "Paulin, 12 ft X 12 ft" and a "Net, camouflage, 45 ft X 45 in" were "strapped to boom" (3). M4 and M4A1 Shermans were equipped with a pair of cast scoops (arrow) to increase the air flow to the fuel tanks. The T5 and T5E1 pilots retained these, but, for some reason, most or all of the production versions of these models done by Pressed Steel Car had the scoops replaced with blank off plates.

As M4A1 production came to an end at Lima Locomotive in September 1943, the company was contracted to develop fording kits for the Army's tank and "tank-like" vehicles. As mentioned previously, these had originally been designed and fabricated by the 5th Army Invasion Training Center in Northwest Africa. The Army wanted improved versions that could be mass produced in the US. The fording kits developed by Lima permitted vehicles to wade in surf for 8 minutes in depths up to 6 feet. The US kits were not available in time for the D-Day Invasion, but were supplied to troops in the Pacific starting in mid 1944. Above shows the T5E1 photographed in September 1943, "test wading" in a pond constructed at Lima. Note the double stack configuration Lima designed for the wading trunks of the retrievers. While the "banana bar" is rarely seen installed, the hinged tow bar (asterisk) was an important and universal item of equipment carried on the M32 series.

It was the practice of the Ordnance Department to preserve pilot models for future reference. This may have been the case with the T5E1 pilot. It would appear that it was taken "out of mothballs," made "Ready for Issue" and shipped to Korea. Above shows USA 3038255 in service with the 120th Engineer Combat Battalion in September, 1952. The T5E1 with its slab sided turret looks nearly unchanged from the previous photos taken 9 years before. However, it is to be noted that stiffeners (asterisks) were retrofitted to the small diameter struts of the original A-Frame boom.

The Ordnance Department wanted a retriever version of each type of Sherman then in production, and the T5 pilot was completed and shipped to Aberdeen Proving Ground in August, 1943. This unit was converted from USA 3010995, an M4 that had been accepted at Baldwin in April, 1943. Note the stowed position of the stabilizer plates on the glacis, and how 2 plates are stacked in each location. "HAND GRINDER" is stenciled just below the block like object (asterisk and inset) protruding from the side of the right fender. This item is something of a mystery. A pair of 3 inch square wood blocks sandwiched a metal plate. It is thought that this served as a mounting for a hand operated grinding wheel. However, we aren't aware of any period photos that show it installed. In any case, this "little block" can be seen on all versions of the M32 series, including the T14E1s. On retrievers with 3-piece differential housings, the front towing pintle was not welded on as it was on units with one piece diffs. Instead, the pintle was configured with a pair of side plates so that it could be bolted on to the flanges of the 3-piece housing (arrow). The inset is from the Technical Manual, and provides a sort of X-Ray view of the pintle as used on the front and rear of the M32 series.

After evaluation, the T5 pilot was used at APG in tests of the T1E2 Mine Exploder. The inset provides an overhead view of the T1E2 assembly, and shows the dangerous gap between the rollers. The T5 was an example of a pilot retained at Aberdeen "for historical purposes," where it was photographed in March of 1947. In October, 1943, the T5 series was standardized, and the nomenclature assigned to each type was "M32" (M4), "M32B1" (M4A1), M32B2 (M4A2), M32B3 (M4A3) and M32B4 (M4A4).

While the T1E2 Mine Exploder did not go into production, a similar version, the T1E1 did. As seen above on a later production M32, this version attempted to provide for more complete anti-mine coverage by incorporating a third roller to the front. Gar Wood Industries (the winch company) produced 75 T1E1 assemblies, and 50 were shipped to the European Theater of Operations, April through June, 1944. The mine exploder assembly weighed over 30 tons, as much as the retriever that served as prime mover. Consequently, like all the pressure type Mine Exploder designs, the T1E1 became easily bogged down. Ultimately, it was concluded that the T1E1 "failed to meet the requirements" for "locating and breaching minefields, and expeditiously clearing and/or detecting scattered mines on roads and trails." Indeed, the 739th Tank Battalion (Mine Exploder), which had been specially trained in the use of such units, withdrew its T1E1s from service in mid February, 1945. The assemblies were removed, and the vehicles were converted back to retrievers, and "applied against an acute tank recovery vehicle shortage."

Author Richard Hunnicutt states that the T5E4 (based on the M4A4) was shipped to Camp Seeley in California after it was completed in August 1943. We have not come across any documentation about it in our research. Due to the complexity of the 30 cylinder Chrysler Multibank engine, the M4A4 was NOT released for overseas (combat) use by the US Army. Instead, 7443 out of a total production of 7499 units were supplied to the Allies as Lend Lease. Ultimately, the T5E4 was the sole version produced based on the M4A4. Above is the only photo we are aware of that shows the T5E4, which must have been shipped back to Aberdeen Proving Ground for historical purposes. It can be seen that the original boom was strengthened at some point with girders. We would assume that the turret was recycled for use elsewhere.

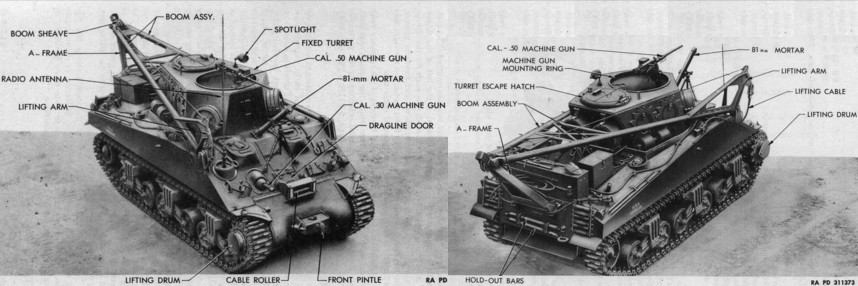

The T5E2 was shipped to the Tank Destroyer Board at Camp Hood, Texas in September 1943. Despite it being a pilot, it was the single unit featured in the M32 series Technical Manual published in December, 1943. The T5E2 pilot was converted from M4A2 USA 3056106, which had been produced by Federal Machine & Welder in April, 1943. The photos above are from the TM, and provide front and rear views with labels. Note that the early stowage configuration included spare tracks installed on the upper rear hull plate, using what appear to be the same fittings as on the T2. The "Hold-Out Bars" could be telescoped to various lengths, and as the name suggests, were used to hold the towed vehicle out from the towing vehicle in order to prevent damage to either. The TM has it that the Hold-Out Bars were stowed "at rear of vehicle" as shown here. However, in most period photos, they are seen stowed on the differential housing just below the cable roller assembly. The M4A2 with its GM twin diesel engine power plant was another Sherman type that was NOT released for overseas use by the US Army. However, the US Marine Corps chose to use them. There is also some evidence that the Marines "required" M4A2s specifically made by Fisher Body. Only 26 M4A2s were converted to retrievers. All were done by Lima for the USMC, and all appear to have been converted from new production Fisher M4A2s. Thus, it would seem that the T5E2 pilot was the only non Fisher M4A2 based retriever conversion.

In the absence of much documentation, we have tried to piece together the story of the T5E2s and M32B2s supplied to the USMC. These were the first production Sherman based retriever conversions. The first 5 units were done in June, 1943, and according to some Ordnance documents, they were assigned Serial Numbers 1 through 5. None of the retrievers converted by Lima were given new 401XXXX Registration Numbers, but simply retained their original Sherman RNs. Our theory is that the first 5 were made before the design was finalized, so that they were somewhat pilot-like in appearance. This well known photo of "Almighty" of the 3rd Marine Tank Battalion was taken on Guam in the Summer of 1944. Unlike the T5E2 pilot of the previous caption, this unit is equipped with the earlier, non standard cable roller assembly without the side rollers (1). Note as well the absence of the front towing pintle. We believe that the 5 T5E2s converted in June were the only production units installed with the flat plate turrets and the original boom with the 4 1/2 inch struts. The turret port (2) can be seen to be in the second, "chute" configuration, but it doesn't look quite right, which leads us to suspect that the original door port was modified. The distinctive welded together drivers' hoods (3) were a feature exclusive to Fisher Body small hatch M4A2s.

The Marines had their own identification number system, and painted out the US Army Registration Numbers. We had a little trouble at the US Archives getting the scan reproduced above to lie flat. However, it shows what we think was one of the first 5 T5E2s, and it has a readable RN - USA 3035141. This indicates that it was converted from an M4A2 accepted at Fisher Body in June, 1943. Note the "T5E2" painted on the side, along with the flat plate turret and the original boom with the 4 1/2 inch struts. It can be seen that the spare return rollers (1) are mounted inside the turret splash. With the introduction of the heavier boom, the return rollers were moved outward, with the attachment fittings welded to the top of the turret splash. We suspect that the "Hold-Out Bars" (asterisk) were only mounted on the upper rear hull plates of T5E2s Serial Numbers 1 through 5, and that these were repositioned to the differential housing on Lima's remaining retriever conversions. Unfortunately, we did not come across a front view of this vehicle. In his book, "Marine Tank Battles in the Pacific," Oscar Gilbert quotes an officer as saying that the 75mm turrets, guns and other items removed during the retriever conversions were retained by the Corps and shipped out as spare parts.

If our theory is correct, there would have been only 5 T5E2s configured like "Almighty." "Battlin'" and "Dude," also of the 3rd Marine Tank Battalion, were photographed on Iwo Jima, and noted with the early plate turrets. A rear view of "Battlin'" is shown in the left side photo above. Note the vertical orientation (1) of the hinge bracket, indicative of an installation with the small diameter boom struts. The rear fitting for the hinged tow bar (circled) is the same as seen on the T5 and T5E2 pilots. This was replaced with a wrap around strap, and it is thought that only T5E2s Serial Numbers 1 through 5 featured the early fitting. The Marines "required" that their retriever conversions be installed with fording kits. The Ordnance Department ordered the production of such kits only for the M32, M32B1 and M32B3 models. However, Lima provided them for the 26 M4A2 based conversions done for the USMC. Lima's design for retrievers featured a double stack wading trunk set up (2), as seen on "Battlin'." Period photos suggest that some Marine crews preferred to mount a .30 caliber machine gun (3) on the turret in lieu of the standard .50 caliber. The unit in the photo on the right has been identified as "Almighty," and was taken on February 25, 1945, just after she came ashore on Iwo Jima. The serious bend that can be seen in the boom strut of this veteran T5E2 provides graphic evidence of why the diameter of the struts was increased to 5 9/16 inches.

The first 14 T5E2s were converted by Lima on Production Order T-9273. As mentioned, the first 5 were converted in June. There was a 3 month lag, and then Lima converted 6 units in October and the last 3 in November, 1943. We suspect this delay provided the time needed to procure the redesigned and updated components. An Ordnance document has it that these 9 were assigned Serial Numbers 97 through 105. The photo above was taken at the Lima plant on October 6, 1943. Based on the date, we would guess that this was the first production unit built with the later features, including the turret formed of rolled armor, and the heavy duty boom struts. Note how the "chute" sits an inch or two higher than the one seen on "Almighty." The fittings for the Hold-Out Bars are on the differential housing, and, indeed, "Hold-Out Bar" is stenciled on just below the standard type cable roller assembly. This T5E2 can be seen to be USA 3035206, indicating that it was converted from a Fisher Body M4A2 produced in June 1943. Most small hatch, welded hull Shermans had cast drivers' hoods, but in order save foundry casting capacity, Fisher was asked to fabricate a number of components from rolled armor. Aside from the drivers' hoods, the antenna bracket (1), the bow machine gun socket (2) and the turret splash (3) were produced in this manner. Note that this unit is "still" identified as "T5E2." We would interpolate that the 14 units produced by Lima in 1943 had "T5E2" on their dataplates, and that all were converted from new production, small hatch Fisher M4A2s.

Unfortunately, there aren't many decent images of Marine retrievers. The units shown above were photographed on Saipan in the Summer of 1944. Both are based on Fisher small hatch M4A2s with the distinctive fabricated drivers' hoods. Both have the same features as 3035206 in the previous caption, including the heavier boom with the improved 3 point lifting arm (1) and the formed turret (2). Indeed, there is a 1 in 9 chance that either of these is 3035206. The T5E2 on the left has been identified as being with the 2nd Marine Tank Battalion, and features the Hold-Out Bars in the "standard" position on the differential housing (3). The unit on the right is thought to be "Lulubelle" of C Company, 4th Marine Tank Battalion. The large opening in the roof of the retriever's turret exposed the crew to artillery and sniper fire, not to mention Japanese tank swarming attacks. Marine records mention that some retrievers were retrofitted with covers and hatches. Lulubelle can be seen to have been modified in this way, and installed with an additional commander's split hatch (arrow). A pair of .30 caliber machine guns have been fitted to the pintles built into each hatch, in place of the standard .50 caliber skate rail mount. The Sherman in the foreground of the right side photo is "Joker," a large hatch M4A2 of the 4th TB that was later field converted to a mine flail using truck parts and other odds and ends.

The last 12 M4A2s converted by Lima Locomotive were done from March through May 1944 on Production Order T-12508. These are reported to have been assigned Serial Numbers 906 through 917. Their USA Registration Numbers are listed as 3036487 through 3036498. We have no way to confirm if this is accurate, but these RNs would have been assigned to large hatch M4A2(75)s produced by Fisher Body in February, 1944. For more information about large hatch M4A2(75)s, see our webpage. The Marines are stated to have been issued a total of 493 M4A2(75)s. We interpolate that about 200 of these, including the final 12 retrievers, had the larger drivers' hatches introduced starting in the Fall of 1943 as part of the "Second Generation" redesign of the Sherman series. In the 3rd Marine Division photo above, it can be seen that this unit is identified by the standard tank retriever nomenclature as evidenced by the "M32B2, Lima Locomotive Works" stenciling. This is probably the only known image showing a verifiable large hatch M32B2. Note the absence of a ventilator beside the driver’s hatch (area circled), indicative of a large hatch Sherman. We continue to search for a "combat shot" of a large hatch Marine retriever that can be identified as an M32B2.

M4A2(75) production ended in May 1944, so that the only 75mm gun tank available to the USMC from the second half of 1944 through to the end of the war was the gasoline powered, "Second Generation" M4A3(75) Wet Stowage Sherman. The Corps was issued approximately 328 M4A3s, some of which took part in the Iwo Jima and Okinawa campaigns in 1945. For the sake of uniformity, Lima was contracted to convert 20 new production M4A3(75)Ws to M32B3s for use by the Marines. These were completed June through August, 1944. Apparently, the Lima M32B3 conversions were not issued retriever Serial Numbers, but simply retained their original M4A3(75)W Serial and Registration Numbers. They are listed as SN 49459/USA 3082056, 49485/USA 3082082 and 49498/USA 3082095, which would have been accepted in May 1944, along with 17 units accepted in June with SNs 49904/USA 3082501 through SN 49920/USA 3082517. Again, we have no way to confirm if this is accurate. In any case, it is obvious from period photos that a few of the large hatch "VTRs" as the Marines called them, were used on Iwo Jima and Okinawa. Because they are so similar in appearance, it is difficult to distinguish a large hatch M32B2 from a large hatch M32B3. The photo above shows a unit of the 6th Marine Tank Battalion on Okinawa. The battalion was equipped with new M4A3(75)Ws before the campaign, so it is assumed that this large hatch retriever would have been an M32B3. The non standard location of the periscope and guard (arrow), suggests that this unit was retrofitted with some sort of cover over the open part of the turret roof. We would note that in the few period photos of USMC VTRs, all are seen with the "chute" turret port, and the "early" stowage configuration with the spare drive sprockets (or fittings) on the turrets.

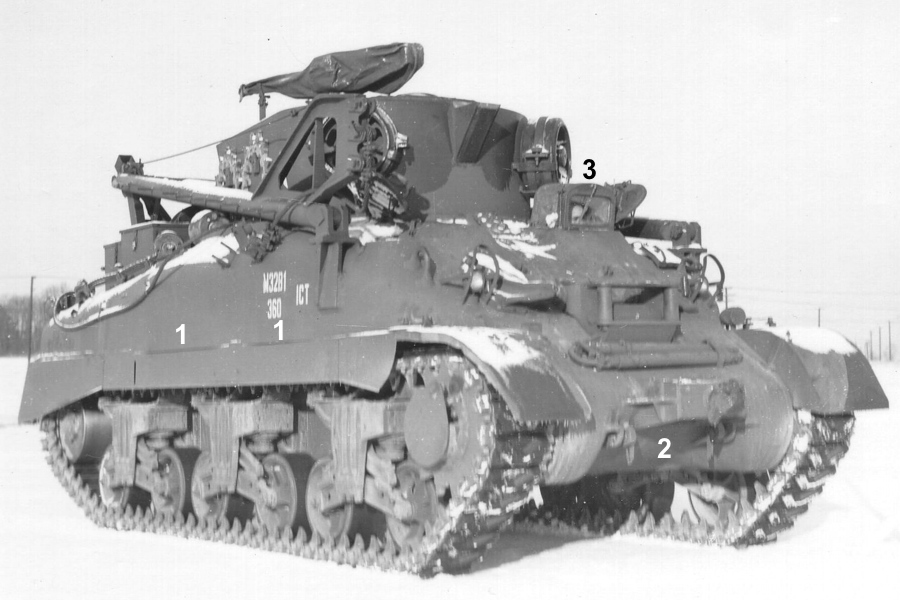

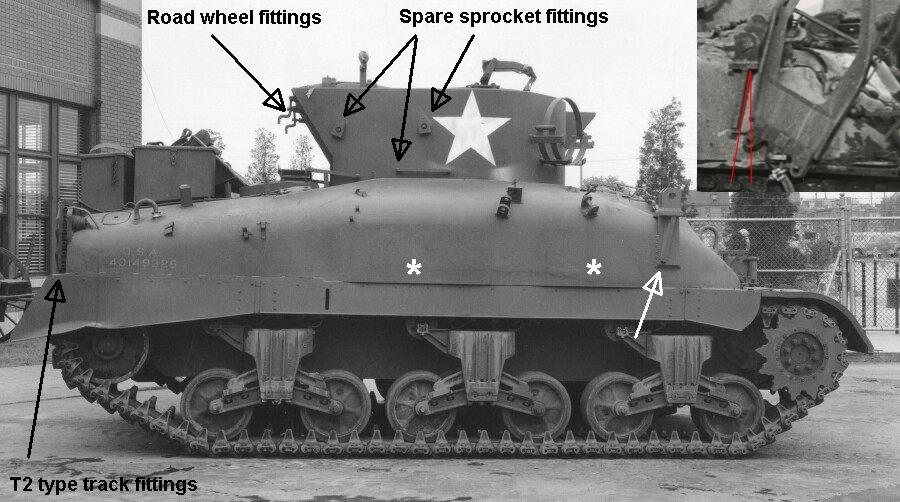

Lima converted new production Shermans for the Marines, but it was the policy of the US Army to employ used tanks for conversion projects. In the Summer of 1943, Pressed Steel Car was contracted to convert 936 M4s, M4A1s and M4A3s to M32 series tank retrievers. Production commenced in December, 1943, but there had been some difficulty in rounding up used Shermans. In order to get the program underway, an exception was made, and it was agreed that 91 new M4A1s would be pulled from the line at PSC. The new Shermans required only conversion, not remanufacture, which was a much more extensive process involving the replacement of engines and other internal systems with new or rebuilt components. The 91 new conversions were done from December, 1943 through March, 1944, and were assigned Serial Numbers 6 through 96, and USA Numbers 40149307 through 40149397. As some of the earliest M32 series conversions done for Army requirements, a number of these were shipped to the UK in time to take part in the D-Day Invasion and subsequent build up in Normandy. Above shows a front view of Serial Number 59, USA 40149360, completed in January, 1944, and photographed at APG in February. The new M4A1s provided for conversion would have been from PSC's last few months of production, and so would have had later features such as the cast in thickened sides in the areas of the sponson mounted ammunition bins (1), and the sharp nosed E8543 differential housings (2). This M32B1 can be seen in the "early" configuration with the "chute" turret port, and the turret mounted spare sprockets. For operations in inclement weather, Shermans were provided with a "Driver's Hatch Hood" (3) with windshield wiper and defroster as shown here.

This rear view of Serial Number 59 shows the original location of the spare road wheels (1) on the back of the turret, along with the initial position of the spare tracks (2). We suspect that not more than 100 of the PSC M32 series retriever conversions were built in the "early" stowage configuration. A number of the pioneer tools were stowed on the long tool box (3) that ran across the rear of the engine deck. A pair of snatch blocks (4) were carried just behind the turret. The boom can be seen locked in the traveling position by an A-Frame (5), pinned to a pair of sockets affixed to the hull. In this configuration, the A-Frame supported the boom during lifting and towing operations from the rear. We would note that the lower cross support members (6) are in the early configuration. It is thought that a pulley was added between the cross members around June, 1944. PSC is reported to have introduced the Barber-Colman type exhaust deflector (7) into M4A1 production starting December 1, 1943. Thus, many of the 91 new M32B1 conversions would have had this item factory installed beforehand. Any that didn't, along with the conversions based on used M4s and M4A1s, would have had the B-C deflector retrofitted during conversion. This unit can be seen with the double rear tow lugs (8) introduced into M4A1 production at PSC in late September, 1943. These served to accommodate the quick release towing shackle with handle, which can be seen in place. We don't find any evidence that second tow lugs were retrofitted to any of the PSC retriever conversions that lacked them. For future reference, note the "hollow" configuration of the boom brackets (arrow) used on the cast hull conversions.

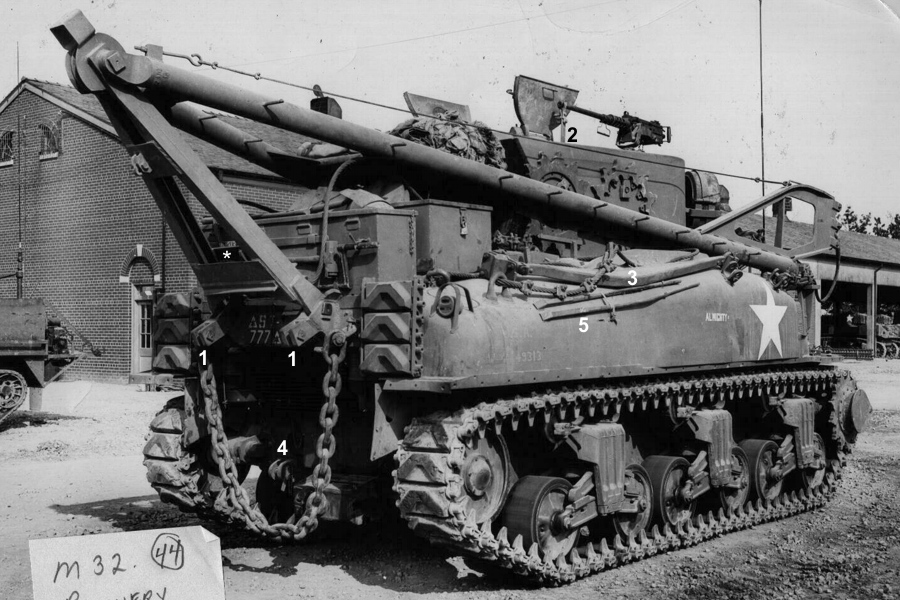

Above shows M32B1 USA 40149313 which would have been converted from a new M4A1 in December, 1943. "Almighty" served with the 777th Tank Battalion, which was a test unit at Ft. Knox in 1944. Most notably, the unit conducted trials of the M4A6 radial diesel, the rarest Sherman variant. Almighty can be seen with a pair of nonstandard fittings (1) retrofitted to the A-Frame sockets. These suggest that this retriever may have been involved in testing of the automatic tow hook, which we will discuss later. A barrel clamp (2) was provided to secure the .50 caliber AA machine gun in its traveling position as seen here. Note that the elusive "banana bar" (3) is in place. This unit is outfitted with the double rear tow lugs (4) as on SN 59 from the previous caption. It was common practice to paint the last 3 digits of the USA Number on the pioneer tools, and this can be seen on the track adjusting wrench (asterisk) and perhaps on the crowbars. The M32 Technical Manual has it that, like Sherman gun tanks, only one crowbar was provided, but it is obvious in a number of period photos, that there were fittings for 2 on the right rear and 1 on the left rear. We would guess that the bent crowbar seen here was not a standard issue item.

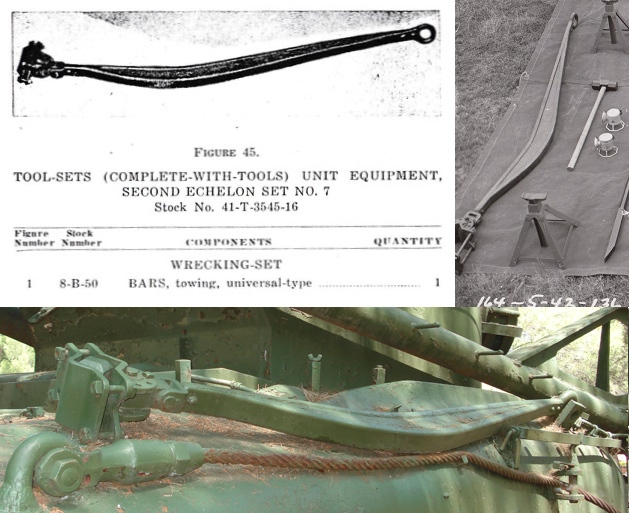

Above shows the 8-B-50 Universal Tow Bar colloquially known as a "banana bar" or "swan neck" bar. It was a pre-war light weight design used to tow disabled trucks by placing the curved section under the truck's front axle and attaching the bar to the axle with the mating clamp seen here. The bar was more commonly seen stowed on the right hand rear side of Diamond T 969 Wrecker trucks and occasionally on CCKW 2 1/2 ton trucks in US Army service during WWII. As mentioned earlier the bar was stowed on M32 series TRVs by attaching the axle clamp to a square post on the right rear upper hull of the TRV. Given that many units preferred to use wrecker trucks rather than the larger tracked TRVs to recover their disabled wheeled vehicles, it may be that only some units such as Armored Infantry Battalions, which contained a higher proportion of trucks and wheeled vehicles than tanks, regularly used the "banana bar" and this may explain why it is not commonly seen in period photos of M32 series TRVs.

Production based on the conversion of 845 used M4s, M4A1s and M4A3s commenced at PSC in December 1943 and ran through to December 1944. These were manufactured on a different Production Order from the 91 new conversions. The official Government documents are hopelessly jumbled, but we did come across a PSC Production Order which has it that 800 units were assigned Serial Numbers 106/USA 40154680 through SN 905/USA 40155479, and that the last 45 were assigned SNs 1943/USA 40191700 through SN 1987/USA 40191744. Within these ranges were 163 M32s, 384 M32B1s and 298 M32B3s. M32B1, SN 245/USA 40154819 would have been accepted in May 1944, and was the subject of an Inspection Control Test at APG that same month. It was photographed in October testing a rotating ring mount for the .50 caliber Anti-Aircraft Machine Gun. "As built," the gun was mounted on a skate which could be traversed around a fixed ring mount (inset). SN 245 is in what we think of as the "standard" stowage configuration. Note the proximity of the boom strut to the turret (arrow). It is thought that the spare drive sprockets were relocated from the turret to the hull sides because of potential interference issues created by the introduction of the larger diameter struts. SN 245 provides an overhead view of the original tool fittings (asterisks) mounted on each fender. Counting heads suggests that the "plate with 3 clamps" was replaced with a "frame" starting in late June 1944 at around Serial Number 375. This unit was converted from a used M4A1, and unlike the example in the previous captions, did not have the periscope guards factory installed.

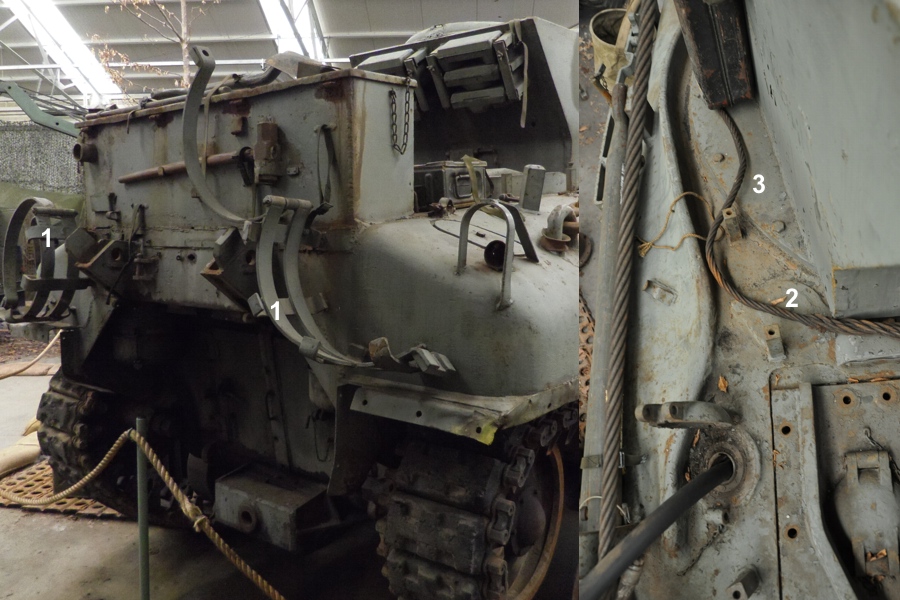

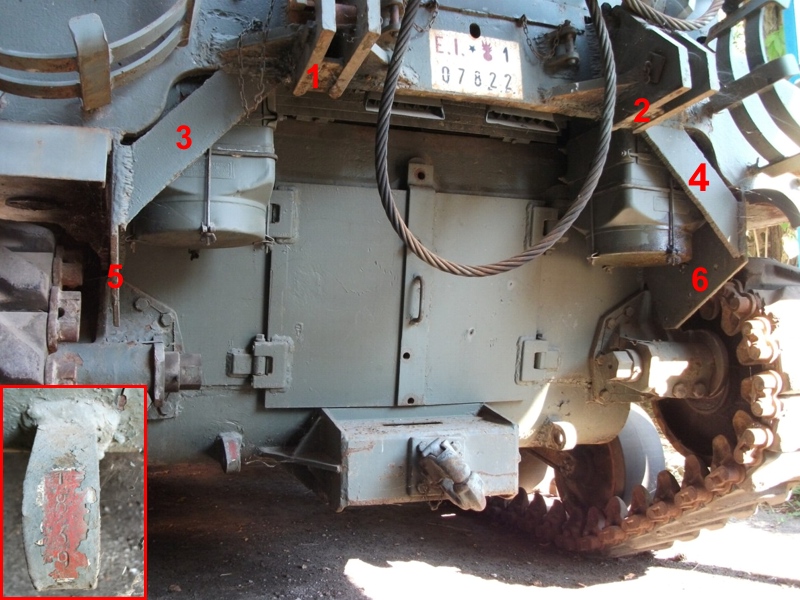

The M32B1 shown above is Serial Number 224, and would have been accepted in April 1944. It is in storage at the Bastogne Barracks, and may be a runner. At present, this unit has the lowest known serial number of any surviving PSC retriever we have encountered. Although we have not come across any documentation, it is obvious that sometime between January and April, 1944 PSC transitioned to the "standard" stowage configuration. The drive sprockets were relocated to the hull sides as seen here. After this change, the turret sides were devoid of any "official" stowage items. The use of the "chute" turret port (1) continued into the late Summer of 1944. M32 series conversions dispensed with the 2 ventilators installed on the gun tanks. The ventilator position on the right front (2) was used as the standard location for the retriever's antenna mount. This unit has hull lifting rings (3) typical of Lima Locomotive built M4A1s. Lima stamped its logo and a loose build sequence code (inset) into the right front armor of its Shermans, and the stamping seen here indicates that this tank had been accepted in March 1943, over a year before it was converted to retriever.

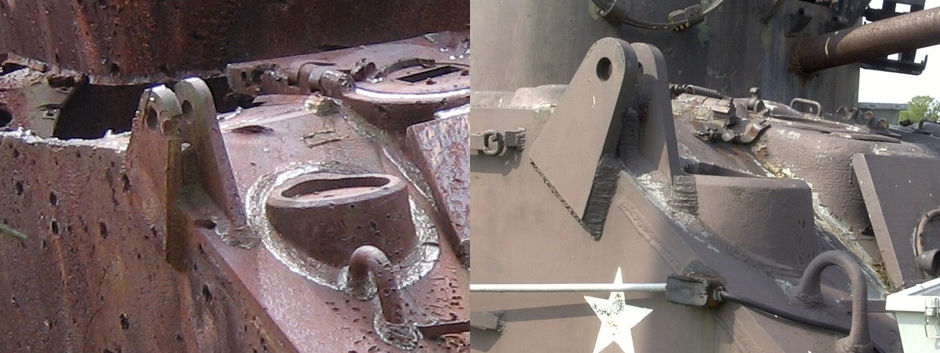

The photo above provides a look at the small hinged door (1) that covered the rear turret port on M32 series retrievers equipped with the front "chute" type turret. When not in use, the rear door was secured in the closed position by a retaining pin (2), which is partially pulled out on this example. In the standard stowage configuration, the spare tracks (3) were moved from their original location on the upper rear hull to the rear of the turret. The fittings that held the track blocks in their new location are the same as used on "second generation" Shermans with VVSS suspension. As mentioned, the ventilators were eliminated, and the opening on the right rear was blanked off. A block (4) can be seen welded on top of the blank off. Along with block 5, it held a spare return roller. On the T5E1 pilot, the two return rollers stored on both sides of the vehicle were located right next to each other. At the introduction of the larger diameter boom struts, the second return roller on M32B1s was relocated further to the rear as shown in the inset.

When the spare tracks were relocated to the rear of the turret, the spare road wheels were repositioned to the upper rear hull, and secured with the fittings (1) shown above on the left. The M32 series also dispensed with the auxiliary generator carried by Sherman Medium Tanks. As a consequence, the generator's fuel filler hole was blanked off (2) and the forward spare return roller was stowed over this area, as can be seen in the right side photo. In this view, note how the flange (3) at the bottom of the retriever turret was bolted on to the Sherman's turret ring.

At present, we are not aware of any surviving M32 series retrievers in the "early" stowage configuration. The photos above are screen captures from some Signal Corps motion picture footage shot around July 11, 1944 at Utah Beach. They show "Bring Em Back," an M32B1 of the 709th Tank Battalion. This unit can be identified as USA 40149343 (inset) indicating that it was converted in January, 1944 from a new production Pressed Steel Car M4A1. Note the thickened sides in the areas of the sponson mounted ammunition bins (1), and the sharp nosed E8543 differential housing (2). While the spare drive sprockets have been removed from the turret, the fittings (3) remain. The spare tracks (4) are stored in the T2 type track holder fittings typical of the "early" stowage configuration. This unit landed "dry shod," but just in case, it was waterproofed and installed with the single stack wading trunk fabricated in the UK for use on retrievers slated for the D-Day Invasion and subsequent build up.

Only 6 used M4A1s were available for conversion in December 1943 when the retriever program commenced at Pressed Steel Car. We would guess that the M32B1 pictured above might have been one of them. It can be seen with the riveted lower hull typical of PSC M4s and M4A1s manufactured up to about May, 1943. This would not have been a feature of any of the 91 M32B1s converted from new M4A1s. The used conversion program didn't really get underway until March, 1944 for the M32, April for the M32B1 and May for the M32B3. Given the typical 4 to 5 month factory to combat troops shipping times, not many of the used conversions would have been available for overseas service in the Summer of 1944. "Shoot Six Bits" was photographed "passing through the village of Ste. Mere Eglise on the way to the front lines" on June 13, 1944. The records of the 746th Tank Battalion have it that elements of the Service Company landed at Utah Beach on D-Day at "H plus 300...including a portion of the maintenance platoon consisting of 1 retriever T5..." "The second T5 retriever from the maintenance platoon" is reported to have come ashore the next day. These may have been some of the first M32 series TRVs to enter combat. The photo caption simply describes it as an "American Tank," but we suspect "Shoot Six Bits" was one of the T5s of the Maintenance Platoon of the 746th TB.

Another early configuration M32B1 was photographed on the streets of Sainte Mère Eglise in June. Based on the earlier 1-piece differential housing, we identify "Step N Fetchit" as another conversion of a used M4A1. This may have been the "sister" TRV of "Shoot Six Bits." We did a magnifying glass examination of the original Office of War Information print, and recorded the last 3 digits of the Registration Number as "684," which would lead us to think that this might have been USA 40154684, one of the 6 used M32B1 conversion done by PSC in December, 1943. Of interest is the vise installed on the left fender (1). The crew have moved the snatch blocks (2) from their usual stowage positions. Item 3 is one of the two chock blocks provided. These were normally stowed on the engine deck with the snatch blocks as seen in the inset. An oddity noted on "Step N Fetchit" is the "closed off" hinge brackets (arrows). This may have been done on "Shoot Six Bits" as well. Perhaps a modification to correct a defect?

In addition to the 109 T2s converted to M33s, Chester Tank Depot converted 24 M32B1s to M34 Prime Movers in March 1944. The photo above appears to have been taken at CTD, and shows USA 40149326, which had been converted from a new production M4A1 by Pressed Steel in December, 1943. We have labeled the major items that are typical of the "early" stowage configuration. The thickened sides (asterisks) in the areas of the sponson mounted ammunition bins show up well in this photo. As with the T2s, sand shields were standard on the M32 series. As seen here, a section of the right front shield was cut back in order to provide clearance for the lifting drum mounted on the retriever’s right sprocket. Of course, the lifting drum was unnecessary to the function of the M34, and was removed along with the boom. Note how the reinforcing gusset (arrow) on the M32B1's right side hinge bracket was welded on at an angle. Again, this appears to have been done to provide clearance for the enlarged, 3 point lifting arm of the standard boom (inset). It should be noted that the gusset on the left side bracket was welded on vertically.

The M34 shown above also appears to have been converted from an M32B1 based on a new production M4A1. We suspect that all 24 M34s were converted from among the 31 new M32B1s produced by PSC in December, 1943. Due to delays in the M6 High Speed Tractor program, the Army required 300 expedient prime movers to be produced by early 1944. It was planned that these would be converted from retrievers, but only 109 T2s were available, and just 24 M32B1s were released. Ultimately the government turned to an expedient of an expedient, and 209 new M10A1 Tank Destroyers were converted to M35 Primer Movers to make up for the shortfall. We have not come across any "combat shots" showing M34s towing 240 mm Howitzers or M1 8 inch Guns. We take the "778 F" painted on the right front of this M34 to be a tactical marking for the 778th Field Artillery Battalion. The 778th was equipped with 240 mm howitzers, and it is thought they may have trained with the M34s in the US, before deploying to the Philippines in 1945. This M34 was likely transferred to Aberdeen for "historical reference" along with an M33 and M35, all of which were photographed there in December, 1946.

During the Korean War, many of the lesser known type AFVs, both Allied and Axis, that had been preserved at APG for historic reference were scrapped in order to free up space for current military needs. The Signal Corps photo above is dated April 4, 1952, and shows what we suspect is the M34 Prime Mover. Note the protrusion of the thickened side on the left (arrow). Since none of the expedient Prime Movers remain in the collection, it is thought that the M33 and M35 were also scrapped at that time.

Aside from Prime Mover conversions, the Army needed a number of M32 series retrievers available for conversion to T1E1 Mine Exploders. Fifty T1E1 (aka "Earthworm") and 72 T1E3 (Sherman based, aka "Aunt Jemima") assemblies were shipped to the European Theater of Operations in the months preceding D-Day. However, "since the plan for the initial assault of the beach had been finalized,...these mine exploders were not initially called for by First US Army." Due to training and organizational issues, the Mine Exploders saw very limited use during the Normandy Campaign and subsequent breakout. Consequently, "two tank battalions (special) were converted to mine exploder battalions in the United Kingdom in September 1944, [and] moved to the Continent late in October." Both M32s and M32B1s were used for the T1E1 conversions. The "Special Mine Exploder" [SMX] Battalions were first employed in late 1944. The photo above is part of a series dated December 19, 1944, taken during a demonstration near Geilenkirchen, Germany. It shows a pair of knocked down Mine Exploders of the 739th Tank Battalion (SMX) being used as retrievers in an attempt to free an "Aunt Jemima" that became hopelessly mired after exploding 6 mines. While all of the telltale features are not visible in this series of photos, we would guess that both of these units were based on "new" M32B1 conversions in the early stowage configuration.

The photo above is datelined January 16, 1945, near Houffalize, Belgium. It shows a T1E1 of the 738th Tank Battalion (SMX) attempting to provide safe passage for a column of the 2nd Armored Division. "New" M32B1 conversions are frequently seen in the few period photos, and we would judge this unit to be one, based on the thickened side visible on the left. In order to mount the T1E1 roller assembly, it was necessary to remove the retriever's front towing pintle. In cases where the hold out bars were mounted on the differential housing, they were removed, and a number of photos show them relocated to the left side of the vehicle as seen here (1). This unit appears to have been retrofitted with some sort of cover (2) over the opening in the turret. The T1E3 "Aunt Jemima" had only 2 rollers, and consequently left a dangerous "mine gap" in the center during operations. The front roller of the T1E1 permitted the vehicle to "clear a continuous path equivalent to the width of the tank." Uneven terrain was a great problem for the pressure type mine exploders. It appears to have been the intention of the designers that the retriever's boom would be deployed forward during rolling operations. A boom cable would support the rollers, and act "as a leveling device and prevent the exploder units from impeding the advance of the prime mover over irregular terrain." However, the few available period photos show rolling operations with the boom secured in the traveling position (mounted to the rear) as seen above. A disadvantage noted was that "the T1E1 does not have the firepower to double as a "fighter" tank."

Click on photos for more detail

This photo is dated March 1, 1945, and highlights one of the new T26E3s of the 9th Armored Division as it heads for the Rhine River. On March 7, the 9th AD had the distinction of capturing intact the Ludendorff Bridge at Remagen. The background offers a rear view of one of the 738th Tank Battalion's T1E1s in the early configuration, and based on one of PSC's "new" M32B1 conversions. Again we see the relocation of the hold out bars to the left side of the hull. Gar Wood Industries produced a total of 75 T1E1 assemblies in April, 1944. The T1E1 featured 3 "exploder units," each with 6 roller discs. Each disc was 4 feet in diameter and 2 inches thick. The entire assembly weighed 32,270 pounds. These were shipped overseas as kits to be installed "in the field." Aside from the 50 sent to the ETO, a few period photos suggest that a small number of T1E1s were used in the Mediterranean Theater.

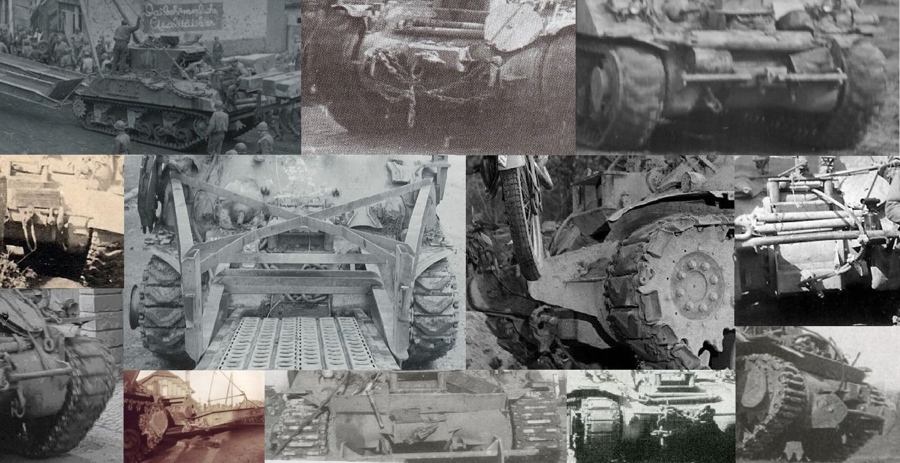

During WWII the US Army did not develop a standardized armored bridgelaying vehicle, so a number of units took it upon themselves to modify either their M31 or M32 series TRVs to allow them to cross smaller combat obstacles under fire. Due to these modifications being performed at a division or battalion level in-theatre they differed in detail, but were essentially of a similar design. Improvised mounting brackets or bars were usually attached to the transmission housing or lower glacis of the TRV to mount a single section or a pair of parallel sections of Treadway bridge and the TRV's boom was utilised to lower the bridge section into place. On some vehicles multiple Treadway sections were carried and a counterweight was required on the rear of the TRV to offset the weight of the bridge spans. The above photo-montage shows a small selection of some of the expedient mountings seen on M32 series TRVs.

Pressed Steel converted 163 M4s to M32s. Above shows one of Patton's 3rd Army crossing a pontoon bridge over the Moselle River, September 13, 1944. This unit can be identified as having been converted from a 1942 production PSC M4 by the early "bent rod" lifting ring (1). Note PSC's use of a riveted lower hull (2), along with a vertical upper rear hull plate (arrow). The later type of bogie units, including 2 with the "upturned" returned roller arms (3), would not have been available in 1942, so would have been retrofitted during the retriever conversion. PSC began M32 production in March, 1944 with 42 units followed by 63 accepted in April. This retriever appears in a sort of "Version 1.5" or "intermediate" stowage configuration. The spare drive sprockets have been moved from the turret to the hull, typical of the standard configuration, while the spare road wheels and tracks are in their early configuration locations. However, the spare track holders are the later type, not the T2 style fittings typical of the early stowage configuration. It has not been possible to "count heads" on the "intermediate" configuration, except to note that it has been seen so far only on a small number of M32s thought to have been produced in March or April, 1944. Note the "plate with 3 clamps" tool fitting (4) and the first type of A-frame cross support members (5). As mentioned previously, counting heads suggests that both of these items were reconfigured in June, 1944. PSC did not do any M32 conversions in May or June, and built only 1 unit in July, followed by 19 in August, with the final 38 produced in December, 1944. The hold out bars (arrow) can be seen mounted at the rear. Unfortunately, the USA Number is obscured by road dust, but considering the date of the photo and shipping times, it seems fairly certain that this unit would have been one of the 105 M32s produced in March or April, 1944. For future reference, note the continuous nature of the sand shield attachment strip (asterisks), and the "caution plate" seen on the lifting drum.

Unlike the T2/M31 series, the design characteristics of the M32 series called for the use of the heavier M4 type bogies. Thus, any Shermans turned in for conversion that had M3 bogies installed as original equipment would have had these replaced. While it was policy to refurbish and use as many original parts as possible during conversions, in this situation it would have been necessary for PSC to procure at least some new M4 bogies. As the retriever program got underway in early 1944, new production M4 bogies featured "upturned" return roller arms. These eliminated the need for the spacers (circled in red above) installed on the earlier “straight" type return roller arms. As mentioned previously, the front and rear bogies were modified in order that stabilizer plates could be fitted. The Technical Manual illustrations above show the changes that were made.

Some Government documents have it that Federal Machine & Welder and Baldwin Locomotive produced some M32s along with M32B1s, while other references state that these companies only did M32B1 conversions. Based on the small number of available period photos, we suspect that PSC alone manufactured M32s, and total production amounted to only 163 units. The 4th Armored Division appears to have been equipped with either M32s or M32B1s while in the UK. The Division landed in Normandy in mid July, 1944. The photos above are screen captures of some Signal Corps motion picture footage taken around this time, and show an M32 of Company A, 37th Tank Battalion. Note the riveted lower hull as used on PSC M4s and M4A1s produced up to the Spring of 1943. The elongated drivers' hoods replaced the direct vision castings at PSC in late 1942. Again we see some of the later "upturned" return roller arms (1). This M32 is another one of the few seen in the "intermediate" configuration with the spare road wheels (2) "still" mounted at the rear of the turret, and the spare tracks (3) still mounted on the upper rear hull plate, but with the later type of track holders. Note the absence of the "hold out bars" or their fittings on the differential housing. A frame by frame examination of the Registration Number (inset) leads us to think that this M32 might have been USA 40154698, indicating March, 1944 acceptance.

Until we can collect more information, we can only guess that the rear location of the hold out bars may have been part of the "intermediate" configuration. Or perhaps it was used on the early (March-April, 1944) retriever conversions with 3-piece differential housings? (There are period photos that show the hold out bars "officially" mounted on 3-piece diffs.) The T5 pilot had a 3-piece differential housing, and the hold out bars were affixed to the A-Frame sockets as shown above in the left side photo. The photo on the right shows an intermediate configuration M32 with the rear mounted hold out bars (1). Of course it is not possible to tell if this unit had a 3-piece diff. The T2 type track holders (2) of the early configuration can be compared to the "second generation" Sherman type holders (3) as used on M32 series in both the intermediate and standard configurations. It is our working theory that the early stowage configuration was a feature of most or all of the 91 new M32B1 conversions, along with the 6 used M32B1s done in December, 1943. We have not seen the early configuration on anything but M32B1s. We would interpolate that the intermediate stowage configuration was used on "many" of the 105 M32 conversions done in March and April, 1944, and would mention that we have not seen the intermediate configuration on anything but M32s. The transition to the standard configuration appears to have been completed sometime in late April or early May. Counting heads, all of the known Serial and/or Registration Numbers we have recorded that are higher (later) than the May production M32B1 SN 245/USA 40154819 shown in an earlier caption, are noted to be in the standard configuration.

The photo above is dated November 11, 1944, and was taken in a small town near Nancy, France. In the photo's caption, the crew members are stated to be "men of the 4th Armored Division." We identify this retriever as an M32 based on the continuous sand shield attachment strip (1). Note that the hold out bars are mounted on the 3-piece differential housing, leading us to posit that this unit is in the "standard" configuration. It is thought that all of the 58 M32s produced from July through December 1944 would have been in the standard configuration. At present, all of the small hatch, welded hull retriever conversions done by PSC, both M4 and M4A3 based, are seen installed with the drivers' hood applique plates. The plates were notched to accommodate the 81mm Mortar fittings as pointed out above. This unit is seen with the "chute" type turret port. Counting heads suggests that PSC transitioned to the final configuration with the "door" turret port in August, 1944.

There are very few surviving M32s. Above shows an example on a range in France. This unit was converted from a 1942 production Pressed Steel Car M4 with direct vision drivers' hoods. The sharp nosed differential housing (1) did not enter production until the late summer of 1943, so would not have been original equipment. It may have been installed at the time of the M32 conversion, possibly because the original differential housing was faulty. On the M32 series retrievers that we have examined, the sides of the chute type turret are seen assembled from two pieces of armor. The largest section comprises about 75% of the assembly. It is wrapped around the front, and joined to a much smaller section on the left side of the turret. The weld seam is circled in the photo on the right. Note the spare road wheel fitting (2) attached to the left side of the upper rear hull plate, typical of the standard stowage configuration.

An interesting overhead view of the M32 on display at the Technik Museum in Speyer, Germany. The Germans are reported to have received 46 M32 series retrievers as Military Assistance in the early 1950s. Like the previous example, this is another “standard stowage configuration“ unit which was converted from a 1942 production Pressed Steel Car M4 with direct vision drivers' hoods. The Museum added a cover (1) over the open section of the turret roof. As mentioned earlier, the Marines appear to have done something similar in some cases, and then added an additional commander's split hatch (2) to the cover. Photo courtesy of Mathieu George.

A single "Vehicle, Tank Recovery, M32 series" was supplied to Brazil as Military Defense Assistance in the early 1950s. We would assume that the M32 shown above running in a parade is the unit that was provided. Note the riveted lower hull (1), which identifies this as yet another conversion of a PSC M4, although, in this case, we see the later, elongated drivers' hoods. A correspondent was able to record that this vehicle has its USA Registration Number stamped into the glacis plate on the right front. We have seen this on a few surviving Shermans and variants, and would judge that it was done during rebuilds of the late 1940s or early 1950s. As mentioned in an previous caption, the last 45 M32 series conversions done by Pressed Steel were reported to have been assigned SNs 1943 / USA 40191700 through SN 1987 / USA 40191744. At present, the Brazilian M32, USA 40191719, is the only example we have recorded that falls within this range. The last 45 conversions completed at PSC would have been accepted in December, 1944, and it can be noted that this M32 has the final "door" type of turret port, which is thought to have replaced the earlier "chute" type by the end of August, 1944. This tank currently belongs to 8th Logistic Battalion of the Brazilian Army. Photo taken by Alisson Paese in Porto Alegre, in an event of the Reserve Officials Preparations Center – CPOR.

The Ordnance Department had determined that the 500 HP Ford V8 engine was the best tank power plant, and the US Army sought to train as well as equip its troops for combat with as many M4A3 series as industrial conditions would permit. PSC's original retriever Production Order for the conversion of 850 used Shermans had wanted the majority to be based on the M4A3 at 450 units. However, by August 1944, the company was short 155 M4A3s. The contract was amended, and readily available M4A1s gathered from the training program were substituted for the M4A3s. Ultimately, 298 M32B3s were produced, and it is thought that this figure represents the sum total of retriever conversions based on the Ford built, small hatch M4A3. M32B3 production did not commence until May 1944, and they are not mentioned in unit records or shown in overseas photos until late 1944. The image above is part of a series taken on December 15, 1944 near Guising, France, shortly after the combat debut of the 12th Armored Division. It shows a pair of M32B3s of the 23rd Tank Battalion attempting to recover an M4A3(75) Wet stowage Sherman that had fallen into a bomb crater. The souvenir history of the 12th AD "Hellcats" notes that mechanics and drivers were pleased to be equipped with Shermans with "Ford tank motors" when they arrived in the UK in the fall of 1944. It is thought that PSC used the same sand shield attachment strips on its M32B3 conversions as on its M32s and M32B1s. The slightly longer hull of the M4A3 resulted in a pair of gaps (circled), which prove useful in distinguishing M32s from M32B3s.

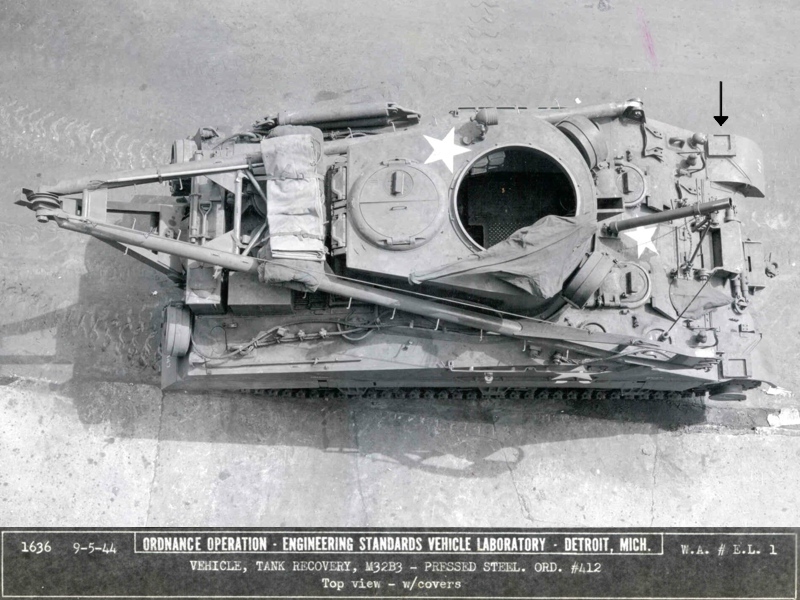

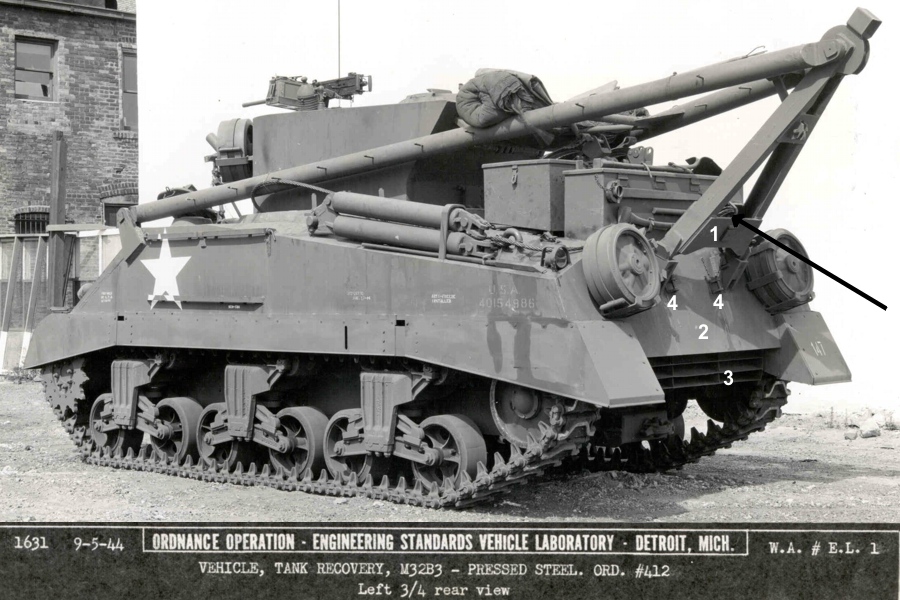

The photo above shows M32B3 Serial Number 412, USA 40154986, which would have been converted by PSC in June, 1944. Shortly thereafter, it was evaluated by Chrysler's Engineering Standards Vehicle Laboratory in Detroit. In this overhead view, it can be seen that the unit was converted from a 1942 production M4A3 with direct vision drivers' hoods and "padded" hull lifting rings. PSC did not begin to convert M32B3s until May 1944, and it is thought that all of them were built in the standard stowage configuration. Counting heads suggests that the original "plate with 3 clamps" tool fittings on the fenders were replaced in June, 1944 with the frame type fittings seen here.

In this right front view of Serial Number 412, one can see the mounting of the 81 mm mortar. The platform pieces (1, 2 & inset) appear to have been introduced by Pressed Steel in mid 1944. It is believed that all of the Lima conversions, including the large hatch M32B2s and M32B3s, were built using the earlier mortar mount configuration. Note that SN 412 "still" has the "chute" type turret port. Counting heads suggests that PSC transitioned to the final configuration with the "door" turret port in August, 1944. As with the T2 / M31 series, sand shields were ordered installed on the M32 series. The small gaps (circled) typical of PSC's M32B3s show to good effect in this photo. Just above the forward gap is a stencil that reads, " Prepared by L.T. D. 8/13/44." The sand shield can be seen cut away in the right front to accommodate the lifting drum. Note the metal caution plate (3) affixed to the lifting drum. The antenna brackets on Ford built M4A3s had larger diameters than the mounts used on M4s, and came much closer to the edge of the glacis. As a consequence, it was necessary to weld the internal boom pivot brackets to the antenna fittings, as indicated by the arrow. The antenna bracket was provided on all "first generation" Shermans, although it was rarely used except for command tanks which were equipped with a second, longer range radio mounted inside on the right front sponson. According to the Technical Manual, retrievers were supplied with standard SCR 528 or SCR 538 radios. The antenna is shown mounted in the bracket. In general, the antenna was made up of three sections, each approximately 3 feet in length. They were joined together using ferrules (arrow), not unlike multi-piece fishing rods.

Each retriever was supplied with a base plate for the M1 81mm Mortar as standard equipment, so that the mortar could be dismounted from the vehicle and fired from the ground if required. Page 141 of the Technical Manual describes the procedure required to remove the mortar from the glacis as “Pull out pins which secure bipod legs on lugs on front plate of tank (fig. 82)”, as seen above left. It later states to “Remove feet from bipod legs which are used on vehicle, and clamp on bipod feet which are used on ground." These spiked ground feet (red arrows) are shown in fig. 86 (above middle). The two small adaptor platforms attached to the lugs on the glacis and stood proud of the glacis when the mortar was fitted. They contained a frame type bracket that permitted the mortar to be mounted on the vehicle with the spiked ground feet still attached to the bipod, facilitating faster mounting and dismounting of the mortar, as it no longer required the feet to be swapped over.

The metal caution plate appears in a small number of period photos. It has not been possible to do an effective head count on its introduction. Due to the seemingly random nature of its presence, we think it is possible that it may have been installed only at Lima Tank Depot on retrievers processed through there. The caution plate is still on a few surviving retrievers. As best we can determine, it reads, " CAUTION: HOLD RADIO ANTENNA AWAY FROM BOOM WHEN BOOM IS RAISED OR LOWERED.” Thus, it would appear that the right front mounting of the antenna had the potential to cause interference issues. This was also the case with Sherman gun tanks, although the problem there had to do with the antenna fouling on the main gun when the turret was rotated.

The photos above show (left) a surviving M32 converted from a Pressed Steel Car M4, alongside an M32B3 converted from a Ford built M4A3. It can be seen that the larger diameter of the antenna bracket castings used by Ford made it necessary to weld the internal boom pivot brackets directly to the antenna castings.

The “touching” boom pivot brackets on M32B3s rarely show up in period photos. However, the image above is from “The Pictorial History of the 493rd Armored Field Artillery Battalion of the 12th Armored Division in the European Theater of Operations.” The forward “gaps” in the sand shield strips can also be seen, providing further aid in identifying these as M32B3s.

This left rear view of Serial Number 412, shows another change that appears to have been introduced at about the time this retriever was converted in June, 1944. Note how a pulley (arrow) has been added between the cross support members of the A-Frame boom. The new configuration of the cross support members features a removable square plate (1) that held the pulley’s axle. Absent are the L shaped brackets seen on the original configuration of the cross support members. From June until the end of the program at Pressed Steel in December, 1944, we would judge that all of their conversions were equipped with pulleys. Furthermore, period photos and surviving examples suggest that all of the M32 series conversions done by Federal Machine & Welder and Baldwin Locomotive from the start in late 1944 to the end of their programs in mid 1945 featured pulleys. If it can be seen in a photo, M4A3 Shermans or M32B3s can be distinguished from M4s or M32s by the much "deeper" upper rear hull plate (2). The sheet metal exhaust deflector (3) is typical of the M4A3, and was introduced at the start of production at Ford Motor Company in the Summer of 1942. The fittings numbered 4 were used to mount the hold out bars during lifting and towing operations from the rear.

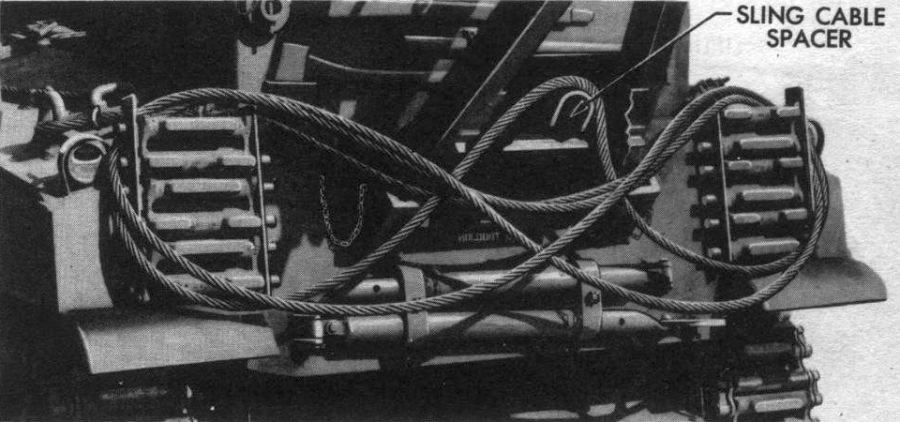

As mentioned earlier, the T5E2 pilot was the single unit featured in the M32 series Technical Manual published in December, 1943. The view above is from the Tech Manual. In it, the outer cross support member of the A-Frame boom has been cut away to reveal the “Sling Cable Spacer,” a half round object used before the introduction of the pulley. We have not come across any documentation that explains why the spacer was replaced with a pulley. We suspect the pulley was simply more efficient, and put less stress on the sling cable. However, there doesn’t appear to have been a Modification Work Order mandating the replacement of the original spacer with the pulley.

As mentioned previously, in both the European and Mediterranean Theaters, a small number of M31 and M32 series retrievers were adapted to emplace treadway bridges. Above shows M32B3 USA 40154977 of the 61st Armored Infantry Battalion, 10th Armored Division laying such a bridge in St. Julien, France in January, 1945. The square plate on the cross support member identifies this unit as equipped with a pulley. For forward lifting operations, the Sling Cable was threaded around either the pulley or the half round spacer and attached at each end to the tank's rear lifting rings (white arrow) as seen here. Also of note is the “lifting cable safety connection” (red arrow) designed “to prevent boom from falling back on the vehicle if the lifting cable should break, or the load is released suddenly.” Photo courtesy of Mike Haines.

The photos above provide details of the the pulley set up as seen on a pair of surviving M32B1s. It would appear that the plate (1) held the pulley’s axle, and that it was secured on the other side with a large castellated nut (2).

Counting heads suggests that PSC transitioned from the "chute" type turret port to the much larger "door" configuration in late August, 1944. As with the pulley, period photos and surviving examples suggest that all of the M32 series conversions done by Federal Machine & Welder and Baldwin Locomotive featured the "door" turret port. Note the curved configuration of the door, and the construction of the side pieces that flanked it. One of the ferrule connections (arrow) that joined the antenna sections is painted blue, and shows to good effect on this unit, M32B1 Serial Number 793 on display at the Armor Museum at Saumur in France.

In a previous caption, we showed the asymmetrical assembly of the sides of the chute turret with its single joint on the left. The sides of the door turret featured two identical formed plates that were welded to a curved front plate. In these photos of the M32A1B1 on display in Auto & Technik Museum in Sinsheim, Germany, the arrows point to the weld seams on the left and right sides.

The smaller rear port (1) of the chute turret is shown on the left. On door type turrets, the port (2) was elongated as seen in the photo on the right. The rear port of the chute turret was opened and closed from the outside, and was locked in the closed position by a removable pin at the top (missing in our photo). In contrast, the port of the door turret was opened and closed from the inside.

An interior view of the small door of the chute type turret is shown on the left. This can be compared with the elongated rear port of the door turret on the right. It can be seen that the pulley (1) of the chute turret was stationary. Evidence from surviving examples suggests that the axle of the door turret's pulley (2) permitted side to side travel, which may have had the purpose of enabling a better distribution of the cable on the drum of the winch. While the rear port of the chute turret was opened and closed from outside the turret, the door turret was opened and closed from inside, possibly in the interest of greater crew safety. Two L shaped pins (3) secured the door in the closed position. A chain (4), with a small handle on the end (5), was attached to the middle of the inside face of the door to pull it closed. The configuration of the front pulleys of the door and chute turrets closely corresponded to those of the rear pulleys seen here.

While it is possible that some of the 91 new production PSC M4A1s converted to M32B1s could have had large hatches, we have yet to see any evidence supporting this. In 2008, a set of “GI photographs” surfaced showing a large hatch M32B1 in Germany shortly before or after VE Day. Tactical markings show that the vehicle was with Service Company of the 20th Tank Battalion, 20th Armored Division. A portion of the Registration Number (1) beginning with 40155 can be seen in one of the photos, which is outside the range allocated to the vehicles converted from the 91 new M4A1s (40149307 to 40149397) confirming that this retriever was instead one of the 384 M32B1s converted by PSC from used M4A1s. This retriever can be seen with the spare drive sprockets mounted on the hull side as per the standard stowage configuration (2), the door type turret port (3), frame type tool fitting on the fenders (4) and the adaptor platforms for the mortar feet (5), all later style fittings introduced after the retrievers built on the 91 new PSC M4A1s had been completed. Note that the hull does have thickened sides indicating it was manufactured with the cast in hull armor (6). Large hatch M4A1(75)s were pretty rare. Our research suggests that about 100 of the 175 M4A1(75)s produced by PSC in December, 1943 had them.

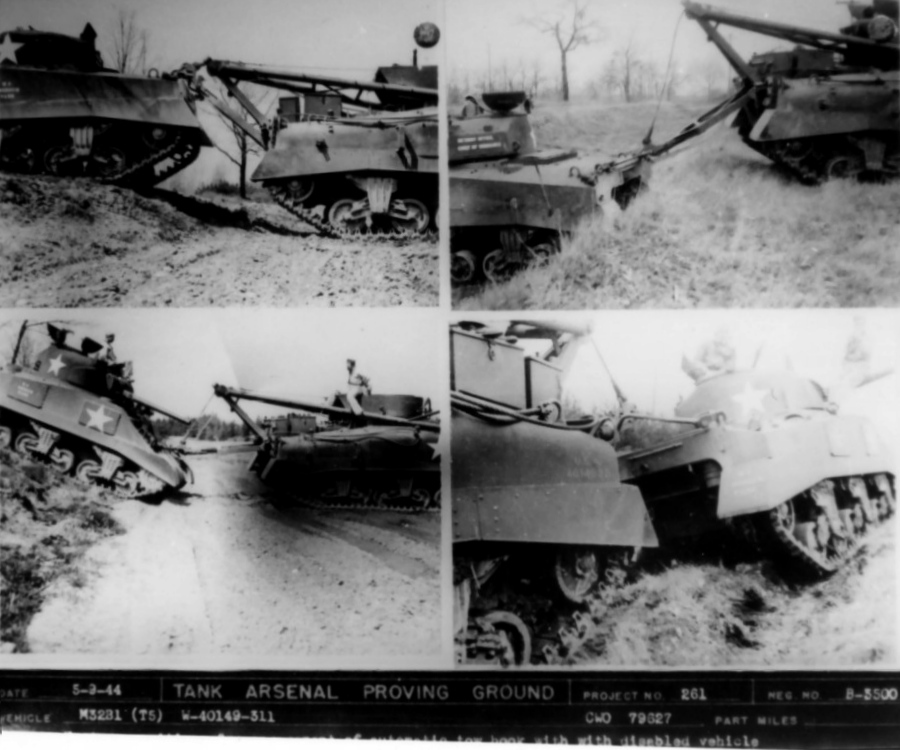

In early 1944, the Ordnance Department began work on an "Automatic Tow Hook." Its purpose was to enable retriever crews under sniper or artillery fire to recover tanks without leaving the safety of their vehicle. The montage above was filmed at Chrysler's Tank Arsenal Proving Ground in May, 1944. In this case, the tow hook was a prototype with a girder style of construction. It can be seen that the hook caught hold of cables (bridle assemblies) retrofitted to both the front and rear of the M4 in the photos. The information panel identifies this retriever as USA 40149311, one of the first of the new production M4A1(75)s converted to M32B1 in December, 1943.

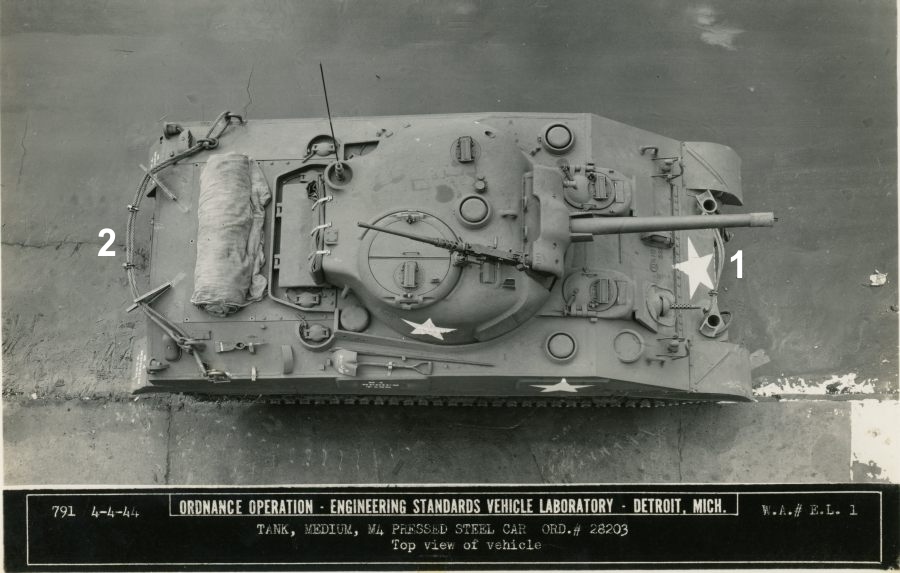

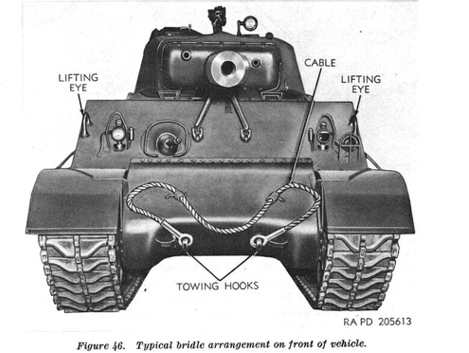

The photo above was taken on April 4, 1944, and provides an overhead view of a PSC M4, Serial Number 28203, the tank used in the tow hook trials shown in the photos of the previous caption. Note the bridle assemblies retrofitted to the front of the vehicle (1) as well as the rear (2). At first, it was intended to provide Bridle Assembly Modification Kits for retrofit to every tank in, or scheduled for shipment to, combat zones. Photo courtesy of George Fancsovits.

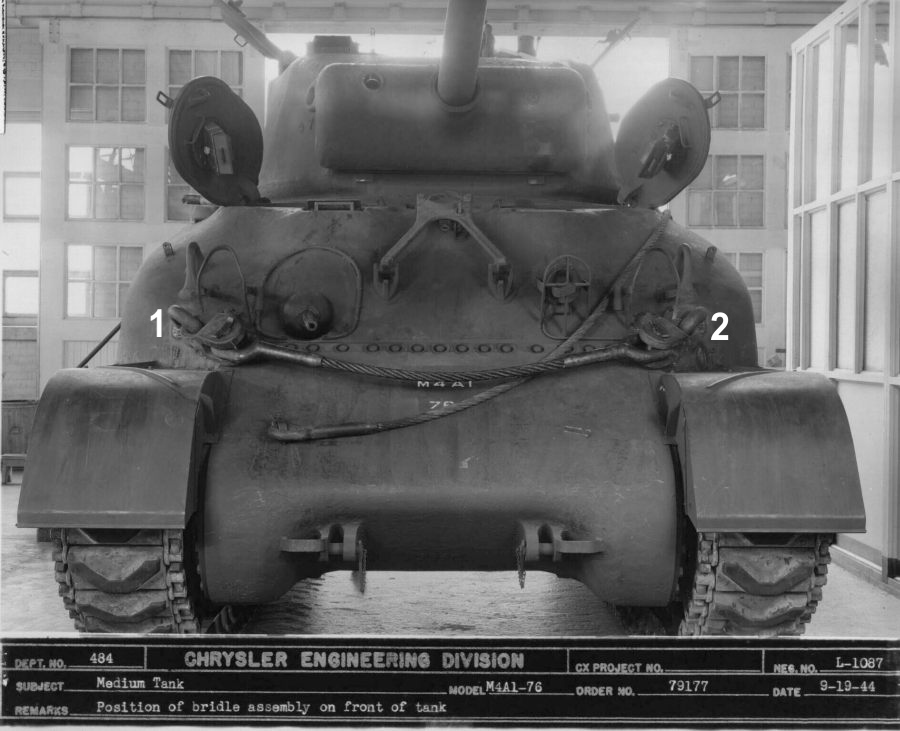

The M4A1(76) shown above was photographed in September, 1944 and shows what we believe to be the standard bridle assembly which would have been supplied in both front and rear versions in a Modification Work Order. Note that a pair of attachment rings (1 and 2) were welded on to the glacis at an angle in order to hold the heavy duty towing cable. It is assumed that these bridle assemblies were intended to be permanent fixtures on US tanks in combat zones. An Armored Fighting Vehicles and Weapons (AFV & W) Memo from the ETO dated January 27, 1945, noted that "Action has been taken to requisition MWO G1-W26 which provides the cable (for engagement with the recovery hook) for installation on all tanks." As best we can tell, this MWO never went into production. However, we would note that the front bridle assembly shown here was part of MWO G1-W24, the Automatic Tow Hook Modification kit, published 30 April, 1945.

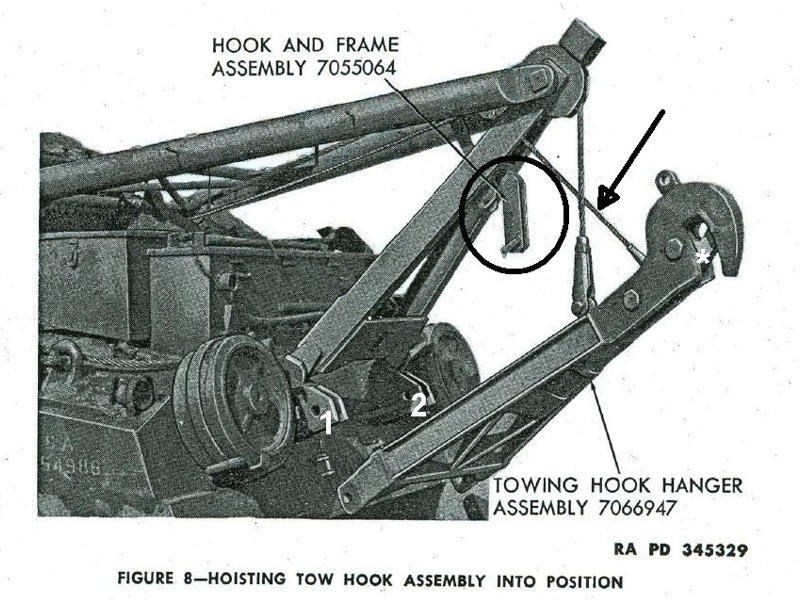

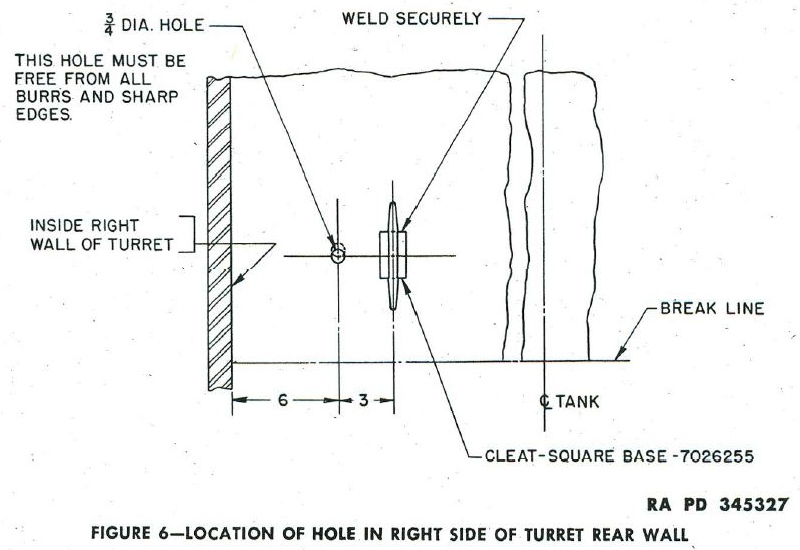

Chrysler used M32B3 Serial Number 412, USA 40154986 to test and model the Automatic Tow Hook. The illustration above is from MWO G1-W25 and shows the tow hook assembly being hoisted into position. A pair of extension assemblies (1 and 2) were included with the MWO and were welded to the retriever's existing A frame support sockets. It should be noted that the items shown have been mislabeled. The tow hook assembly should be labeled "Hook and Frame Assembly (Part Number) 7055064, and the "Towing Hook Hanger Assembly" should point to the item circled. An extension plate and the Towing Hook Hanger Assembly were installed on the boom A Frame. The Hanger Assembly held the Tow Hook in the stowed position. A "Control Rope" (arrow) was provided and was attached to the hook's trigger eye. By means of a pulley the control rope was guided into a 3/4 inch diameter hole drilled into the rear of the turret. Thus, at least in theory, from inside the safety of the turret, the jaw (asterisk) of the tow hook could be opened and closed when grasping the cable of a tank's bridle assembly.

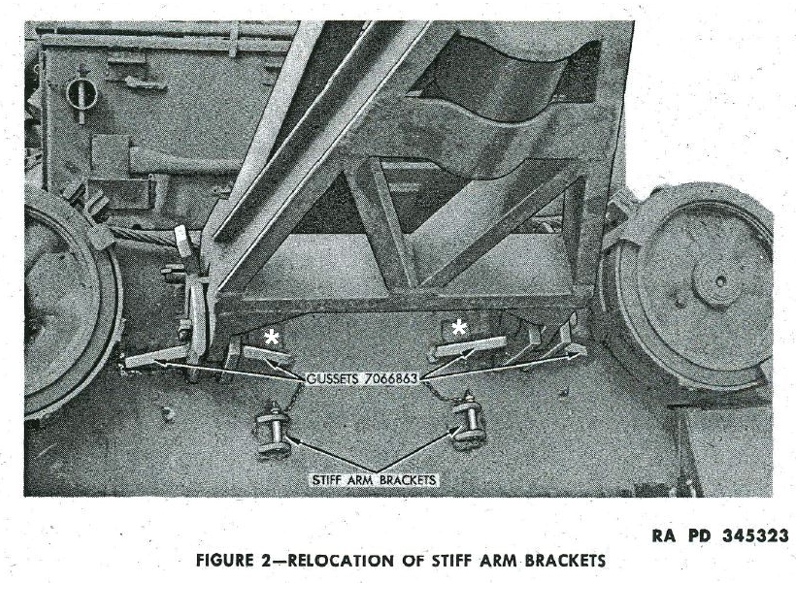

In this view from the MWO, one can see that each extension assembly was supported by a pair of gussets included with the modification kit. The instructions state that "Some vehicles may require the relocation of the hold-out bar (stiff arm) attaching brackets to allow the gussets to be located properly." On SN 412, the hold-out bar (or stiff arm) brackets were originally located in the area of the inside gussets (asterisks), and were removed and repositioned as shown. Some surviving examples that received the tow hook modification have been noted to have had the brackets relocated, while on others, the brackets are "still" in their original positions.

The schematic shown above provides instructions for cutting a 3/4 inch hole in the rear of the turret for the control rope. A cleat was also provided to secure the rope when not in use. Oddly, the "control rope hole" is seen on just about every surviving retriever, even those that do NOT show evidence of having received the automatic tow hook modification.

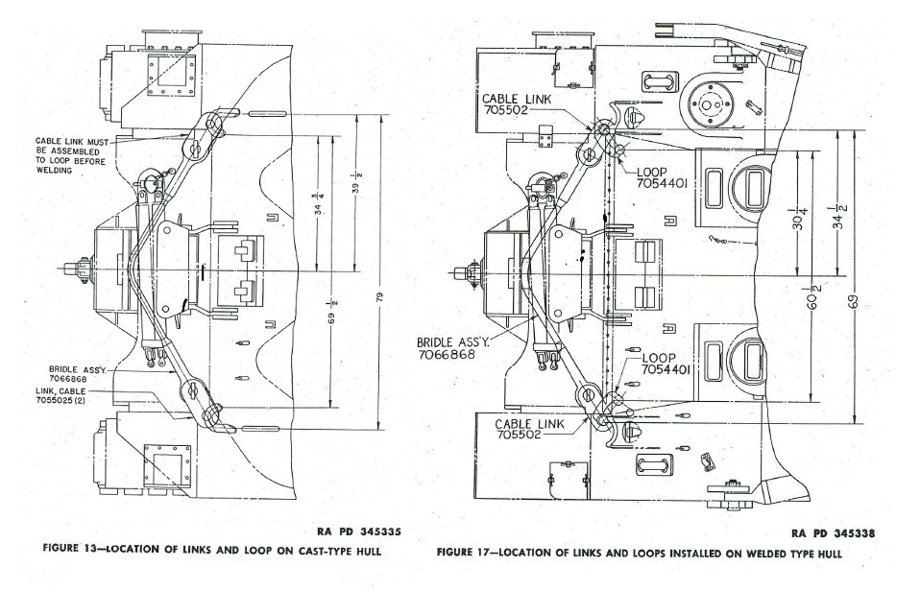

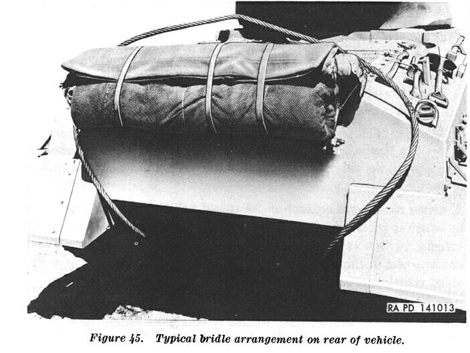

MWO G1-W25 provided the necessary parts and instructions for installation of the bridle assembly on the front only of cast and welded hull retrievers as shown above. "The bridle on the front of the Tank Recovery Vehicles can be used to recover the vehicle if disabled, or to allow another Tank Recovery Vehicle to hook into the bridle and assist in pulling a heavy towed load through mud or up steep inclines." Note the instruction, “Cable Link must be assembled to loop before welding.” Thus the cable links (Part Number 705502) become permanent fixtures on retrievers once the loops are welded on.

Due to terrain and other factors, we suspect that it would have been very difficult for the Automatic Tow Hook to work as intended. Most likely crew members would have had to get out and expose themselves to enemy fire in order to guide the hook on to the bridle of a tank or other disabled combat vehicle. Of course, it would have been necessary for each disabled vehicle to have been pre-installed with bridle assemblies in order for the system to work at all. As mentioned previously, the modification relating to the installation of bridle assemblies on tanks and other types of combat vehicles appears to have been cancelled. Instead, per MWO G1-W25, "The field will be instructed to improvise bridles on combat vehicles to allow the hook to be connected to the vehicle and tow it to a protected area for repairs." We did not come across the instructions regarding the improvised bridles, but the illustrations above are from the September, 1954 M4A3 Technical Manual, and show "standard 20-foot towing cables" arranged for use as bridles on the front and rear of the M4A3. We would note that aside from the test tanks shown earlier and a few M32 series TRVs themselves, we have not encountered any WW II or even Korean War era photos that show bridle assemblies on any combat vehicles.

The Armored Fighting Vehicles and Weapons Memo from the ETO dated January 27, 1945, states that, "A total of 1,070 ["Remote Control Recovery Hook"] kits have been requisitioned by the theater, all for shipment to Northern France. Of the total, 185 are for Southern France. These items are scheduled for loading the latter part of February." The 1070 figure may provide a clue as to the number of M32 series retrievers in the ETO (or expected to be there) circa March or April, 1945. It may also hint at the number of MWO kits that were produced? In any event, MWO G1-W25 was not published until April 30, 1945, so we doubt if any kits were ever shipped to Europe. The modification was wanted on M32 series retrievers slated for the Invasion of Japan, although the numbers needed would have been considerably fewer than 1070. The last instructions in the MWO..."Major items affected will not be shipped overseas after 30 April 1945 unless this work order has been applied." As yet, we haven't come across any WW II era overseas photos that show the automatic tow hook modification on a retriever. The photo above is dated October 30, 1944, and once again shows M32B3 Serial Number 412. The M7B1 Priest has been installed with bridle assemblies on both the front and rear. The control rope has been pulled taut, and the jaw (red asterisk) of the tow hook can be seen to be partially open, ready to grasp the Priest's front bridle assembly.

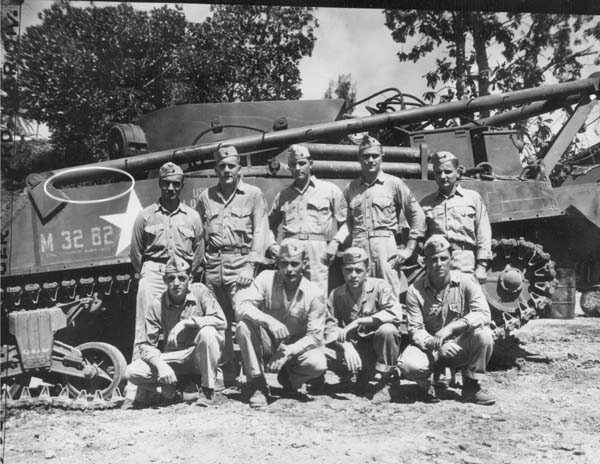

Pressed Steel Car completed its orders for M32 series retrievers in December, 1944 with a total of 936 units. These and the conversions done by Lima for the Marines would be the ones that would have had the best chance of being sent overseas during WW II. Baldwin Locomotive Works built its last new Sherman in January, 1944 at which point its Production Orders were terminated, as it was determined that requirements for new tanks could be met by just three producers - Chrysler Corporation, Fisher Body and Pressed Steel Car. Federal Machine & Welder Company's Production Order for M4A2(75)s was also terminated, and its last new Sherman was accepted in December, 1943. As mentioned previously, the Army Supply Program called for the conversion of approximately 1200 additional retrievers for 1945. Federal Machine was given an order to "remanufacture and convert" 400 "M32 & M32B1.” This order was started in November, 1944 and completed in May, 1945. Baldwin's original order was for 800 conversions, but as the end of the war approached, this was cut back, and ultimately, the company produced 180 M32B1s, "37 M32A1B1" [sic] and 30 T14E1s starting in November, 1944, and ending, we suspect, in July, 1945. The photo above shows the factory floor at Baldwin at the outset of their conversion program in the Fall of 1944. We would point out that the turrets removed from these M4A1s and other of the later conversion donors were not scrapped. Instead, starting in October, 1944 "at the rate of 100 per month," the old turrets were shipped to Fisher Body where they were refurbished up to current standards, and used to equip some of their new production M4A3(75)Ws.