Tank Recovery Vehicles

Most of the information on this page is courtesy of Joe DeMarco. Note: Some of the data was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving retrievers. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

Part 1 : M31 Series

Series

production of the M3

Medium Tank got underway in June, 1941, and almost immediately the

Ordnance

Department began experimenting with specialized conversions based on

the tank's

chassis. One such effort called for the creation of a full tracked

prime mover

for heavy artillery pieces. In April, 1942 the Baldwin Locomotive Works

delivered 2 pilot models of the prime mover, which were assigned the

nomenclature "Heavy Tractor, T16." Tests at the Desert Training

Center in California found the T16 to be unsuitable as a prime mover

due to a

lack of stowage space. However, in the Summer of 1942, the Desert

Warfare Board

shifted focus, and began testing the T16 in the role of Tank Recovery

Vehicle. Above

shows T16 Number 1 at the DTC in January, 1943. By that time, it was

being used

as an object of recovery itself in trials of the recently designed M26

Tank

Transporter. The T16s were converted from diesel engine M3A5 Lees. In

the

photo, it can be seen that a 40000 pound capacity winch was mounted to

the

lower rear of the vehicle. This displaced the dual muffler assembly,

which was

relocated to the engine deck. As a result of tests at the DTC and

Aberdeen

Proving Ground, suggestions were made for a new Tank Recovery Vehicle

design

based on the M3 Medium chassis. In August, 1942, 100 new M3A3 and

M3A5s, and

100 used M3 Lees were released to Baldwin for conversion "under the

name

Heavy Tractor, T16."Most of the information on this page is courtesy of Joe DeMarco. Note: Some of the data was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving retrievers. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

Part 1 : M31 Series

These

charts represent our working theory of the M31 Tank Recovery Vehicles

monthly production figures, including the Serial and Registration

Numbers assigned.

The new Recovery Vehicle was re-designated "T2," and by late September 1942, the design was far enough along that Baldwin was directed to produce 750 units. 150 would be conversions of new diesel M3A3 or M3A5 Lees diverted from Baldwin's M3 Production Order. The remaining 600 (later reduced to 509 units) were to be repaired, reconditioned and converted from used gasoline powered M3s "sent in from field troops." These units were to be retrofitted with the improved 80 Octane R-975-C1 Radial engines, which included the "high engine outlet exhaust," and externally mounted air cleaners such as used on M4 and M4A1 Medium Tanks. All units of the program were to be equipped with "the Lipe type clutch." The exact design for the first 108 units had been finalized, but it was noted that the design of the remaining conversions "may be changed in minor details as the results of the tests conducted by the using arms." Somewhat optimistically, the Ordnance Department directed that the 750 T2s were "to be produced by April 1, 1943." In fact, only 163 units had been completed by the end of March. Gar Wood Industries was the sole manufacturer of the winches and booms, and an acute labor shortage in the Detroit area hindered their ability to deliver these components on time. The Government attempted to remedy the situation by giving a higher priority to the entire T2 program, but labor shortages remained. In the event, Baldwin completed the conversion program in December, 1943 with a total production of 805 units. Above shows the 60000 pound capacity Gar Wood winch mounted in the crew compartment directly below the turret. Note the "mobile shop" arrangement of the left side stowage cabinets.

The pilot model of the T2 Tank Recovery Vehicle was delivered to the Armored Force Board at Ft. Knox in November, 1942. "Katrinka" was converted by Baldwin from an August, 1942 production M3A3 (welded hull, diesel) Lee, USA 305373. While Baldwin scrambled to procure the various T2 stowage items, the pilot was shipped with its original late production M3 Lee stowage. Retrievers were relatively helpless, so a pair of dummy guns were welded on in an attempt to conceal the vehicle's purpose. The winch cable was threaded under the vehicle, and could be set up to perform recovery operations in either the front or rear. For lifting, a crane assembly was mounted on a plate designed to fit the opening of the M3 Lee turret's 37mm gun mount. The lifting capacity of the crane assembly and winch was 10000 pounds (5 tons) without boom jacks, and 30000 pounds "with boom jacks mounted on ground base." In mid 1942, a number of changes were introduced on the M3 Lee series including the elimination of the side doors, and the addition of 3 ventilators to the hull and turret. These changes can be seen on Katrinka. Many of the used Lees that were converted to T2 had working side doors, which were welded up during the conversion.

In this rear view of Katrinka, one can see the method by which the boom assembly was bolted to the Lee turret. While the turret mounted boom was capable of rotating 360 degrees, testing by the Armored Force Board revealed that this was the weakest part of the design due to looseness in the turret's retaining race, as well as an inadequate traversing mechanism. A pair of adjustable boom jacks (1) are shown in their traveling position on the boom assembly. On the pilot, one of the boom jack pin assemblies (2) was welded onto the support angle (3) at the vehicle's center line. In production, the pin assembly was relocated, slightly offset from the right edge of the support angle as seen in the inset. Fittings for a pair of spare return rollers were added to the support angle in the space between the pin assemblies. The inset shows the upper rear hull plate typical of M3s with radial engines. This plate (4) was much taller and mounted on an angle on M3s equipped with the GM twin diesel engine power pack. It provided partial protection for a pair of radiators and a muffler assembly mounted on the vehicle's lower rear hull plate. The "bumps" along the upper edge (arrow) are not rivets, but slotted bolts which held the removable rearmost engine deck section. Item 5 is the exhaust deflector typical of diesel Lees, Grants and early M4A2 Shermans.

The photo above shows Serial Number 2, USA 4096599, the second T2 delivered to the Armored Force Board in early 1943. This unit was based on an M3A5 (riveted hull, diesel) Lee, and was more completely stowed than Katrinka. This photo was used in the Technical Manual to demonstrate the crane's 15 ton lifting capacity "with boom jacks mounted on ground base." The AFB reported that the M3 Medium's volute springs were overloaded during lifting operations, and this can be seen in the splay of the middle and rear bogie units. It is thought that the transition from the use of M3 to the heavier duty M4 type bogies was completed on the Sherman series by October 1942. It would have been logical to retrofit the T2 conversions with M4 bogies, but it is obvious that this was not done, possibly because the improved bogies could not be spared as Sherman production ramped up. However, period photos suggest that Baldwin did retrofit "spacers" to the bogies of its T2 conversions in order "To increase the clearance between the track support roller and the suspension bracket by installing a spacer A295847 [Part Number]." Field Service Modification Work Order G104-W15 was released on 23 February 1943 and applied "to every Tank, medium, M3 and M4, that is not equipped with the revised [M4] type bogie and roller suspension assembly D47527." We would note in passing that the 497 M3 series Medium Tanks that were remanufactured and converted to Canal Defense Lights in 1943 and 1944 were retrofitted with M4 bogies. It is somewhat curious that USA 4096599 can be seen with a ventilator on the turret, but not on the forward roof of the hull. What can be seen there is a driver's periscope (above the asterisk). While not part of the original M3 design, at the request of the British, a driver's periscope was installed on many of the Grants and a few of the Lees assigned to Commonwealth Lend Lease. Baldwin was the only company that produced both the Lee and Grant versions of the M3 Medium. The company completed its M3 series Grant contract for 685 units in July 1942. Its US contract was for 685 M3 series Lees and was completed in December 1942. However, the US Production Order was reduced by 150 units, when these were converted new to T2 Diesel retrievers.

In December 1942, Captain Robert Van Zant of the Maintenance

Company, 13th Armored Regiment, 1st Armored Division was asked to submit

ideas for improving maintenance operations based on his experiences up

to that time in the fighting in Algeria and Tunisia. One of his

recommendations was for a full track recovery vehicle using the M3 Lee,

"It might be possible to improvise such a "recovery" track vehicle from

some of the M-3 mediums which we hope to replace. There are some whose

turrets and/or guns are inoperative, but the chassis is still

serviceable to a limited extent. Such a vehicle might possibly be

converted and "improvised" upon by our own maintenance battalion or

possibly attached ordnance unit." Apparently, Van Zant was unaware that

such a tank recovery vehicle had been designed and was just entering

production in the US. Above provides a rear view of USA 40103652. It was

photographed at the Chester Tank Depot circa January 1943 as it was

being prepared for shipment. In the absence of accurate Government

records, we have resorted to "counting heads" in an attempt to establish

the Serial and Registration Number ranges that were assigned to the

T2s. From that, we interpolate that Serial Numbers 1 through 150 were

assigned to the T2 diesel conversions based on new M3A3s and M3A5s, and

that Serial and Registration Numbers 151/USA 40103652 through 659/USA

40104160 were assigned to the 509 used, gasoline powered, radial engine

M3 Lee conversions. If our theory is accurate, the retriever in this

photo would have been the first M3 to T2 conversion, and, officially,

would have been accepted in October 1942. Counting heads also suggests

that spare tracks were stored on the rear of the stowage boxes starting

in mid-January 1943 after about 30 units had been produced. The shovel

seen here was displaced, but its subsequent location is not given in the

T2 Technical Manual. Most M3 Lees were built with R-975-EC2 radial

engines with pepper pot exhausts and internal air cleaners. However, the

photo shows the "high engine outlet exhaust" (1) and the externally

mounted air cleaners (2) typical of the R-975-C1 radial. The T2

Technical Manual lists the engine types as the "Continental R-975-C1" or

the "Twin GM Diesel Series 71, Model 6046." We take this to mean that

any of the used M3 Lees shipped to Baldwin with R-975-E2 engines would

have had these changed out during the "remanufacturing and conversion"

process. The original pepper pot holes would have been blanked off, such

as seen in the inset on SN 258 in France. Baldwin appears to have used

both the round (2) and square versions of the externally mounted air

cleaners. If necessary, plates 3 and 4, along with the little door stops

(5) would have been added by Baldwin.

This T2 was photographed at the Hampton Roads Port of Embarkation in Virginia on February 28, 1943. By our production theory, this would have been the 41st of the T2s converted from used M3s and would have been accepted in January 1943. Note that unlike the previous example, USA 40103693 has spare track links affixed to the rear of the stowage boxes. The U-shaped fittings (arrow) affixed to the front and rear bogies were used to secure the vehicle to a rail car in the manner shown here. These are seen in a number of photos of early Shermans overseas. The initials "C.T.D." are stenciled on in a dark color by the side door. They stand for "Chester Tank Depot." Three Tank Depots, one on the East Coast, one in the Midwest and one on the West Coast, were established to process, modify and seal military equipment for overseas shipment. Chester was the East Coast Depot and was within walking distance of the Baldwin plant in Eddystone, Pennsylvania. In the campaigns in North Africa, both the British and US noted an urgent need for purpose built, full track armored vehicles for the recovery of tanks. As they became available, the US shipped T2s to Northwest Africa, and they began to arrive in the Spring of 1943. A report from the Services of Supply dated 13 February 1943 states that the first 9 units were "shipped to North Africa; three (3) to each of the three (3) Tank Destroyer Battalions." It is thought that these may have been some of the first diesel T2s, specifically intended to support TD Battalions equipped with diesel engined M10s. The report notes that a further 95 T2s had been shipped or were scheduled for subsequent shipments to Northwest Africa.

A few T2s were likely used in service before the end of the Tunisian Campaign on 13 May 1943. The photo above is part of a series taken in the "El Guettar Valley...1943", which suggests that the unit shown here may have supported the 1st Armored Division's "Benson Force" during the Battle of El Guettar in late March/early April. In this instance, the crew appears to have "painted" their retriever with mud and mounted a .30 caliber machine gun to a field made pedestal. The stowage of the shovel suggests that this was one of the first 30 or so radial T2s. The U-shaped railroad shipping fittings can be seen to have been retained but re-installed upside down. We suspect that this T2 was received with sand shields that the crew opted to remove.

Above shows USA 40103727 awaiting processing for issue at a vehicle dump in Oran, Algeria. By our count, this would have been the second gas powered T2 accepted in March 1943. This photo is dated May 11, 1943, 2 days before the final Axis capitulation in North Africa. Note that 40103727 has a vertical upper rear hull plate (arrow) typical of M3 series tanks with gasoline powered radial engines. The same plates on diesel engine M3s were mounted on an angle and extended down much further. Primary access for the 6-man crew was through a door retrofitted in the 75mm gun's sponson. It can be seen that the door's dummy 75mm was somewhat flimsy, and easily damaged. Baldwin was required to retrofit sand shields to the T2 conversions. They were fashioned in the same pattern as the ones installed on most of their Grants. The Technical Manual advised..."Sand guards are provided for use on the vehicle on desert or other dusty or sandy terrain. Sand guards should be removed when the vehicle is operated in wooded territory. Otherwise, guards will become badly bent and damaged."

The photo above is dated July 2, 1943 and is thought to have been taken at Bizerte Harbor in Tunisia as the tanks of G Company, 66th Armored Regiment, 2nd Armored Division assembled on LCTs before the Invasion of Sicily. Note that "Go Get It" and the M4A1 to its front have been been installed with wading trunks for shallow water fording during amphibious operations. These were developed a few months before by the 5th Army Invasion Training Center in Oran, and saw their first use in Sicily. "Go Get It" can be seen to have a solid armor plate hull side. From the start, the side doors were seen as a ballistic weak point of the M3 Medium design. However, nearly a year passed before the Ordnance Department ordered that the doors be eliminated, and that an escape hatch be installed in the tank's belly plate in their stead. The manufacturers began welding up the doors around May, 1942, and by the end of the Summer, the remaining production of the M3 Lee series featured solid side armor plates. The .30 caliber antiaircraft machine gun can be seen mounted inside the "British type" turret hatch.

The turret hatch was a British contribution to the T2 design. Opened and closed views are shown above on a pair of surviving Grants. We've circled the pintle mount for the .30 caliber anti-aircraft machine gun. The tank commander could fire the machine gun from inside the protection of the tank, but this arrangement was not very practical. Left side photo used by kind permission of the Tank Museum in Bovington. Right side photo courtesy of David Doyle.

Above

shows the British type hatch on a surviving M3A5 based T2 at Fort

Benning in Georgia. Note that, unlike most Grants, a periscope was

not mounted in the hatches of the T2s. As best we can tell, Baldwin did

not install a lifting handle on the hatches of its T2 conversions, but

it can be seen in some period photos, which suggests it was added to

some as a simple field modification. A "Spot and Signal Lamp" entered

the Sherman production pipeline in late 1942, and it is thought that

this item was installed on most or all of the T2 conversions done by

Baldwin starting in 1943. Note that this turret does not have a

ventilator, although there are two on the hull "roof" in the usual

locations. This retriever is SN 81, which we believe indicates that it

was converted in June, 1943 from one of the 150 new M3A3 or M3A5

diesel Lees diverted from Baldwin's M3 Production Order. The vast

majority of diesel Lees were late production, from July through

December, 1942, and would have had the ventilators, along with welded

up side doors. So, we would guess that the original turret of this Lee

would have had a ventilator. Counting heads suggest that

ventilators were not a requirement of the T2 conversion program. That

is to say that if the Lee converted had them, of course they were not

removed, and if it did not have them, they were not added. Photo

courtesy of David Hobbs.

The original design of the M3 Medium included a pair of .30 caliber machine guns mounted in the bow of the tank a little to the left of the driver's seat. The effectiveness of these guns was severely limited, as they were fixed, so could not be traversed. In June 1942, the Ordnance Committee recommended their elimination, but ultimately it was decided to retain one of the guns. The image above is from the T2 Technical Manual and shows the single gun arrangement, along with other elements of the driver's position. The port for the eliminated second machine gun was filled in with a plug.

The T2 Technical Manual, published in August 1943 has it that "This vehicle may be manufactured from any of the following medium tank chassis: M3, M3A1, M3A2, M3A3 and M3A5." The M3A2 was built with an all-welded hull like the M3A3. Only 12 units were made, and 10 were produced as Grants and supplied to the Commonwealth as Lend Lease. The first M3A2 Lee, Serial Number 1040, was delivered to Aberdeen Proving Ground for inspection in November 1941. This unit had a truly all welded hull. A few rivets were used on production welded hull models. After inspection at APG, SN 1040 was officially accepted in January 1942, as was the other M3A2 Lee, believed to be SN 1082. Anyway, it is possible that one or both of these could have been "brought in from the field" and converted to T2. We are keeping an eye out for any photos that might show a welded hull with M3 type rear configuration, welded up doors and no ventilators. However, practically speaking, it seems safe to assume that any welded hull T2 seen in period photos would have been converted from an M3A3 diesel Lee.

From February through August 1942, American Locomotive produced 300 units of a cast hull version of the M3 Lee. These were assigned the nomenclature "M3A1." The fact that this model is mentioned in the T2 Technical Manual hints at the possibility that "some" conversions were done, or, at the least, consideration was given to future conversions should circumstances require. The rounded contours of the cast hull, and the location of the roof hatch, would have necessitated some adaptation of the standard internal and external stowage items. In any case, if Baldwin was asked to attempt a trial conversion, we did not come across any photos or notes about it in the company documentation we examined.

It is obvious from photos that the T2 series was the primary type of retriever used by the US Army to the end of the campaign in the Mediterranean Theater of Operations. We have not been able to determine the exact number of T2s shipped to the MTO but suspect that it was over 300. The US Army determined that its tanks would run on gasoline powered engines. Consequently, diesel engine tanks, such as the M3A3, M3A5 and M4A2, were not approved for overseas use, and most of these were supplied to the Allies as Lend Lease. An exception was made for the M10 Tank Destroyer, which employed the same GM twin power pack as the diesel Medium Tanks. M10s served as the primary weapon of most US Tank Destroyer Battalions. A similar exception was made for the diesel T2s simply because they were available and needed at the time. Above shows one of the T2s converted from a new welded hull M3A3. We interpolate that the first 100 M3A3 and M3A5 conversions were assigned 7-digit Registration Numbers: USA 4096598 through USA 4096697. (The rest of the T2 series appears to have been assigned 8-digit RNs.) This particular unit looks to be 4096645 (inset), and if so, would have been accepted in April 1943. The VI Corps' offensive out of the Anzio perimeter kicked off on May 23, 1944. On that day, Combat Command B's attack east of Cisterna was hindered just past the start line, as 23 Shermans and 7 Tank Destroyers were disabled when they ran "into an uncharted minefield hastily laid by US troops sometime during the hectic winter defense of the beachhead." It is thought that this scene shows a retriever from the 1st Armored Division's Maintenance Battalion hauling away an M10 of the 701st Tank Destroyer Battalion that had been damaged in the minefield.

The photo above is dated January 13, 1944 and shows members of a T2 crew as they haul a captured StuG III to the rear along Highway 6 near Monte Lungo, Italy. This T2 was converted from a used M3 that was delivered to Baldwin with working doors. The company would have welded up the doors, and we've used an arrow to point out some of the "bumps" where the door hinge holes were filled in. On such a conversion, Baldwin would have to have added an escape hatch in the belly plate in the right rear of the fighting compartment. On the other hand, the escape hatch would already have been factory installed on any units built in May, 1942 or later with welded up or no side doors. The original design of the M3 included 5 pistol ports equipped with indirect vision devices known as "protectoscopes." These were installed in the hull, turret and side doors. When the side doors were eliminated, it was decided to retain the right side pistol port with protectoscope, even on units built without doors. As mentioned previously, the mount for the machine gun in the British type turret hatch was not very practical, and photos show that a number of T2s were retrofitted with MG pintles. On this example, the crew has gone so far as to install a ring mount on the turret.

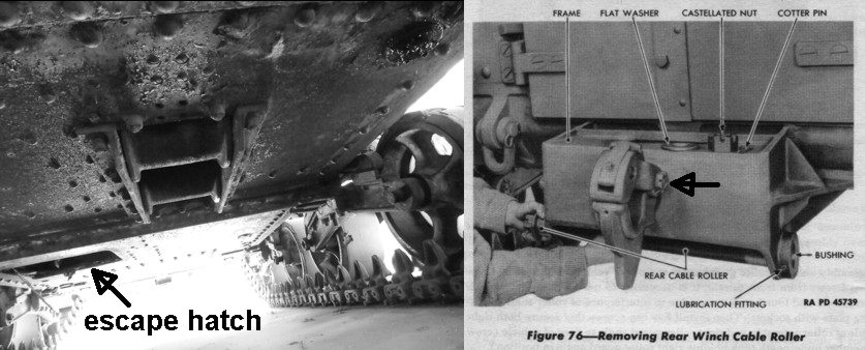

The view on the left shows the belly plate of Serial Number 81, the M3A5 based T2 currently in storage at Ft. Benning, Georgia. Note the location of the escape hatch which was factory installed on M3 series Medium Tanks at the elimination of the side doors. This would have been retrofitted to any of the M3s shipped to Baldwin with working doors. The winch cable could be threaded to either the front or rear of the T2 using the two cable rollers seen here. The cable would have been passed under the hull through to the "Winch Cable Roller" assemblies affixed to the front and rear of the T2, as shown in the Tech Manual illustration on the right. A pintel (arrow) was installed on the Winch Cable Roller assembly for simple towing operations. Left side photo courtesy of Dave Hobbes.

This scene shows LCTs, LSTs and Liberty Ships assembling in convoy in Salerno Bay two days before the amphibious assault at Anzio on January 22, 1944. The caption does not identify the soldiers in the photo, but they "look" British, which would lead us to assume that they were part of Task Force Peter, the British half of the initial 2 division assault. The 46th Royal Tank Regiment was attached to the 1st Infantry Division (Br) for Operation Shingle, and the T2 seen here may have been part of the Regiment's maintenance section. This unit was converted from one of the new M3A3s produced without side doors. The arrow points out the angle and the depth of the upper rear hull plate typical of diesel M3s. Note that the "Spot and Signal Lamp" (asterisk) is in place on the turret. As best we have been able to tell, the Commonwealth did not "require" or officially receive any T2s as Lend Lease. They had determined to provide for their own Tank Recovery Vehicles, based on conversions of surplus Grant and Churchill tanks. However, it is obvious in period photos that "some" T2s were supplied to Commonwealth units on an informal basis, particularly those attached at one time or another to the US Fifth Army. Aside from the British, they are seen in service in Italy with units from Poland, Canada, and New Zealand. The Canadians brought some T2s with them when they redeployed to the ETO. Unit records list USA 40103713, 40103715 and several others as "struck off service" by the 5th Canadian Armoured Brigade in July, 1945.

Above shows T-23673, a Baldwin built, radial engine Grant converted to Armored Recovery Vehicle by the British. This prototype was designated "Grant ARV Mk I." It was obviously a much simpler conversion than the T2, more like the Heavy Tractor, T16, but without a winch. T-23673 was filmed in December, 1942 assisting in the recovery of a Churchill tank at the Minehead AFV Range in the UK (source:IWM). In the film, the ARV can be seen with what appear to be British made grousers fitted (bottom right) struggling to pull a (turretless) Churchill up a rise in a muddy field. Our photo of the "Grant ARV Mk I" shows 12 of the end connectors painted white. No doubt this was an indication of where the grousers would be installed. It is thought that the M3 Medium series was provided with 26 grousers as On Vehicle Materiel. Per the Tech Manual, "The grousers are attached to every eighth track shoe by steel pins and a cap screw..." After trials, the British preferred the ARV based on the lower silhouette of the Churchill Tank, and in December, 1942 it was reported, "D.M.E. is arranging to convert 120 Churchills...to Recovery Vehicles." Thus, it is thought that T-23673 was the only example of a Grant ARV Mk I produced. In any case, most likely due to delays in production or delivery of the Churchill ARV, Commonwealth Troops in Italy obtained some T2s. The British labeled all versions of the T2 "Grant ARV Mk II." This has created some confusion, as there is the implication that some T2s may have been converted from Grants. In fact, of the 1686 Grants produced, only 1 was held by the US Ordnance Department, while all of the others were shipped to the Commonwealth as complete gun tanks. On an M3 Medium without turret, a clue of a Lee as opposed to a Grant, is the little "antenna pot" mounted on the left rear of the superstructure. This antenna mount was original equipment on the Lee, but not the Grant. The larger Grant turret provided space for the tank radio, while it was mounted inside the fighting compartment of the Lee. The photo on the upper right shows the antenna pot on the "fake" Grant that was once on display at APG. This tank is Serial Number 1054, and was accepted as an M3 Lee at Baldwin in November, 1941. The Ordnance Museum wanted to display a Grant alongside the few Lees in its collection, and the accession records note that the Grant turret came from "battlefield scrap" returned from the Middle East.

Documentation about the employment of the T2s is pretty sparse, so we have attempted to "count heads" using unit records and period photos. First, it would appear that the vast majority of the T2s were shipped overseas. Out of a total production of 805 units, we would guess that very few remained in the US for test and training purposes. From August through December 1943, Baldwin produced 146 diesel T2s specifically for shipment to the Soviets as Lend Lease. Of the remaining 659, 109 of the radial engine T2s, mostly from the last 3 months of production, were knocked down and converted to M33 Prime Movers by the Chester Tank Depot. It might be noted that the M33 was similar to the "Heavy Tractor, T16" which had been deemed unsuitable as a prime mover. However, delays in production of the "suitable" heavy artillery prime mover - the M6 High Speed Tractor, caused a reconsideration, and the M33s were produced as an expedient from December 1943 through February, 1944. In late December, some of the first M33 conversions were "redballed" to Italy along with 2 batteries of 240 mm Howitzers. They went into action near Mignano in late January, 1944. Above provides an idea of how the massive howitzers and the 4 M1 8 inch guns that arrived in theater in April, 1944 were transported. The "gun load" was towed by one M33, while the "carriage load," part of which can be seen in the background, was pulled by another. This scene shows men of the 697th Field Artillery Battalion with "Berlin Bound III" in the Apennine Mountains near Pietramala, October, 1944. This was most likely the unit's last fire mission in Italy. To the US High Command, the ETO was the primary theater of operations, and the limited supply of "big guns" was wanted there, so "by November 1944 none of the 8-inch guns and 240-mm howitzers were left in Italy."

Above provides something of an overhead view of one of the M33 conversions, USA 40104057. The turret and its boom were removed, and a commander's hatch ring as used on Sherman turrets, was adapted to fit on the roof of the hull above the 75mm gun sponson. This was rotatable, and appears to have served as an expedient machine gun mount. The few photos available suggest that the hatches were not installed on the hatch ring. The stowage box and the grouser box on the hull roof were eliminated, although the grousers can be seen strewn on the roof of 40104057. A bit of the winch is visible through the turret opening, and it is noted that the M33s were equipped with compressors "to provide high pressure air for the gun and howitzer carriage braking system." Since one is visible here, we would observe that, unlike Shermans, Lees and Grants were built with straight removable hinge pins for the armored fuels caps (circled and inset). M33 Registration Numbers were almost entirely in the 40104XXX range. Nearly all of the last 2 months' production of radial T2s were converted to M33s. At present, we haven't come across any photos showing M33s in service outside of Italy. However, "An Informal History of the 697th Field Artillery Battalion" records that they arrived in Marseilles on October 25, 1944 and 2 weeks later "the T2s [sic] were loaded on a train." The Battalion moved by rail to La Neuvelle where they entered combat in support of the First French Army. The first mention of the use of the M6 High Speed Tractor in the 697th History comes in the Spring of 1945 at Nurnberg. We would assume they would have replaced the unit's M33s as they became available in the ETO in early 1945.

After deducting the 146 Diesel T2s sent to the Soviets, along with the 109 M33 conversions, 550 T2s would have remained available. Production of both gas and diesel versions up to June, 1943 amounted to 314 units, and we would interpolate that almost all of these were shipped to the Mediterranean Theater of Operations, with the first arriving in Northwest Africa in the Spring of 1943. As they became available, they would have been distributed on the basis of 1 per Medium Company in independent Tank Battalions, with 2 more in each Battalion's Maintenance section. Self propelled Tank Destroyer and Armored Field Artillery Battalions would have been similarly equipped. After Sicily, only one US Armored Division remained in the MTO - the 1st AD. The unit started out as a "heavy" Armored Division. At full strength, it would have had 232 Medium Tanks distributed in 2 Regiments, each with 1 Light and 2 Medium Tank Battalions. One source has it that a total of 37 Tank Recovery Vehicles serviced the "heavy" AD. In mid July 1944, the 1st AD was reorganized to the "light" armored division structure with 168 Medium Tanks distributed in 3 Tank Battalions. The Table of Organization and Equipment provided for 24 TRVs in the "light" armored division. The caption of the photo above is dated September 19, 1944, and reads "A new Ford tank mounted with 76 mm gun afire after being hit by German artillery." This tank was actually produced by Chrysler, but with a Ford V8 engine, considered by the Army to be the best Sherman power plant. The 1st AD had received its initial allotment of M4A3(76)s about a month earlier, and this unit of Company A, 1st Tank Battalion was probably one of the first to be lost in combat. The crew was unharmed (inset). AFVs that had burned were usually written off, and Maintenance units would salvage what they could from the hulks.

The records of the 1st Armored Division's 123rd Ordnance Maintenance Battalion were most helpful for the purposes of "counting heads." They list the Registration Numbers of everything they serviced that had an RN, including 44 T2s. The chronology that emerges is that the T2s sent to the MTO were made from October, 1942 through June, 1943. The diesel units had USA Numbers in the 40965XX/40966XX range, while the radial engine T2s had USA Numbers running from 40103652 through 40103878. Shown above is a sample worksheet from the last two weeks of July 1944, as the Division reorganized from a "heavy" to "light" armored division. Over 1000 vehicles were rendered surplus by the reorganization, including about 12 T2s. Some of the excess Shermans and retrievers turned in by the 13th Armored Regiment are listed above. It's obvious that the 1st and 13th ARs turned in their most worn out vehicles. After reorganization, the Division had 3 Tank Battalions - the 1st, 4th and 13th. Note that one of the T2s is listed with its new unit designation - the "4th Tk Bn." By the Registration Numbers, the 4 T2s listed would have been radial M3s converted in March and April, 1943.

In the Spring of 1943, the "French in North Africa"

began to receive large quantities of AFVs as Lend Lease, enough to

train and equip 3 Armored Divisions, each with 165 Shermans, plus

reserves. It is obvious from period photos that the French ADs were

provided with Tank Recovery Vehicles, but it has been difficult to

"count heads," since officially, the French did not receive any

retrievers as Lend Lease. However, reading between the lines of the US

Army "Green Book" "Rearming the French," leads us to think that

shipments of T2s to the Mediterranean Theater of Operations took into

account the 3 French ADs, and that eventually, each was supplied at or

near the US TO&E of 24 per division. The 2ème Division

Blindée was chosen to take part in the Normandy Campaign,

and they brought their AFVs with them when they redeployed from

Northwest Africa to Great Britain in the Spring of 1944. They brought

some retrievers, but are reported to have been issued a few additional

"chars de depannage "Recovery"" while in the UK, no doubt intended to

bring them up to full TO&E. There is some evidence that the ones

received in the UK, had matricule numbers in the 90xxx range, while

those from Africa were in the 445xxx range. The 3 tank regiments of the

2ème DB were equipped with M4A2 (diesel) Shermans, and

the Régiment Blindé de

Fusiliers Marins with M10 Tank Destroyers which used the same

diesel engine as the M4A2s. It would appear that an effort was

made to outfit each of these units with 3 diesel T2 retrievers, at

least at first. Above is an M3A3 based T2 of the 12ème

Régiment de Cuirassiers on Boulevard Brune in Paris, on 25

August 1944.

The T2s allocated to the other units of the 2ème DB appear to have been "regular" T2s/M31s with gasoline radial engines and riveted hulls. Counting heads from period photos and documents suggests that each of the Division's 3 artillery groups was issued one retriever. The Régiment de Marche du Tchad, an infantry unit, was reportedly equipped with three, as was the 15ème Groupe d'Escadron de Réparations or "GER XV", which was the 2ème DB's recovery and maintenance unit. Above shows "FAYA", which is thought to have been part of the Régiment de Marche du Tchad. This photo is reported to have been taken in the UK as the Division prepared for its long-awaited return to French soil on August 1, 1944. Based on its appearance, we believe that “FAYA” was converted from a late production (June/July/August 1942) Chrysler M3 Lee built without the side doors. Note the bogie units with horizontal “ribs” (circled). These particular castings appear to have been factory installed exclusively by Chrysler beginning in the Spring of 1942.

The T2s allocated to the other units of the 2ème DB appear to have been "regular" T2s/M31s with gasoline radial engines and riveted hulls. Counting heads from period photos and documents suggests that each of the Division's 3 artillery groups was issued one retriever. The Régiment de Marche du Tchad, an infantry unit, was reportedly equipped with three, as was the 15ème Groupe d'Escadron de Réparations or "GER XV", which was the 2ème DB's recovery and maintenance unit. Above shows "FAYA", which is thought to have been part of the Régiment de Marche du Tchad. This photo is reported to have been taken in the UK as the Division prepared for its long-awaited return to French soil on August 1, 1944. Based on its appearance, we believe that “FAYA” was converted from a late production (June/July/August 1942) Chrysler M3 Lee built without the side doors. Note the bogie units with horizontal “ribs” (circled). These particular castings appear to have been factory installed exclusively by Chrysler beginning in the Spring of 1942.

Starting in the Summer of 1943, we estimate that something over 150 T2s were shipped to the United Kingdom as part of the build up for the Invasion of France. Going by the chronology reflected in the USA Registration Numbers we have recorded, these were converted June though September, 1943. The ETO T2s with radial engines have Registration Numbers running from 40103858 (June, 1943 production) to 40104006 (September, 1943 production). Our theory is that the last 49 diesel T2s would have had RNs running from 40103602 (June production) through 40103650 (August), and the few ETO examples recorded fall within this range. These T2s were distributed to the first US Armored units to arrive in the UK, including, among others, the 2nd and 3rd Armored Divisions, and the 70th, 741st, 743rd, 745th and 746th Tank Battalions. The Sherman based M32 series TRVs went into production for the US Army in December 1943, and the first of these arrived in the UK in early 1944. They equipped a few units after the supply of T2s was depleted. Of course, the M32 series became the standard retriever of the many US armored units that arrived in Europe from the second half of 1944 to the end of the campaign. Above shows USA 40103603 (inset), an M3A3 based T2, loading aboard LCT 209 in Falmouth Harbor on December 30, 1943 as part of "Exercise Duck." This was the first US amphibious training operation conducted in England. It is thought that this T2 served with the 1st Engineer Special Brigade, one of the units designed to set up the logistics necessary for follow up troops to exploit a beachhead after the initial assault.

Above shows an M4A1 named "Adeline II" under tow by one of the T2s of the 741st Tank Battalion. This scene was filmed in Colleville-sur-Mer, a day or two after D-Day, June 6, 1944. The 741st was one of the 3 US Tank Battalions that employed 2 companies of Duplex Drive swimming tanks on D-Day. The decision to launch the unit's 32 DDs in rough seas was disastrous. All of C and 11 of B Company's DDs sank after launch, while 2 DDs of B Company managed to swim to shore, and 3 were deposited directly on the beach by their LCT. Twelve "regular" Shermans of A Company and 6 Tank Dozers landed a few minutes after H-Hour. The crews of these few tanks performed heroically in support of the 1st and 29th Infantry Divisions on Omaha Beach. In the afternoon, 4 reserve tanks and 2 T2s landed, and the retriever crews attempted salvage and repair operations on the chaotic beach. At the end of the day, only 7 of the Battalion's Shermans were operational, out of 27 that had landed. Thirty of the unit's Shermans, which might have made a difference on "bloody Omaha," never even made it to shore. During the next few days, the 5 T2s of the 741st attempted to salvage and repair what they could. "Adeline II" was reported damaged in its suspension on D-Day (asterisk), but stayed in the fight. This scene was also filmed from the front, and in one photo, the T2's Registration Number can be seen as either 40103938 or 40103958 (inset). Whatever the case, it would have been converted from a used M3 Lee and accepted at Baldwin in July 1943.

In an earlier caption, we showed "GO GET IT," a "no doors" T2 of G Company, 66th Armored Regiment. When the 2nd Armored Division redeployed to the UK after the Sicilian Campaign, it is noted that they left their vehicles behind. Here we see "GO GET EM," the "welded doors" T2 that replaced "GO GET IT." This scene was filmed on September 29, 1944 in Nieuwstadt in The Netherlands, and shows the recovery of an early production M4A1(76) that had slid into a ditch. These were the first of the "second generation" 76mm Shermans to be shipped overseas, and they had their combat debut in late July 1944.

The T2s and their crews served with distinction to the end of the War in Europe. They were designated "Limited Standard," which essentially meant "use until dead." No special effort appears to have been made to replace them with the M32 series retrievers which were designated as the US Army's "Standard" type on October 7, 1943. TRVs did not suffer the attrition of the Sherman battle tanks, although, of course, some were damaged or destroyed, such as the example from the 3rd Armored Division shown above. This screen capture is from some raw Signal Corps motion picture footage taken in Normandy on July 11, 1944. While attempting to recover a damaged Sherman, something, perhaps a mine, set this T2 on fire. A loss such as this might have been replaced with an M32 series retriever, assuming no T2s were immediately available in the 3rd AD's reserve pool. Note that the crew had rigged up some sort of pintle, and re-armed their T2 with a .50 caliber machine gun.

The photo above is dated January 7, 1945 and was taken in Wingen-sur-Moder in Alsace Lorraine during Operation Nordwind, the last German Offensive in the West. The caption identifies the soldiers as 70th Infantry Division. In their baptism of fire, the 276th Infantry Regiment, 70th ID, supported by B Company, 781st Tank Battalion, drove the Germans from the vital crossroads town after several days of fierce combat. The T2 can be seen as another with a .50 caliber machine gun retrofitted. Note that the crew have supplemented their on vehicle equipment with the addition of oxygen (1) and acetylene (2) cylinders. These would have enabled them to perform field repairs such as heating up seized parts, along with some cutting and minor welding jobs.

Above provides two snapshot views of another 3rd AD T2, which served with the Division's 54th Armored Field Artillery Battalion. These appear to have been taken in the Winter of 1944/45. The USA Number can be read as 40104006, indicating September 1943 production. At present, this is the highest Registration Number we have recorded on a T2 in the ETO. This retriever had obviously seen hard use, as evidenced by the various replacement road wheels. No doubt the M4 bogie unit was retrofitted to the left front simply because replacement M3 bogies were no longer available.

The Soviet Union was the only allied country that was "officially" allocated and shipped any T2 series retrievers. Unfortunately, little is known about their use if any in Soviet armored units. As mentioned previously, from August through December 1943, Baldwin remanufactured and converted 146 diesel T2s from units gathered in "from the field." US Lend Lease documents have it that the Soviets were charged for 115 retrievers as Lend Lease. Perhaps the other 31 were lost at sea? Or they may have been repossessed and distributed elsewhere. Above shows a fuzzy photo reported to have been taken at Kubinka Proving Ground in 1943, according to the website “Engines of the Red Army in WW II”. An Ordnance document has it that the Lend Lease T2s were assigned Serial and Registration Numbers 751/USA 40142501 through 896/USA 40142646. At present, we cannot confirm if that is accurate, since there don't appear to be any historic documents/photos or any surviving examples within that range. We would note however that a number of WW II documents from the Russian Archives identify US Lend Lease AFVs by their US Registration Numbers, so perhaps some Soviet T2 listing will come to light in the future?

There has been the thought in some circles that all of the diesel based T2s were converted from welded hull M3A3s. Most likely, this is because there are very few period photos of riveted hull T2s that can be identified as diesel models. It would appear that the majority of the diesel conversions were indeed M3A3 based, but, for instance, in June 1943, Baldwin provided a break down of the 35 diesel T2s produced in that month, "twenty-six (26) were of welded hulls, and nine (9), of riveted hulls." Above shows the riveted hull, diesel T2 featured in the Technical Manual. This unit was USA 4096671, and by our reckoning, would have been accepted in May, 1943. The Registration Number falls into the range of the 150 T2 conversions of new M3A3 or M3A5 Lees diverted from Baldwin's original M3 Lee series Production Order for 685 units. We would note in passing that these 150 units were never actually accepted as M3A3 or M3A5 Lee gun tanks. All but 9 of the diesel Lees were built in the months July though December, 1942, after the Ordnance Department had determined to eliminate the side doors and replace them with an escape hatch in the belly plate. At first the side door holes were blanked off by welding on the original door plates, as seen on the example above. Eventually solid side armor plates entered the pipeline, and we have included photos of 3 solid side armor M3A3 based T2 in previous captions. If any readers know of any photos of solid side M3A5 based T2s, we'd be pleased to see them. Ventilators were introduced on Lees at about the same time as the doors were eliminated, so these will be seen on most of the T2s not originally built as Lees with working side doors.

Above shows the M3A5 based T2 on display in Thun, Switzerland. This example and a few other survivors have been seen with the Serial Number stamped on both the front and rear towing lugs. Anyone looking for Serial Numbers is advised to take what is on the rear lugs as the true SN, since a number of surviving Lees, Shermans, Priests, etc. have been retrofitted with replacement differential housings. The Thun actually has its original diff, as it has "68" stamped on both the front and rear lugs (inset). If our production theory is accurate, this unit would have been converted in May 1943, and would have been assigned USA 4096665.

Of course, the Serial Number would also be found inside stamped on the dataplate. The dataplates of the T2 series appear to have been installed in the same location as on Grants and Lees - on the sponson wall to the right of the driver's seat. The example shown above is rusted unreadable. We are interested in cataloging dataplates from surviving Shermans, predecessors and variants, and hope to come across an intact T2 dataplate in the future.

Aberdeen Proving Ground conducted Inspection Control Tests (ICT) on various AFVs throughout WW II. Here we see front and rear views of Serial Number 597, USA 40104098, which would have been produced in November, 1943. This is the highest Serial and Registration Number we have recorded from a T2. As mentioned previously, Chester Tank Depot converted 109 units to M33 Prime Movers. After Serial Number 597, according to the CTD list, only SNs 599 and 602 were NOT converted to M33. Serial Number 597 can be seen with the "bumps" indicating that it had been converted from an M3 originally built with working side doors. The tank's M3 type drive sprockets were replaced with the "plain" type seen here (1). The initial welded spoked idler wheels had some reliability issues, and starting in mid 1943, the Ordnance Department directed that all new production Shermans would be installed with the "disc type" idler wheels constructed with pressed metal spokes (2). We suspect that Baldwin was also directed to retrofit these to its mid 1943 and later T2 conversions. In late August 1943, the Ordnance Technical Committee assigned the nomenclature "M31" to conversions based on the M3 Medium, with "M31B1" and "M31B2" assigned to those based on the M3A3 and M3A5 respectively. We have not used these terms simply because unit reports and other documents of the period consistently refer to these as "T2," sometimes with "gas" or "diesel" in parenthesis. Although we have never seen an intact example, we would guess that something like "Tank Recovery Vehicle, T2" was on the dataplates of all of the conversions.

Above shows "BIG WELDON" marked as "B-18," the retriever of Company B, 752nd Tank Battalion, photographed on November 8, 1946 in Udine, Italy. It is somewhat surprising that this unit was still in service over a year after the end of WWII. T2s were not considered an "asset" by the US Army in the post war years. Indeed, the entire M31 series had been declared obsolete in August, 1945. The 88th Infantry Division, to which the 752nd was attached, was serving occupation duty in northeastern Italy, an early Cold War hotspot, due to the dispute between Yugoslavia and Italy over the city of Trieste. Battalion records indicate that, for most of its service during WW II, the 752nd was equipped with 6 T2s, including 1 in the Light Tank Company. In early 1945, a T2 was replaced with a "T5" retriever, such as the M32B3 that is seen next to "BIG WELDON" in the photo. There are comments in the unit's records that suggest that some members preferred the T2 over the T5. With thanks to Bob Holt. For more information about the 752nd Tank Battalion see his website.

This photo is from the same series, taken by the same photographer on the same day, but at the 752nd's base in Cormons, Italy. Two of the obsolescent T2s are visible. Note that the one on the right has been retrofitted, at least on the right side, with a complete set of M4 type bogies. In the center, one can see a pair of the distinctive M32 type A-Frames. Coupled with the previous photo, it would appear that the 752nd had 3 T2s and 3 M32 series Tank Recovery Vehicles in service in November, 1946.

There is little evidence of widespread postwar use of the T2. However, it seems likely that any army that still had a few in working order, or had obtained some from, say, post war tank dumps, would have kept them in service as long as they could be repaired economically, or until more modern replacements became available. This diesel based, welded hull T2 (M31B1) is on display in Tel Aviv-Jaffe in Israel. It can be seen to have been retrofitted with M4 bogies. Note the presence of a few rivets, as compared to the welded hull pilot shown earlier. In his book, "Israeli Sherman," author Thomas Gannon speculates that it was "Probably captured from Egypt," and states that the T2 "was not used by the IDF [Israeli Defense Forces]." If any readers would be in the position to examine this retriever, we would be very interested to know the serial number, and if it has a dataplate. Photo courtesy of Jim Goetz.

The French are stated to have received 175 M32 series, along with 29 of the later T74 and/or M51 Tank Recovery Vehicles as post war Military Assistance [MDAP] up to 31 January 1954. On top of that, Indochina, which was basically a French colony, is reported to have been shipped 5 M32 series up to the same date. Nevertheless, the image above shows that the French used at least one T2 during the First Indochina War (1946 -1954). This photo is part of a series datelined January 1952, Tonkin, Indochina. The records of the Régiment Blindé Colonial d'Extrême-Orient for 23 December 1951 report that the M4A1 "Hoche" of the 1er Escadron was disabled when it drove onto a booby-trapped shell. While attempting to retrieve "Hoche", the unit's Tank Recovery Vehicle "Brest" had its left running gear damaged when it ran over an undetected mine or bomb. "While we were trying to free these 2 vehicles, a Viet Minh attack was repelled...Given the late hour, GM7 gave the order to return, abandoning the 2 tanks on the ground." The wrecks of the 2 vehicles were reportedly removed from the Đan Thệ-Ap Dá Chông Road on 5 January 1952. It seems likely that the T2 shown in the photo was "Brest." The way the superstructure is cracked open suggests that the Viet Minh may have used a demolition charge to render it unsalvageable. It would appear that this retriever had had an M4 bogie retrofitted to the left front. If any readers have information about other post war use of T2s, we would be pleased to have a report. Photo from the ECPAD (French Military Archives) Collection.

Go to M32 series page