Note: Not much information about Federal Machine and Welder was found in the US Archives, since like all M4A2s, the vast majority were sent out as Lend Lease, & consequently "disappeared" to the researcher. To date, the authors have located two surviving M4A2 chassis that have FMW Serial Numbers. It is hoped a few more examples might be found, perhaps in France, Italy or Russia? Meanwhile, this page must be considered a work in progress, which the authors would hope to update if and when more info is discovered. Any reader submissions concerning FMW Shermans would be most welcome.

Federal

Machine and Welder

manufactured 540 M4A2(75)s from December 1942 through December 1943.

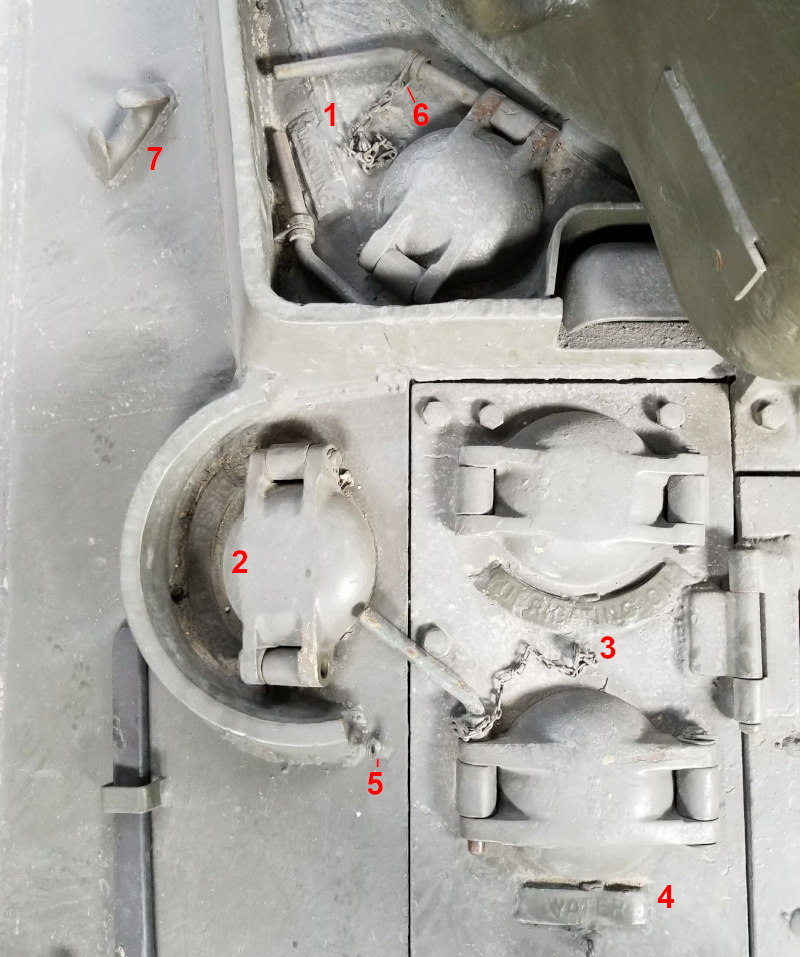

Federal Machine and Welder was contracted “by the War Department on February 3, 1942 to provide additional facilities at an existing plant for the production of Diesel powered medium weight tanks, model M-4A2.” The original Order was for 650 units plus spare parts, with production scheduled to begin in September, 1942. As it was, due to parts shortages, FMW was the last of the original 11 Sherman manufacturers to commence production. Its first 21 M4A2s were not accepted until December 1942. The photo above provides a view of Serial Number 14801, USA 3055981, one of the M4A2s accepted in December 1942. Note the early drivers’ hoods with Direct Vision slots. These were determined to be ballistic weak spots, and as a result, the Ordnance Department eliminated DV from welded hull Shermans in August, 1942. It would take some months before the new elongated drivers' hood castings could be manufactured and procured, but most manufacturers had completed the transition to the later drivers’ hoods by December, 1942. This photo makes it clear that Federal Machine had not completed the transition at the outset of production. Serial Numbers 14801 and 14806 were shipped to Aberdeen Proving Ground for inspection and evaluation in February, 1943. In regard to quality, it was remarked that these were some of “the best production tanks received.” The step bracket (1) and the dust cover for the bow machine gun (2) were not part of the original Sherman design, but were introduced in production in the Fall of 1942. The T49 "interrupted parallel bar" tracks (3) were utilized when Japanese conquests in Asia created a rubber shortage which compelled the Ordnance Department to employ some steel track alternatives.

In early 1943, Lima Locomotive Works was contracted to develop a new tank retriever design based on the Sherman. Five pilot models were produced, each of which utilized a different version of the M4 series. “T5E2” was the test model designation given to the retriever based on the M4A2. Upon approval of the design, Sherman based Tank Recovery Vehicles were designated as the M32 series, with M4A2 models labeled “M32B2.” The T5E2 pilot was completed in the Summer of 1943 and shipped to the Tank Destroyer Board at Camp Hood, Texas shortly thereafter. Despite it being a pilot, it was the single unit featured in the M32 series Technical Manual published in December, 1943. The T5E2 pilot was converted from M4A2 Serial Number 14926, USA 3056106, which had been produced by Federal Machine & Welder in April, 1943. We would observe in passing that 3056106 features the later elongated drivers' hood castings with the additional periscopes in front of the drivers’ hatches. On the other hand, the hull lifting rings are “still” the earlier “padded” type (inset), also present on Serial Numbers 14801 and 14815. Only 26 M4A2s were converted to retrievers. All were done by Lima for the US Marine Corps, and all appear to have been converted from new production Fisher M4A2s. Thus, it would seem that the T5E2 pilot was the only FMW based retriever conversion.

With a total acceptance of only 540 M4A2(75)s, Federal Machine and Welder in Warren, Ohio was one of the smaller manufacturers of Shermans, averaging less than 50 units per month for the year that they were in production. By contrast, the Chrysler Corporation produced 907 M4A4s in December, 1942 alone. The black & white photo above is captioned "Three women riding on a General Sherman tank manufactured at the Federal Machine & Welder Co. in Warren, Ohio in the Civilian Defense Parade, May 8, 1943." We've superimposed the photo over a recent image from Google Street View which confirms that the scene was shot on Mahoning Avenue in Warren. Two of the WOWs [Women Ordnance Workers] are buckled into Sherman seats (1) that have somehow been attached to the hull. The tank appears to be freshly minted, and has yet to be installed with drivers' hatches (2). An Ordnance document has it that FMW introduced the M34A1 gun mount on 15 April, 1943, at Serial Number 14892. One of the lifting rings on the gun shield is just visible (3), indicating that this example is equipped with the early type of M34A1 as explained in the next caption. As with a number of builders, FMW appears to have begun production with "padded" hull lifting rings, and this tank "still" has them on both the front and rear (4). Note that the grouser compartment blank off plate is mounted proud of the hull armor (5). Additionally, this tank "still" has the M3 Lee type drive sprockets (6) not commonly seen on Shermans after 1942. The track skid on the front bogie is the earlier "asymmetric" type (7), while the middle and rear skids are in the final configuration (8) that should have been standard by May, 1943. The bogies and idler wheels are the welded spoke type. The welded spoked idlers (9) gave trouble, and the Ordnance Department mandated that Shermans change over to the "Disc Type Idler Wheels" with pressed metal spokes. FMW is reported to have made the change on 30 May, 1943 at SN 14975. Photo courtesy of the Ohio History Connection (AL00100).

The photos above provide comparative views of the early and late type M34A1 gun shield castings. As can be seen, the early version had lifting rings and a bolt flange on the right. The lifting rings were eliminated on the later type, and the gun shield casting was widened a bit, so that the bolts on the right side were no longer exposed. The gun shield was secured from inside the turret as had been the case from the start on the left side. We don't have enough counting heads data to say more than "FMW transitioned to the later type gun shield sometime in the second half of 1943."

The next Sherman in our chronology is Serial Number 14993, which would have been accepted in June 1943. It was tested and photographed at Aberdeen Proving Grounds in July. This is the first period period photo we could find that shows the installation of the "universal" type of sand shields. These were characterized by a vertical slit at the rear of the middle panel. They were designed in such a way that they could be fitted to any Sherman, and were ordered installed on all new Sherman production starting in mid 1943. FMW reported their introduction specifically as 23 May, Serial Number 14960. These strike us as a tremendous waste, since the universal sand shields were almost universally removed in service. Note that this tank is equipped with the positive hatch lock mechanisms on both the commander's and drivers' hatches. It can be seen to have the "final" type of hull lifting ring castings, but "still" has the M3 style drive sprocket. While the M4A2 in the preceding photo can be seen with the early one-piece differential housing, 14993 has the three-piece, suggesting that FMW received supplies of both types. In the same vein, 14993 can be seen with the "pressed spoke" road wheels while other examples have the welded spoke type. FMW made use use of both rubber and steel tracks, with the steels possibly becoming more prevalent towards the end of production.

The photos above show the open sided exhaust deflector, and the long pintle on a surviving FMW M4A2 named "Mort-Homme." Unlike some other exhaust deflectors, this unit could not be pivoted up and out of the way for mechanical service. Instead, the brackets (1) were unbolted, and the muffler guard (2) and exhaust deflector (3) were disconnected and removed as a single unit. The bottoms of the twin radiators (4) can be seen, and it is obvious that they were vulnerable to shrapnel damage. As a consequence, an armored exhaust deflector was designed, but it did not enter the M4A2(76) production pipeline until around March, 1945.

A view of the Federal Machine and Welder M4A2, Serial Number 15056, accepted in July, 1943. It is currently on an active target range in Western France. This tank was probably received as Lend Lease by the Free French Army in North Africa in late 1943. Traces of the gun travel lock can be seen, and certain Ordnance Department documents suggest that this unit was one of the first to have it factory installed by FMW. On the other hand, this tank appears to have been shipped without some of the more common modifications of the second half of 1943, such as the appliqué plates on the front and sides. Period photos and a number of surviving French Shermans show that the side appliqué plates were crudely tack welded on, something that wouldn't have been acceptable at a US factory or tank depot. One theory is that French units training in the UK before D-Day were supplied with a number of these modification kits, but lacked the time and manpower to do a proper installation. US units in the UK had the same problem, but were able to contract British firms to apply the modifications assembly line style. In any case, 15056 shows evidence of having had the side appliqué plates tack welded on.

A rear shot of Serial Number 15056. The authors suspect this tank survived WWII, & that the commander's vision cupola & MG stowage mods were added by the French postwar. Otherwise, the turret could be original to the tank. The welded up pistol port and factory installed application of the turret patch are appropriate to July 1943 production.

These photos don't show confirmed surviving FMW M4A2s, but illustrate the construction of the front glacis as seen on our two surviving examples. The red lines indicate the weld joints. Note that the "plate" that includes the bow MG was actually a casting, whereas the other sections of the glacis were armor plates.

The direct vision slots were considered ballistic weak points, and it is obvious that FMW dispensed with them at "some time in early 1943." The modified drivers' hood casting featured an additional periscope in front of the drivers' hatches. Note that these drivers' hoods castings are what are informally referred to as the "narrow" type, and were used by most producers of small hatch M4s and M4A2s.

FMW and Pullman M4A2s produced from the Spring of 1943 to the end of production are so similar in appearance that we have had difficulty identifying the maker of the few surviving examples. From counting heads on an admittedly small sampling, it seems possible that FMW mounted the grouser compartment blank off plates on top of or "proud" of the sponson armor. Pullman, on the other hand, appears to have mounted them "flush." Flush mount required the additional step of providing a "ledge" (arrow) under the sponson armor to hold the blank off.

Although the authors don't have any proof, we would assume that some or all of the FMW M4A2s made before Serial Numbers 14801 and 14815 also had direct vision. Perhaps a few after SN 14815 had it as well? In the right side photo of Serial Number 14815, the DV slots are "hidden" behind the drivers' hood appliqué plates, which were probably installed during a remanufacture done by Fisher in 1944.

The few known FMW built Shermans are equipped with the cast type of head lamp sockets used by most of the manufacturers of small hatch Shermans.

Production Order T-3337 : 540 M4A2(75) tanks: Serial Number 14785 / USA 3055965 through S/N 15324 /

USA 3056504

Federal Machine and Welder was contracted “by the War Department on February 3, 1942 to provide additional facilities at an existing plant for the production of Diesel powered medium weight tanks, model M-4A2.” The original Order was for 650 units plus spare parts, with production scheduled to begin in September, 1942. As it was, due to parts shortages, FMW was the last of the original 11 Sherman manufacturers to commence production. Its first 21 M4A2s were not accepted until December 1942. The photo above provides a view of Serial Number 14801, USA 3055981, one of the M4A2s accepted in December 1942. Note the early drivers’ hoods with Direct Vision slots. These were determined to be ballistic weak spots, and as a result, the Ordnance Department eliminated DV from welded hull Shermans in August, 1942. It would take some months before the new elongated drivers' hood castings could be manufactured and procured, but most manufacturers had completed the transition to the later drivers’ hoods by December, 1942. This photo makes it clear that Federal Machine had not completed the transition at the outset of production. Serial Numbers 14801 and 14806 were shipped to Aberdeen Proving Ground for inspection and evaluation in February, 1943. In regard to quality, it was remarked that these were some of “the best production tanks received.” The step bracket (1) and the dust cover for the bow machine gun (2) were not part of the original Sherman design, but were introduced in production in the Fall of 1942. The T49 "interrupted parallel bar" tracks (3) were utilized when Japanese conquests in Asia created a rubber shortage which compelled the Ordnance Department to employ some steel track alternatives.

A view of what

remains of Federal Machine and Welder M4A2, Serial Number 14815,

currently stored at the Saumur Tank Museum in France. Quite frankly,

the authors were a little surprised to see that this Feb 1943

production unit "still" has Direct Vision although it

is hidden somewhat by the drivers' "appliqué"

plates. Certain clues on 14815 suggest it was one of the 218 M4A2s

remanufactured by Fisher Body in mid 1944. For instance, the chassis

has what look to be factory applied appliqué plates, along with

fittings for the blanket roll rack modification. However, we would

observe that the "sloping armor" plate or "hatch guard" in front of the

bow gunner's position appears to have been cut in half. According to

the Modification Work Order, the hatch guards provided in the kit were

both 15 inches tall, and the instructions state that "Due to wide

variations in the outer contour of the 30 caliber machine gun mount, it

will be necessary to cut the lower edge of Plate C101543 to fit the

contour of the mount." Perhaps whoever did this misunderstood the

instructions? In any case, some original wartime shipping markings

can still be read on the sides. "Shipping Order 5-G-53" was code for

372 Lend Lease M4A2(75)s allocated to the United Kingdom in August,

1944. Based on some War Forwarding Corporation docs, this tank was

probably shipped to the UK in Sept, 1944. Further evidence of this

tank's Commonwealth history can be seen in the British type fittings

for spare track holders on the front hull, & fire extinguisher

clamp remains on the rear sponsons.

In early 1943, Lima Locomotive Works was contracted to develop a new tank retriever design based on the Sherman. Five pilot models were produced, each of which utilized a different version of the M4 series. “T5E2” was the test model designation given to the retriever based on the M4A2. Upon approval of the design, Sherman based Tank Recovery Vehicles were designated as the M32 series, with M4A2 models labeled “M32B2.” The T5E2 pilot was completed in the Summer of 1943 and shipped to the Tank Destroyer Board at Camp Hood, Texas shortly thereafter. Despite it being a pilot, it was the single unit featured in the M32 series Technical Manual published in December, 1943. The T5E2 pilot was converted from M4A2 Serial Number 14926, USA 3056106, which had been produced by Federal Machine & Welder in April, 1943. We would observe in passing that 3056106 features the later elongated drivers' hood castings with the additional periscopes in front of the drivers’ hatches. On the other hand, the hull lifting rings are “still” the earlier “padded” type (inset), also present on Serial Numbers 14801 and 14815. Only 26 M4A2s were converted to retrievers. All were done by Lima for the US Marine Corps, and all appear to have been converted from new production Fisher M4A2s. Thus, it would seem that the T5E2 pilot was the only FMW based retriever conversion.

With a total acceptance of only 540 M4A2(75)s, Federal Machine and Welder in Warren, Ohio was one of the smaller manufacturers of Shermans, averaging less than 50 units per month for the year that they were in production. By contrast, the Chrysler Corporation produced 907 M4A4s in December, 1942 alone. The black & white photo above is captioned "Three women riding on a General Sherman tank manufactured at the Federal Machine & Welder Co. in Warren, Ohio in the Civilian Defense Parade, May 8, 1943." We've superimposed the photo over a recent image from Google Street View which confirms that the scene was shot on Mahoning Avenue in Warren. Two of the WOWs [Women Ordnance Workers] are buckled into Sherman seats (1) that have somehow been attached to the hull. The tank appears to be freshly minted, and has yet to be installed with drivers' hatches (2). An Ordnance document has it that FMW introduced the M34A1 gun mount on 15 April, 1943, at Serial Number 14892. One of the lifting rings on the gun shield is just visible (3), indicating that this example is equipped with the early type of M34A1 as explained in the next caption. As with a number of builders, FMW appears to have begun production with "padded" hull lifting rings, and this tank "still" has them on both the front and rear (4). Note that the grouser compartment blank off plate is mounted proud of the hull armor (5). Additionally, this tank "still" has the M3 Lee type drive sprockets (6) not commonly seen on Shermans after 1942. The track skid on the front bogie is the earlier "asymmetric" type (7), while the middle and rear skids are in the final configuration (8) that should have been standard by May, 1943. The bogies and idler wheels are the welded spoke type. The welded spoked idlers (9) gave trouble, and the Ordnance Department mandated that Shermans change over to the "Disc Type Idler Wheels" with pressed metal spokes. FMW is reported to have made the change on 30 May, 1943 at SN 14975. Photo courtesy of the Ohio History Connection (AL00100).

The photos above provide comparative views of the early and late type M34A1 gun shield castings. As can be seen, the early version had lifting rings and a bolt flange on the right. The lifting rings were eliminated on the later type, and the gun shield casting was widened a bit, so that the bolts on the right side were no longer exposed. The gun shield was secured from inside the turret as had been the case from the start on the left side. We don't have enough counting heads data to say more than "FMW transitioned to the later type gun shield sometime in the second half of 1943."

The next Sherman in our chronology is Serial Number 14993, which would have been accepted in June 1943. It was tested and photographed at Aberdeen Proving Grounds in July. This is the first period period photo we could find that shows the installation of the "universal" type of sand shields. These were characterized by a vertical slit at the rear of the middle panel. They were designed in such a way that they could be fitted to any Sherman, and were ordered installed on all new Sherman production starting in mid 1943. FMW reported their introduction specifically as 23 May, Serial Number 14960. These strike us as a tremendous waste, since the universal sand shields were almost universally removed in service. Note that this tank is equipped with the positive hatch lock mechanisms on both the commander's and drivers' hatches. It can be seen to have the "final" type of hull lifting ring castings, but "still" has the M3 style drive sprocket. While the M4A2 in the preceding photo can be seen with the early one-piece differential housing, 14993 has the three-piece, suggesting that FMW received supplies of both types. In the same vein, 14993 can be seen with the "pressed spoke" road wheels while other examples have the welded spoke type. FMW made use use of both rubber and steel tracks, with the steels possibly becoming more prevalent towards the end of production.

Here

we have a rear view of Serial Number 14993, USA 3056173. This tank can

be seen with a welded up pistol port. Most such turrets would have had

the "thin spot" turret patch factory added at the same time, or at a

Tank Depot before shipment. However, it is obviously not present in the

front photo of the previous caption. Note the open sides of the exhaust

deflector. This was the original design as used on diesel Lees and

Grants. The evidence suggests that Fisher introduced a more robust

closed sided exhaust deflector in the Summer of 1943, but we can't

confirm if FMW ever did, due to a lack of photos/documentation. We

feature S/N 15161 / USA 3056341, a September 1943 production unit, a bit

later on this page, and would observe that the rear photo shows that

tank "still" with the open sided exhaust deflector. Another item seen

here is the "long" towing pintle. This was introduced on the Sherman

series in the Spring of 1943, reportedly 30 April at FMW. The long

pintle could get bent up in service and cause problems, and was replaced

with a shorter design on 2nd Generation Shermans. Finally we would

observe that an odd "flat spot" (arrow) is just visible on the weld

seam where the side plate is joined to the glacis.

The photos above show the open sided exhaust deflector, and the long pintle on a surviving FMW M4A2 named "Mort-Homme." Unlike some other exhaust deflectors, this unit could not be pivoted up and out of the way for mechanical service. Instead, the brackets (1) were unbolted, and the muffler guard (2) and exhaust deflector (3) were disconnected and removed as a single unit. The bottoms of the twin radiators (4) can be seen, and it is obvious that they were vulnerable to shrapnel damage. As a consequence, an armored exhaust deflector was designed, but it did not enter the M4A2(76) production pipeline until around March, 1945.

A view of the Federal Machine and Welder M4A2, Serial Number 15056, accepted in July, 1943. It is currently on an active target range in Western France. This tank was probably received as Lend Lease by the Free French Army in North Africa in late 1943. Traces of the gun travel lock can be seen, and certain Ordnance Department documents suggest that this unit was one of the first to have it factory installed by FMW. On the other hand, this tank appears to have been shipped without some of the more common modifications of the second half of 1943, such as the appliqué plates on the front and sides. Period photos and a number of surviving French Shermans show that the side appliqué plates were crudely tack welded on, something that wouldn't have been acceptable at a US factory or tank depot. One theory is that French units training in the UK before D-Day were supplied with a number of these modification kits, but lacked the time and manpower to do a proper installation. US units in the UK had the same problem, but were able to contract British firms to apply the modifications assembly line style. In any case, 15056 shows evidence of having had the side appliqué plates tack welded on.

A rear shot of Serial Number 15056. The authors suspect this tank survived WWII, & that the commander's vision cupola & MG stowage mods were added by the French postwar. Otherwise, the turret could be original to the tank. The welded up pistol port and factory installed application of the turret patch are appropriate to July 1943 production.

These photos don't show confirmed surviving FMW M4A2s, but illustrate the construction of the front glacis as seen on our two surviving examples. The red lines indicate the weld joints. Note that the "plate" that includes the bow MG was actually a casting, whereas the other sections of the glacis were armor plates.

The direct vision slots were considered ballistic weak points, and it is obvious that FMW dispensed with them at "some time in early 1943." The modified drivers' hood casting featured an additional periscope in front of the drivers' hatches. Note that these drivers' hoods castings are what are informally referred to as the "narrow" type, and were used by most producers of small hatch M4s and M4A2s.

The 6 surviving M4A2s confirmed to have been built by FMW are

thought to have a single variant of the bow machine gun socket casting.

All are noted with little "buttons" on the corners of the piece (circled

in red). On the 4 without protective plates in front of the bow

gunner's hood, the stylized Pratt & Letchworth logo (inset, shown

upside down) is visible. What we take to be the part number (outlined in

red) is cast in on the upper left, but in every case, it is obscured by

the dust cover fitting. This trapezoidal bow gun casting is very

similar to what is seen on Pullman M4A2s produced starting in the Spring

of 1943. However, we suspect that the castings supplied to Pullman were

made by another firm, or perhaps we should just say that the ones

observed so far on the few known Pullmans do not have the corner

"buttons."

Here we have the typical cast antenna bracket seen on FMW built

Shermans. Note how the bracket is mounted on top of the glacis plate, as

opposed to the flush mounting seen on some other makers' Shermans. The

antenna casting on the historic survivor "Mort-Homme" carries Part

Number D52416 and can be seen with the stylized "PL" caster's logo of

Pratt and Letchworth. For what it is worth, of the 7 surviving M4A2s

known or thought to have been built by FMW, only SN 14815 does not have

this particular P-L D52416 casting. Again, this part is similar to what

is seen on Pullman M4A2s (and M4s for that matter) produced starting in

the Spring of 1943. However, so far, the antenna brackets seen on the

few surviving Pullmans are not noted with the same casting marks.

FMW and Pullman M4A2s produced from the Spring of 1943 to the end of production are so similar in appearance that we have had difficulty identifying the maker of the few surviving examples. From counting heads on an admittedly small sampling, it seems possible that FMW mounted the grouser compartment blank off plates on top of or "proud" of the sponson armor. Pullman, on the other hand, appears to have mounted them "flush." Flush mount required the additional step of providing a "ledge" (arrow) under the sponson armor to hold the blank off.

Although the authors don't have any proof, we would assume that some or all of the FMW M4A2s made before Serial Numbers 14801 and 14815 also had direct vision. Perhaps a few after SN 14815 had it as well? In the right side photo of Serial Number 14815, the DV slots are "hidden" behind the drivers' hood appliqué plates, which were probably installed during a remanufacture done by Fisher in 1944.

The few known FMW built Shermans are equipped with the cast type of head lamp sockets used by most of the manufacturers of small hatch Shermans.