Most of the information on this page is courtesy of Joe DeMarco. Many thanks to Peter Brown, Jim Goetz, Leife Hulbert and Tom Gannon for their assistance! Note: some of the information on this page was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

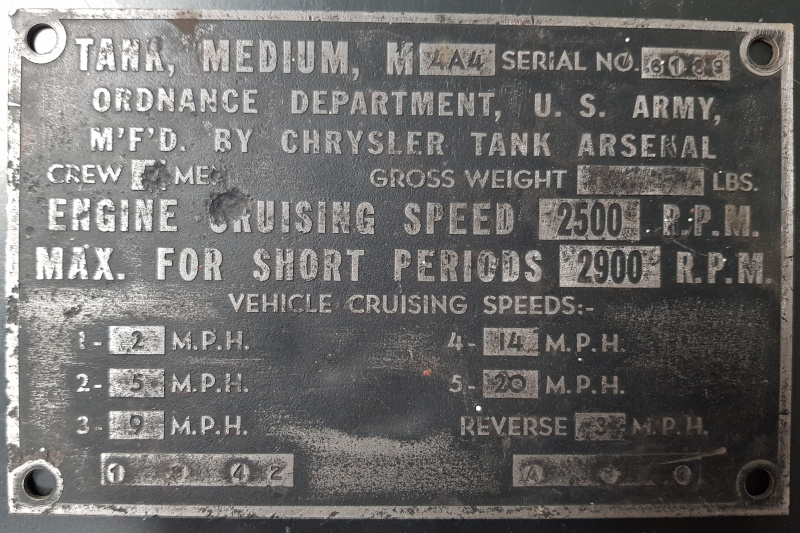

The Chrysler Corporation was the sole manufacturer of the M4A4, and produced 7499 units from July 1942 to November 1943.

Production Order T-2593: 1401 units: Serial Number 4805 / USA 3056615

through S/N 6204 / USA 3058014 *

Production Order T-3333: 4000 units: Serial Number 16555 / USA 3016861

through S/N 20554 / USA 3020860

Production Order T-3603: 2077 units: Serial Number 20555 / USA 3029082

through S/N 22631 / USA 3031158

Production Order T-3603: 21 units: Serial Number 22632 / USA 3031162

through S/N 22652 / USA 3031182

From the beginning, the M3 was thought of as an interim design. Its major shortcoming was, of course, the limited traverse of the sponson mounted 75mm gun. In August 1940, even before the M3's design was finalized, the Ordnance Committee, Technical Staff emphasized that the next step in development would be "modification of the Medium Tank, M3" by "relocating the 75mm gun in the turret." It was intended to replace the M3 in production as quickly as was practical. However, the press of world events created an urgent need for tanks, and Chrysler's original contract for 1000 M3 Medium Tanks was increased several times so that, ultimately, the company produced 3243 M3s and 109 M3A4s from July 1941 to August, 1942. Chrysler more or less hand built the first two tanks, which are shown above on "Presentation Day," April 24, 1941, a little over a month after the M3 pilot was completed at Rock Island Arsenal. Chrysler President K.T. Keller presented General Charles M. Wesson, Chief of Ordnance, the first M3 (Serial Number 2, USA 301000, the scuffed up tank on the right in the photo) as a gift from Chrysler employees. This gift tank created a "one serial number short" bookkeeping problem that does not appear to have been resolved until near the end of M4A4 production in September, 1943.

The US Medium Tank was designed around an "off the shelf" 9-cylinder Wright radial aircraft engine that was widely used by the Army Air Corps and had a proven record of reliability. As the military commenced its massive build up in the early 1940s, materials priority appears to have been given to the Navy and Air Corps. Recognizing that there would be a critical shortage of aircraft engines, the Army turned to the automotive industry for alternate power plant designs. In July 1941, just as M3 Medium production was getting underway, the Ordnance Department asked the Chrysler Corporation if it could design an alternate tank power plant "in a hurry." The expedient that emerged used the "off the shelf" 6-cylinder engine from Chrysler's "Royal" line of automobiles and combined five of them into a "star" configuration. The Army found Chrysler's "stop gap" design acceptable, and in December 1941, Ordnance contracted for the installation of 109 "experimental multiple engine power plants" in the Medium Tank, M3. This configuration was given the nomenclature "M3A4" and approved for production later that same month. This was not a simple engine swap. The massive "Chrysler Multibank" required an 11-inch elongation of the existing hull. Chrysler also designed and installed heavier duty bogie units to carry the engine's greater weight. It was agreed that the cost would be "$15,000 per tank in excess of the then current unit price of the M3." Above shows what we believe was the first production M3A4. Official M3A4 production figures are given as 33 in June, 73 in July and 3 in August 1942. For a sense of the chronology, we would observe that these were immediately replaced in production by the M4A4, with the first 2 accepted in July, followed by 167 in August as the last M3s and M3A4s rolled off the line. Note the new heavy-duty bogies with trailing return roller arms. Contrary to some sources, the M3A4 was the only tank of the M3 series to have these factory installed. For convenience, we refer to them as "M4 bogies," because, as quickly as they could be produced, they replaced the older M3 type bogies, and became standard on all M4 series Shermans.

This overhead view of the pilot was taken in February 1943 shortly before the tank was converted to a mine flail. "Counting heads" suggests that the first 400 or so M4A4s did not have the "second" turret antenna bracket, or the commander's blade sight factory installed. (We've circled the future locations of these items.) The drivers' hatch handles (1) were in the "first" position, mounted towards the rear and on an angle. This can also be seen on Serial Number 4805, the first production unit. The grouser compartment holes were simply blanked off (2) rather than equipped with air scoops. Holes for a pair of fuel shut off valves (3) were located on the the rear engine deck panel, and right next to them, the lifting handles were positioned side to side. It is thought that in August 1942, the shut off holes were eliminated, the engine deck lifting handles were reoriented front to back, cast air scoops were added, and the drivers' hatch handles were installed in the "standard" position.

Japanese conquests in Asia created a rubber shortage which compelled the Ordnance Department to employ some steel track alternatives. The M4A4 pilot was used to test T49 "interrupted parallel bar" tracks in August, 1942. The photo above was marked up to show the areas in the front vulnerable to 37mm and larger armor piercing projectiles. One can see that the glacis of the M4A4 was rather elaborate, made up of 5 sections. Sections 1 and 2 were rolled armor plate, while 3, 4 and 5 were castings. The drivers' hood castings were "wide," and joined in the center to form the upper glacis. In a front photo, this glacis configuration along with Chrysler's distinctive antenna bracket casting serve to identify the type as an M4A4. It can be seen, however, to have been mislabeled an M4A2 in the information panel. Note the door stops (circled) supporting the open drivers' hatches. These were not present on the pilot when shipped, so must have been added at APG.

Chrysler President K.T. Keller was fond of recording milestones, and sending little notes with photos to Ordnance officials. Above shows the scene at the Detroit Tank Arsenal on August 3, 1942 as "CHRYSLER M4 TANKS CROWD LAST M3 OFF THE LINES." A close examination of the glossy print revealed that the M4A4 in the middle has its Serial Number 4840 chalked on, making it the 36th production unit. During the course of the M3 Lee program, Chrysler designed the pressed metal type of road wheels that can be seen, and used them throughout its production of VVSS equipped Shermans. The M4A4s shown are "still" outfitted with the same type of drive sprockets used on the M3. The M34 gun mounts are in the first configuration, with the gun shield lifting rings mounted very close to the rotor shield. While the M3 is outfitted with flat block rubber tracks, the Shermans can be seen with T48 rubber chevron tracks, which came to be the US Army's preferred type in Europe.

On August 25, 1942, Serial Number 4872, USA 3056682 was received for evaluation by the Armored Force Board at Ft. Knox, Kentucky. A report specifically mentions that it was the 67th unit built. In the "Final Report of Medium Tank, M4A4, With Chrysler Multibank Engines," dated December 15, 1942, the AFB recommended that "The Chrysler Multibank engine be considered unsatisfactory as a power plant for medium tanks and its production discontinued at the earliest possible date." The Desert Warfare Board made the same recommendation a few months later. In the event, "the earliest possible date" turned out to be September 1943, after 7500 M4A4s had been produced along with 5000 spare Multibank engines. After such a negative evaluation, Serial Number 4872 was subjected to the further indignity of ballistics tests as shown above. The M4 bogie units can be seen with the first type of track skid which had a "half round" shape. These were installed on M3A4 Lees, as well as on other early production Shermans aside from the M4A4.

The M4A4 was NOT released for overseas (combat) use by the US Army. Many served as training tanks in the US, but the majority, 7167 units, were provided to the British as Lend Lease. The first allocation, Shipping Order 3-G-1025, for 329 M4A4s was made in September 1942. The first of the tanks were shipped from New York in late November and arrived in Liverpool in mid December. 20 of them were the subject of a joint UK/US study exploring "the most satisfactory method of sealing tanks for shipment to overseas theaters of war." Chester Tank Depot in Pennsylvania used various methods to seal the tanks, and had completed the work by November 9. 15 were loaded "on deck," and 5 were loaded "under deck." Some of the deck loaded tanks were covered with "prefabricated wooden hoods" as shown above left. Upon arrival in the UK, the tanks were inspected. The study concluded with recommendations regarding standard sealing practices to be used in the future shipment of tanks. The lowest M4A4 Serial Number listed was 4830 (T-146219), and the highest was 5561 (T-146225), indicating that the tanks had been produced August through October, 1942. In the right side photos, the sand shields that can be seen were retrofitted at the request of the British. As part of the study, CTD added the so called "comb" device (arrow) to these tanks. This provided an external means of unlocking the brakes, and permitted the tanks to be manipulated into position without having to enter the vehicles, thereby ruining the shipping sealing of the driver's hatches.

Starting in January 1943, Chrysler sent technicians to both the UK and Middle East to train "artificer and driving personnel in the servicing of the power plant." T.A. Demetry one of the Chrysler techs at the Base Work Shop at El Kroub in Algeria, reported that the officers and trainees were "well satisfied with the performance of our units, and were greatly relieved upon absorbing instruction, that the power unit was not at all as complicated as they had originally imagined." In fairness to Chrysler, it must be said that, after a number of engineering changes were made, the Multibank performed well in service with the Commonwealth. At 7167 units, the M4A4 or "Sherman V" in British parlance, was the most numerous of the M4 series received by the British Empire as Lend Lease. Even after production had ceased in September, 1943, the British agreed to accept remanufactured M4A4s as part of their 1944 Lend Lease requirements, and would have taken more, had they been available, in lieu of radial engined Shermans. Credit : Dwight E. Dolan / Library and Archives Canada / PA-201361.

The combat debut of the M4A4 appears to have occurred on 10 July 1943 when C Squadron of the 12th Canadian Army Tank Regiment (Three Rivers Regt.) made an assault landing in support of the 1st Canadian Infantry Division at Pachino Bay in Sicily. The photo above depicts a later scene, and is captioned, "A British [sic] Sherman tank advancing near Catania, Sicily, 4 August 1943." The only Commonwealth unit in Sicily with M4A4s or Sherman Vs was the 1st Canadian Army Tank Brigade, which was composed of the 11th, 12th and 14th Canadian Tank Regiments. The Brigade's War Diary lists the War Department Numbers of over 240 M4A4s issued to its regiments in Scotland prior to its deployment to Sicily. The Brigade's Headquarters Squadron was issued 4, the 11th C.A.T.R. 65, the 12th 66 and the 14th 68. In addition, the 1st Canadian Tank Delivery Regiment (Elgin Regt.) was issued 41 reserve units. "Condor" appears to be T-146514. If so, the Diary has it that it was issued to the 11th Canadian Tank Regiment (Ontario Regt.). It is not possible to determine production dates if all one has to work with are British WD Numbers. However, the appearance of the tank can provide a time "window". For instance, "Condor" can be seen to have the elongated drivers' hoods that were introduced in production at Chrysler in November 1942, but it still has the M34 gun mount which was phased out before the end of February 1943. We were wondering why we could not find a single photo of a Canadian M4A4 with direct vision in Sicily or Italy. It would appear that the 240 odd M4A4s that the Canadians received had to have certain features in order to be considered "operational" for deployment to Sicily. These are listed as "single water pump engine, strengthened clutch throwout yoke, sealed and lubricated clutch throwout bearings, ventilated clutch and dust deflector." Chrysler records state that the single water pump was introduced into production at Serial Number 5804 (October 1942). The requirement for this was a must for operational status. The other item that Chrysler lists by Serial Number is "ventilated clutch" reportedly introduced at 17794 (January 1943). From this we might assume that all of the Sicily M4A4s would have to have had serial numbers of 17794 or higher, but there does seem to have been a little "wiggle room" offered in the Brigade's records regarding the clutch and dust deflector features, probably because there were not enough M4A4s with SNs above 17794 available in the UK at the time. For instance, the only WD Number we could cross reference to a US Ordnance Serial Number is T-146408 issued to the 11th Cdn. Tank Regiment. A Chester Tank Depot Shipping Ticket dated 27 Jan. 1943 lists this as Serial Number 17667, which would have been Jan. 1943 production but below the 17794 ventilated clutch threshold. Courtesy of the Imperial War Museum, Photo NA5522.

The caption of the photo above has it that the scene was filmed on 3 September 1943 at Reggio during Operation Baytown, the Eighth Army invasion of the "toe" of Italy. Based on unit histories and the date, the M4A4s would likely have been from the 14th Canadian Tank Regiment (the Calgary Regt.). According to the Official History "The Canadians in Italy", "a Calgary squadron had landed with the assault brigade [3rd Cdn. Brigade, 1st Cdn. Division] on D Day and assisted in the capture of early objectives." Chrysler transitioned to the M34A1 gun mount seen here in mid-February 1943. Note that the trailing Sherman still has the M34 gun mount. Another February addition was the "spot and signal lamp." The lamp's bracket can be seen next to the turret ventilator. Chrysler introduced the standard type of hull lifting rings seen here in January 1943. The Commonwealth retrofitted 4-inch smoke dischargers to the turrets of many of its AFVs and requested that future Sherman production include a 2-inch bomb thrower (smoke mortar) in the Sherman's turret. In the Canadian's War Diary, a late July 1943 entry has comments from Capt. W.T. Hunter regarding his visit to the 12th C.A.T.R. He noted "that only tks in HQ of Sqn have been equipped with smoke, but it has now been proved necessary that all tks carry smoke - approx 10 rds." In this case, we think Capt. Hunter was referring to 75mm White Phosphorous, since, in the following sentence he states, "They have been going into battle with 130-140 rounds and not 90 rounds as laid down." Photo courtesy of the Imperial War Museum, Photo NA6209. With thanks to Canadiana and the Canadian Research Knowledge Network for digitizing their country's WW II War Diaries and making them available online.

While the majority of M4A4s were assigned to British Lend Lease, the "French in North Africa" received 274 units that arrived in the Spring of 1943. Above shows a pair at a depot in Algeria on April 23, 1943. The stripes painted on the sides and front were in the colors of the French flag. The shipping code included "NAFUS" which we believe stood for "North Africa French - US." "SR (Sequence Requisition) 10668" indicates that this unit was one of 125 allocated and "floated" in February, 1943. The later drivers' hoods among other features suggest that the tank was produced in January 1943. Some of the many changes made to Shermans in late 1942 show up well on this tank. The gun shield with cast in lifting rings (1) can be seen to good effect. The rotor shield (2) is the later type with cast in "wing" pieces. The head lamp plug holders (3) are mounted in the later vertical position. The bogie units feature the second type of track skid (4), and the return rollers have been raised up an inch by the addition of a spacer (5). The bogie arms are the final type with the "wrench holes" (6). The Chrysler designed pressed metal or "disc type" idler (7) replaced the original welded spoke idlers in all Sherman production by the Summer of 1943. The distinctive Chrysler drive sprocket (8) replaced the M3 type sprocket around October, 1942. This tank can be seen to be equipped with the "aircraft type cowl fasteners" (circled) used to secure sand shields before the introduction of the standard or "interchangeable type" sand shield design in mid 1943.

Click on the pictures for larger size

The scene above was filmed on 14 April 1943 at "Dump #165" in Casablanca, French Morocco. It shows long lines of M4A4s and M5A1 Light Tanks awaiting processing for issue. On Vehicle Materiel (OVM) boxes can be seen stacked in the foreground. The USA Number, 3018736, of the lead M4A4 can be seen painted on in what appears to be blue drab. This tank was produced in February 1943, right at the time that Chrysler transitioned to the M34A1 gun mount, which is present on a number of the M4A4s in the background. In a "side shot," the gap (1) between the road wheels is a good recognition feature of the elongated M4A4 hull. Pierre-Olivier measured the gap and found it to be about 10 inches (25.4 cm). On other Sherman type hulls, he measured the gap at about 3 inches. Unlike our previous example, this tank has the "final" type of track skid (circled). As supplies increased, it became standard on all models to the end of VVSS production. The quarter round object on the rear deck is the exhaust deflector (2), introduced by Chrysler in January 1943. A Field Modification Kit was released in July 1943 which provided defectors for retrofit to earlier production M4A4s.

There are more surviving M4A4s, more US/Commonwealth test reports and more period photos available compared with other types of 1942/43 production Shermans. Thus, at this point, we propose to illustrate the various features of the M4A4 in greater detail. The overhead view from the M4A4 Technical Manual provides the names of various components. The Multibank was so large that there was no room for vertical fuel tanks in the front corners of the engine compartment, as on other types of Shermans. However, the elongated hull enabled the sponson fuel tanks to be enlarged to hold 80 gallons each. The height of the massive radiator required blisters on both the engine deck and the belly plate. Commonwealth users noted that the forward location of the radiator was preferred to the rear mounted, partially exposed radiators on their Lend Lease M4A2s, which were often damaged in battle.

M4A4 Hull Features

The earliest welded hull Shermans were designed with the so-called "narrow" drivers' hood castings (inset). These became standard first on M4A2s, and later on M4s. Chrysler designed the M4A4 pilot with "wide" drivers' hoods castings, and used them throughout production. Above shows a machining operation on the center assembly of the M4A4 glacis. The weld seams that joined the 3 sections stand out on the unpainted assembly. All 3 sections were castings. The lower section, part number D52417 was 62 inches wide, and included the bow machine gun fixture. Ford also used wide drivers' hoods in the manufacture of its M4A3s. However, Ford used rolled armor plate for the lower section. The bow machine gun socket used by Ford was a small casting that was welded into the plate.

In the study of Shermans, it is not unusual to encounter anomalies. The April 1943 production M4A4 shown above can be seen to have a glacis pattern in the Ford configuration. It has an armor plate lower section, with the bow machine gun casting welded in to it. The caster's logo on the MG fixture is "GAD," indicating that it was made by Ford. This is the only such example we have seen out of, say, 50 surviving M4A4s examined. Should readers come across any others, we'd be pleased to have a report.

The earliest Shermans, including the M4A4, had direct vision drivers' hoods. These were found to be ballistic weak points, and the Ordnance Department ordered them eliminated from welded hulls on August 13, 1942. Some lead time was needed to secure the new driver's hood castings. At present, our counting heads method suggests that the transition was started and completed by Chrysler in November 1942. Serial Number 5868 is the first known example we have recorded without Direct Vision, and Serial Number 5908 is the last unit recorded with Direct Vision. 5868 / USA 3057678 was designated "M4A4E1," and was used to test the installation of the 105mm gun in the Sherman. The new elongated drivers' hoods featured auxiliary periscopes in front of the drivers' hatches. The new periscopes are seen in the "up" position above. The bow machine gun dust cover fitting was a recent addition, introduced in October 1942. 5868 can be seen with the second type of track skid, pressed metal idler and the T54E2 or "Cuff Type" steel tracks.

It would appear that the original design of the M4A4 envisioned an upper rear hull plate that went straight across from sponson to sponson, as on the M3A4 Lee. We suspect that plates were cut to this pattern, but it was then decided to extend the middle section down by about 4 inches. In any case, early production M4A4s, including the pilot, can be seen with 2-piece upper rear hull plates. At present, the highest serial number we have recorded with a 2-piece plate is 5457, shown above. This tank would have been accepted in September 1942. All later examples have been noted with a single piece upper rear hull plate. We saw 5457 years ago in Brantford, Ontario. Although it is missing a lot, what is left appears to be “as built.” We believe this tank was part of an early Lend Lease shipment to the UK and was later sent to Canada. The fittings on the hull sides suggest it was once outfitted with the Canadian Indestructible Roller Device (CIRD). It is now thought to be in storage at the Canadian War Museum in Ottawa. For future reference, we would observe that SN 5457 does not show any weld scar evidence of ever having had sledge hammer fittings on the upper rear hull plate.

At the start of production, M4A4s featured cast hull lifting rings with rectangular bases. These "padded" lifting rings were phased out by early February 1943.

Above shows what we call the "standard" hull lifting rings. These castings were introduced on most Sherman types in January 1943, and were standard on the "second generation" M4 series. Our photographs show the lifting rings on Serial Number 18157, an historic French Lend Lease combat casualty on display in Dijon. This is the first M4A4 we have recorded with the standard rings. In some cases during the transition, hulls were equipped with both types. For instance, Serial Number 18223, an early February 1943 unit, has the "padded" rings on the front, and standard castings on the rear. 18223 is the last example we have recorded to date that is still outfitted with the padded type. Every unit after has been noted to have the standards on both the front and rear.

The M4A4 featured a distinctive "radio antenna bracket" casting. Two views are shown above. A pair of tiny drainage holes are indicated by the arrows. Chrysler produced most of its own parts, including gun mounts, power trains and suspension components. Some of these items were supplied to other builders, but as best we can tell, their antenna casting was used exclusively on the M4A4. Most surviving examples are noted to have the "C-H" (Continental-Hubbard) caster's logo in the position seen above. Pierre-Olivier examined the inside of one of these brackets and found the cast in Part Number D52416 (inset). As a matter of Sherman minutia, we would note that this is the same part number as has been observed on some antenna brackets cast by Pratt & Letchworth, although the shapes are noticeably different. In any case, the M4A4 casting was wider than most others at 16.5 inches at the base. While the brackets on some other Shermans were flush mounted, the Chrysler casting was mounted on top of the armor. It was positioned about 2 inches in from the edge of the glacis, and nearly touched the weldment of the bow gunner's hood. Small hatch, welded hull Shermans used an assortment of antenna brackets. In a front photo, the characteristic appearance of the Chrysler bracket can help identify an unknown type as an M4A4.

A pair of castings (1) with Part Number B200876 were welded on to the glacis to mount the headlamps. The M4A4 was equipped with 2 service headlamps and one driver's blackout headlamp. The blackout lamp was "hooded," and emitted "a thin flat beam of light that cannot be seen from high above, yet provides enough illumination to permit the driver to avoid most obstacles." When not in use, the headlamps were store inside, and the sockets were sealed with a plug. At first the headlamp plug holders (2) were oriented parallel to the glacis as seen above, but towards the end of 1942, they were reoriented to a vertical position, presumably to keep the plugs from falling out during travel.

The siren most commonly used on the M4A4 was the Federal Type 160 with the "V for victory" grill. The driver operated the siren by means of a foot switch located just above the clutch pedal. Note the conduit coupling (1) affixed to the glacis. Unlike some other Shermans, the siren remained mounted and unprotected on the left front fender throughout M4A4 production, including remanufacture.

The bow machine gun dust cover was introduced around October 1942. Above left shows the formed steel rod with snaps, referred to as the "fastener ring for canvas cover." The illustration on the right shows the dust cover in place. While the tiny fittings (arrow) were installed early on, it is thought that supplies of the "driver's windshield and hood" only became available to the Detroit Tank Arsenal at about the same time as the dust cover. For power, the windshield wiper and defroster were plugged into a utility outlet on the instrument panel. When not in use, this item was stored on a shelf above the transmission.

The crews of early production Shermans were subject to injury from falling hatches. Positive hatch lock mechanisms with equilibrator springs were reported to have been introduced at the Detroit Tank Arsenal in late April 1943 at Serial Number 20157. A modification kit was also provided for retrofit at Tank Depots and "in the field." The Firefly at Bovington is Serial Number 21188, and would have been accepted in June, 1943. This tank lacks armor applique, which leads us to think that it was one of about 1740 M4A4s shipped as built to the Commonwealth in the Summer of 1943. The locking mechanisms (1 and 2) secured the hatches when opened. The springs (3) were provided to assist the drivers in opening and closing the heavy hatches. A chain (4) held the padlocks when not in use.

Modifications came about as a result of user experience and subsequent feedback. A few surviving Commonwealth M4A4s can be seen with some simple fittings (1 and 2) that secured the open hatches. Their appearance is fairly standard, so we would assume these were installed on a number of the Lend Lease Shermans received before the introduction of the positive hatch lock modification. Our example is a December 1942 production M4A4, Serial Number 17299 which was on display for many years at the Panzermuseum in Thun, Switzerland. Crews experienced some difficulty in climbing on Shermans, so starting in late 1942, a small step (3) was factory installed to provide a little extra traction. The British actually considered adding a ladder (inset) but rejected the idea for obvious reasons. Item 4 is the fitting that held the "driver's windshield and hood."

All of the M4A4s were produced with power trains that were protected by 3-piece differential housings. These had been designed originally for the M3 Medium, but were carried over to the M4 series. It was intended that they be replaced by a simpler and stronger 1-piece housing which entered production in mid 1942. However, some power train manufacturers, including Chrysler, stated they could not retool for the new configuration without it creating a serious slowdown in Sherman production. Consequently, it was agreed that Chrysler would complete its run of M4A4s with the 3-piece differential housing, and switch over to the later (Part Number E8543) type 1-piece housing when it started production of the M4 Composite in August, 1943. Chrysler power trains were assembled at their Dodge Main Plant in the Hamtramck section of Detroit. Above left shows an early example. In December, 1942, Chrysler began the transition to a new configuration in which a "lip" was added to each of the cast sections in order to protect the top bolts from bullet splash damage. At the transition point, some differential housings were assembled with a combination of lip / no lip sections.

The M4A4's differential housing consists of 3 castings bolted together. In general, the right hand section is part number E4151, the middle or "carrier" piece, part number E1232, and the left hand section is part number E1231. E1232 casting marks are rarely seen on the middle piece of surviving M4A4s. The photo above shows one of the few exceptions. "Duguay-Trouin" is a monument Sherman on display in Dijon, France. She served with the 2ème Régiment de Cuirassiers, and was knocked out with the loss of 3 of her crew on September 11, 1944, during the fight to liberate the city. This M4A4 is Serial Number 18157, and was accepted in January, 1943.

As a matter of Sherman minutia, we would mention that some of the early "no lip" differential housings have been seen with alternate part numbers on the right and left hand sections. C99338 has been noted on a very few right hand sections, while D50993 has been seen more frequently on the left hand pieces. The M4A4 shown above is on display at the Kubinka Museum near Moscow, and isone of two examples we know of that has both alternate part numbers on the same differential housing. Photo courtesy of Roger Davis.

Chrysler started M4A4 production with the same type of drive sprocket they had used on their M3 Lees. This is shown above on the left. Counting heads suggests that they completed the transition to the rather distinctive sprocket seen on the right by October, 1942. For want of a better term, we refer to this as the "Chrysler sprocket," since they installed it exclusively throughout their remaining production of Shermans, including those with HVSS.

During the course of their M3 Lee program, Chrysler replaced the original welded spoke road wheel with a pressed metal type. Only the pressed metal was factory installed on Chrysler built Shermans with VVSS. The company transitioned to a pressed metal idler wheel in October 1942, at about the same time as the "Chrysler sprocket." Ordnance documents note that the rims of the original welded spoke idlers were so frequently damaged in service that the government mandated that they be replaced in all Sherman production with the pressed metal type in mid 1943. The Firefly at Bovington provides a good "as built" view of the pressed metal road wheels and idler. The inset shows the grease nipple, a couple of the formed spokes, and 2 of the 12 rivets that secured the body of the road wheel to the rim.

The M3 type bogies with the center mounted return rollers were overtaxed by the weight of the M3 Medium, and suffered numerous volute spring failures. The introduction of the Multibank engine, and the heavier weight of the new M4 series designs only exacerbated the problem. As a solution, Chrysler designed a larger bogie unit with heavier volute springs and a trailing return roller arm. The new bogies were released for production in January, 1942. The earliest version featured half round track skids. These were installed on all production M3A4s. Incremental changes were made to the bogies in order to increase their strength and reliability, particularly with the use of the heavier steel tracks. The early skids appear to have been replaced on the M4A4 after about 150 units. A new track skid (inset) with a larger contact area was installed starting in August and ending in early 1943.

The use of steel tracks created a friction problem with the track skid. This was remedied by the addition of a spacer (1) that elevated the return roller by about an inch. Chrysler production incorporated the spacer in early 1943. Modification kits were also provided shortly thereafter so that spacers could be retrofitted to any M3 or M4 Medium type AFV built without them. The "final" type of bogie arms (2) were also introduced in early 1943. In order to prevent the bogie arm rubbing plate bolts from working loose, they were secured at the bottom with a nut. "Wrench holes" provided access to the nuts. Chrysler appears to have introduced the "final" type of track skid (3) in February, 1943. We believe the bogie unit shown above is typical of those installed on M4A4s from March 1943 up to the end of production in September. Modelers and restorers might note the use of "cap screws" (4) to secure the bogie bracket cap. This can be compared to the nut and bolt configuration shown in the inset. Unlike other builders, Chrysler continued to use cap screws until the end of 1943. Many of the bogies supplied to Chrysler can be seen with the production date cast in. These will generally precede the tank's acceptance date by a month or two. Our example is dated 4-43.

Chrysler appears to have started M4A4 production with T48 rubber chevron tracks. Throughout production, it is noted that the ratio of rubber to steel track was approximately 50%. Unlike the US, the British preferred steel track, and noted that "Chrysler will complete the order of 6000 [T54E2] on the 15th of December [1942] and it has now been decided that...they will manufacture the T62 type...developed by this firm." We interpret this to mean that the T54E2 or "Cuff Type" would have been replaced by the T62 sometime in early 1943. These 3 types are the tracks most commonly seen in period photos of new production M4A4s. However, we would note that others, such as the T49 "cast block with interrupted parallel tread" can be seen on some of the 1610 M4A4s remanufactured for British Lend Lease from December, 1943 through October, 1944.

The M3A4s and a few of the earliest M4A4s were shipped with the grouser compartment holes blanked off. However, it was found that the fuel tanks of the first M4s, M4A1s and M4A4s suffered an excessive heat condition, which caused melted solder joints and other fire hazards. This was remedied by the addition of a pair grouser compartment covers with air inlet grills that permitted greater air flow as shown in the Tech Manual illustration above left. The TM also noted that starting at M4A4 Serial Number 17794, the fuel tanks were encased in insulation. Some early M4s and M4A1s were equipped with welded together "air scoops." These are thought to have been post production additions, fashioned at Tank Depots. They may have been retrofitted to a few of the earliest M4A4s, but we know of only one example - the third production M4A4 (SN 4807). The standard casting shown above right entered the pipeline at DTA in August 1942. It was made in left and right hand versions. Note that it was mounted on top on the sponson plate, not inset. The long bolt that can be seen behind the wire mesh, secured it to the hull by means of a clamp.

The M4A4 engine deck layout is shown above on Serial Number 18117, a January 1943 production unit. The rearmost section (1) was not removable but welded to the hull. Starting in January 1943, with the introduction of the exhaust deflector, the 10-pound sledgehammer was reported to have been mounted on this plate. In the instructions for installing the exhaust deflector, the implication is that the sledge hammer was originally mounted on the upper rear hull plate possibly above the track wrench, and that "Before the deflector can be installed, the sledge hammer stowage must be removed and relocated on the top rear hull plate." The inset drawing shows the "new" location. This is something of a mystery to us because, if the sledge hammer and fittings were ever mounted on the upper rear hull plates of M4A4s built before January 1943, we have never come across any period photos that show it there. It simply seems to have been missing on 1942 production M4A4s. The lifting handles (2) on the center section were oriented side to side on some of the first units but appear to have been reoriented front to back sometime during August 1942. The cast armor blister (3) protected the top of the massive radiator, and included a water filler cap. The air intake grill (4) was made up of 17 closely spaced steel rods. Curiously, the short and long bullet splash plates (5) were not always welded to the air intake grill as seen on this example.

Above left provides a closer view of the bullet splash plates welded to the air intake grill as seen on Serial Number 19617, an April 1943 production unit outfitted by Chrysler with an early version of HVSS. This configuration is also present on the M4A4 pilot. However, our examination of period photos and surviving M4A4s, shows that in many cases, the plates were welded to the hull. For instance, Serial Number 4807, the third production unit can be seen above right in this alternate configuration. This would have created an interchangeability issue, but we have not come across any Chrysler or Ordnance correspondence that discuss it. Our speculation is that the preference may have been to have these parts permanently welded to the hull. However, the tolerance of the turret ring appears to have varied from almost nothing to an inch, so if the splash couldn't fit on the hull itself, it was affixed to the air intake grill instead.

In this unusual view, we see an example with very little surface area available at the centerline to permit the bullet splash plates to be welded directly to the hull. Presumably, in this case the plates would have been welded to the air intake grill, but that engine deck section is long since gone from this M4A4. It can be noticed that the fire extinguisher housing (1) has been moved from its original position as indicated by the filled in holes (2). The weld seams (3 & 4) show the method of construction used to assemble the rear part of the hull's top around the turret ring. The same method was also used on 2nd Generation welded hull Shermans. This tank is Serial Number 5791 indicating October 1942 production.

The photo above was taken at the Detroit Tank Arsenal in March, 1944 during the remanufacture program. The tank in the foreground can be seen to have the bullet splash plates mounted on the hull, perhaps with a slight overhang. We have seen "overhang" as well as "fully on the hull" on surviving examples. Note that the long section is in two pieces joined at the tank's centerline. Some surviving examples come to a slight rearward point at this junction. Although we can't confirm, it seems possible that the bullet splash plates were "forced" on to the hull for uniformity during the remanufacture program. The bullet splash (1) surrounding the fire extinguisher housing was also introduced in April, and retrofitted to remanufactured M4A4s. This surround was installed from the start on some M4 series Shermans. On most, it was 3 inches high, slightly taller than the fire extinguisher housing. In contrast, the M4A4's surround was only 2.5 inches high.

We have not come across any official documentation regarding the "little plates" shown on the left above. They appear to have been factory installed only on M4A4s and M4A6s, and only starting around mid April, 1943. It was noted that the original weep holes were too small, and often became clogged with debris. Water trapped inside the turret splash could foul the gasoline supply of the auxiliary generator, or cause a build up of dirt in the turret bearing race. The drain holes were enlarged, and it is assumed that the little plates were added to protect them. Remanufactured M4A4s were retrofitted with enlarged holes and the plates as required. Above middle shows the original size of the drain hole. On the right, one can see the larger hole on a range target M4A4 from which the protective plate was shot away.

The Sherman V Crab on display at the Tank Museum in Bovington is serial number 19925 indicating April, 1943 production. We would judge that this tank was shipped "as built" to the British in the Summer of 1943, and converted in the following months. 19925 is the first example we can document that has both the "little plates" and the fire extinguisher surround installed. On this unit, the bullet splash sections are welded to the hull. They are about 2.5 inches high, as is the surround. Note that the low bustle D50878 turret barely clears these items. The weld remnants on the air intake grill suggests that a British designed wading trunk was once installed.

As mentioned previously, we have found no documentation to explain the hole that appears in the turret splash, only on the left side, and only on some M4A4s produced up to the end of 1942. Above left shows it on the M4A4 with the highest Serial Number we have encountered so far - 16733. This December 1942 production unit shows evidence of having been remanufactured by Chrysler, and later converted to Firefly by the British. It is on display at Arsenalen - Swedish Tank Museum in Strängnäs, Sweden. A few period photos show what appears to be a 1-inch plumbing plug (above right) inserted from the inside. However, Pierre-Olivier inspected the hole on SN 16733 during his visit to the Pansarmuseet, and found that it is not threaded. An M4A4 owner theorized that the hole may have served as a means to insert or remove the front hinge pin from the armored filler cover of the auxiliary generator (red line). If so, the convenience of it may have been sacrificed for ballistic safety. After all, when the drain holes were enlarged, Chrysler spent considerable effort applying the "little plates" to protect those openings.

The side armor plates of most surviving M4A4s have nicely beveled top edges, such as can be seen on Serial Number 19617 above left. In July, 1943, Chrysler transitioned to the use of square cut side armor plates, a practice already employed by most of the other builders. Our example on the right, shows Serial Number 22169, an August 1943 production M4A4 on display in Avranches, France. It is thought that, from August, 1943 to the end of production in June, 1945, all Shermans manufactured at the Detroit Tank Arsenal were built with square cut side armor plates.

The "as built" lower rear hull configuration of the M4A4 is shown above. Unlike other Sherman types, the lower rear hull was oriented vertically. Section 1 was a quarter round casting with a raised area at the center, to which the engine access door flange was bolted. Sections 2, 3 and 4 were 1.5 inch armor plate. A breather tube (5) vented exhaust gasses that built up in the crankcase. The small tube next to it was the radiator overflow. Fishtail exhaust pipes (inset) emerged from each side of the engine compartment. Later models are seen with 2 crankcase breather tubes, and an exhaust pipe for the auxiliary generator.

The Ordnance Department directed the installation of trailer towing pintles on Shermans starting in April 1943. However, it was found that on M4A4s, many bent up in service, causing a misalignment of the rear engine mount, and making it impossible to open the engine access doors. Consequently, "It was immediately burnt off as many new tanks M4A4 as possible," and further installation was suspended. The Brits mention that 15 - 20 M4A4s "slipped through" Lend Lease with the pintles. This would have been the first or "long" type towing pintle (above, left). It is thought that this problem wasn't limited to M4A4s and led to the design of the "short" pintle, installed on second generation series Shermans. The British preferred their removable leaf spring towing pintle design but were unsuccessful in their request for the US to manufacture and install it on their Lend Lease Shermans. Above right is a photo of SN 19617. The lowest section of the engine access door flange was removed, and the "bump" to which it was bolted was ground off. The weld scars suggest that this April 1943 production unit had the pintle factory installed, but later removed.

The exhaust deflector was introduced at the Detroit Tank Arsenal in January, 1943. The photo above left shows it in the "down" position. A pair of offset hinges (1) secured the deflector to the hull. For engine access, the deflector could be raised as shown on the right. It was secured in the up position by a couple of locking pins (2). This February 1943 production M4A4 was filmed at the Chester Tank Depot as it was being prepared for overseas shipment. One can see that the engine access doors were taped up, and sprayed with a "heavy black mastic sealer." Suspension components were sprayed with a rust preventative compound known as Par-Al-Ketone.

M4A4 Turret Features

Chrysler used D50878 low bustle turrets throughout M4A4 production. Continental Steel and American Steel Foundries were their primary suppliers of turret castings. The turrets produced by these foundries had a feature not found on those cast by other companies - three 1 inch diameter "bumps" (1) in the positions indicated above. The lifting rings (2) of Continental and ASF turrets supplied to Chrysler were not welded on, but were part of the overall casting. It is thought that all but the pilot M4A4 had the rear turret lifting rings in the "low" position.

Click on the pictures for larger size

We suspect that the photo above was taken at about the same time as the preceding image, but further down the assembly line. These tanks can be seen with gun shields that incorporated the lifting rings as part of the casting. This image was extensively "photoshopped." The installed hatches were painstakingly censored out. The censor even spent a lot of effort "hiding" the rubber chevron tracks, including the coils in the middle distance on the left. Just behind them, are the air cleaners. On the M4A4, these were installed inside the fighting compartment, against the firewall. Unlike some of the earliest factory shots at DTA, these M4A4s can be seen to be equipped with the cast air scoops.

In late 1942, a shield was provided for the .30 caliber coaxial machine gun on Shermans equipped with the M34 gun mount. It was included as On Vehicle Materiel on tanks that were scheduled for shipment to combat zones. The MG shield (1) can be seen on the "Ready for Issue" M4A4 shown above. The caption reads, "Presentation of the last (sic) US Tank to the French Army under the Lend Lease Act at Dump #165, Casablanca... May 4, 1943." While this may have been the last M4A4 presented, the French were allocated a further 382 M4A2s starting in May, 1943. This tank was USA 3018776, indicating serial number 18470, accepted in February, 1943. Not all of the French Lend Lease M4A4s were equipped with the "spot and signal lamp," but 3018776 has the fittings (2) for it. We suspect this was one of the first units to have this factory installed.

The photo above shows M4A4s of the 4e Escadron, 1er Régiment de Cuirassiers (5th French Armored Division) lined up for inspection at Taylor Farm in Berkane, Morocco in 1944. Counting heads suggests that the original 274 French Lend Lease M4A4s were produced in January and February, 1943. Thus, none of them would have had direct vision. We estimate that about a third would have had the padded hull lifting rings. Perhaps less than half would have had the M34A1 gun mounts in the "early" configuration only, with the lifting rings and exposed bolt flange on the right as seen on the first two tanks in the photo. The M34 gun mounts would have been the type with the cast in lifting rings on the gun shield, and the side extensions on the rotor shield. Most or all would have been shipped with the coaxial mg shields as seen in the photo. These tanks were made too early for such features as the little plates, and hatch lock mechanisms.

The original periscope gun sight was found deficient, so the Ordnance Department designed a new gun mount that incorporated a direct sight telescope. A mock up (above) was photographed at APG on June 22, 1942. The sides of the rotor shield were extended to protect the telescope (1) and the .30 caliber coaxial machine gun (2). Designated "Combination Gun Mount, M34A1," the new design was released for production on October 16, 1942. Most changes to the Sherman were introduced "with obsolescence." This permitted the manufacturer to use up supplies of the old parts, even as the new parts were introduced into production. The addition of the direct sight telescope was deemed so important that the M34A1 was initially released "without obsolescence," with a cut off date of January 15, 1943. The manufacturers could not obtain all of the parts necessary to meet such a rigorous deadline, and ultimately, the M34A1 did not completely replace the M34 gun mount in Sherman production until the end of April, 1943.

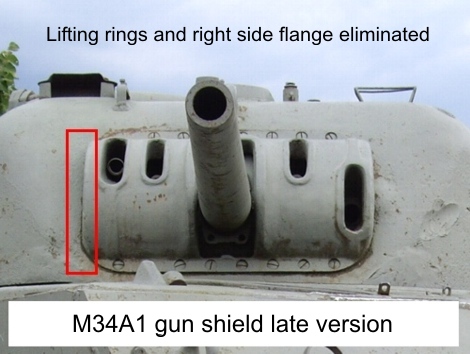

Chrysler's DeSoto division produced gun mounts, and the Detroit Tank Arsenal was an early adopter of the M34A1. A company memo dated January 22, 1943 states, “we have scheduled gun mount M-34A1 (76mm) [sic] to be incorporated in tanks after No. 3499 M-4A4. This tank will be built about February 15 and we do not anticipate interruption of production to accomplish.” By our math, the 3499th M4A4 would have been around SN 18652. A British Situation Report differs slightly in noting that they had been advised that the M34A1 gun mount would be installed on M4A4s in February, starting at serial number 18531. At present, the first period photo we have recorded showing a factory new M4A4 with M34A1 gun mount is SN 18776. Whatever the exact Serial Number, all of this leaves us with little doubt that the introduction date indeed came in mid to late February. The photos above provide comparative views of the early and late type M34A1 gun shield castings. The late type appears to have been introduced by Chrysler in early May, 1943, at around the same time as the incorporation of the positive hatch lock mechanisms.

As originally designed, the Sherman’s D50878 75mm turret featured a pistol port on the left side towards the rear. The montage above shows the pistol port in the open and closed positions from both inside and outside the turret. One of the authors recently had the opportunity to operate a pistol port, and his first impression was that it was much heavier than expected. The L shaped handle or “lever,” served as a simple prop, which held the door open, and locked it into position by means of a “lever locking pin” (1) which could be slipped into a “notch” (2) with a rotation of the handle. To secure the pistol port door in the closed position, the handle was rotated until a fixed “latch” (3) contacted a fitting (4) welded on just above the pistol port opening. The “lever handle” (5) was installed with a rubber bicycle type grip which is missing from this example.

Users reported some problems with the locking device of the pistol port. On top of that, Ordnance Department tests found the pistol port to be a ballistic weak point. A couple areas on the inside right front of the turret casting had been thinned to allow for the proper operation of the traversing mechanism. As the first Shermans entered combat, troops began to report that the enemy aimed for these "thin spots." In April 1943, the D50878 turret was revised to eliminate the pistol port, as well as "increase thickness of turret in area of the traversing mechanism." The revised turret castings began to enter the production pipeline at Chrysler around June, 1943. We estimate that the last 1600 M4A4s were produced with either "no pistol port" turrets, or earlier turrets with welded up pistol ports. Above provides two views of M4A4s awaiting overseas shipment at the Hampton Roads Port of Embarkation in September, 1943. These tanks would have been mid 1943 production, and can be seen with no pistol port turrets, and the "interchangeable type" sand shields, which were standardized for the M4A4 in May. Some of the British WD Numbers recorded from this series of photos are T-212566, T-212567 and T-212573.

Starting around mid 1943, Tank Depots were directed to weld up the pistol ports on the Shermans they processed for shipment. As tanks with welded up or no pistol port turrets were delivered to the troops, the feedback was universally negative. Without the pistol port, it often took three men to load ammunition. A man on the ground passed rounds up to a man standing highly exposed on the tank, who passed the rounds through to a man in the commander's hatch. Only one man on the ground, and somewhat protected by the tank, was needed to pass ammunition through to a man at the pistol port. "In response to British requirements," any tanks assigned to them, and awaiting processing in Depots, were exempted from the "weld up the pistol port" directive. However, the Commonwealth received many Shermans with welded up pistol ports. The scene above depicts one such M4A4 of the Pretoria Regiment, 6th South African Armoured Division, near Monzuno, Italy, December 28, 1944. In response to the demand, the pistol port was reinstated on July 23, 1943, but the new turret castings didn't begin to enter production until late 1943.

Period photos show 2 of the Firefly (Sherman Vc) prototypes (T-148350 and T-148471) had welded up pistol ports, but without the turret applique modification. This combination was probably somewhat unusual in combat service, in that the idea in the Summer of 1943 was to correct the flaws of the original D50878 turret by the addition of these mods. The Firefly at Bovington is another such example. It is to be noted that the turret patch kits were made available to the Commonwealth for field modification in the months leading up to D-Day. Despite their position in favor of the pistol port, it is obvious in period photos that the British Firefly program involved a large number of M4s and M4A4s that had either welded up or no pistol port turrets. The conversion program commenced in January 1944, and many of the new, suitable Lend Lease Shermans with M34A1 Gun Mounts and Oil Gear Power Traverse would also have lacked working pistol ports. Left side photo courtesy of Mathieu George.

In mid 1943, armor applique kits were produced to protect the "thin spots" on earlier turret castings. Approximately 900 of the first of these were shipped to the Mediterranean Theater of Operations, and arrived in September. The turret applique is often the only modification seen on early production Shermans serving in Italy. Additional shipments were made to the UK starting in September for installation on US and Allied Shermans slated for the D-Day invasion. Soon US Army Ordnance officials in the UK were reporting back to the Office of the Chief of Ordnance that the 350 pound patch coupled with the weight of the M34A1 Gun Mount, created a nose heavy turret condition which would require 1100 pounds of counterweight. OCO rejected the counterweight idea, with the advice that retrofit of the new Oil Gear Traversing Mechanisms which were en route to the UK in November and December was the Ordnance approved solution to the nose heavy problem. It would appear that Chrysler only factory installed the turret patches to welded up pistol port turrets used on M4A4s in August and September, the last 2 months of new production. It was a standard item where needed on every remanufactured M4A4. The photo above shows the shape and overall appearance of the patch used by Chrysler. Note the machining at the bottom edge of the turret casting (arrow). This is not present on every D50878 turret, but is commonly noted on the turrets of surviving M4A4s.

Quoted from a British status report..."The installation of the 2" Smoke Mortar becomes effective on vehicle No. 7300. This means that tanks coming off the production line as from the 26th of August, will have these mortars fitted. Since only a total of 7500 M4A4s are being produced, we shall get 200 tanks from the final production with these mortars in addition to the...reworked M4A4s." The British repeatedly requested that the mortar be provided and installed by the US as a standard item on Shermans. It was felt that a factory milling operation of the hole would be preferable. Despite the difficulty of burning the hole in the turret, which also weakened the surrounding armor, a number of earlier production Shermans, particularly the Firefly conversions, were retrofitted with the Smoke Mortar in Commonwealth workshops. The Brits often added an oval shaped combing as shown on the right. The combing held some sort of canvas (?) cover, which, according to a British schematic, was kept “in rear bin”. It should also be noted that US Tank Depots were charged with installing the Smoke Mortar modification starting in the Fall of 1943. Left side photo courtesy of Carl J. Dennis.

The introduction of periscope guards and the commander's vane sight to new production M4A4s is somewhat murky. The photos above show USA 3031035, which was pulled from the line at the Detroit Tank Arsenal and installed with the Allis Chalmers suspension and tracks developed for the M6 High Speed Tractor project. This would have been about the 7356th M4A4 produced out of 7500. 3031035 can be seen to have a welded up pistol port turret with smoke mortar. It has just about every modification available up to September 1943, including the full suite of armor applique and the gun travel lock. However, it is "still" fitted with the original commander's blade sight, and lacks the periscope guards. The new sight and periscope guards were just entering the production pipeline as Chrysler ended M4A4 production. Aside from processing tanks for shipment, the Tank Depots served as modification backstops. As supplies became available in Fall of 1943, the Depots were directed to install these items to Shermans scheduled for shipment overseas. We suspect that the use of welded up pistol port turrets (as opposed to those with no pistol ports) so late in production, may have been a "last ditch" attempt to use up remaining supplies of the earlier turrets.

The "Sun Compass Bracket" (circled) is present on many of the turrets of Commonwealth Lend Lease Shermans. The Sun Compass seen on some British AFVs during the North African Campaign was a disc type affair, as on Monty's Grant (inset). It might have been useful for navigation in the featureless deserts of Egypt and Libya, but was hardly needed in the subsequent campaigns in Europe. Despite the questionable utility, starting around mid 1943, the British prevailed on the US to have the fitting welded on at Tank Depots to all Shermans assigned to Commonwealth Lend Lease. We did not come across a list of Depot modifications for the M4A4, but above right shows those for the "British" M4A2 at Chester Tank Depot as of October 22, 1943. "Install Sun Compass Brackets" is item 12. One might assume that a Sun Compass was also provided as On Vehicle Materiel?

Remanufactured M4A4s

The US Army wanted to terminate production of 75mm Shermans at the end of 1943. However, quoting from General Bernard Montgomery, "The gun in the tank must be able to fire a good H.E. shell...For this reason we definitely do not want any 76mm Shermans." Thus, the British continued to require 75mm models in 1944. It was agreed that 75mm Shermans in the hands of troops in the US, would be collected up and remanufactured in order to meet Commonwealth requirements as far as possible. This consensus actually dovetailed nicely with US policy "That rebuilt tanks be utilized to meet International Aid requirements to whatever extent necessary to insure equipping United States troops in combat theaters with the latest production type vehicles." M4A4s were recalled to the Detroit Tank Arsenal starting in the Summer of 1943. For instance, the 7th Armored Division is reported to have had 232 M4A4s on hand at Camp Young, California. 100 were in transit back to DTA by late June, 1943. The scene above is thought to have been photographed in the Spring of 1943. It shows 1942 production M4A4s of the 7th AD's 40th Armored Regiment on maneuvers at the Desert Training Center. Note the absence of spot lamps and step brackets.

The British and US agreed to certain conditions regarding the remanufactured Shermans. All tanks would be equipped with M34A1 gun mounts and Oil Gear Power Traverse. These were considered necessary by the Brits, in that they planned to convert a number of these tanks to Fireflies. They also intended to convert many to various types of "Funny Tanks," including recovery vehicles and mine flails. For this purpose, they requested that 600 be shipped "Completely Knocked Down" (CKD). This was often done with wheeled vehicles, where the components were boxed to save shipping space. The vehicles were then assembled in theater. The CKD request was denied by the US, since the Lend Lease Protocol called for the shipment of combat ready tanks, not a collection of unassembled parts. However, Chrysler was directed to provide the British with everything left over at the end of the M4A4 remanufacture program. Presumably, this "All Time Buy of Spare Parts" included Multibank engines, Chrysler 3-piece differential power trains and other components no longer needed for the later Shermans produced by the Detroit Tank Arsenal. The well-known photo above is dated June 1944. The rows of used M4A4s on the left and center are on "disassembly lines," where they will be completely stripped down. A few units nearing completion can be seen on the right along with some new production M4A3(105)s. From a company memo dated October 30, 1943, “Rebuilding these tanks requires two and a half times as much work as assembling the tanks new. They are to be completely torn down, then each part will be inspected, cleaned, reconditioned, or replaced, whatever the needs may be. Also, certain modifications are to be made. In all respects they are to be the equivalent of new tanks when they leave the Arsenal.” Chrysler remanufactured 1610 M4A4s from December 1943 through October 1944.

20,000 "Quick Fix" kits were produced from July through September, 1943. Manufacturers began installing them on new production Shermans in August. As supplies became available in the Fall of 1943, Tank Depots retrofitted the mod to Shermans intended for overseas shipment. With this modification, 1 inch "sponson side protector" plates (Chrysler drawings shown above) were welded to the exterior of the tank in the areas of the sponson ammunition racks. Inside, the racks were encased and "doored" in 1/4 inch armor. The turret basket was "skeletonized," meaning that the sheet metal grating was removed. This was a Commonwealth recommendation. They had experimented with "skeletonization" on some of their early Shermans to provide for more escape options, since the grating tended to isolate the turret crew from the drivers. Ready rounds were deemed "worth the risk" by the British, although any rounds clipped to the turret basket wall, defeated the purpose of skeletonization. One British drawing provided an option for a total of "5 rds armoured" clipped beside the loader's seat. However, the "Quick Fix" modification eliminated the original 12 unprotected ready rounds completely.

A British officer described the Quick Fix modification "as neither quick nor a fix," since the ammunition racks were NOT relocated "below the sponson line," and the entire procedure consumed over 140 man hours. It was necessary to remove the turret in order to retrofit the 1/4 inch armor plates and doors to the ammunition racks. Above shows 3 of the armored bins inside a restored M4A1. (We hope to be able to provide a similar photo of an M4A4 in the future.) The 30 rounds directly behind the escape hatch were fitted with a folding armored door (1). The 17 (2) and 15 (3) round racks on the right sponson were also encased in armor, and fitted with doors. The 15 round rack on the left front sponson, and the 8 round ready rack on the turret basket floor were protected in a similar manner. Photo courtesy of Roger Condron.

Above left shows a pile of original turret baskets at a remanufacturing facility. One can see that the basket had 3 openings, but depending on the turret’s orientation during emergencies, crew members could be trapped inside or outside of the basket. Above right provides an unusual view of a skeletonized turret basket inside a stripped out M4A4. In order to relocate the ammo racks to the floor of the hull on the second generation series of Shermans, the turret basket was raised up to the level of the sponsons. That is, the "well" of the original design, as represented by item 1, was eliminated.

Crews liked to carry as much ammunition as possible, and there was "a universal demand for ready racks from battlefield commanders." Nonetheless, the 12 rounds clipped to the original turret basket wall were eliminated by the Quick Fix modification, as well as by the "second generation" Sherman redesign. Thus, the only rounds immediately available in the turret were in an armored bin at the foot of the loader. This decision was nearly as controversial as the decision to eliminate the pistol port. Ready round proponents won out with the Sherman's replacement - the M26, as it included 10 ready rounds. We suspect that the instruction to remove the ready rounds was not always followed when the Quick Fix modification was done "in the field" on a non-contract basis. A few surviving remanufactured M4A4s have been noted to have the old ready round clips. The question as to when and where this was done needs more study. A British Report mentions that Base Workshops in the Middle East had made a modification to the Quick Fix kits..."All conversions include the addition of another layer of four rounds to the existing eight round ready bin on the floor of the platform."

The applique armor on a new or remanufactured M4A4 was applied very neatly with the weld bead running "with the grain" as shown above. The welding often looks somewhat different on plates applied in the field or at a Tank Depot. Part Number A347061 was used on both sides in the front. In most cases, Chrysler (or its subcontractor) appears to have applied the entire plate to the right front, but in some instances, the top front edge was cut a bit in order to avoid the glacis weld seam (inset).

Starting in August, 1943, 10,000 of the so called "hatch guard" modification kits were produced for installation on new production Shermans, as well as those already overseas or scheduled for shipment to combat zones. It was reported that DTA began installing this mod to new M4A4s in August 1943 at Serial Number 22161. It was also standard on the 1610 remanufactured M4A4s. For some reason, the Field Service Modification Work Order which was published in late August only applied to M4 and M4A3 Shermans. Thus, it is fairly common to see combat photos of M4A2s and M4A4s with the Quick Fix applique, but not the hatch guard plates. On the other hand, the Tank Depots did not discriminate in this regard, but were directed to install the mod on all Shermans processed for International Aid.

Although the FSMWO does not provide instructions for such a process, some surviving M4A4s have been noted to have had the direct vision visors welded up before installation of the armor plates. This can be seen above left on a remanufactured M4A4 that had the hatch guard plates shot away on a target range. The FSMWO instructs that on tanks equipped with a dust cover fastener ring, the top section of the ring be cut and removed. The section was to be bent and reapplied to the hatch guard plate, but the instructions note that the dust cover might "not fit perfectly" afterwards. It is thought that the Detroit Tank Arsenal simply replaced the old fastener rings with new ones instead, as seen above right.

Richard Hunnicutt, author of the magnificent "Sherman, A History of the American Medium Tank," described the tank in the photo above as "a late production M4A4." However, the USA Number, 3017084, indicates that it was originally accepted in December, 1942. The confusion arises because an M4A4 built in August or September 1943 (the last 2 months of production) will have a lot of the same modifications as a remanufactured job. Many of the remanufactured M4A4s were 1942 production, so some telltale signs of a remanufactured as opposed to a late production M4A4 can be the presence of older features such as direct vision, padded hull lifting rings, and "no lip" differentials. Remanufactured M4A4s were equipped with the new commander's vane sight, whereas DTA appears to have ended new production with the old blade sight. In some cases, both sights are present in period photos, which would indicate that the new vane sight was added as a modification. Late production M4A4s had welded up or no pistol port turrets, while most or all of the remanufactures had turrets with working pistol ports, and the "thin spot" applique patch. Note that the little step bracket was eliminated with the introduction of the gun travel lock.

The beautifully preserved Sherman pictured above is on display at the Imperial War Museum in London. This tank has all the hallmarks of a DTA remanufactured M4A4. Serial Number 19388 is stamped on both the front and rear towing lugs. That indicates that it was accepted in March, 1943. From the Serial Number, we can determine through a math formula that this tank was assigned USA 3019694. In the absence of a period photo or other documentation, there would be no way to confirm if the painted on WD Number, T-232274, is authentic. From the standpoint of counting heads, we can observe that the WD Numbers of the "reworked" M4A4s, as the British called them, almost all fall within the T-23XXXX and T-28XXXX ranges. If this tank still has its dataplate, we would be very interested to see a photo of it. Examination of surviving examples suggests that companies that remanufactured Shermans replaced the original dataplate with a new one of their own. Since Chrysler was both the original manufacturer and the remanufacturer, we've wondered what they did? Both photos above courtesy of Carl J. Dennis.

There is a mathematical correlation between the Ordnance Serial Number and the USA Registration Number of AFVs built for the US Army during WW II. The British chose to use their own War Department or "T-Number" system on their Lend Lease Shermans. These numbers were assigned to each tank by a British representative, and painted on at the Depots before the tanks were shipped. We've been asked numerous times, but there is NO correlation between the T-Number and a US built tank's Serial Number. Thus, there is no way to determine the maker or the production date of a Sherman if all one knows is the T-Number. However, there is a loose chronology to the way T-Numbers were assigned. In general, earlier production Shermans will have lower T-Numbers. Remanufactured Shermans would be the exception, as they were shipped in 1944. The table above is a very informal "counting heads" survey of the T-Number ranges that we believe were exclusive to the M4A4. There may have been some with T-26XXXX numbers. We've recorded a few textual listings in that range where the tanks were described as M4A4 or Sherman V. These may be typos, as period photos of Shermans in the T-26XXXX ranges show a mix of radial engine models, including M4(75)s, M4A1(76)s and M4(105)s. In any case, at present, we don't know of any photos that show M4A4s with clearly readable T-26XXXX numbers.

World War II use of the M4A4

For most of the conflict, the diesel powered M4A2(75) was the predominant type of Sherman used by the Commonwealth in Italy. Not all of the British "AFV Situation" Reports break down Sherman holdings by type, but on November 20, 1943, it was reported that there were 1135 M4A2s "with formations" or in reserve in Italy and North Africa. As with Sicily, the 1st Canadian Armoured Brigade appears to have been the only unit in Italy fighting with M4A4s at the time, and they are reported to have held 153. The British 1st Armoured Division is the only other formation listed with M4A4s (64), but they were reorganizing in North Africa, and did not arrive in Italy until May, 1944. A further 377 M4A4s were listed with "Ordnance and Training" (presumably for other Commonwealth units forming in North Africa) and 101 were in transit from the US. Above shows what are thought to be M4A4s of the Ontario Regiment, 1st Canadian Armoured Brigade in the Liri Valley, circa May 1944. The lead tank can be seen with the interchangeable type sand shield strips and other features which suggest Summer 1943 production. Most likely, this M4A4 was received as a replacement in late 1943 or early ‘44. In March 1945, the 1st Canadian Corps (including the 1st CAB), redeployed to Northwest Europe where it finished out the war with the rest of the Canadian Army Overseas. Courtesy Canadian Army Photo.

M4A4s continued to arrive in theater, so that by September 23, 1944, the number of Sherman Vs recorded as "with formations" in Italy had increased to 961, almost on par with the 992 M4A2s reported. The 1st Canadian Armoured Brigade, which had debuted the type in Sicily, was the only Sherman formation at the time composed entirely of M4A4s at 174 units. The other units had a mix of Sherman types. For instance, the 5th Canadian Armoured Division which had had its combat debut in May, 1944, is also listed with 174 M4A4s, but this is supplemented with 46 M4A1(75)s. The 6th South African Armoured Division had the most M4A4s on strength at 200, but also had 14 M4A1(76)s, a "new," 2nd Generation model of Sherman, that had recently arrived in the MTO. These, along with M4(105)s and Fireflies would be doled out in the MTO as they became available. The veteran British 1st Armoured Division, had reorganized in North Africa, and is listed with the most diverse group of Shermans, including 33 M4A1(75)s, 45 M4A2(75)s, 75 M4A4s, 28 M4A1(76)s and 17 M4(105)s. Finally, the 7th Armoured Brigade is reported as having 105 M4A1(75)s and 56 M4A4s. The photo above features an M4A4 named "Falkirk" and is captioned, "Two Sherman tanks of 6th Royal Tank Regiment in action against German machine-gun positions on the walls of San Marino, 19 September 1944." It would appear that the 6th RTR was equipped with M4A4s, while the Brigade's other Regiments, the 2nd RTR and the 7th Hussars, had M4A1(75)s. "Falkirk" can be seen with a lot of 1943 modifications, including the full applique treatment, periscope guards, and 2 inch smoke mortar. However, no gun travel lock appears present, and the turret has no pistol port. This leads us to speculate that this tank was not remanufactured, but was built with these features in Sept. 1943, at the end of M4A4 production. Courtesy of IWM, photo NA 18734.

Click on the photo for larger size

The 6th South African Armoured Division organized and trained in Egypt before being committed to Italy in April, 1944. The interesting Signal Corps photo above is dated April 21, 1945, and was probably taken in Casselecchio a little southwest of Bologna. At the time of the 1945 Spring Offensive, the Division was attached to the US Fifth Army. The Arm of Service marking seen on the lead M4A1(76) (item 1) is "52" indicating the Pretoria Regiment. The British did not care for the M4A1(76), and passed a lot of them off to their Commonwealth partners. Three of the M4A4s appear to be new 1943 production, while the one with the gun travel lock was more than likely remanufactured. Two of them are set up as command tanks with antennas mounted on the glacis brackets (2). Both are outfitted with reels for communication wires. The lead M4A4 can be seen with the "Swabey Sight" (3) designed in the Middle East, and installed on many Commonwealth Shermans there and in India starting in December, 1943.

Most of the M4A4s were shipped to the UK. In the months preceding D-Day, many were converted to Fireflies, DD Swimming Tanks, Crab Mine Flails and Armoured Recovery Vehicles. M4A4s made up the bulk of Commonwealth 75 mm Sherman gun tanks in Normandy. At the end of June 1944, the 21st Army Group reported they had 762 M4A4s, compared with 391 M4s /M4A1s, and 316 M4A2s. 318 Fireflies were listed on strength, with all but 2 being M4A4 based (Sherman Vc). 180 Flails were all reported as "Sherman V Crabs." 93 Sherman V Armoured Recovery Vehicles were on strength. Above shows a Sherman Vc, thought to be with the 3rd County of London Yeomanry, landing on Sword Beach, June 7, 1944. The appearance of this M4A4 suggests May through July production. Most likely the smoke mortar was added in the UK during the Firefly conversion. Courtesy of the Imperial War Museum, Photo B 5130.

The British converted 693 Shermans to DD from March through December 1944. 400 were based on th M4A4, and 293 on the M4A2. ALL of the British DD conversions used for the Invasion are believed to have been M4A4 based. We invite readers to have a look at our Duplex Drive pages. As best we have been able to determine, Commonwealth units embarked with 118 Sherman V DDs and 80 M4A1 DDs converted in the US. One of the Canadian DDs was recovered off Juno Beach in 1970, and is on display at Courseulles-sur-Mer, France (above, right). "Bold" is reported to have been the tank of Major J.S. Duncan, commander of B Squadron of the 6th Canadian Armoured Regiment (1st Hussars). This tank was one of the approximately 50 DDs that sank or foundered in the rough seas while trying to swim in on D-Day. The serial number is not quite readable, but this M4A4 appears to have been produced just before the introduction of the positive hatch lock mechanisms, so probably early May 1943 acceptance.