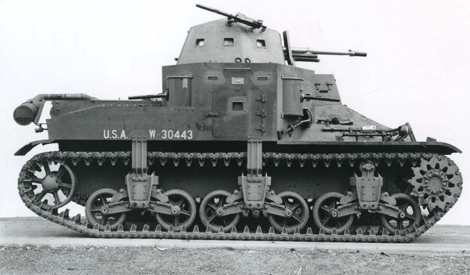

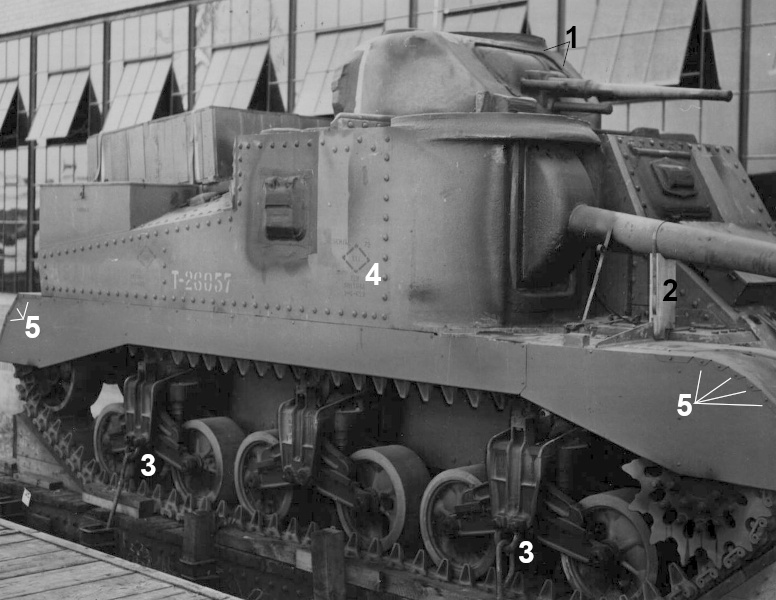

In the 1930s, as the United States struggled through the Great Depression, the country was overwhelmingly isolationist. These conditions were not conducive to the development of a costly offensive weapon like a Main Battle Tank. The Ordnance Department had designed a few Light Tanks to support the infantry, and similar "Combat Cars" to support the [still] existing horse cavalry. Late 1930s efforts to develop a Medium Tank resulted in the T5 / M2 series (above, left, T5 Phase III in 1938), which were essentially enlarged versions of the M2 series Light Tanks. It was soon realized that the T5's 37mm main gun would be inadequate on the modern battlefield, but the engineers appear to have lacked the knowledge, resources and technical ability to come up with a design that could mount a larger caliber weapon in a revolving turret. As an expedient, in 1939, the T5 Phase III was modified to mount a 75mm pack howitzer in the right front of the hull (above right), in the manner of the French Char B1 bis. The Fall of France in June of 1940 changed the political landscape, and created a sense of urgency that the United States begin mass production of a Medium Tank as soon as possible. A design was needed immediately that could meet the Army's requirements for mobility, protection and firepower, and this resulted in the M3 Medium Tank.

Aberdeen Proving Ground in Maryland was the Ordnance Department's Research and Development facility for armor projects in the inter war years. Rock Island Arsenal in Illinois was tasked with producing the few Light and Medium Tank designs that were approved on the Army's very limited budget. RIA basically hand made these tanks, using "tool room methods." The culmination of the inter war Medium Tank program was the M2A1. The tank was equipped with the same 37mm gun as the latest Light Tanks, which essentially rendered the design obsolete. However, production went ahead at RIA simply because the Army desperately needed some Medium Tanks to equip its newly created Armored Force. There was also a sort of educational aspect to the order, since the government and private business had very little experience in what would be required for the mass production of tanks. In any case, RIA manufactured 94 M2A1s from December 1940 through August 1941. In the Summer of 1940, the Ordnance Department had begun work to redesign the upper hull of the M2A1 to mount a 75mm gun. In an unusual move reflecting the sense of urgency of the time, the nascent, drawing board concept was actually standardized on 11 July 1940 as the "Medium Tank, M3." The photo above was taken at Aberdeen and shows an M2A1 beside the original wooden mockup of the M3 Medium. Note that the M3 can be seen mounted on the lower hull of an M2 series tank. The M3 was designed around the same 9-cylinder Wright Radial aircraft engine and a similar type of VVSS suspension. It is assumed that the M2A1 seen here was the prototype, since this photo is dated October 30, 1940, about a month before M2A1 production commenced at RIA.

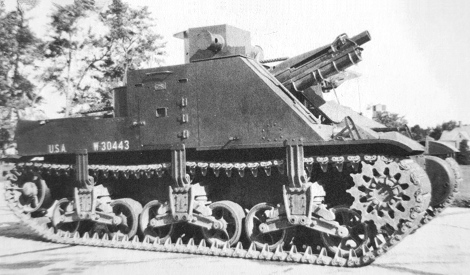

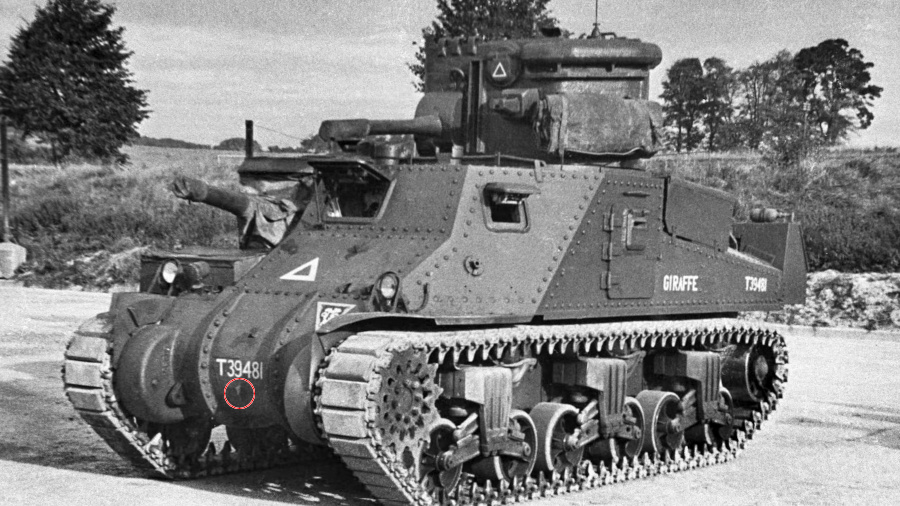

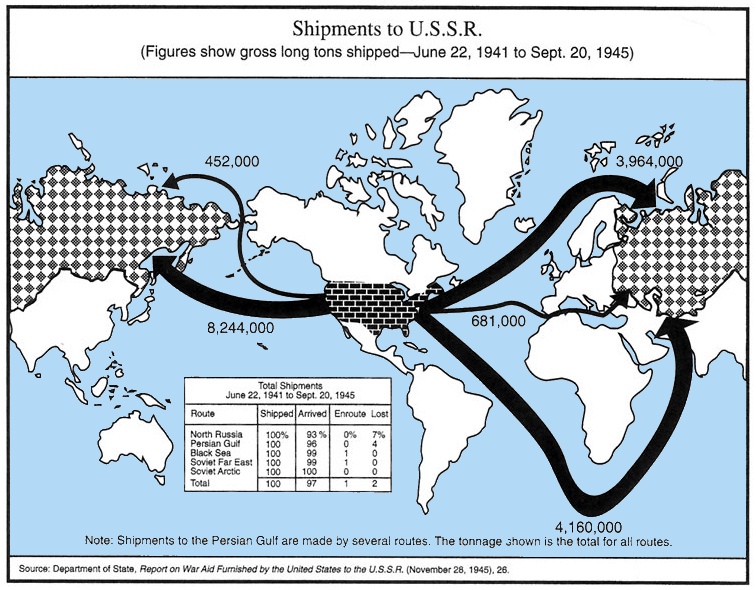

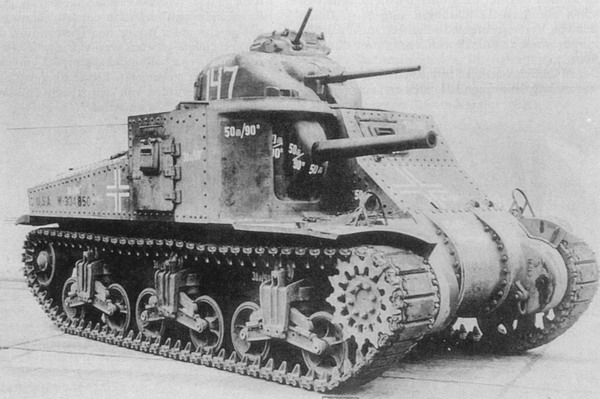

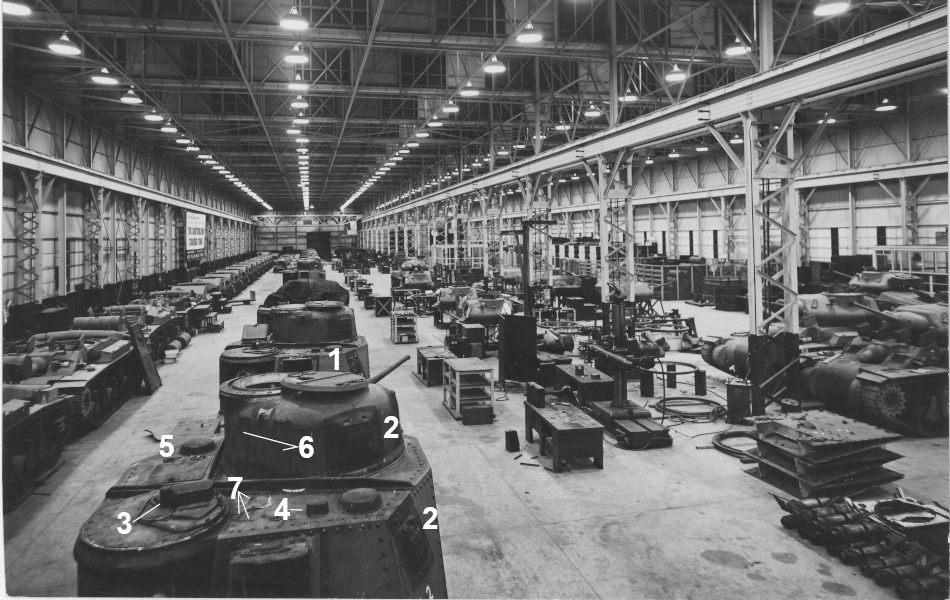

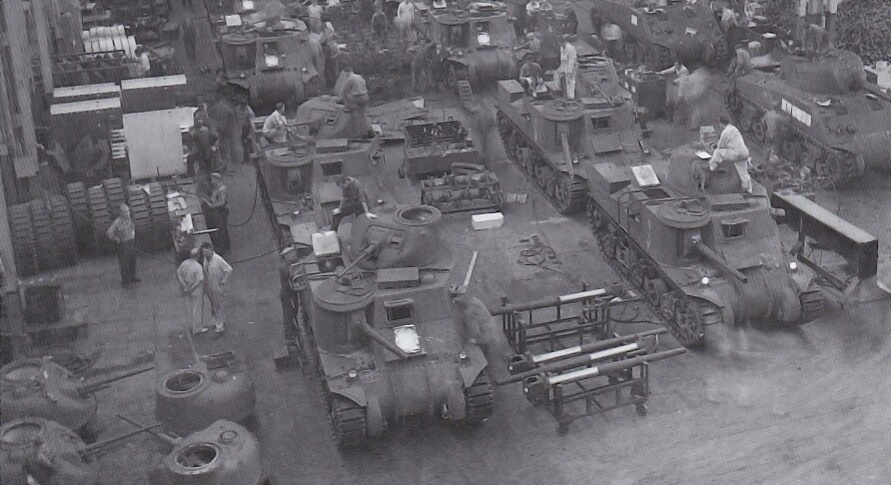

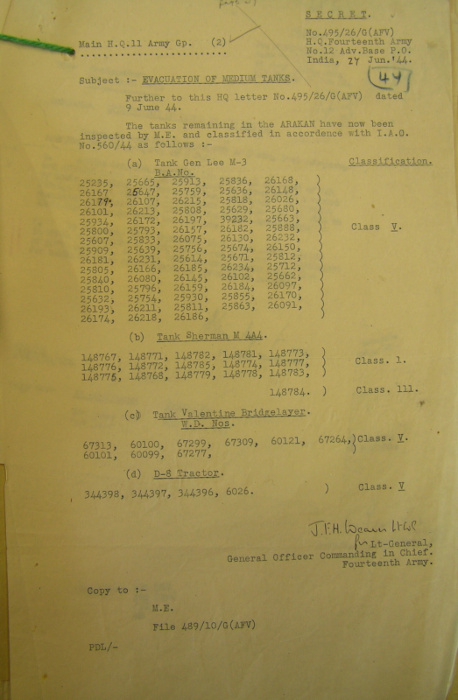

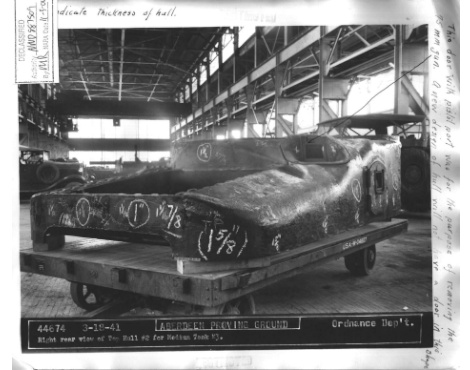

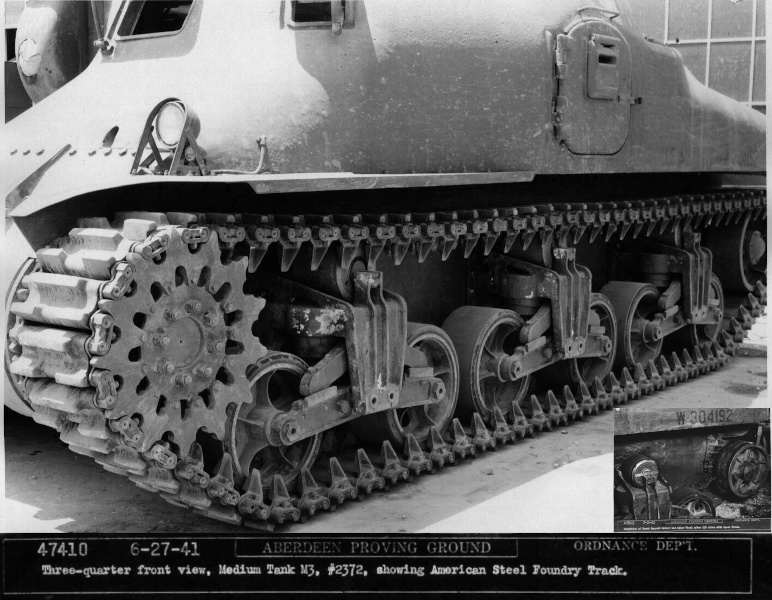

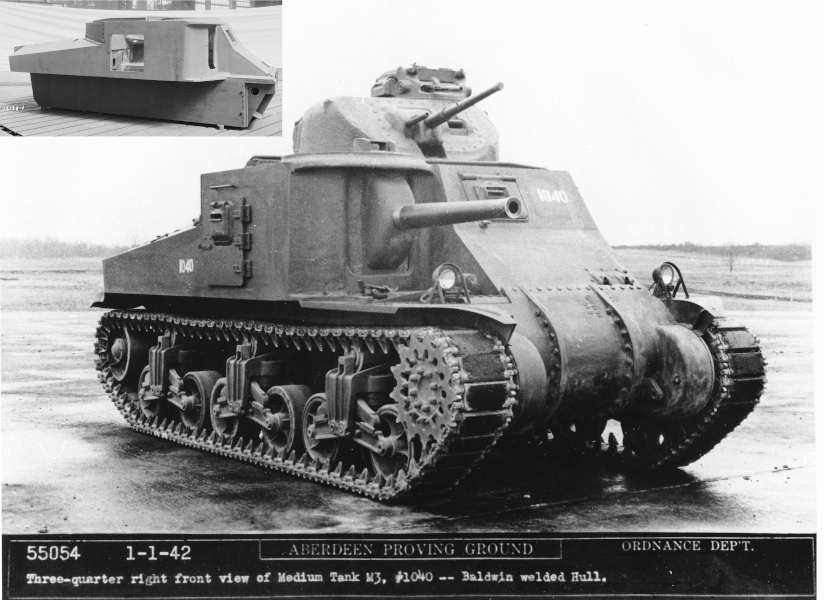

On 15 August 1940, the Chrysler Corporation was contracted to produce 1000 M2A1 Medium Tanks. For this purpose, the US Government financed construction of a dedicated tank plant in Warren, a small township outside of Detroit, Michigan. The original designation as the "Detroit Ordnance Plant," was somewhat confusing, so the name was changed on 29 May 1941 to the "Detroit Tank Arsenal." Before the end of August, the Ordnance Department abandoned plans for the mass production of the M2A1 with its 37mm gun, in favor of the M3 "design concept" with its 75mm main gun. Unfortunately, in the Summer of 1940, the Army engineers did not have the technical ability to mount such a large gun in a revolving turret. Instead, they came up with an interim design which mounted the 75mm gun in a sponson. The M3 pilot was completed at Rock Island Arsenal in March 1941, and photographed at Aberdeen Proving Ground, Maryland shortly thereafter. The riveted construction harkened back to World War I. The sponson mounted 75mm gun along with the turret mounted 37mm, evinced such descriptions as "land battleship" and "rolling fortress." The tank stood over 10 feet tall, causing one tanker to remark, "It looked like a damn cathedral coming down the road." Although originally intended to be a limited run model, the geopolitical situation forced its mass production, so that ultimately, 6258 M3 series Medium Tanks were manufactured from June 1941 through December 1942. 4373 were supplied to the Allies as Lend Lease.

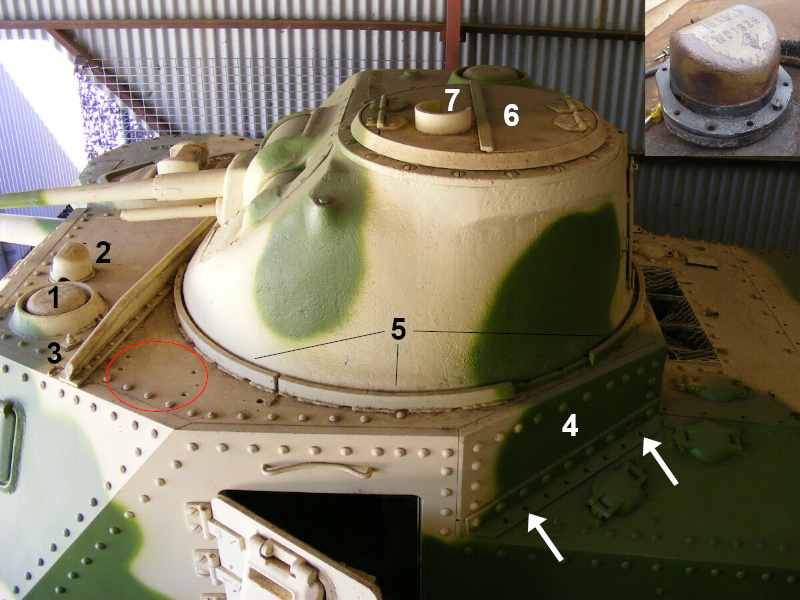

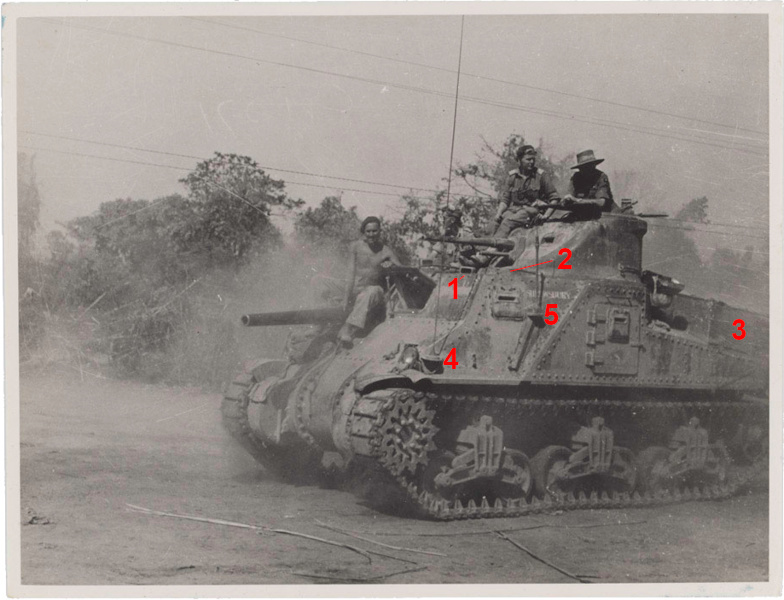

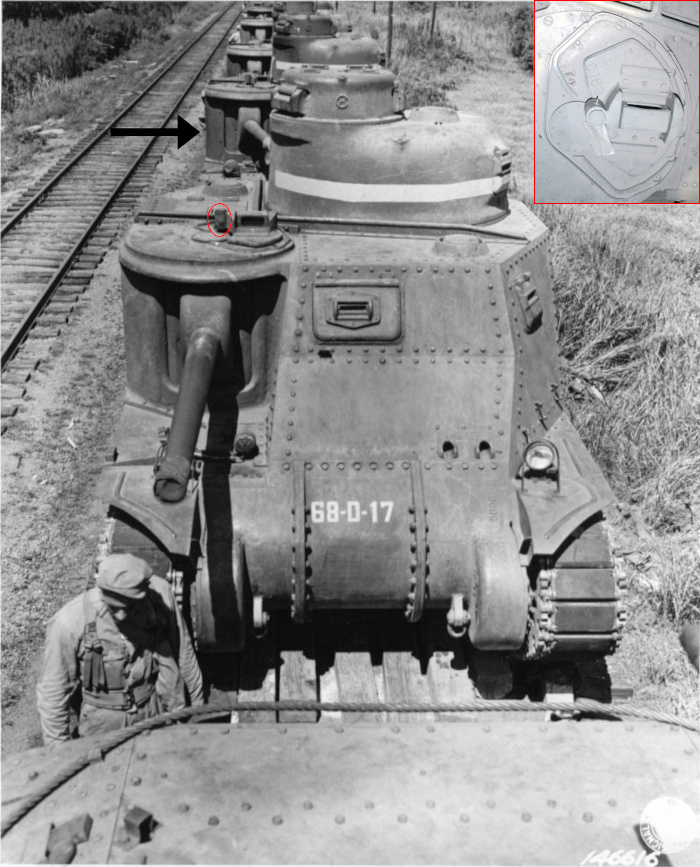

In this front view, we see the familiar "3-piece differential housing" typical of all production M3 series Medium Tanks. This item certainly played a prominent role in creating the overall "steam punk" look of the M3's design. Three separate castings with raised flanges were bolted together to form the armor cover which protected the transmission and final drives. In the Summer of 1940, the Ordnance Department turned to The Spicer Manufacturing Company, which had experience with the Light Tank, to design the "M3 Medium Tank Transmission." The design was accepted, and a few months later, the Mack Manufacturing Corp. was contracted for the production of 1508 units for the US Army and 900 for the British Purchasing Commission. These figures were inadequate to meet planned Medium Tank requirements, but it was not until after the passage of the Lend Lease Act in March 1941 that another manufacturer, the Iowa Transmission Company, was contracted to produce additional powertrains starting in September 1941. Chrysler retooled its Dodge Main Plant for the production of M3 powertrains, and it is thought that they provided these for all of their Lees and M4A4 Shermans from start to finish. The M3 Medium Transmission and Final Drive unit weighed 7600 pounds, including the 3600 pound 3-piece armor casting that protected the front. The transmission had 5 forward speeds and 1 reverse. The "Maximum Speed" listed on surviving M3 dataplates is 19.3 M.P.H. An item of note seen here is the dust cover (1) over the gunner's periscope. This was secured by "snaps" or "press studs" (2) which can also be seen around the 75mm gun, suggesting that it was intended to provide a dust cover for the main gun as well. It was intended for the M3 to be equipped with a siren near the right head light, but it is not present in the March 28 APG walk around photos. An additional bolt hole (3) is visible in the righthand piece (Part Number E1230) of the differential housing. A single bolt was obviously the default configuration, but a few early diffs can be seen to have had two.

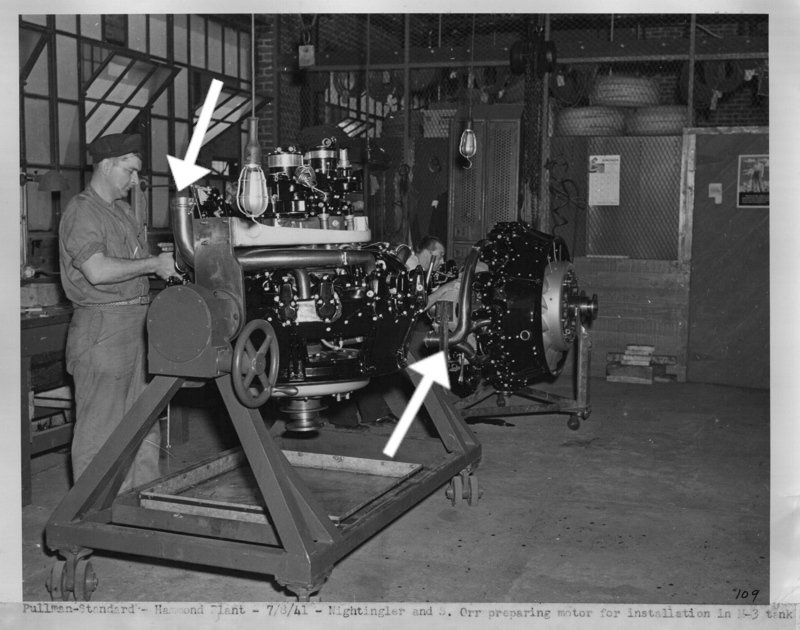

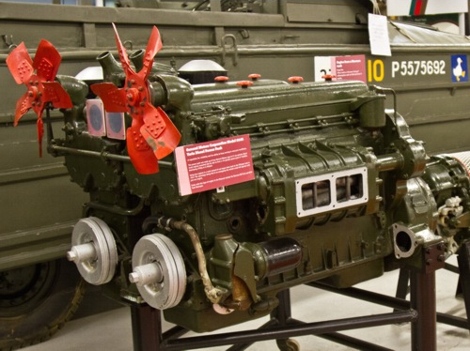

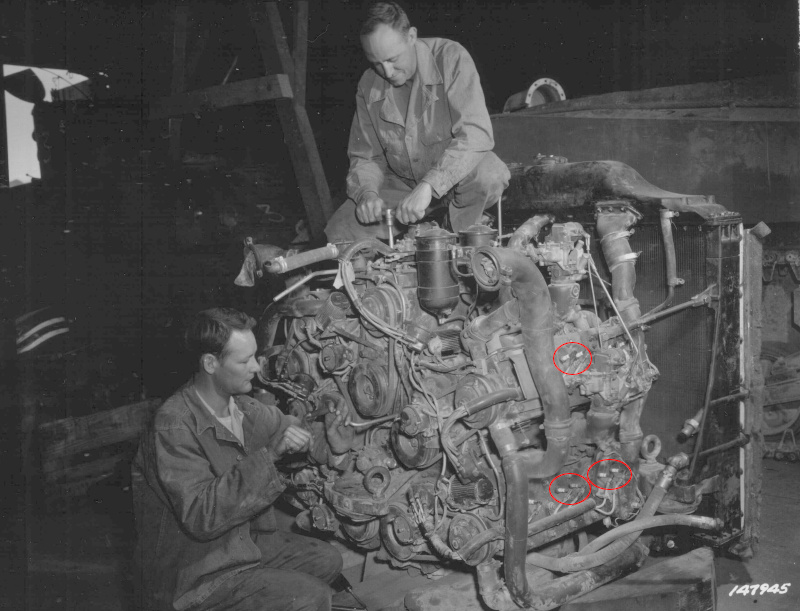

The M3 Medium stood so high primarily because it was designed around the Wright 975 Radial, an aircraft engine with a proven history in the aviation industry. (An earlier version of this engine powered the Spirit of St. Louis on its epic flight across the Atlantic in 1927.) Wright Aeronautical only produced 750 tank engines up to the end of 1941, after which its production capacity was devoted entirely to the Army Air Corps, which had a higher priority rating than the A-1-G assigned to the Tank Program. In the meantime, the Continental Motor Company was contracted to set up its Detroit facility for the manufacture of license-built Wright 975 tank engines at the initial rate of 20 per day and increasing to 1000 per month by January 1942. At the outset, shortages of machine tools and other fixtures hampered production, which, of course, affected the Medium Tank program. The photo above is dated 8 July 1941 and shows a pair of Wright Radials awaiting installation into the first Grants at the Pullman Plant. There is some confusion about the nomenclature, but as built by Continental Motors, these engines were labeled "R-975-EC2". For our purposes, we shall use this designation to refer to the engines that ran on 91 octane aviation gasoline and were fitted with what is described as a "low outlet exhaust collector ring." In this view, the exhaust manifolds can be seen with their exhaust pipes in the so called "low" position (arrows). These were connected to a pair of mufflers mounted on the lower rear hull plate.

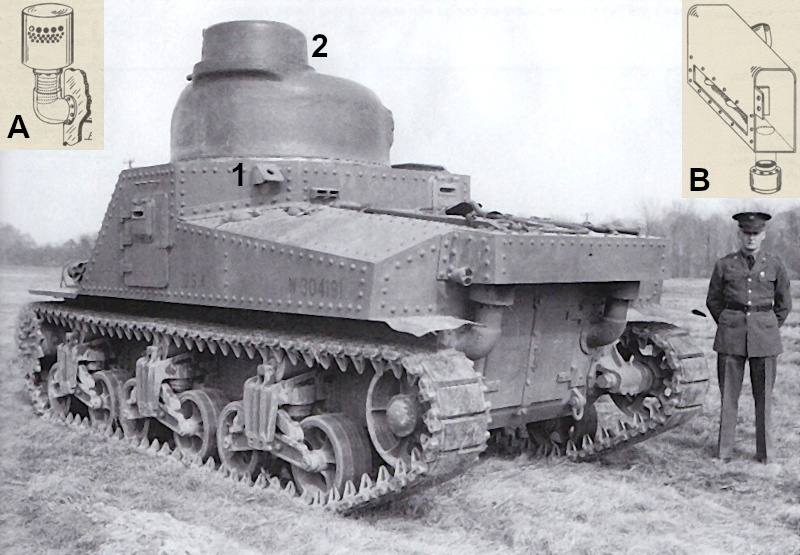

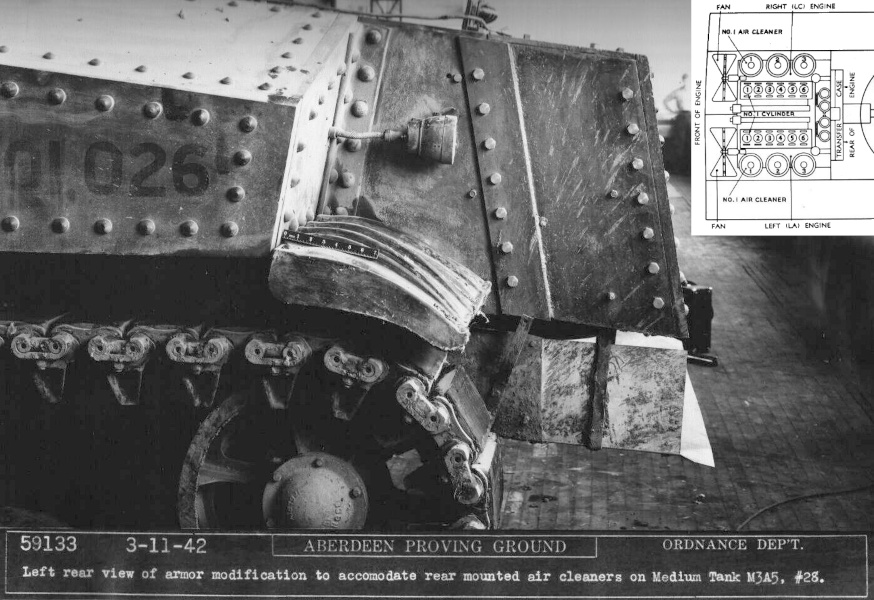

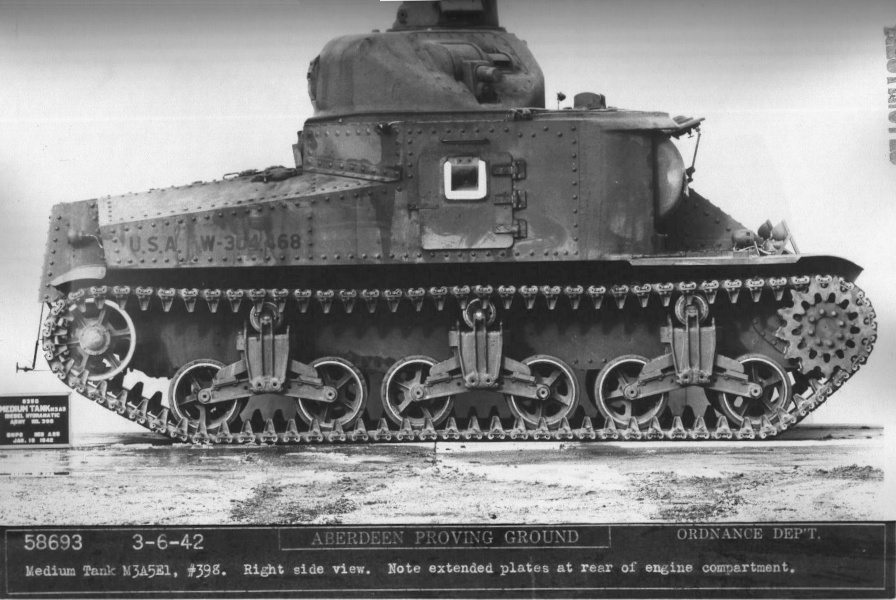

In this left rear view from the 28 March walk around series we see the M3 Medium's original exhaust and muffler configuration. This has come to be known informally as "the pepper pot exhaust." The Oxford English Dictionary defines a "pepper pot" as "a small container with several holes in the top that contains pepper." The "holes in the top" of the muffler can be seen in inset A. The air cleaners were mounted on either side of the radial engine. The original cleaners were rectangular in shape and had three oil sediment cups screwed on to the bottom as shown in inset B. While these air cleaners were protected inside the engine compartment, they were hard to service within the confined space. Indeed, several reports note that it was often found that the sediment cups were "put on the filter[s] but not rotated far enough to lock them in place so they soon shake off." The problem with the pepper pot was that the hot exhaust vented up, directly under the engine deck. This created an intense heat buildup in the engine compartment which degraded the performance of the engine. Furthermore, the engine deck often got so hot that it became a danger to the crew (or riders). In early 1942, a "Quick Fix" modification was devised that replaced the pepper pots with a pair of fishtail exhausts that directed the exhaust out and away from the vehicle. At the same time, the internal air cleaners were replaced with new externally mounted cleaners. These were vulnerable, but the tradeoff was that they were much easier to service. The "Quick Fix" was factory installed starting in the Spring of 1942. A Field Service Modification Work Order G104-W16 was released on 4 July 1942. This was the most important and the most widely distributed of the M3 Medium FSMWOs. Note that the pilot and a few early production Lees were equipped with a very simple, fabricated antenna base (1), as seen here. The machine gun cupola (2) of the M3 was designed with direct vision ports on both sides, but the visor on the left side is conspicuous by its absence on the RIA pilot.

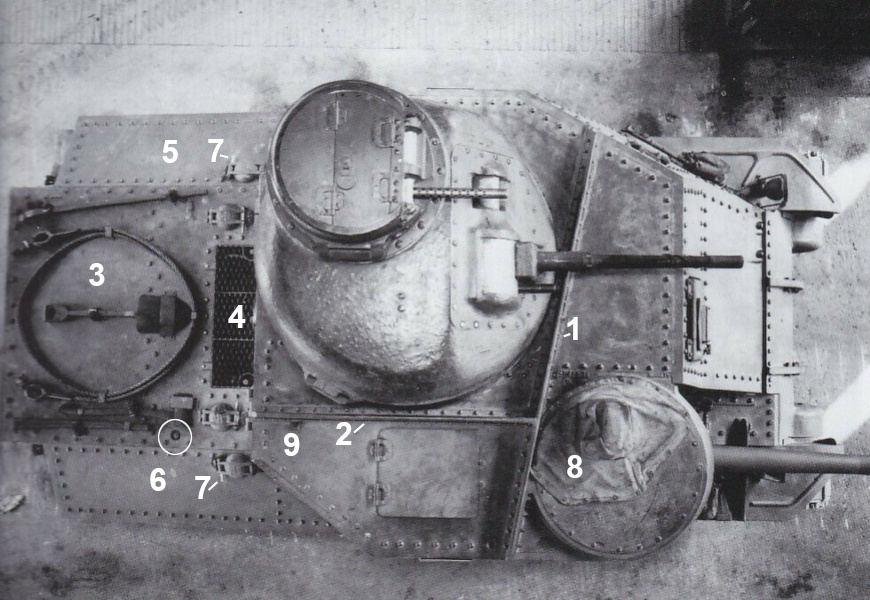

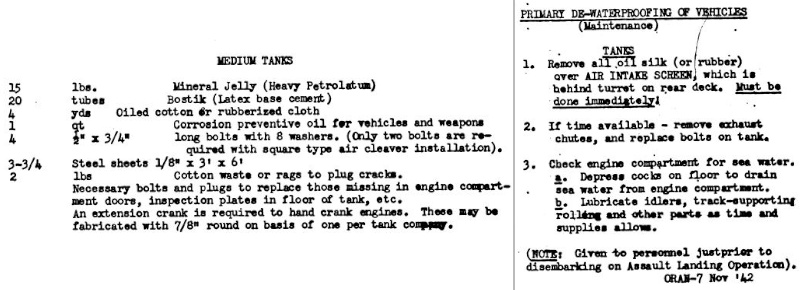

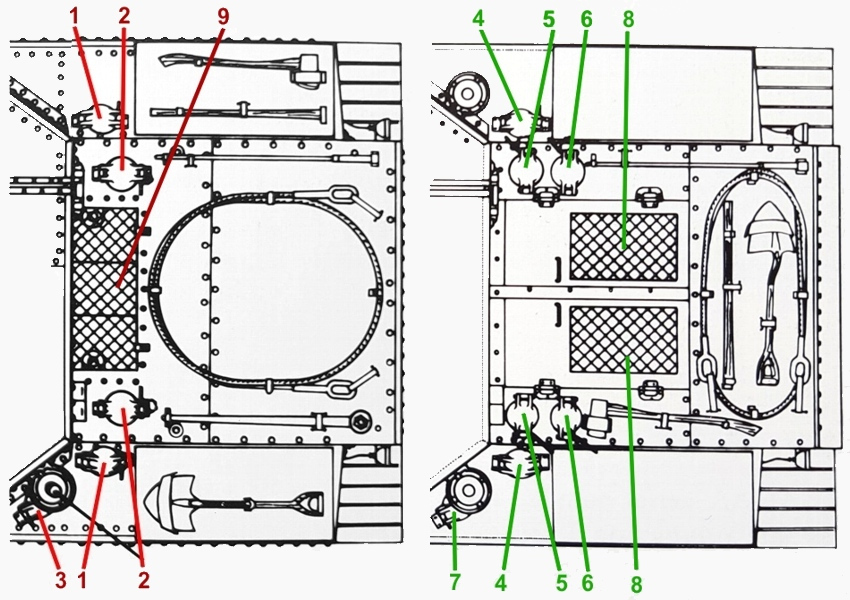

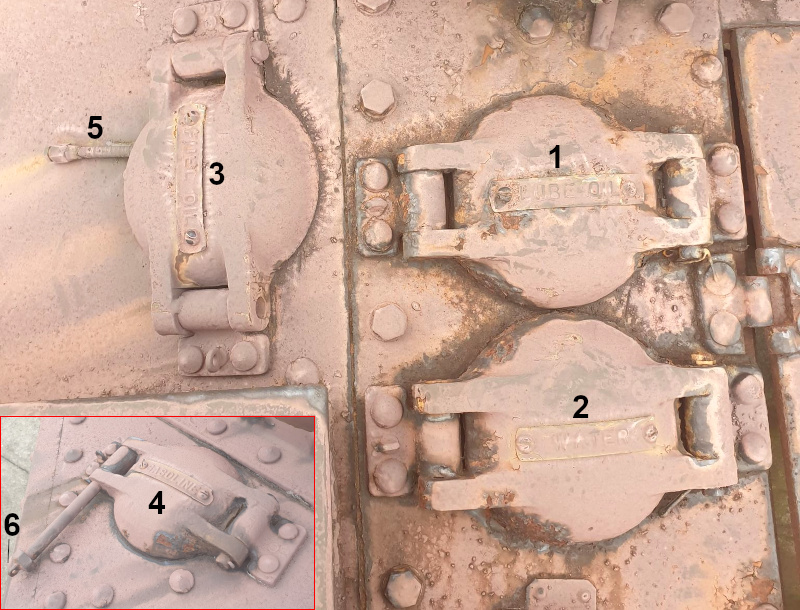

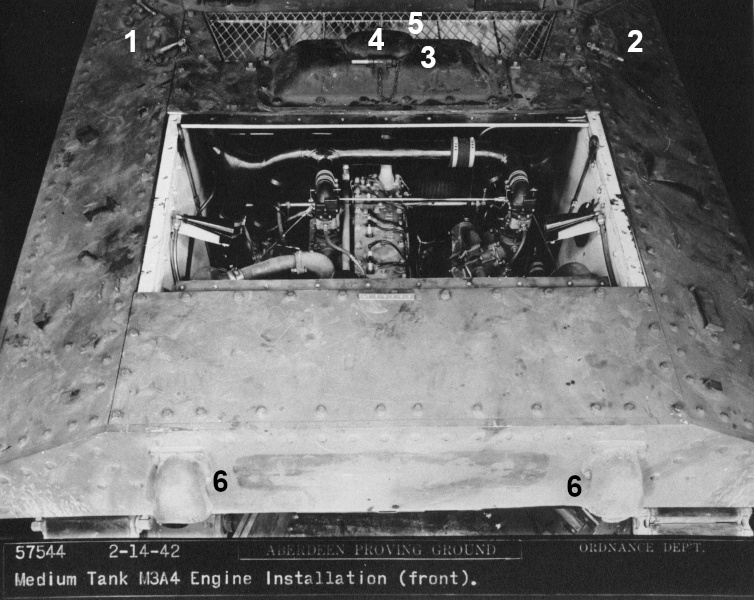

This overhead view from the 28 March walk around series shows a somewhat quirky feature of the M3 design - the reinforcing struts (1 & 2) atop the fighting compartment. The struts helped to support the weight of the 2-ton Lee and 2.75-ton Grant turrets, and also served as bullet splashes, protecting the turret ring area from being jammed by small arms fire or shrapnel. The turret ring had a diameter of only 60 inches, and 3 men were crammed into the relatively small Lee turret - the tank commander, the 37mm gunner and the loader. The fighting compartment crew consisted of 4 men - the driver, the radio operator, the 75mm gunner, and the loader. The initial positions of the pioneer tools and tow cable (3) are shown. (The engine crank and 5 ft. crowbar apparently had yet to be included.) The engine air intake was unprotected and simply covered with a screen (4). The M3 with radial had 4 fuel tanks. Two were mounted vertically in the forward corners of the engine compartment, just below the armored fuel filler covers adjacent to the engine air intake. Two were positioned horizontally in the sponsons at locations 5 and 6. Each fuel tank was provided with a shut off valve (we've circled one). Total fuel capacity is given as 175 gallons. As best we can tell from counting heads, the armored fuel filler covers on the M3 Medium series used the "short and straight" hinge pins (7) shown here from the start of production to finish. The pilot was provided with a dust cover (8) for the 75mm gunner's periscope. However, at present we have found no evidence that this or dust covers for the guns were ever issued as On Vehicle Materiel. A report on the pilot notes that "During rain, tank leaks very badly all over." Production units were sealed with caulk at the joints, but we suspect that they too leaked "very badly all over." The Technical Manual notes that a 12 by 12 ft "Paulin" was provided "In tank." The same equipped the Sherman, and there were many complaints regarding its insufficient size. Note the little catch (9) that locked the top hatch when in the open position.

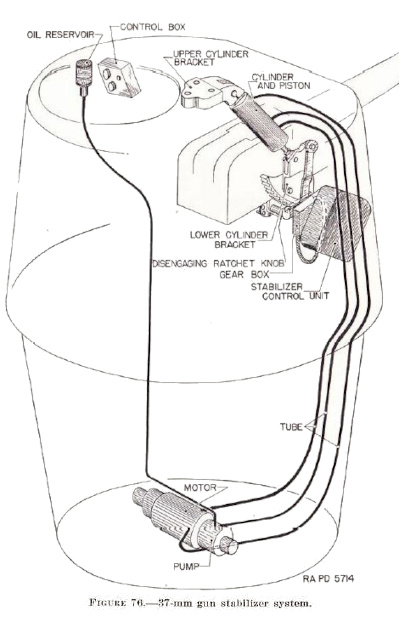

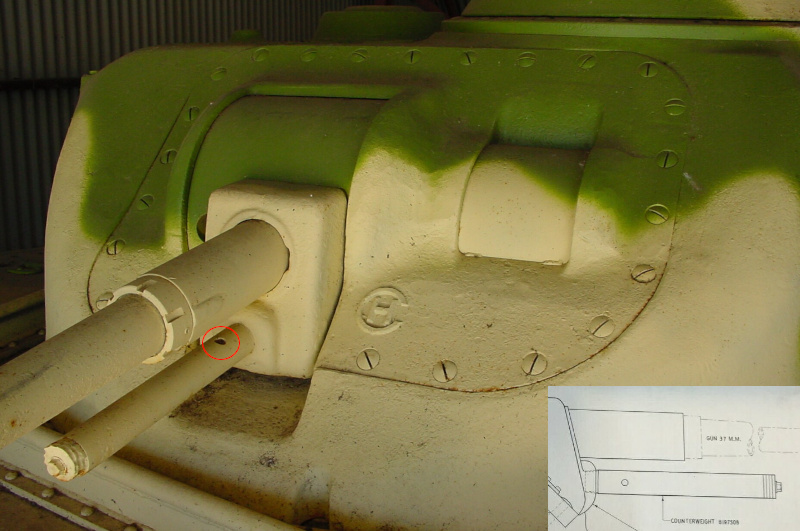

On 24 April 1941 a demonstration of "the Army's new Medium Tank" was put on at APG "for the benefit of high ranking army officers, members of the Office of Production Management, British Representatives, and engineers of the firms which will fill $250,000,000 worth of orders for huge fleets of the mechanical monsters." In this view on the test course, the USA Registration Number can just be made out as 304191. The APG Daily Log for 31 March to 5 April refers to the vehicle as "Medium Tank M3 #1 (R.I.A.)." For "counting heads" purposes, we interpret this to mean that the pilot was assigned Serial Number 1. During this week, the tank was installed with a gyrostabilizer for the 37mm gun. In the photo, note the counterweight (1), which looks to be a capped plumbing pipe. It had been decided that the M3's guns would be equipped with gyrostabilizers, and it is mentioned that during a firing practice on 3 April, the "Stabilizer was not used because of repairs in progress." The inclusion of gyrostabilizers in the M3 and M4 Mediums strikes us as an unfortunate decision, simply because we find no evidence that it was effective enough to warrant the money, time and training spent on it, not to mention that it was "in the way" in the already cramped turret. It was a great idea, but the technology was not yet "there" to make it practical. A much better decision was the inclusion of power traverse. This was one of the best features of US Medium Tanks, since it enabled rotation of the turret with a good deal more speed than hand traversing. On 4 April, the log reports "Had demonstration for manufacturers and personnel from Washington using all guns on the tank. Later used for taking personnel around test course." We would have been interested in any comments about the use of the gyrostabilizer during the firing demonstration, but none were made. Note that a siren (2) was retrofitted. The gleam of it (stainless steel?) seems a bit out of place. Perhaps it was borrowed from the local police or fire department?

In

this photo, the man in the commander's hatch dressed in civilian

clothes is Major General Charles Wesson, Chief of Ordnance from 1938-42.

Note that the Registration Number, W [War Department] 304191, appears

to have been painted on in black, not blue drab. Here we are afforded a

closer view of the capped plumbing pipe (1) used as counterweight for

the 37mm's gyrostabilizer. In the realm of "minutia," we would observe

that the rivets on the pilot can be seen with "round heads" (2) and two

appear to have been "flattened" (flush riveted?) on this example

(circled). If there was any protective padding on the top hatch (3) of

the pilot, it was paper thin compared to what was fitted on production

units. The tracks can be seen fitted with grousers (4) in this photo,

but not in some of the others. We would assume that they were installed

at some point during the demonstration on April 4th. The M3 series

Technical Manuals are not very helpful regarding the On Vehicle

Materiel." They do not list the number of grousers provided, and simply

state that they are stored "In tank." (We would guess the number was 26

as on the Sherman.) Per the TM, "the grousers are attached to every

eighth track shoe by steel pins and a cap screw in a hole provided in

the end of the pin in the track block" [sic]. Note the M2A1 Medium Tank

in the background.

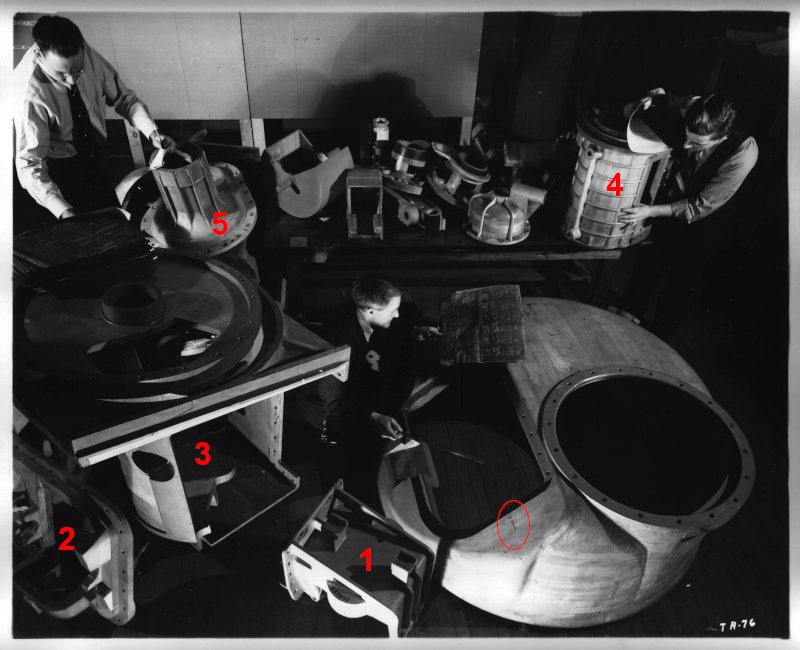

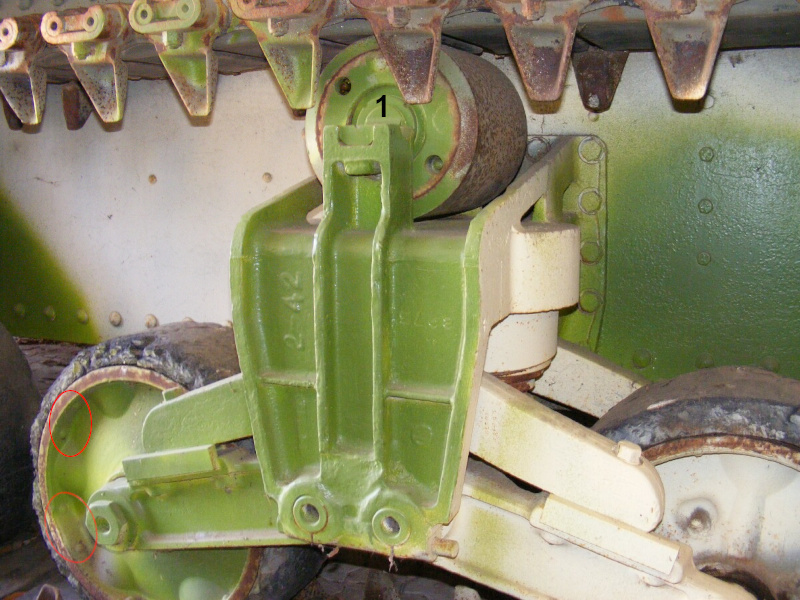

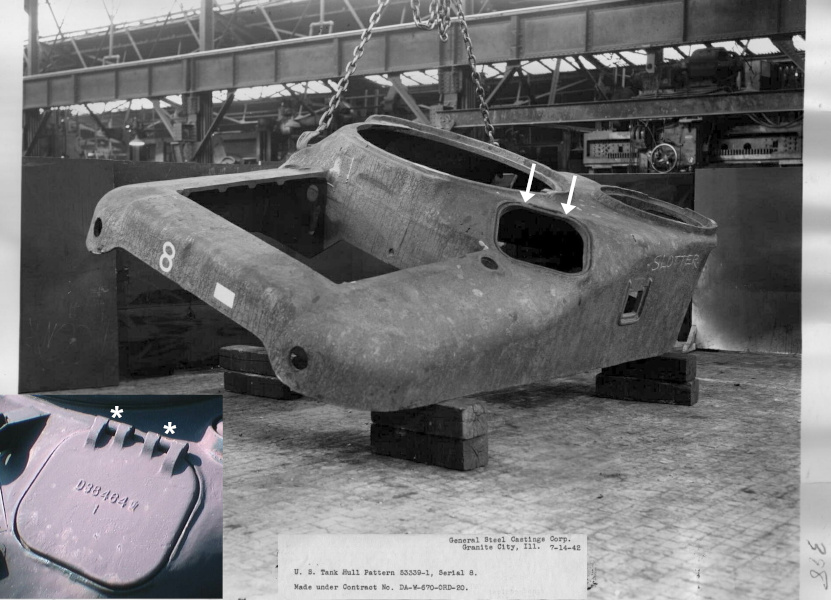

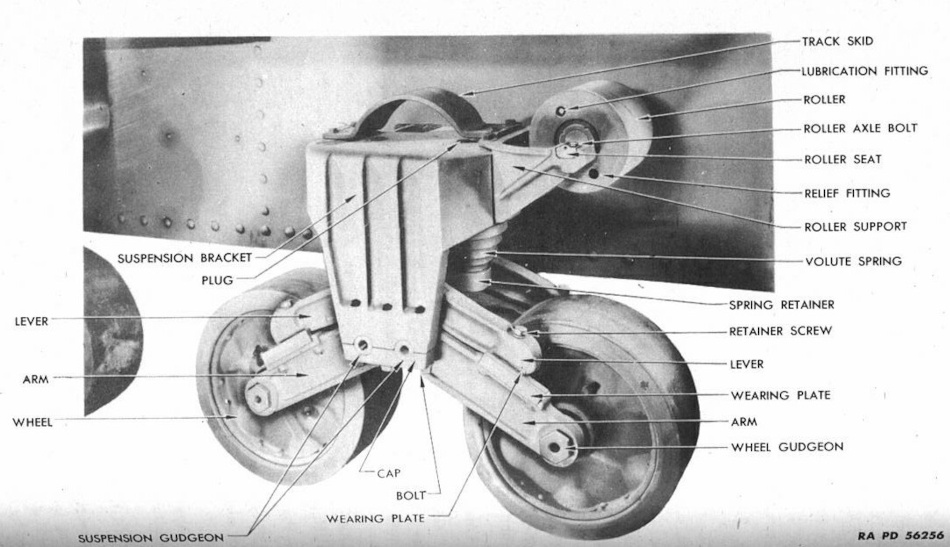

With the nearly immediate contract change from M2A1 to M3, engineers at APG and RIA scrambled to provide Chrysler with the enormous stacks of the necessary blueprints. In the 30 January 1941 DTA photo above we see that the blueprints have been converted to full size wooden models or patterns of various components. Most of the items seen here would serve as the basis for production of the real things by casting. It had been determined that the M3's turret would be cast, and it can be seen to have its Part Number, D 38530, (circled) written on with something like a magic marker. Other items include the bogie bracket (1), the 37mm gun shield (2), various pieces of the 75mm sponson gun mounting and housing (3), the transmission housing (4), and the final drive (5). Since Chrysler and the other manufacturers had never built any tanks, according to an RIA history, the firm "did everything short of setting up these contractors in business. The arsenal provided descriptions of manufacture route sheets; copies of tool, die, jig, gauge, and fixture drawings; machine-tool requirements; and updated component and assembly drawings."

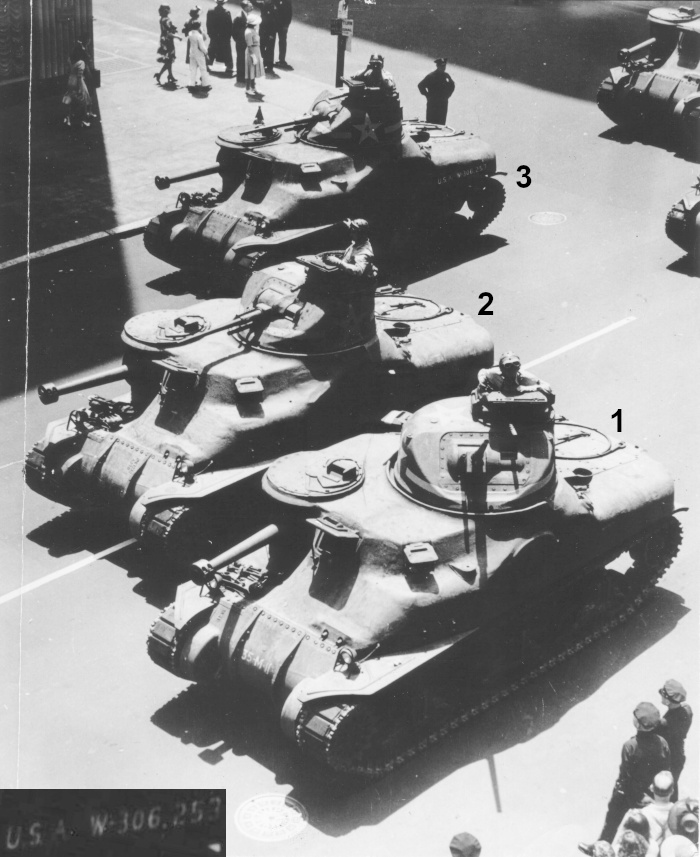

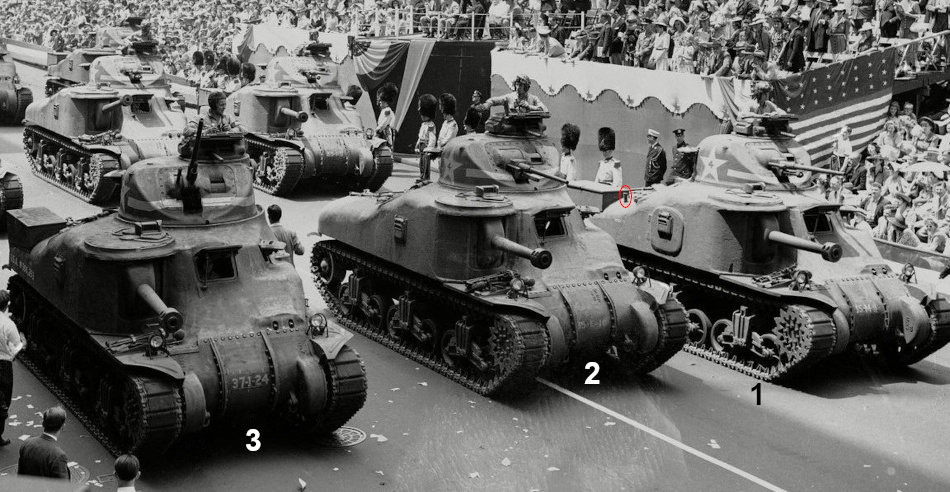

From the beginning, the M3 was thought of as an interim design. Its major shortcoming was, of course, the limited traverse of the sponson mounted 75mm gun. In August 1940, even before the M3's design was finalized, the Ordnance Committee, Technical Staff emphasized that the next step in development would be "modification of the Medium Tank, M3" by "relocating the 75mm gun in the turret." It was intended to replace the M3 in production as quickly as was practical. However, the press of world events created an urgent need for tanks, and Chrysler's original contract for 1000 M3 Medium Tanks was increased several times so that, ultimately, the company produced 3243 M3s and 109 M3A4s from July 1941 to August, 1942. Chrysler more or less hand built the first two tanks, which are shown above on "Presentation Day," April 24, 1941, a little over a month after the M3 pilot was completed at Rock Island Arsenal. Chrysler President K.T. Keller presented General Charles M. Wesson, Chief of Ordnance, the first M3 (Serial Number 2, USA 301000, the scuffed up tank on the right in the photo) as a gift from Chrysler employees. This gift tank created a "one serial number short" bookkeeping problem that does not appear to have been resolved until near the end of M4A4 production in September, 1943.

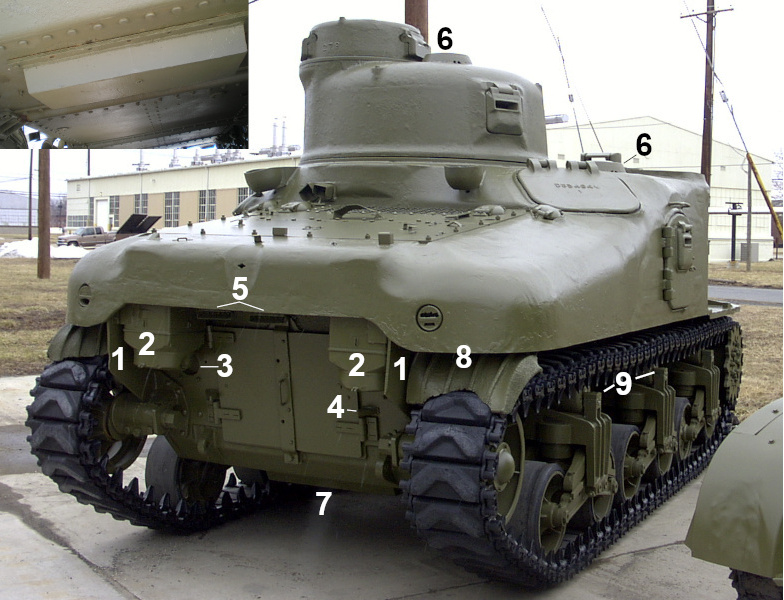

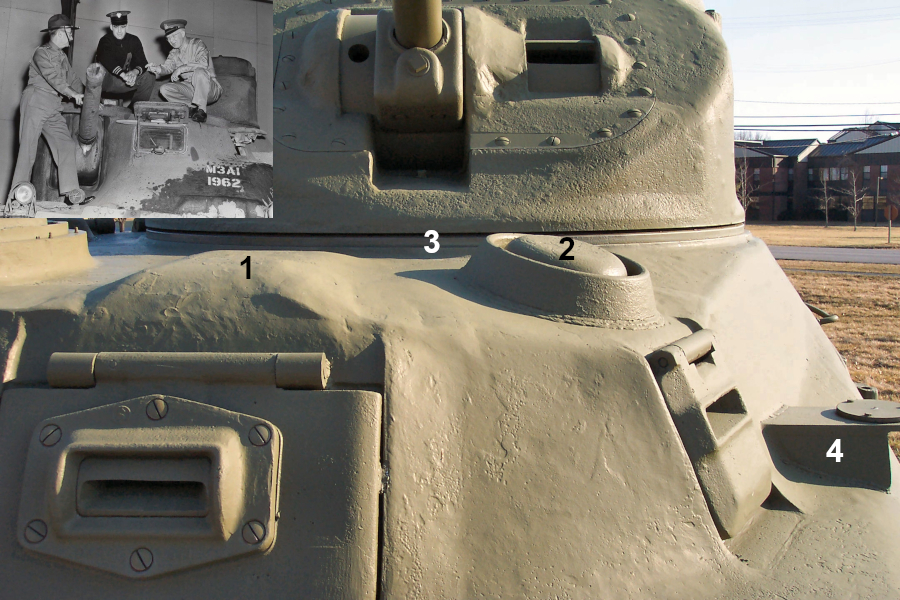

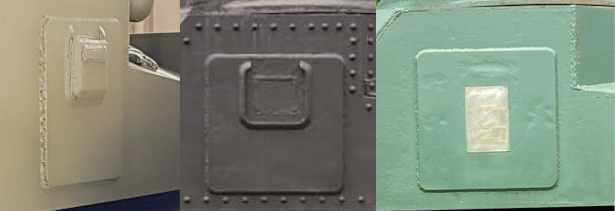

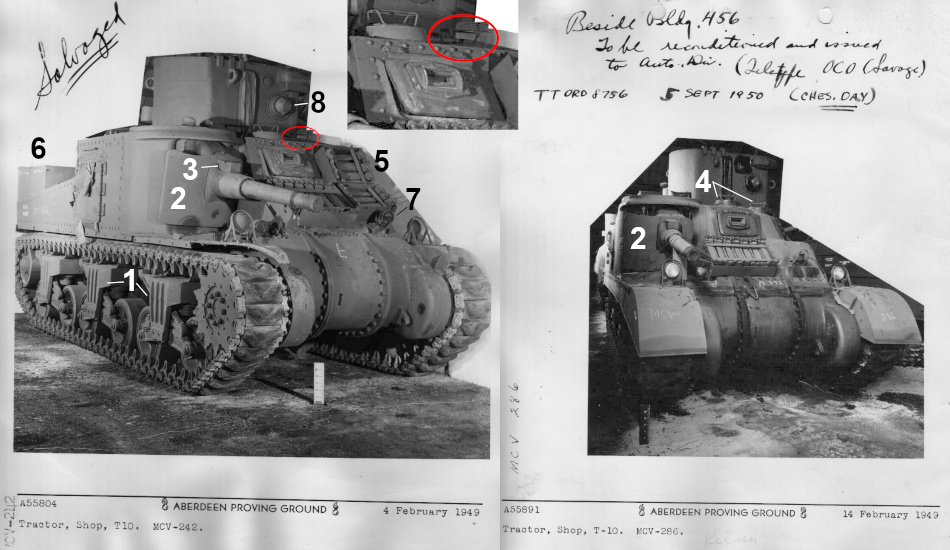

During

a "Sherman spotting" trip years ago we encountered an M3 Lee with

Serial Number 2 stamped on the rear tow lugs. We were a little surprised

that it was on display as a monument at a VFW Post in Newark, Delaware.

This was the first tank built at the Detroit Tank Arsenal and is the

scuffed-up Lee shown alongside SN 3 in the previous caption. SN 2 was

received at Aberdeen Proving Ground on 5 May 1941 and SN 3 on 31 July.

Both served as test tanks there during WW II. We would observe that

while the RIA pilot was built with "press studs" around the main gun and

gunner's periscope, SNs 2 and 3 were not. Both can be seen with a pair

of small rivets (circled) on the side. These seem to have "disappeared"

on subsequent units. Speaking of rivets, SN 2 and the rest of the few

surviving Lees identified as Chrysler built are noted to have

"pyramidal" shaped rivets as opposed to the "round heads." As might be

expected, some changes were made to SN 2 over the years. For instance,

it would not have been built with the "plain" sprockets (1) or the

pressed metal idler wheels (2). The replacements probably reflect the

fact that this tank was used in a number of track tests at APG. The

original front fenders may have been replaced during service. At least

the present ones (3) look like they were fashioned in a metal shop. The

faux fixed machine guns (4) possibly illustrate the irresistible impulse

of many to "arm" their monument tanks with plumbing pipes.

Here we see the first Chrysler-built Lee sans guns on 4 May 1942 involved in one of the many APG test projects for which it was used. In this case, an evaluation of "Trailer T32, Armored." Note that the tank has been installed with "Experimental Sprocket with resilient teeth" (inset). As the M3 was distributed, reports began to come in regarding worn or broken sprocket teeth. The "Experimental Sprocket" with its replaceable teeth appears to have been an overly complex solution to a fairly simple problem. The teeth, which were affixed with nuts and bolts, moved back and forth a little, losing their ability to engage and drive the tracks, and the project was dropped. The Ordnance Department observed that problems experienced with sprockets appear to have been the result of poor manufacturing techniques. Indeed, after the early failures, there is no evidence that sprocket failure was a major issue with Medium Tanks. In many instances, APG painted the vehicle Serial Number on its test subjects as seen here. Just visible in a light paint color is the USA Registration Number 301000. This is not seen in the numerous photos taken on presentation day as the tank put on a show knocking down a telephone pole and busting through a wooden "house." Perhaps it was painted on at APG? In any case, as researchers, we are always happy to have textual listings or photographs that provide known good Serial and Registration Numbers together.

An

unidentified woman in a "vintage" flower print dress waves to the crowd

on "Presentation Day," 24 April 1941. If any readers can identify "our

lady of the tank," we'd be pleased to add her name. This Lee can be seen

with "USA W-301.001" painted on in black, identifying it as the second

Chrysler-built M3. The Army Ordnance people were expecting the premier

of only the first Lee, but President K.T. Keller and company surprised

them with two. We would point out that these tanks were not officially

accepted until July. The armor surface of the open side door appears to

have been painted olive drab, but the protective padding (1), the pistol

port/protectoscope (2) and the handle (3) are painted white and stick

out like the proverbial sore thumb. The interior surfaces of the doors

and hatches were painted olive drab on the pilot, but apparently

Chrysler didn't get the memo. As a matter of minutia, we would point out

that the bogie bracket castings seen here in the bright sun have

"raised lines" running across the top and sides (arrow). Such variations

in the castings are generally typical of a particular supplier. As it

sits today, SN 2 has a full set of these castings, but they do not a

have logos (that we could see) that might identify the producer. SN

3/USA 301001 was installed with a Guiberson diesel engine in late 1941.

At the same time, the RIA pilot was installed with "Chrysler engines"

which we take to mean the first A-57 Multibank. It is not known what

became of these tanks afterwards, but a part of the second Chrysler Lee

survives, since "3" (inset) is stamped on the tow lugs of the

differential housing of SN 2 in Newark. (This is why we always "trust"

the rear tow lugs first when looking for the Serial Number on a Sherman,

variant or predecessor.) For a little timeline of the events before and

after "Presentation Day" 24 April 1941, the German Blitzkrieg had

overrun the Netherlands, Belgium, and France by June 1940. By October

1940, the Luftwaffe had been defeated in the Battle of Britain, and

Hitler turned his attention to the Soviet Union, which the Germans

invaded on June 22, 1941. In the US, the Lend Lease Act was signed into

law on 11 March 1941, and the Japanese attacked Pearl Harbor on 7

December 1941.

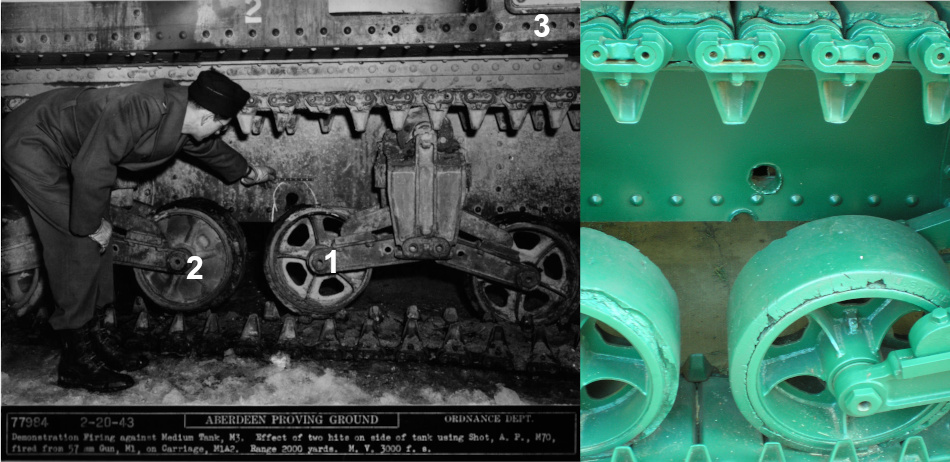

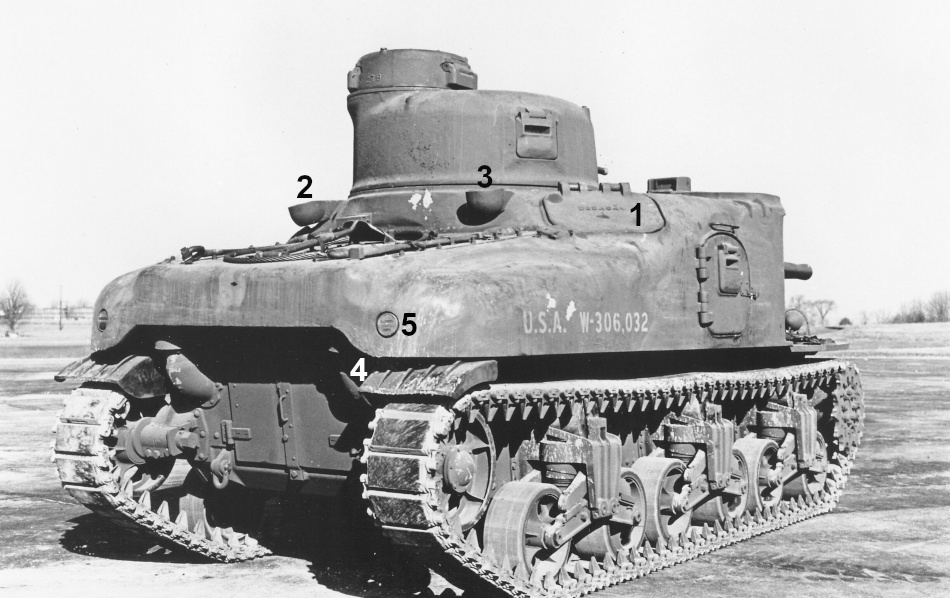

On 20 February 1943, SN 2 was the target of a demonstration firing "using shot A.P., M70, fired from 57 mm Gun, M1." It is not known if a conscious effort was made to preserve this tank, but as it sits now, it shows these two hits and no others. As can be seen on the right, the upper hit penetrated completely while the lower glanced off the bottom edge. One would think the penetration might have caused harm to the mechanicals, but the quartermaster at the VFW said that the Lee was driven in parades for years until the city of Newark asked them to stop because it was damaging the roads. M3 Mediums were built with welded spoke road wheels (1) from start to finish except at Chrysler, where pressed metal wheels were introduced into production around March 1942. The pressed metal wheel (2) seen here, which was obviously a replacement, became the most common type of road wheel used in Sherman VVSS production. A bit of the open side door (3) can be seen, and we would note that it is "still" painted white. According to a Chrysler history, SN 2 was next "turned over to the Ordnance school for the training of tank-recovery companies. These lads gaily rolled it over cliffs and into ditches in order to pull it out and patch it up again."

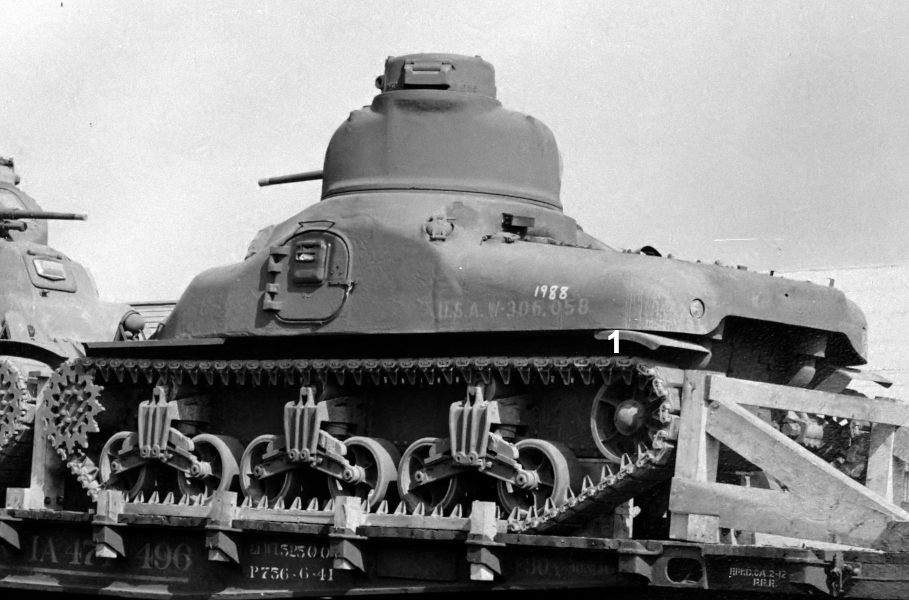

The photo on the left shows the "gift tank," Serial Number 2, USA 301000, on a railcar with officials holding a sign that reads, "No-1 M3 Tank Returned to CTA May 17th 1945." Of course, "CTA" stood for "Chrysler Tank Arsenal." (The US determined to avoid brand name advertising in its contracts, and the official name of the Government owned, Chrysler operated plant was "Detroit Tank Arsenal.") The arrow shows what appears to be a pepper pot exhaust still present when SN 2 was returned. We suspect that Chrysler restored the tank to running condition by retrofitting the new engine, exhaust and air cleaner set up it has now. In 1951, the Government financed a new tank plant in Newark, Delaware to be run by Chrysler for production of the M48 Main Battle Tank and other Cold War era designs. It is assumed that SN 2 was shipped to Newark to serve as a sort of mascot, and the photo on the right shows it there as "The First Production Tank Built By Chrysler 4/24/41." The occasion celebrated the white M48 as the "30,001st Tank Built By Chrysler 11/3/53." In April 1957, most of the plant was converted for the production of Plymouth and Dodge automobiles. At some point after that, we would guess that SN 2, which was meant to be "a permanent exhibit" at Chrysler, was given (or loaned?) to the VFW located a few blocks away from the Newark plant, which was shuttered in December 2008. Comparing the Lee, once described as "a damn cathedral coming down the road" with the Patton, we can only conclude that the US Army liked tall tanks.

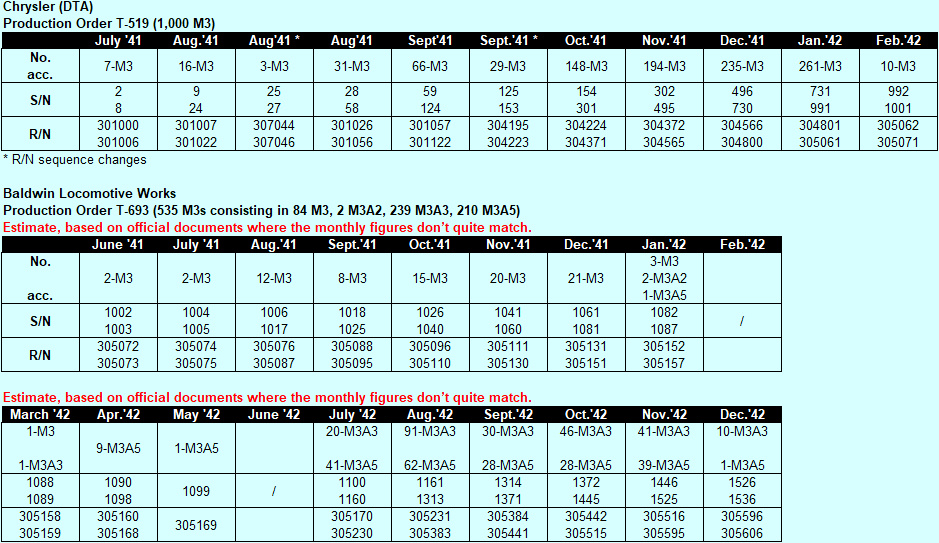

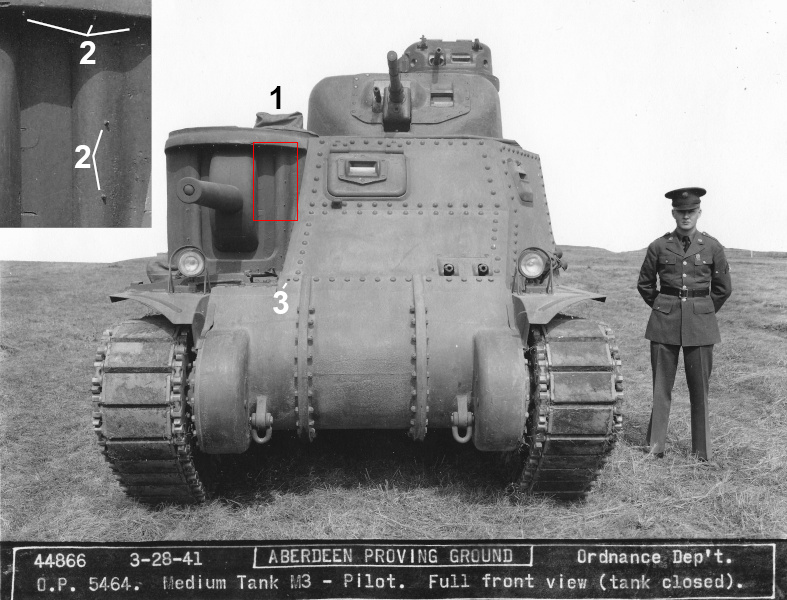

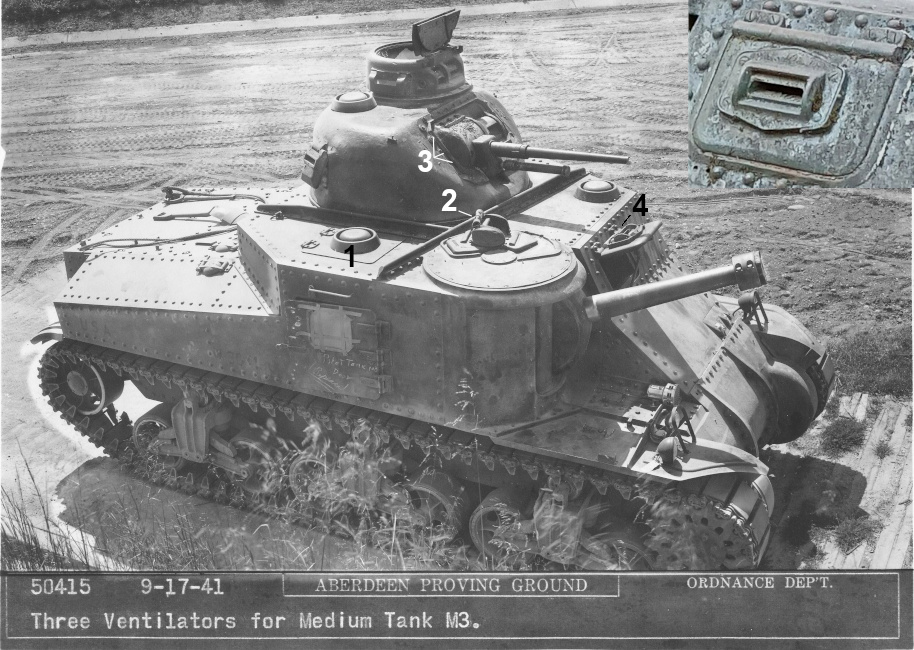

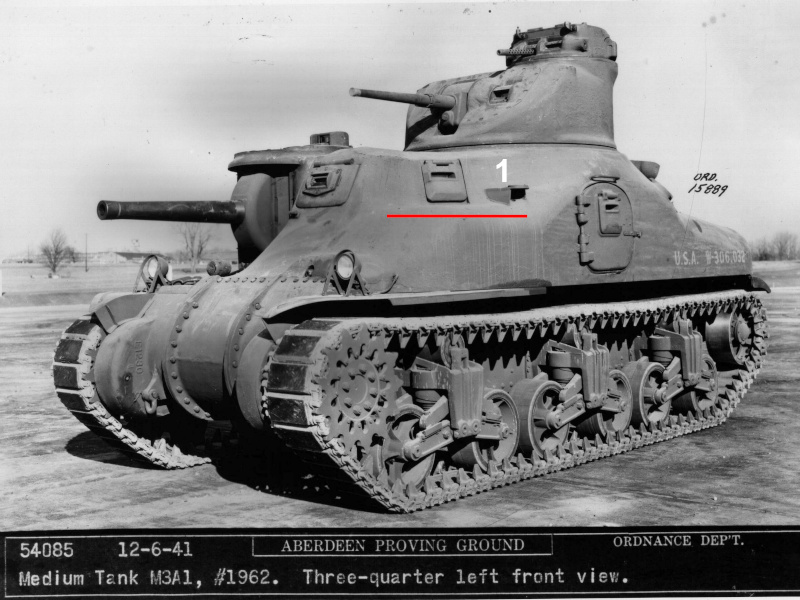

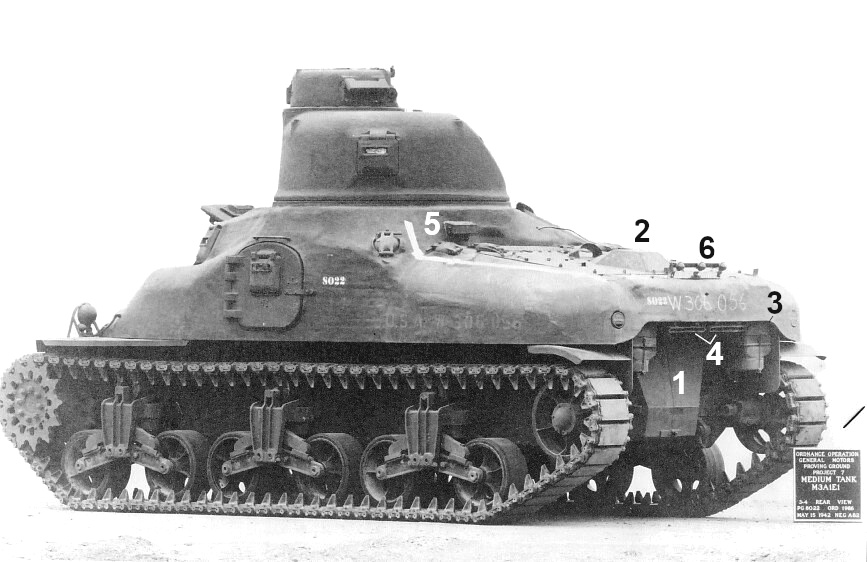

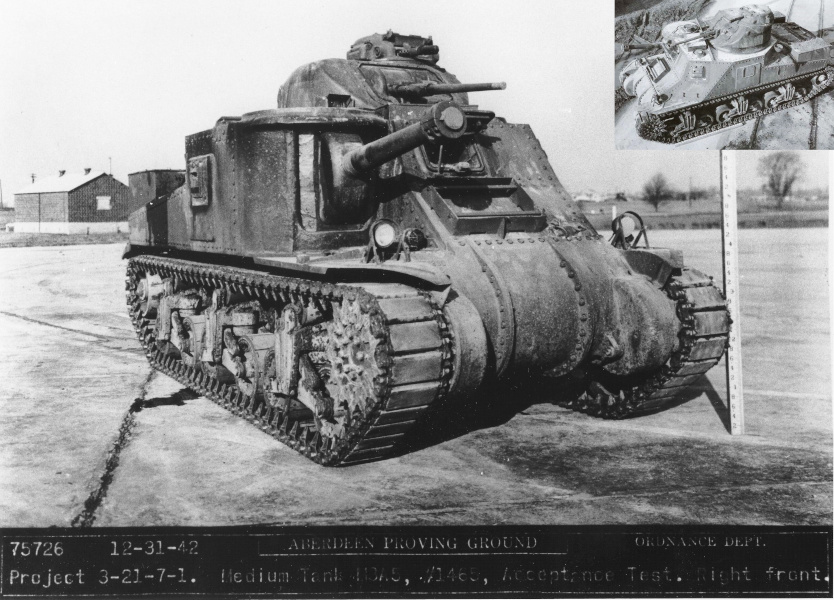

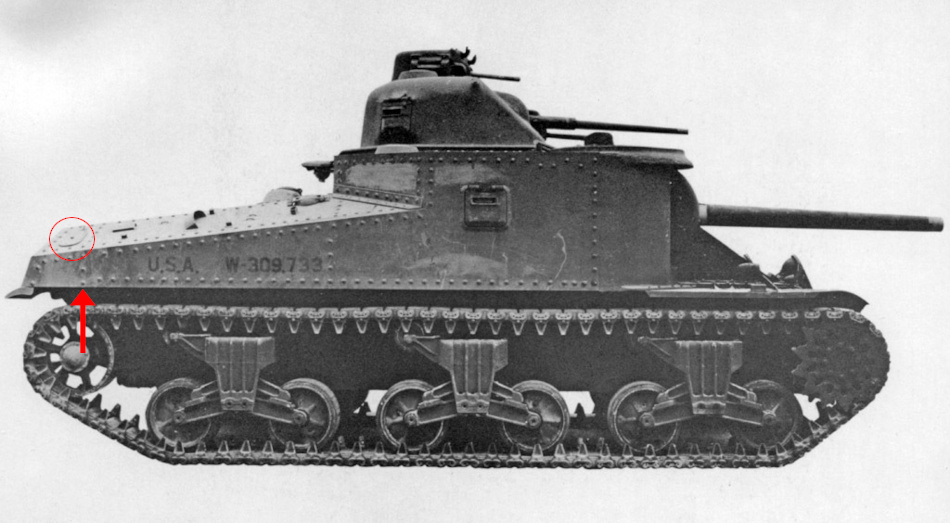

The Ordnance Dept. documents are somewhat confusing with a number of gaps, typos and downright errors regarding the Serial and Registration Numbers assigned to the M3 Lee series. We hope readers will indulge us in a little "thinking out loud" math exercise, while we try to establish a base line. As stated previously, Chrysler's initial contract was for 1000 M3 Medium Tanks. From counting heads, we are quite certain that the Serial Numbers assigned ran from 2 though 1001 (2 + 999 = 1001). Baldwin's contracts called for the production of 685 Lees and 685 Grants. The Lees were originally assigned the next available block of US Army Ordnance Serial Numbers - 1002 through 1686. However, in the Fall of 1942, 150 diesel Lees were diverted from the contract to be converted by Baldwin to T2 Diesel Tank Recovery Vehicles. Thus, in the end, Baldwin officially produced 535 M3 Lee series tanks. We interpolate that the highest Serial Number assigned to a Baldwin Lee would have been 1536. This leaves us with "orphan" Serial Numbers 1537 through 1686. ALCO's contract originally called for production of 685 M3 Lees, but this was soon changed to include 300 M3A1 (cast hull) models. Again, these were assigned the next available block of Serial Numbers - 1687 through 2371. As far as we can tell, all of the M3 Medium series Serial Numbers higher than 2371 would have been assigned to the additional 2352 M3s and M3A4s that the Government ordered from Chrysler. From this, we interpolate that the highest Lee Serial Number would have been 4723. The highest SN we have recorded is close at 4718 as shown above during an Acceptance Test at the General Motors Proving Ground on 30 September 1942. Again we see the USA Number, 3058309, painted on in black. The evidence is that Chrysler used black paint, as opposed to the prescribed blue drab, for the Registration Number on its M3s from start to finish. This tank would have been accepted in August 1942 as the M4A4 Sherman completely replaced the M3 on the production lines at the Detroit Tank Arsenal. Unlike the Grant, the Lee design underwent a few modifications which we shall discuss going forward. The most obvious changes seen here are the elimination of the side doors (1), and the addition of ventilators (2). Like the M3 pilot, this unit can be seen with a dust cover over the gunner's periscope (3). A dust cover can also be seen over the 37mm gun (4), but not the 75mm. We regret to say that we have not been able to confirm if dust covers were ever included as On Vehicle Materiel on the M3 series. Indeed, this is the only Ordnance or factory type photo we've encountered that shows a dust cover on one of the main guns.

The American Locomotive Company, or ALCO, had been engaged in the manufacture of locomotives at their plant in Schenectady, New York for more than 100 years. In November 1940, the Government contracted with the firm for production of 685 "medium weight tanks, M3." Originally, the production order provided for additional plant and facilities designed to enable a monthly capacity of 575 medium tanks. ALCO engineers also assisted APG in the design of the 105mm Howitzer Motor Carriage, M7 [Priest], a conversion based on the M3 Medium. When all is said and done, the M7 was actually a more useful addition to the arsenal than the M3. It certainly remained in service longer. ALCO manufactured 3314 M7s from April 1942 through October 1944. Just because it is mentioned in a report, we thought we'd add, "The starting wage for workers is 74¢ an hour. Semi-skilled workers receive from 90¢ to $1.00 an hour, and skilled mechanics receive $1.25 an hour." The photo above shows "Presentation Day" of the first M3 at ALCO, 19 April 1941. According to the US Army History, "The Ordnance Department: Procurement and Supply," "In April, when American and Baldwin were about to complete their first tanks, the Mack Manufacturing Company had only one power train available. It was delivered to American, and completion of that company's first tank was heralded with a demonstration before Secretary Patterson and other high-ranking Army officials. The power train was then quickly removed and delivered by truck to the Baldwin Locomotive Works so that company could celebrate completion of its first tank a few days later. Meanwhile Chrysler, which built its own transmissions, had completed its first tank on 11 April but the acceptance ceremony did not take place until 24 April." In the photo, note that the righthand piece of the differential housing has two bolts installed where it joins to the hull.

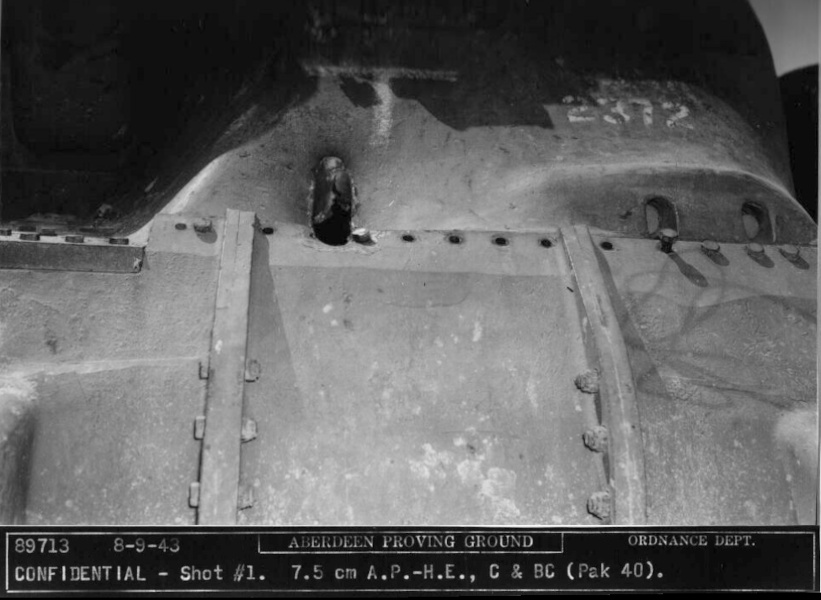

The "Presentation Day" Lees were far from complete and most served as test vehicles at Aberdeen Proving Ground and other Ordnance facilities. The photo above provides us with both the Serial and Registration Number of the first ALCO M3 - 1687/USA 305757. Note that the Registration Number appears to have been painted on in black. As can be seen here on 8 August 1941, the tank was subjected to a bit of "Caliber .30 Aimed Ball Ammunition." It would appear that two shots were directed at the side door to test the strength of the hinges. A few other rounds were aimed at the lower edge of the turret. This was likely done to determine if there was a susceptibility to the turret jamming, since this area was unprotected by any sort of bullet splash. The area circled showing 2 missing rivets and a small and large hole was the mounting point for the antenna base on the Lee series. It is thought that this early unit would have been built with the fabricated base that was replaced with a casting a few months into production.

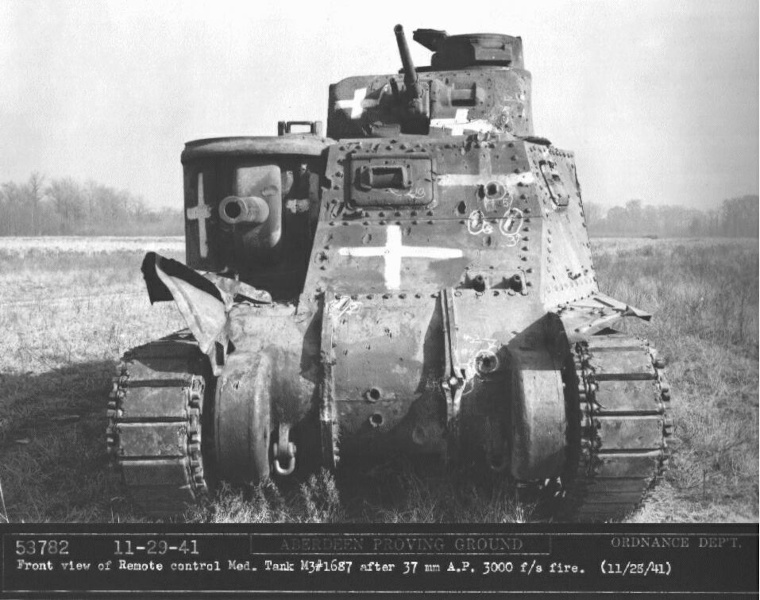

At some point before 29 November 1941, SN 1687 was installed with "Remote control" which we take to mean that it could be driven around the target range like a drone. The tank was painted with white aiming crosses and subjected to 37mm armor piercing fire. A number of penetrations can be seen, and we can't help but think that 1687 may have been permanently immobilized at this point. Perhaps it ended up as a stationary target?

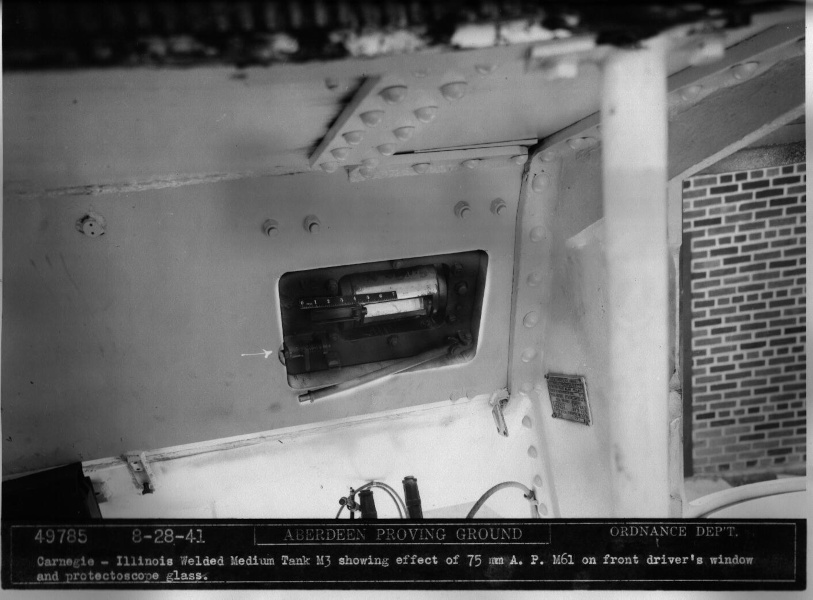

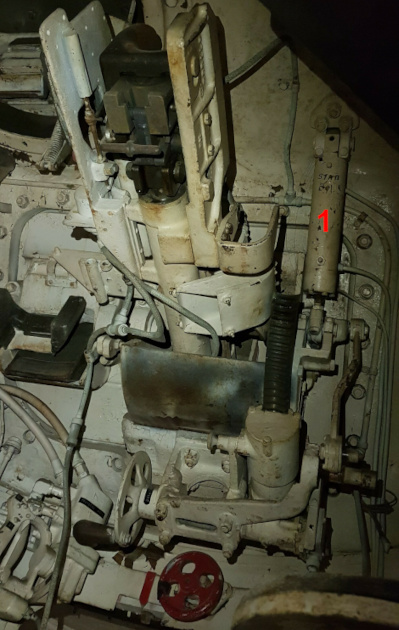

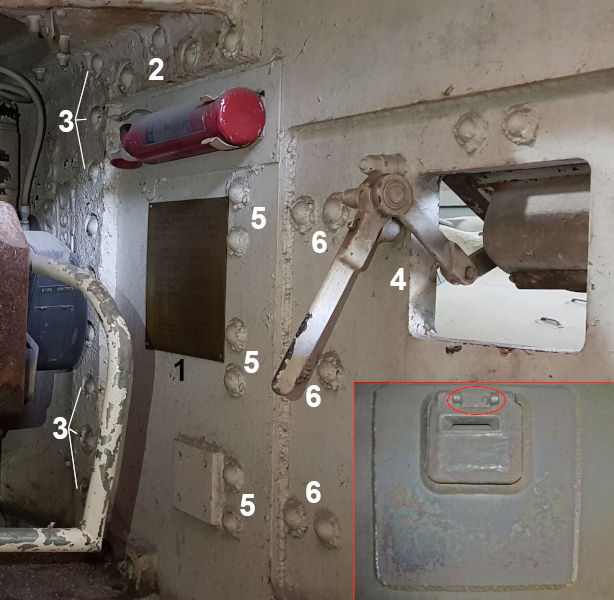

This interior view of 1687 shows how round 10 penetrated the shutter of the "Driver's Indirect Vision Device." The prop (1) for this device is hanging down here, but when not in use, it was actually held by a clip across the bottom of the driver's vision hatch. The junction where the 75 mm sponson casting attached to the front of the hull was a large shot trap, and the penetration of the casting by round 11 is circled. We suspect that some of the rivets were circled with chalk because they had been completely or partially detached by shock, sending shrapnel flying around the interior. The brown paper (2) was installed for the firing tests to help determine the trajectory of shrapnel. The conclusions reached from these tests were published in February 1942, and were extremely negative, "It was recommended that all rotor clearances [around guns] be provided with shields and splash proofing; that armored air intake grilles be provided; that side doors and pistol ports be permanently welded shut; and that the production of riveted hulls be discontinued." Note the protective padding (3) around the Driver's Indirect Vision Device and on the "ceiling" of the hull (4). The M3 Medium appears to have had its combat debut with both the Soviets and the British in May 1942. In both cases, reports came in that the padding was highly flammable, and it was ordered to be removed. Except for the side doors, the padding is rarely seen on surviving M3 Mediums. This photo provides us with the opportunity to show the location of the dataplate (5) on Lees and Grants.

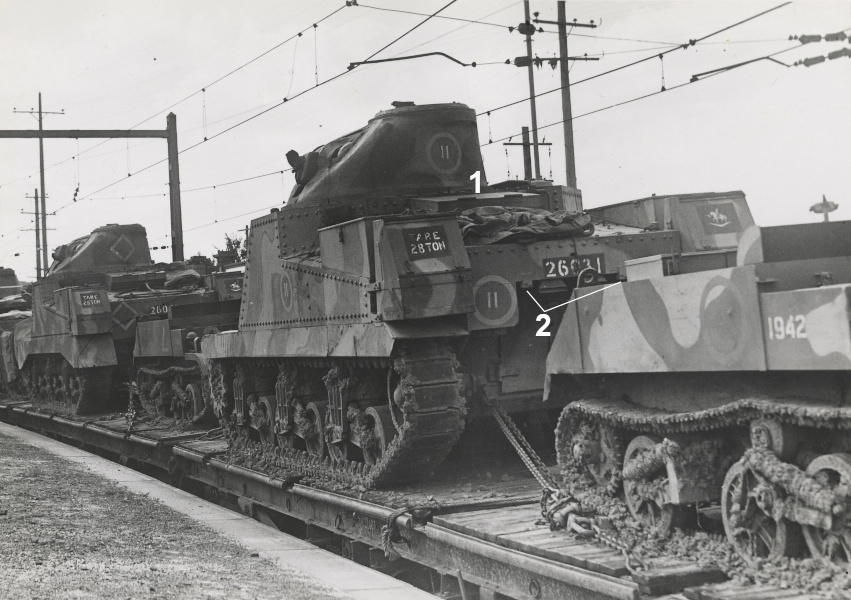

Baldwin

Locomotive was the only company that manufactured both Lees and Grants.

In late 1940, the firm was awarded contracts at a little over $40

million dollars each for the concurrent production of 685 Grants and 685

Lees. The first Baldwin built Lee was accepted in June 1941, while the

first Grant was not accepted until October. A Baldwin History attributes

this delay to the "radical changes" (radio turret, etc.) the British

had negotiated for the Grant, "which were at variance with the design

adopted by our own Government." Right up to the start of production, the

British continued to push for additional modifications, until

"ultimately it became necessary to freeze design changes on the British

vehicle in order to secure quantity production." This "design freeze"

explains why the last Grant was built with features nearly identical to

those of the first. However, it should be noted that a few "radical

changes" were in fact introduced into Grant production at Baldwin. In

particular, the "GM Model 6046" twin diesel powerpack completely

replaced the radial engine on both the Lee and Grant production lines by

early 1942. The photo above shows "Presentation Day" at Baldwin, 24

April 1941, and the caption reads in part, "One of the new tanks that

came off the assembly line here today..." We would point out that this

Lee can be seen with 10 rivets running vertically where the side plate

meets the 75mm sponson casting (arrow). Additionally, the righthand

section of the differential housing has two bolts installed where it

joins to the hull. This is likely the power train that was reportedly

removed from the ALCO Lee and delivered to Baldwin. A "General Steel"

water tower can be seen in the right background, as this foundry was

right next door to the Baldwin plant in Eddystone, Pennsylvania.

This fine

photo was taken at the Baldwin Locomotive Works and is dated

5 June 1941. The "U.S. Army War Department Number," 305072, can be seen

painted on in a bright white "railroad" style font. This Lee was

pictured in various newspapers of the day. It garnered a lot of

attention, as it appears to have been driven the 60 miles from

Eddystone, Pa. to Aberdeen, Md. It is described as "The first M3 Medium

Tank to be delivered to the U.S. Army." Judging by the single

bolt on the righthand section of the diff, and

the "missing" rivets (circled) on the side, this is NOT

the same M3 as shown in the previous caption. Three, as seen here, is

highest number of "missing" rivets we've encountered;

two is more common and seems to have been scattered randomly on

early production Lees and Grants. Ten vertical rivets

were obviously the default. "Counting heads" suggest that

Chrysler-built Lees were produced with 10 rivets from start to

finish. Like the first Chrysler Lees, 305072 does not have

the "press studs" around the 75mm gun and has the

two small rivets (1) on the side. No doubt, these

similarities and/or differences can be attributed to the still evolving

nature of the design at the time. Lee production utilized T41 flat

block tracks with reversible rubber tread (2). On the other hand,

the British ordered WE210 non-reversible rubber tracks with a 'double

I' tread pattern for their Grants. The drive sprocket (3) is what we

call the "M3 sprocket" for want of a better term, since it appears to

have been factory installed on all M3 Mediums from start to finish. USA

305072 can be seen with a painted over "Mack Medium M3 Powertrain"

identification plate (4) affixed to the center of the differential

housing. These plates were soon repositioned to the interior,

where they were mounted above the transmission. The Grant on

display at the Tank Museum at Bovington, which is thought to be the

first tank built by Pressed Steel Car, still has its Mack SN 7 ID plate

on the outside. For the purpose of "counting heads," we would note that

USA 305072 was used as a test tank at APG where it is listed as Serial

Number 1002. So, while this was not the Lee trotted out

on "Presentation Day," it would have been the first M3 accepted at

Baldwin.

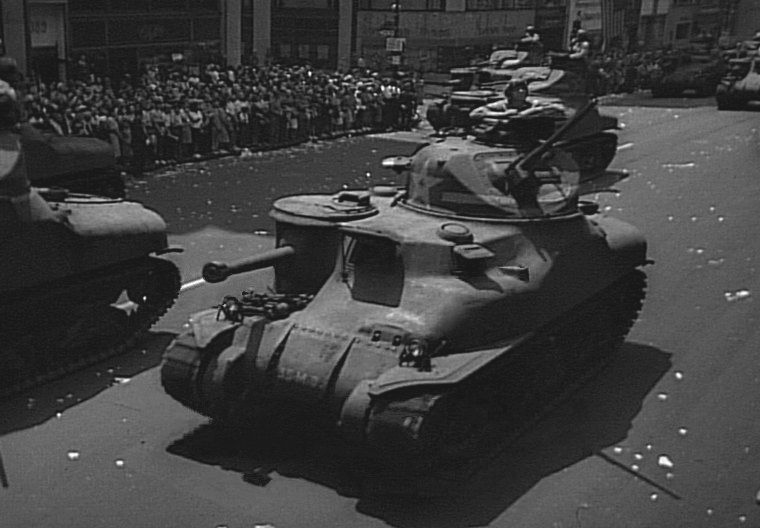

This

photo appeared in newspapers on 18 June 1941 with the caption," A new

M3 medium tank, the first completed at the Baldwin locomotive plant for

the United States army, is shown rolling through Broad street traffic

in Philadelphia enroute to the dedication of a new armor plant. From

Philadelphia it will be taken to Aberdeen, Md." At first glance, we

thought that this Lee might have been 305072 of the previous caption,

but a close examination of the print shows the Registration Number to

be USA W-305073, painted on in white, but not in the railroad style

font of 305072. Furthermore, the casting marks on the left section of

the differential housing are not in the same location as on 305072, and

of course, this unit was shipped with a 75mm gun. Note the 3 "missing"

rivets on the left in front of the side door (arrow). Photos show that

this was also the case with 305072. Again, it is obvious that a full

row of rivets was the default, but "missing rivets" show up in period

photos from time to time, and present us with an interesting mystery.

In any case, we have 3 different Baldwin built M3s where the captions

imply that they were "the first." USA 305073 was not reported to have

been received at APG until 25 June 1941, so it may have done a

week's tour around the Philadelphia area before arriving at its

destination.

USA 305073 was used in various track and grouser tests at APG. On 15 May 1942, nearly a year after it was delivered, the Lee, identified as "#1003," was photographed with guns removed "stuck in rectangular ditch." This tank and SN 1002, are the only examples we have encountered that have 3 "missing" rivets (arrow) in the vertical row where the side plate meets the 75mm sponson casting. We can only guess that the missing rivets may have had something to do with internal interference issues. The removable "short and straight" hinge pins (arrows) securing the armored fuel filler covers can be seen to have worked out of their sockets, but a bit of chain prevents them from being lost.

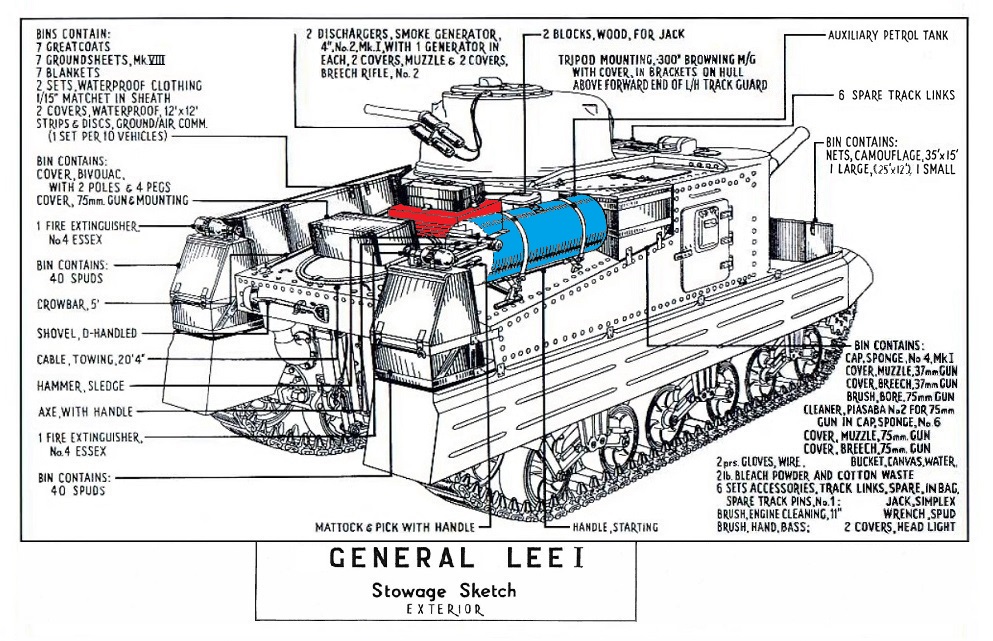

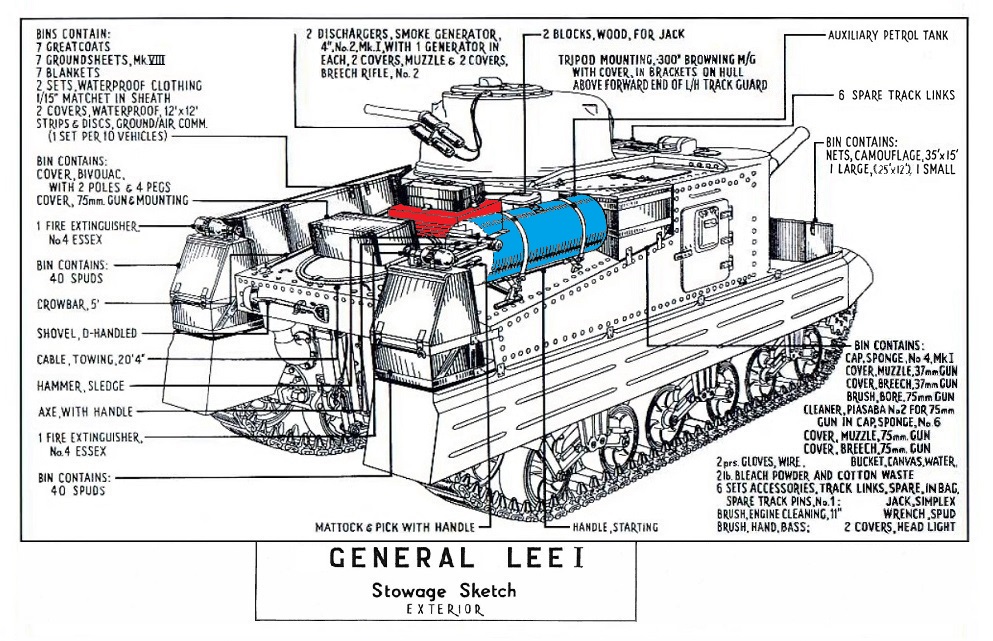

According to the M3 series Technical Manuals, the "Ammunition carried" in the Lee was 50 rounds, 75mm and 178 rounds, 37mm. The above drawing from the TM shows the quantities of the various rounds with their locations throughout the turret and fighting compartment. For instance, the "box on floor crew compartment, right side, directly behind the 75mm gun" (Item 23, highlighted in red) held 41 rounds of 75mm ammo. Not shown in the drawing are 9 rounds of 75mm which were reportedly stored "loose" in three 3-pack cartons. With 2 gunners and 2 loaders, the Lee had a large crew of 7 men. Their seats are numbered 1 through 6 in the drawing. Not shown is the seat for the loader for the 75 mm gun. He was provided with a bench-like pad (inset) attached to the top of the (red) 41 round 75mm ammo bin. The Lee's radio was located on the hull wall to the left of the radio operator's seat (Item 2, highlighted in blue). The British were able to reduce the number of crew members to 6 by housing the radio in the bustle of the larger Grant turret and having the loader of the 37mm gun serve as radio operator as well.

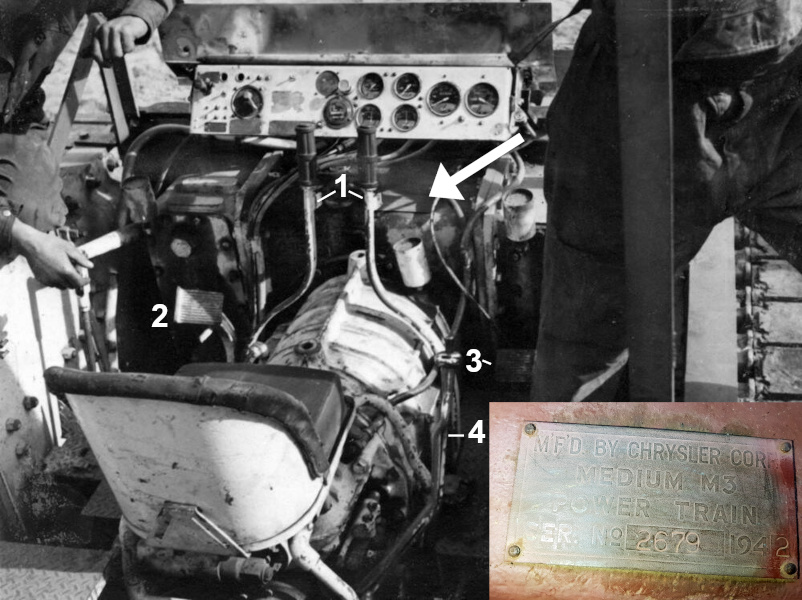

The original M3 Medium transmission featured something called a “Hycon Steering System.” This was basically “hydraulic control power steering,” designed to make it easier for the driver to push and pull the steering levers. This system strikes us as similar to the gyrostabilizer, in that it was ahead of its time, but complicated and undependable. The British were aware of this issue and required that the steering levers on their Grants be made 3 inches longer in order to provide the driver with additional leverage in the event that the Hycon failed. At Chrysler, it was reported that the Hycon System was shipped on "Serial Nos 2, 4 - 45 incl, and 47...All subsequent tanks to have manual control." If accurate, it would mean that Chrysler eliminated, or perhaps at first just disconnected, Hycon on its transmissions in August 1941. ALCO, which like Chrysler only built Lees, reportedly shipped "Serial Nos 1687 - 1803 incl." with Hycon, indicating a change to manual control in November 1941. Baldwin was reported to have shipped "Serial Nos 1002 - 1042 incl" with Hycon. After that, "First 250 M3 Tanks to be equipped with modified Hycon." Since Baldwin built both Lees and Grants, we would assume that "modified Hycon" would have been installed on both for a time. From a British report of December 1941, “U.S. are dispensing with Hycon control and are fitting five (repeat five) inch longer lever on gearbox to increase leverage. This permits steering without Hycon.” On the other hand, “British tanks...retaining Hycon with improved valve.” However, by February 1942, straight manual control was described as “present production,” which we interpret to mean that the manufacturers, Mack, Iowa and Chrysler were making only that, including the transmissions for the new Shermans. In fact, in early 1942, the Ordnance Committee recommended "That the Hycon steering brake control system not be employed on Medium Tanks M4." The photo above shows what appears to have been an ex Australian 1942 production Chrysler M3 Medium that had had most of its superstructure removed in order to convert it to some sort of farming or logging type tractor. It provides a good illustration of how the driver sat astride the transmission. Here we see the presumably elongated steering levers (1), along with the clutch pedal (2), brake pedal (3) and gear shift lever (4). The inset shows a Chrysler "Medium M3 Power Train" identification plate. It can be seen that this particular P.T. was Serial Number 2679, manufactured in 1942. The arrow indicates where it was affixed to the top of the differential case.

Here we have an example of the distinctively shaped Mack Medium M3 Power Train plate. As mentioned previously, only a few of the first Grants and Lees were built with the Mack plates attached to the exterior of the differential housing. They were immediately moved inside and fixed to the differential as seen above. This plate does not appear to have been made of brass, but it held up to the elements pretty well before the power train was scrapped a few years ago. Company records report that the Mack plant in New Brunswick, New Jersey produced a total of 2652 M3 Medium Power Trains plus 361 spares from February 1941 through Feb. 1943. This one can be seen as Serial Number 2136. By the monthly production figures, we'd calculate that this power train was accepted in August 1942. It probably took a month or so before it was delivered to a factory and assembled to a tank. By that time, Grant production had ended, and only Baldwin Locomotive was still making M3 Lees, and all were diesel models - M3A3s and M3A5s. So, this powertrain was likely pulled from one of those. Just behind the serial number are the initials "WPB" (inset). Of course, New Jersey was in the New York Ordnance District which was headed by General Walter Putney Boatwright at the time, so he accepted this power train on behalf of the Ordnance Department. Photo courtesy of Midwest Military.

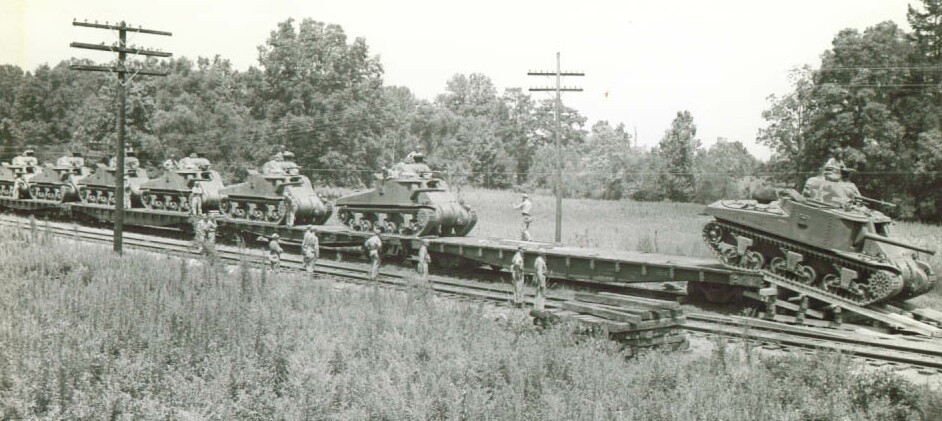

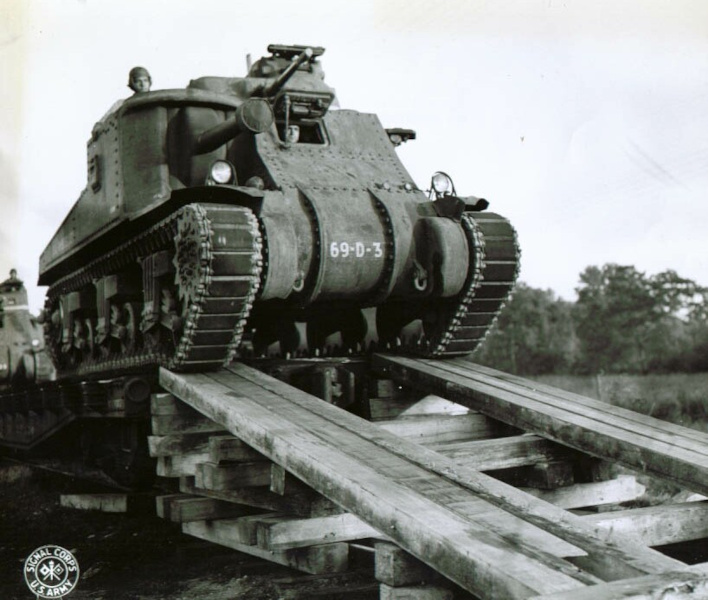

Lees in the US

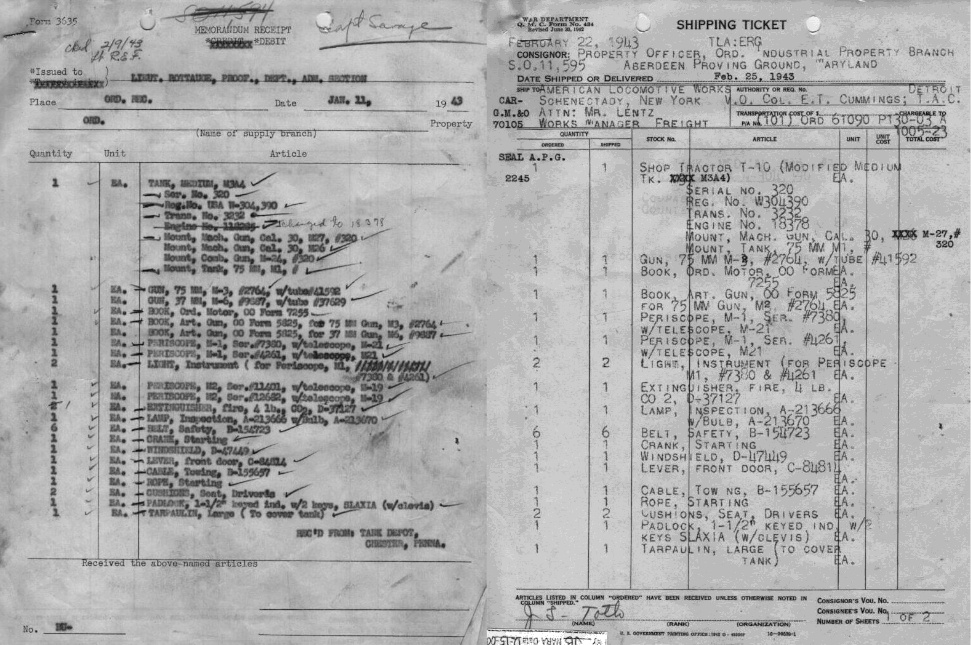

The troops of the Armored Force were anxious to get their hands on the new M3 Medium Tanks, but some time was needed for the Ordnance Department to work out the bugs, finalize stowage arrangements and allocate units for US Army or Lend Lease issue. Only about 100 Lees had been accepted by the end of August 1941. They appear to have made their "combat debut" during the Louisiana Maneuvers in mid-September, possibly at "the Battle of Castor" when the Lees of C Company, 1st Battalion, 69th Armored Regiment (M), 1st Armored Division overran the Blue Army's infantry and anti-tank positions in the town. It can be seen that the attack on Castor had air support in the form of A-20 Havocs. We have not had access to the 1st AD records for that period, but one caption has it that the Division had 13 M3s "which came off the production line less than three weeks ago." Going by the photos from this period, we would assume that all of the available Lees were issued to C Company. In the rush to supply the "Old Ironsides" Division with the new M3s, some were shipped without their 75mm guns, such as the lead tank, C-6 seen here. On 4 December 1941, Captain Sedgley Thornbury submitted "Report of Medium Tank, M3" to The Armored Force Board regarding the condition of the Lees of the 69th AR that he had examined in late November during the Carolina Maneuvers. In the Report, C-6 is listed as 301018, indicating it was built by Chrysler in August, overall, their 17th Lee. Thornbury reported that the Hycon System had failed, and that after 231 hours, the engine was burning oil and needed replacement.

Sledge's Store at the intersection of E. Pine St. and Front St. appears to have been the point where the Blue Army set up its main line of resistance in Castor. Note that the trees seen here are obviously the same as those on the left in the previous caption. The lead tank, C-2, can be seen with the Armored Force triangle painted on the glacis as well as on the hull "roof" just behind the driver's visor. Of course, the "1" indicates 1st Armored Division. Due to a lack of photos, we suspect that Patton's 2nd Armored Division did not have any Lees during the 1941 Louisiana Maneuvers. One account states that the Division was issued 32 just prior to the start of the Carolina Maneuvers which began in October. Counting heads from repair reports and such suggests that, as production ramped up, the 1st AD was issued exclusively with early Chrysler M3s. It struck us as odd that there are absolutely no early Chrysler entries for the 2nd AD. Rather, counting heads suggests that the 67th AR of the 2nd AD received its first Lees from Baldwin and ALCO. This may have been a function of the geography of the manufacturers in relation to the locations of the home bases of the 1st and 2nd ADs, Ft. Knox, Kentucky and Ft. Benning, Georgia respectively. From Captain Thornbury's Report, we would interpolate that C Company was issued the first allotment of Chrysler Lees starting at USA 301005 (July 1941) and running nearly consecutively up to 301018. For instance, C-2, seen in this photo, is listed as 301011 (August 1941). Thornbury interviewed the Motor Officer and the Commanding Officer of the 69th AR, who stated that the schedule of the maneuvers did not "permit adequate time for 1st and 2nd echelon maintenance." His notes reveal that, before the end of November 1941, nearly all of C Company's Lees had had their radial engines changed out after less than 200 hours and/or 1000 miles of operation. Most of us think in terms of the engine life of our cars, but this was actually not that bad. Despite the numerous improvements made by the Ordnance Department and Continental Motors, the average service life of the radial engine never greatly exceeded these parameters.

A

photo caption has it that "The [1st Armored] Division utilized 17

medium tanks and 13 light tanks in the attack" on Castor. Thus, we might

assume that 4 M2 series took part along with the 13 M3s mentioned

previously. In

this view, at least 3 M2A1 Mediums of A Company are shown on Front St.

rumbling past Sledge's Store. We would observe that Rock Island Arsenal

had just completed its production order for 94 M2A1s in August 1941. The

caption of this photo reads in part, "This column of tanks followed a

wave of M3 Medium Tanks which waded into streams of anti-tank fire by

stubborn defending troops." While the "umpires ruled the attack

successful," in combat, US tankers quickly learned to avoid such

tactics. As with C-2 in the previous photo, the lead tank, A-6, can be

seen with a few "jerrycans" on its rear deck. In 1939, the Quartermaster

Corps at Camp Holabird, Maryland got its hands on a German 5 gallon

fuel can, and more or less copied it for mass production. A number of

the Light and Medium Tanks in the maneuvers photos can be seen with

racks holding 6 or 7 of these cans. However, this was not a practice

that was generally adopted for combat conditions. Partly as a result of

the various maneuvers, the US Army learned a thing or two about

logistics, and developed a supply system during WW II that was second to

none.

As the Lees began to roll off the assembly lines, they were issued to the Medium Tank Regiments of the 1st and 2nd ADs - the 69th and 67th Armored Regiments respectively. Captain Sedgley Thornbury 's primary mission for the Armored Force Board "was to check on the operation of two sets of steel tracks under service test in the [69th Armored] regiment" during the Carolina Maneuvers in November 1941. He listed USA 301046 (DTA, August 1941) with B Company, but did not provide a tank number. The Lee had had its power train replaced, and it was stated that after 107 engine hours and 710 miles, the engine was being pulled due to excessive oil consumption. Thornbury noted "Steel track rubber shoe...Bolts coming loose." In addition, USA 301051 was listed in Company D with "Solid steel track...wearing very well...Support rollers break (4)." We take B-10 shown above to be 301046 with a track that appears to be similar to the T47E1 described as "Steel, cast, rubber-backed parallel grouser." In another document, 301051 appears to have been scheduled originally for test by the 67th AR. The tracks are described as "T37," an all-steel type not approved for production. The Ordnance Department was no doubt seeking solutions to improve the Lee's off-road traction, but in addition, they may have been anticipating a rubber shortage brought about by potential Japanese aggression in Asia. Bear in mind that Thornbury's report was made a few days before the Japanese attack on Pearl Harbor, 7 December 1941.

C-2 was featured in a previous caption during the Battle of Castor. Here we have another view of the tank taken in early November 1941 as it disembarked from a rail car in Rock Hill, South Carolina. A crowd gathered as the tanks of the 69th Armored Regiment arrived at the station. At some point after the Louisiana Maneuvers, it would appear that many of the 69th AR's tanks were painted with a series of light colored dashes around the base of their turrets, as seen here. It is thought that the Lees of the 67th AR, 2nd AD made their "combat" debut during the Carolina Maneuvers, and a few photos show them with a solid light color painted around the base of their turrets. They may have been driven from Ft. Benning as one account has it that "At one point, a line of more than 2,500 military vehicles stretched from Fort Benning to Rock Hill, a distance of 425 miles." While it can be seen in our previous photo, this one of C-2 provides a clearer view of what we consider the "standard" cast antenna base. Recall that Captain Thornbury's Report listed C-2 as USA 301011 indicating August 1941 acceptance, and counting heads suggests that Chrysler transitioned to the use of the cast antenna base during that month. We haven't been able to do an effective head count of its introduction at ALCO and Baldwin but believe it came a month or two later.

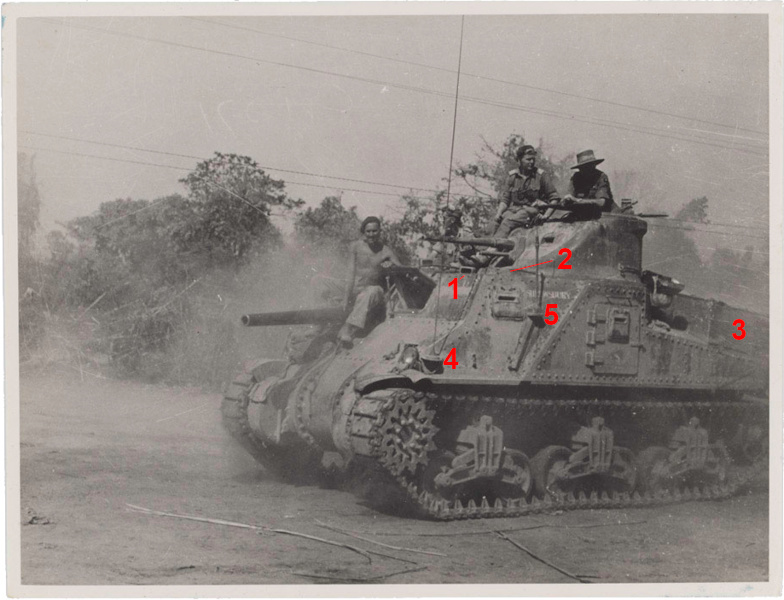

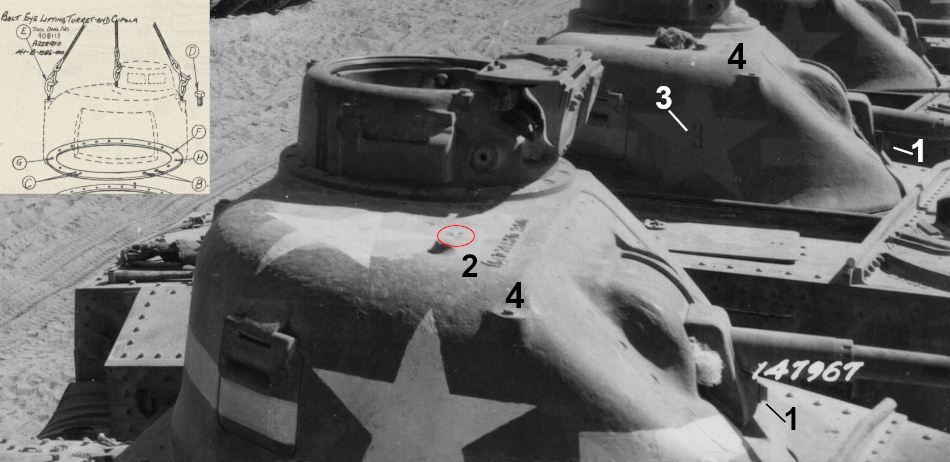

An Inspection Report of December 1941 lists some of the Lees of the 67th Armored Regiment (M). From it we would interpolate that D Company of the 2nd Battalion may have received the first allotment of Lees most of which were produced by Baldwin Locomotive in August or September 1941. In the report, it was stated that D-1, USA 305092 [Baldwin, Sept. 1941] "fell through a bridge" on November 29th. We assume that the scene is depicted in the photo above. Note that this tank still has the fabricated antenna base (1) and is one of the few Lees photographed during the Maneuvers in 1941 that actually had an antenna installed, presumably indicating that it was equipped with a radio. The inset provides four views of the fabricated antenna base on SN 2 in Newark. It can be seen as a steel stamping with rounded edges and few curves, open underneath and on the inside side. The antenna mounting would have been unprotected, and as a consequence this part was replaced with an armored casting, although it strikes us that the additional protection offered would have been minimal. Some of these castings have been noted to carry the Part Number C85029. In the photo it can be seen that the antenna was mounted on an angle with the fabricated base, whereas it was mounted straight up on the casting. In attempting to "count heads," we would simply note that USA 305096, a test tank at APG, would have been the first Lee accepted at Baldwin in October 1941, and the photos show it with the cast "antenna pot." A few late 1941/early 1942 photos show that the Lees of the 67th AR had a solid stripe (2) painted around the base of the turret. This can be contrasted with the dashed stripe seen around the turrets of some 69th AR Lees. Furthermore, 67th AR tanks can be seen with Air Corps type roundels (3) painted on the front and sides. Finally, the company tactical markings (4) were painted rather prominently on the sides of the turret.

Another bridge mishap was filmed during the Carolina Maneuvers on 21 November 1941. This left some children stranded, and a crew member is shown helping them cross so that they could get home from school. We believe that the tactical markings, "1-1," seen on this Lee would denote tank 1 of the Headquarters Section of the 67th AR's 1st Battalion, which would have been made up of Companies A, B & C. This unit can be seen with the solid stripe around the base of the turret, and we would note that the roundels were also painted on the rear of the turret as well as on top. The padding (1) on the top hull hatch looks to be non-standard. The gunner's periscope appears to have a small, well-fitting cover (2) protecting it, although such an item is not listed as On Vehicle Materiel in the M3 Technical Manual. This Lee is installed with the standard cast antenna base (3). Unfortunately for counting heads, we don't have a listing with corresponding Registration Number for Tank 1-1. Note that the antenna is mounted straight up. The antenna or aerial consisted of several sections joined together with ferrules (4) like some fishing rods.

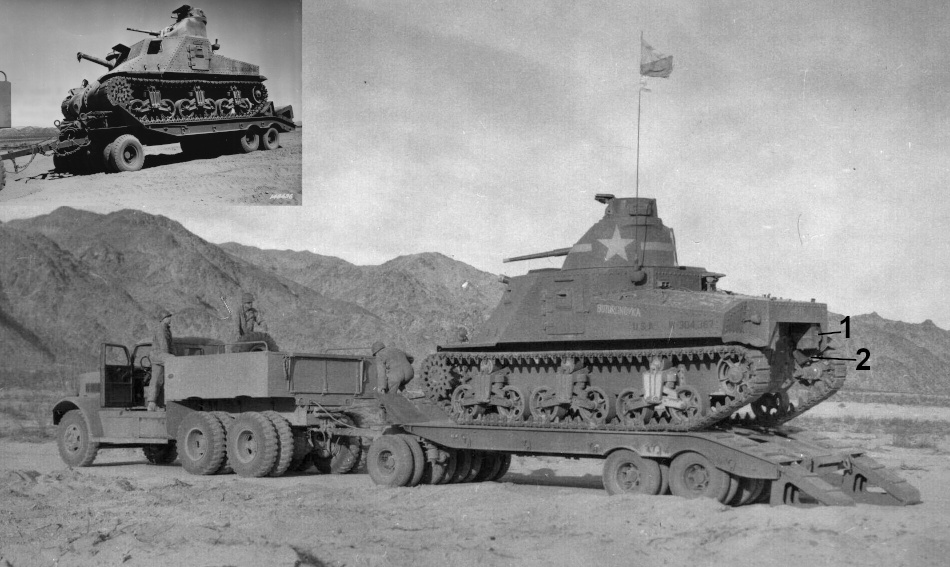

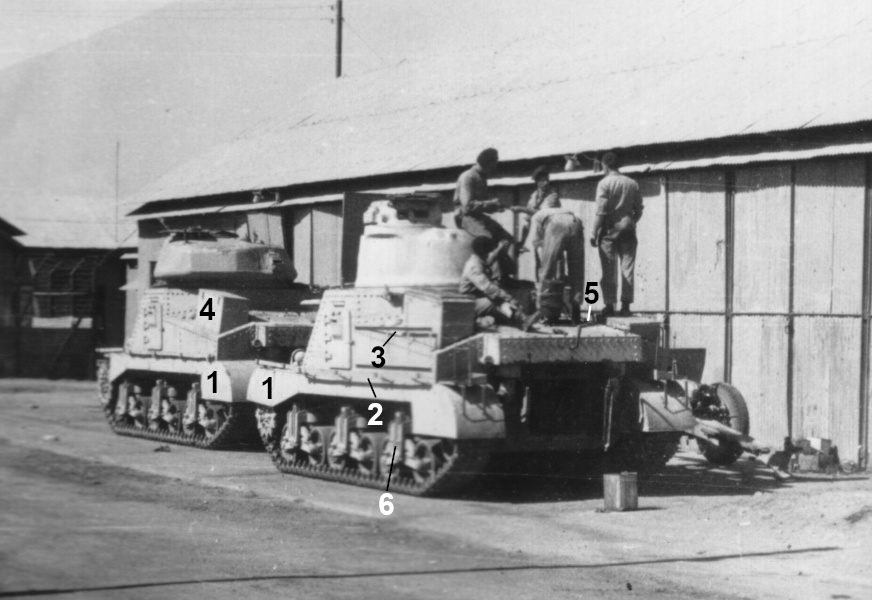

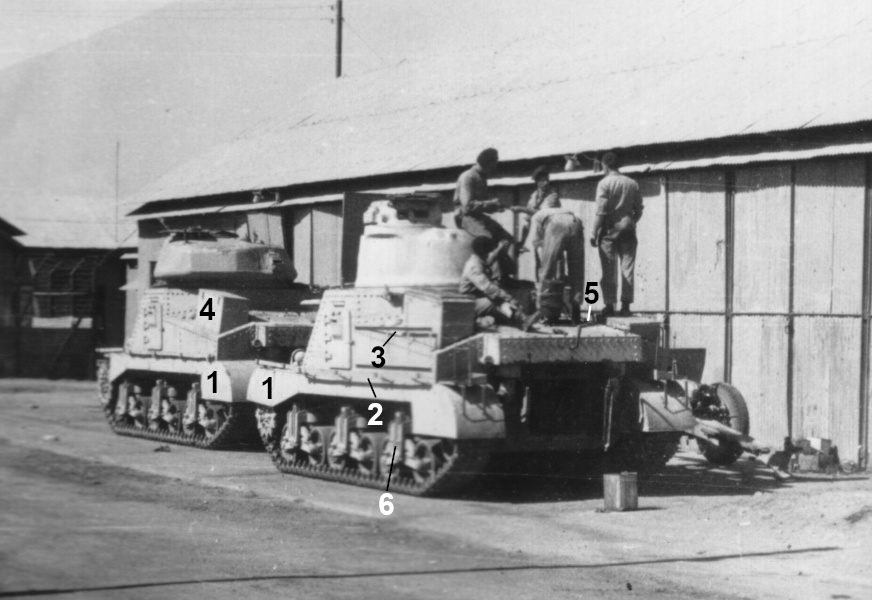

In anticipation of combat under desert conditions, in March 1942, General George Patton was ordered to establish a training facility in the Mojave and Sonoran Deserts in southern California and western Arizona. The "Desert Training Center" was the largest US Army installation ever, described in one account as over "18,000 square miles of nothing, in a desert designed for hell." During the 2 years it was in operation, 13 Infantry and 7 Armored Divisions along with a number of independent Tank and Tank Destroyer Battalions trained there. Ironically, none of them fought in any sort of desert conditions. The above is dated 29 May 1942, the earliest DTC photo we have found with some "Lee" content. It is the practically mandatory "so hot you could fry an egg" photo. No unit information is provided, but the "chefs" are named in the caption: Sgt. Tom Kuka of Havre, Montana and Sgt. Edwin B. Cowan of Hood River, Oregon. Bob Holt of "752nd Tank Battalion in World War II" was able to confirm that these men served with the 752nd. Bob told us, "My dad and the rest of the 752 went to DTC in April 1942. They were part of the first wave of troops to train there...from April through July 1942 in preparation for combat in North Africa." Despite the obvious extreme heat, the Sergeants are wearing full tanker uniforms, including the Rawlings pattern helmets. This was probably at the insistence of General Patton, well known as a stickler for such details. This Lee can be seen with a 75mm gun, but Bob Holt informs us that "Half of them arrived with no main guns." At that time, a Tank Battalion was charaterized as either "(Medium)" or "(Light)" and was entirely equipped with its type. We came across a Feb. 1942 Products Correction Report (Defective Generator Drive Bushings) which provided the Registration Numbers of 51 of the 54 new M3 Lees received by the 752nd as they converted to a Medium Tank Battalion at Ft. Lewis, Washington starting in November 1941. By the Reg. Numbers, these tanks were produced October through December 1941. The British had ordered the 75mm guns for their Grants from the Empire Ordnance Co. There were some quality control issues with these at first, so guns produced for the US were substituted, since many of the Grants were shipped to the combat zone in North Africa. The first Soviet Lend Lease Lees were produced in October 1941 and of course these were shipped with guns. As a consequence, the US Army had to make do with some Lees without 75mm guns until production caught up with demand.

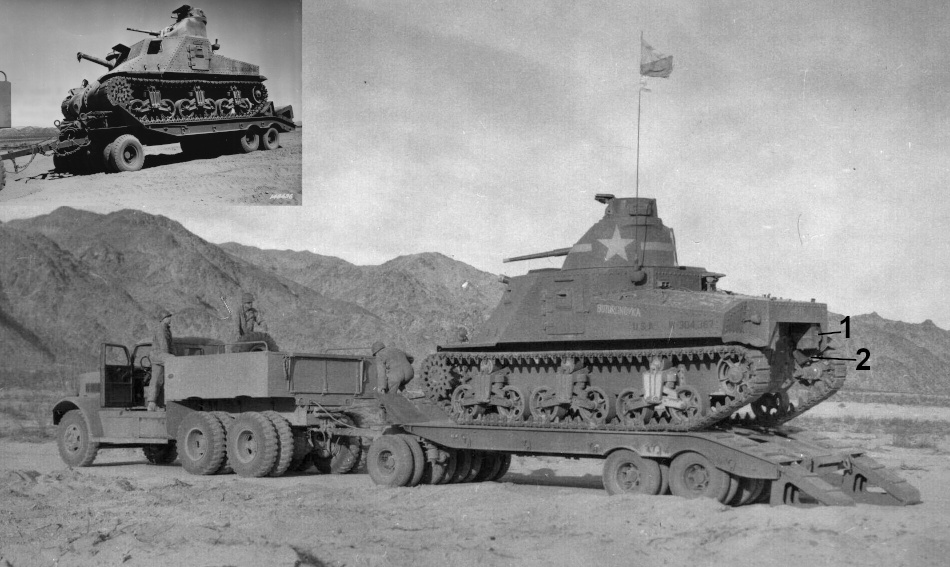

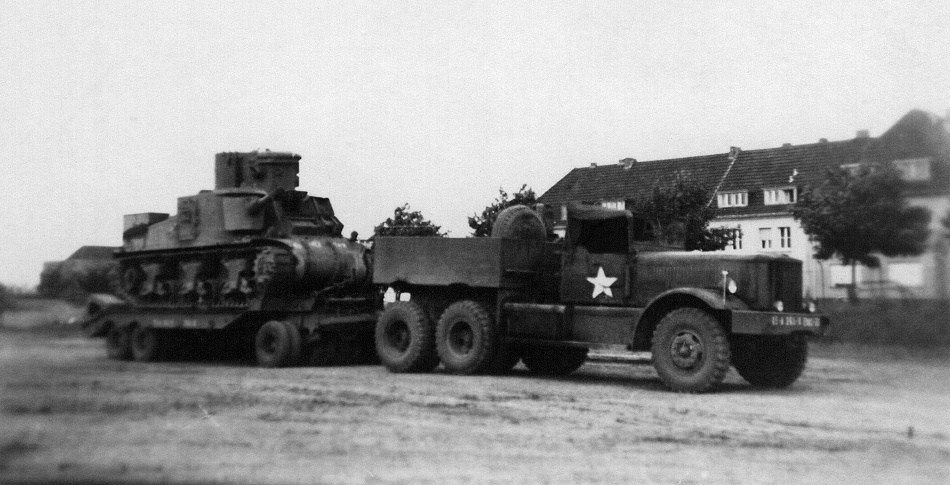

The evidence suggests that it was common practice for units to leave their tanks behind once they completed their tours at the Desert Training Center. After their stint at the DTC, the 752nd Tank Battalion shipped out for the United Kingdom in August 1942. The photo above shows an M3 Lee with the unusual name of "Buturlinovka." According to Wikipedia, Buturlinovka is "a town in Voronezh Oblast, Russia." We suspect the town had some sort of significance to Russian born Captain Peter Meshkoff, the commander of B Company, 752nd at the time. The Registration Number can be seen in the original print as USA 304367, indicating October 1941 production at Chrysler. This RN is on the list of 752nd Lees in the Feb. 1942 Products Correction Report [PCR] previously cited. The photo is dated January 1943, long after the 752nd had departed. This Lee would have been built and shipped with the original "pepper pot" exhaust, but it can be seen to have been retrofitted with the "Quick Fix" modification where the internal air cleaners were replaced with new externally mounted cleaners (1) and a pair of fishtail exhausts (2) were added through the pepper pot holes. This modification became available in the Summer of 1942 and was widely retrofitted to Lees already "in the field." The US/British invasion of Northwest Africa [Operation Torch] in November 1942 highlighted the urgent requirements for tank transporters, such as the Diamond T Heavy Tank Retriever M19 seen here, along with tank-based recovery vehicles. The Desert Warfare Board was established at the DTC to test and evaluate such equipment. Photos suggest that the 302nd Ordnance Regiment conducted trials of the M19 using "Buturlinovka" and at least one other former 752nd Lee, USA 304506 (inset).

In keeping with the theme of "so hot you could fry an egg," here we have a Desert Warfare Board trial of an interesting concept "Air cooler mounted on a tank." The idea appears to have been to install something similar to a "Car Cooler," also called a "Swamp Cooler," through the left front pistol port. Note that a pair of 5 gallon(?) water bags can be seen hanging from the 75mm gun. In a nutshell, the swamp cooler held a sponge like pad inside a container. The pad was saturated with water, so when air was forced through the unit, either by the vehicle's forward motion or, optionally, the use of a fan as seen here, the water would evaporate and provide a mild cooling effect that was directed into the passenger compartment through a vent. Swamp coolers work best in dry, desert like climes, where water, their "fuel," is often at a premium. Indeed, excessive water consumption was the primary reason this project was terminated. In the meantime, the British simply observed "Temperature Recordings in Tanks" in late August 1942 in the combat zone around El Alamein. "The purpose is to determine the temperatures under the worst conditions likely to be encountered by the crew." The Alamein temperatures reported ranged from 87 to 93 degrees Fahrenheit (30 to 34°C), perhaps a bit milder than those in the Mojave and Sonoran Deserts. Inside a few Grants, with the engines off, the temps recorded were 10 or 12 degrees hotter than the outside air - "definitely hot, and perspiration was moderately profuse." With the engines running, temps were about 5 degrees warmer than the outside air - "moderately comfortable, and noticeable perspiration ceased." "When the tanks were moving, conditions were reasonably comfortable." We suspect the definition of "reasonably comfortable" has changed a bit since then. At any rate, this photo is dated July 1942, but it can be seen that the twin .30 caliber machine guns are "still" installed in the bow of the tank. The effectiveness of these guns was severely limited, since they were fixed forward, so that the driver was required to move and point the tank in the direction of any targets before firing. In June 1942, the Ordnance Committee recommended their elimination, but ultimately it was decided to retain one of the guns.

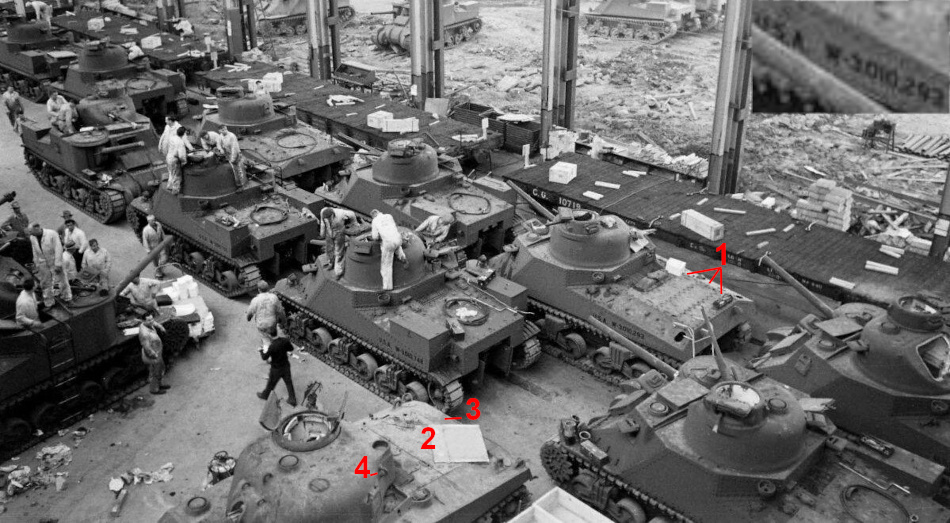

Dated August 1942 and taken at the Ordnance Depot at Camp Young, this Signal Corps photo heralds the arrival of the first Shermans at the DTC, in this case diesel M4A2s. Of course, as they became available in quantity, Shermans replaced Lees in the US Army. In the meantime, soldiers of the 302nd Ordnance Regiment are shown changing tracks on one of the Lees. This tank (A) can be seen as USA 304586 (Dec. 1941 production) another Registration Number listed on the 752nd Tank Battalion PCR list. "C-15" is painted on the upper rear hull plate. Aside from the track change, 304586 appears to have been in the process of being retrofitted with the "Quick Fix" exhaust and air cleaner modification. Only the fishtail exhausts are present, but it is assumed that the external air cleaners and the supportive side and rear plates would have been added, so that eventually it would have the appearance as on tank B. Tank B can be seen as USA 304506 (Nov. 1941 production) with "C-10" painted on the rear. This Lee was widely photographed in September 1942 as it was loaded onto a Heavy Tank Retriever M19. Note the horizontal rib on the left rear bogie bracket, the only such bracket on this tank as best we can tell from the photos. November 1941 is the earliest we have seen one of these ribbed brackets on a Chrysler Lee. Counting heads suggests that they completely replaced the non-ribbed brackets in Chrysler production around February 1942. Tank C probably arrived at about the same time as the M4A2s. This Lee can be identified as an M3A4 primarily by the radiator blister (1) on the engine deck. M3A4 series production commenced in June 1942 and the evidence suggests that all of them were built with what we call "M4 bogies" typified by the trailing return roller (2). The Lee (not Grant) series incorporated ventilators (3) and eliminated side doors (4) in production around mid 1942.

This photo shows what appears to be an entire battalion's worth of Lees, that is 50 odd tanks. It is dated simply "August 1942," and has the terse caption, "View of tanks covered [sic] with tarps." As mentioned previously, M3 and M4 Mediums were provided with a 12 by 12 ft "Paulin" as original equipment. There were many complaints regarding its insufficient size, since it did not cover the whole tank. However, as best we can determine, a larger tarp was never provided either as "On Vehicle Materiel" or as a Depot modification. The Lee in the foreground appears to have a larger tarp, or perhaps two of the 12 X 12 tarps. It seems to be unique in that it looks to have been repainted in a lighter color with perhaps some splotches of the original Olive Drive left in place. Also, we would note that the overwhelming evidence suggests that, with the exception of the M3A4 Lee, all M3 Medium Tanks were factory installed with M3 bogies with the return roller directly over the bogie bracket (1). M3A4 Lees were elongated and had a gap between the roadwheels of approximately 10 inches, whereas the gap was more like 3 inches (arrow) on other models as seen on this M3. The first production M3A4s were accepted in June 1942, and we would guess that at the same time that an M3A4 was shipped to the DTC, a set of "M4 bogies" was sent there for test on a "regular" Lee. There are a few other photos in this series. No Registration Numbers are readable, but the tanks can be seen as early production units, that is with working side doors, M2 75mm guns, no gyro stabilizer counterweights, twin fixed MGs installed and so forth. As best we can determine, from April through at least 10 August 1942, the only Lees at the DTC were those of the 752nd TB. So, we would think that they left these tanks behind when they departed on 29 July 1942. No doubt the unit would have had to turn in "Tally Out" sheets regarding the condition and the exact equipment inside of each these tanks. We came across a small number of such sheets at the US Archives, but we suspect most were discarded as historically unimportant red tape when the records were turned in to the Pentagon.

One of the Registration Numbers listed in the 752nd Tank Battalion PCR document is "USA W-304512," indicating November 1941 acceptance at Chrysler. As a matter of minutia, we would point out that 304512 is the RN that can be seen on the M3 Lee "LULUBELLE" in the 1943 film "Sahara." While the tank's name was likely painted on for the movie, the RN strikes us as real, that is to say, the one that was painted on at the Detroit Tank Arsenal. According to Wikipedia, film production began on 29 January and wrapped on 17 April 1943. It was filmed at the Anza-Borrego Desert State Park near the Salton Sea. The 4th Armored Division reportedly provided equipment, along with 100 extras. The 4th AD was posted to the DTC from November 1942 thru June 1943. It is probable that the Lees in the film, including a few cast hull M3A1s (*), would have been replaced with Shermans by then. At obsolescence, a good number of the Lees here and at other bases in the US would have been rounded up, reconditioned, and converted to T2/M31 Retrievers or Canal Defense Lights and so forth. It can be seen that "LULUBELLE" was retrofitted with 2 open grouser boxes (1), rear stowage bins (2), and the "Quick Fix" exhaust and air cleaner modification (3). The Quick Fix was Field Service Modification Work Order G104-W16. We suspect the other mods were also provided from kits, probably in the range of FSMWOs G104-W31, W32, W36 or W38. Unfortunately, these are listed but not described in the M3 Medium Modifications documents we have come across. We would assume that the FSMWO kits included instruction pamphlets as was the case with Sherman modification kits. Should any readers have the relevant pamphlets, we'd be pleased to have a report.

The records of the 751st Tank Battalion list a Field Exercise on 24 June 1942 at their station at Ft. Jackson, South Carolina. The Exercise was "for British Prime Minister Winston Churchill, General George C. Marshall, and other notables...The demonstration was in the form of a coordinated attack, using infantry, artillery, mortars, air support and tanks. The tank attack was made in close support of the infantry following the artillery preparation and air attack. The entire battalion of tanks was used, and the demonstration was effected with great success. Mr. Churchill commended the troops involved and expressed satisfaction at their state of training." Another viewpoint regarding this demonstration is described in a 2019 article by the Churchill Project. "Toward the end of events, Churchill turned quietly to his own Chief of Staff General Sir Hastings Ismay. “What do you think of it?” Ismay’s reply was blunt: “To put these troops against German troops would be murder.” “You’re wrong,” he told Ismay. “They are wonderful material and will learn very quickly.” Nevertheless, he impressed his American hosts with the maxim: “It takes two years or more to make a soldier.”" The photo above was included with the 751st's report of the event. We were able to read the Reg. Number from the 2nd Lee as USA 304585 (Dec. 1941 production), built one unit before C-15 shown at the DTC in an earlier caption. In this case, the right front bogie bracket can be seen to be "ribbed."

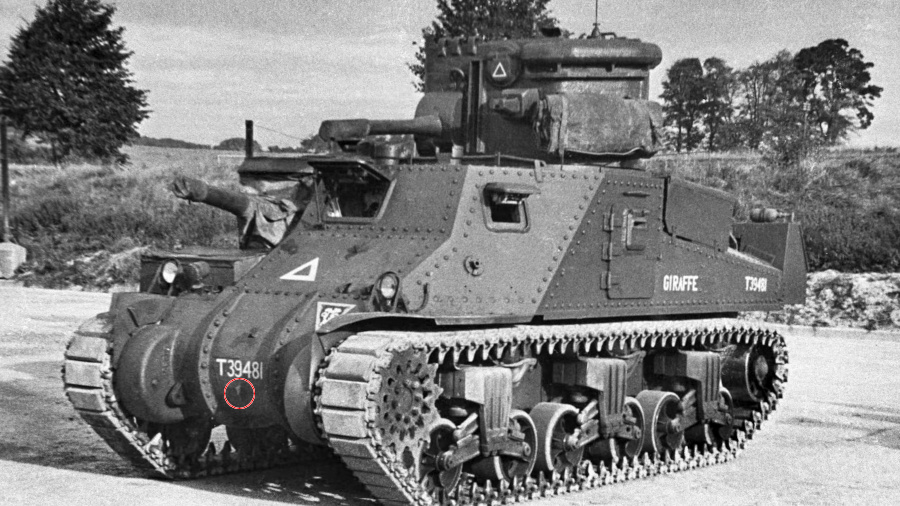

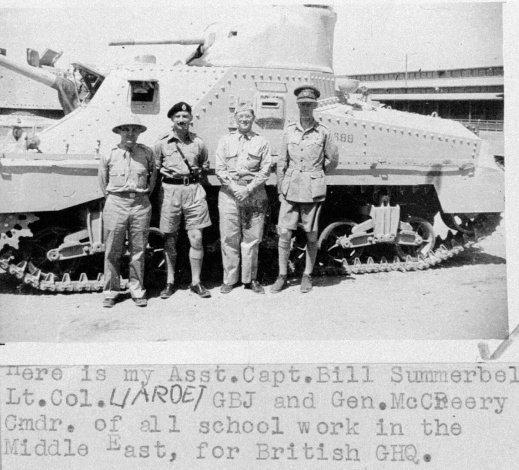

Lees in the United Kingdom

As the US Army began to receive the new Lees in the late Summer and Fall of 1941, others were set aside for Lend Lease. The British were very impatient to receive some M3 Mediums, the Grants in particular, for examination and evaluation. Their internal correspondence even includes a little verse/song entitled "Where Are the Tanks?" In August 1941, it was reported that 3 of the first Pullman Grants (T-24190-92) had been shipped to the Middle East. The fighting front was given top priority, and all but 3 of the 309 radial based M3 Grants produced in 1941 were supplied to the Middle East. The buildup was slow since many of the early production Grants shipped were incomplete, missing guns and radios and so forth. On December 16, 1941, 10 "Mediums" were listed in the Middle East - "five of which are at Schools...five in workshops awaiting issue." These "Mediums" would have been Grants, since the first 7 M3 Lees were reported "On Ship Awaiting Sailing...as at December 19, 1941." The first M3 Mediums with "American turrets" ("AT" as opposed to "BT") that the British actually received were shipped to the UK, and it would appear that, initially, mostly ALCO Lees were set aside for the UK, while mostly Baldwins were allocated to the Middle East. The first 20 units to the UK appear to have encompassed the entire July production at ALCO (SNs 1695 - 1711) with a few more from August. In the absence of a Tank Depot system, they were processed for Lend Lease shipment at Aberdeen Proving Ground. It is thought that the first 11 sailed on the Empire Faith in mid-September. A clue about when they arrived may be had from a Department of Tank Design Field Trials Report on one of the Lees shipped, SN 1708/USA 305778, where the earliest results are dated 20 October 1941. The photos above were taken at the DTD test facility at Farnborough and provide two views of 305778. It can be seen that the tank was received as built, and in the rush, it appears to have been shipped without pioneer tools. General Steel provided the 2-ton Lee turrets to ALCO and Baldwin, and these castings featured the most prominent "bump" (1) just below the commander's cupola. USA 305778 "still" had the fabricated antenna base (2). The fire extinguisher pull handle housing (3) is either covered over or mounted facing down. The Lee design did not incorporate sand shields. It featured rubber mud flaps (4) from start to finish. Of course, the British requested that the same type of sand shields that had been designed for their Grants be installed on to their Lend Lease Lees before shipment. The US would not agree to incorporate sand shields in production but did agree that they could be retrofitted at Tank Depots when they came online and got up and running.

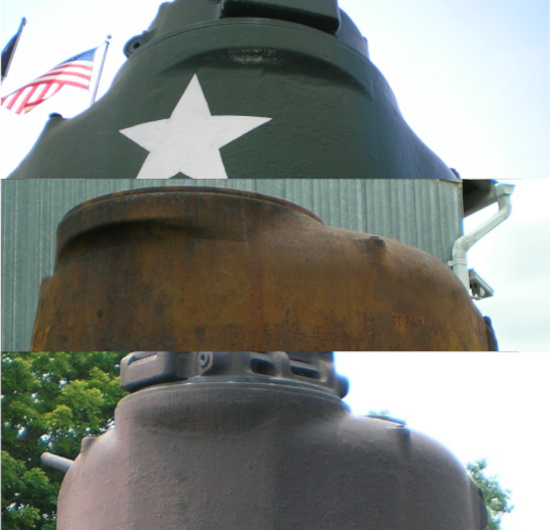

By the end of 1941, a total of 59 M3 Lees and 3 Grants had been exported to the UK. The 5th Canadian Armoured Division arrived in England in late November 1941. The intent was to equip the Division with "Canadian M.3 Med." [Rams]. The Ram, like the Sherman was designed with the main gun mounted in a revolving turret, thereby correcting the major flaw of the M3 Medium. Ram production commenced in December 1941, and it was estimated that 382 would be completed by June 1942, all of which were allocated "to United Kingdom for 5th Canadian Armoured Division and training." In the meantime, a few of the mechanically similar Lees were on hand to serve as substitutes. The 8th New Brunswick Hussars may have been first to receive the new tanks. The first notation of "Tank (Medium M.3)" in their War Diary comes on 2 December 1941 when USA 305768 and USA 305781, both ALCO, July 1941 production, were reported to have been allotted to A Squadron. USA 305826 was issued to A Squadron on 31 December, and USA 305828 and USA 305815 were issued to B and C Squadrons respectively on 5 January 1942. These 3 would have been ALCO, September 1941 production. On 5 January, the Diary contains the list (inset) reporting that replacement of the USA Registration Numbers with British War Department Numbers (in the T-788XX range) "has been completed." In general, US vehicles allocated to British Lend Lease had their War Department Numbers assigned and painted on in the US during processing, but here we have a rare instance in which the T-Numbers were only issued after the tanks had arrived at their destination. In any case, combining the USA Numbers on the list with 305826, 305828 and 305815, we can assume that the 8th NBH had at least 9 Lees in early January 1942. Note that there is a single Baldwin M3 on the list, USA 305104 (October 1941 production), renumbered to T-78864. Except for USA 305817 assigned to B Squadron and 305475 to A Squadron on 6 January, there are no apparent further allotments of M3 Mediums through to the end of February 1942. Our interpretation of the records is that the "War Establishment" for "cruiser tanks" would have been about 54, but the 8th NBH never had more than a dozen M3 Mediums including one or two Grants. Towards the end of February, it is mentioned that 40 Canadian "Ram" tanks "would soon be made available to the division" [5th Canadian Armoured]. The photo above is dated 21 February 1942, and captioned in part, "A Canadian Armoured Division are finishing [sic] their training in this country with American M3 Medium Tanks manufactured in Detroit [sic]." The lead tank can be seen as USA 305811, indicating that it was accepted in September 1941, and built by ALCO whose plant was in Schenectady, New York. Again, we see a few "missing rivets" on 305811.

The Library and Archives of Canada holds an extensive collection of photo albums detailing the WW II activities of the Canadian Army. In one series dated 25 February 1942, five "as built" Lees are shown. The notations at the bottom of the album pages read, "American Tanks used by G.G.H.G. 3.Cd. N.B.H. Frensham Hants." We translate this as "Governor General's Horse Guards" which at the time was the 3rd Canadian Armoured Regiment of the 2nd Armoured Brigade, 5th Canadian Armoured Division. "N.B.H." is also tacked on, and we translate that to be "[8th] New Brunswick Hussars" which at the time was the 5th Armoured Regiment, 2nd Armoured Brigade. The location is given as "Frensham Hants" which we interpret to mean that the tanks were photographed on Frensham Common, a recreational area situated mainly in the County of Surrey in southeast England. During WW II, the Common was converted to a military training ground, and its two lakes "were drained as otherwise they would have provided markers for German bombers." On 24 February 1942, their War Diary reports, "8 NBH will supply 4 M.3. Med Tanks for the demonstration...at Frensham Common." The detachment would be under the command of "Capt. Olgilvie of GGHG." We would theorize that the Lee in the foreground was Capt. Olgilvie's tank and was USA 305811, and that the other 4 were those supplied by the 8th NBH. Both still and motion picture footage was shot on that day, and part of the idea was to create the impression that the maneuver featured a large number of tanks, although as best we can determine, only 5 Lees took part. We have examined quite a few of the images, and only one Lee appears to have had a USA Registration Number, while the others had British WD Numbers painted on as seen on the two tanks in the rear on the right. For a little background, note that at the urgent request of the British, the Canadian Army deployed to England, and with most of the British Army serving on the fighting fronts, "From the autumn of 1941 to early 1944 the defence of the UK and particularly the Sussex coast was largely in the hands of the 1st Canadian Army."