M4(105)

and M4A3(105) Shermans

Most of the information on this page is courtesy of Joe DeMarco and Leife Hulbert, with help from Pierre-Olivier Buan. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

Chrysler Corporation was the sole manufacturer of 105mm armed Shermans. It produced 800 M4(105) Shermans with VVSS, and 841 M4(105) Shermans with HVSS. The production started in February 1944 and ended in March 1945.

Production Order T-9369/1 : 700 M4(105) with VVSS manufactured: Serial Number 56921 / USA 30103603 through S/N 57620 / USA 30104302

Production Order T-9369/2 : 100 M4(105) with VVSS and 315 with HVSS manufactured: Serial Number 58208 / USA 30111769 through S/N 58622 / USA 30112183

Production Order T-9369/3 : 126 M4(105) with HVSS manufactured: Serial Number 64132 / USA 30120071 through S/N 64257 / USA 30120196

Production Order T-9369/4 : 400 M4(105) with HVSS manufactured: Serial Number 73436 / USA 30139426 through S/N 73835 / USA 30139825

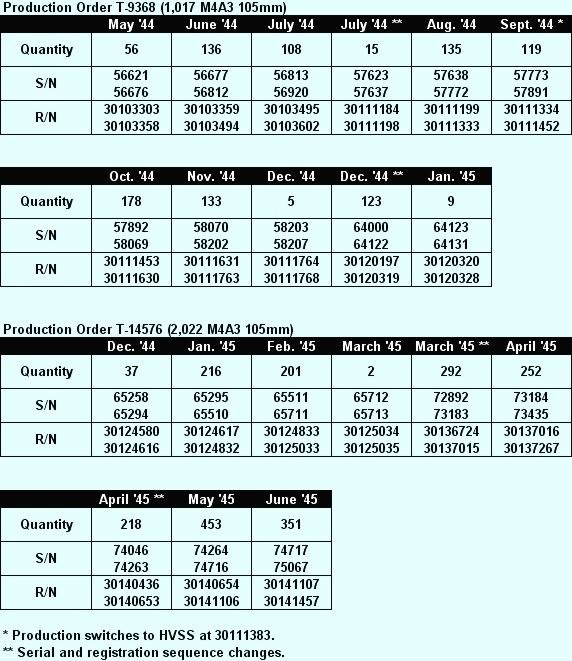

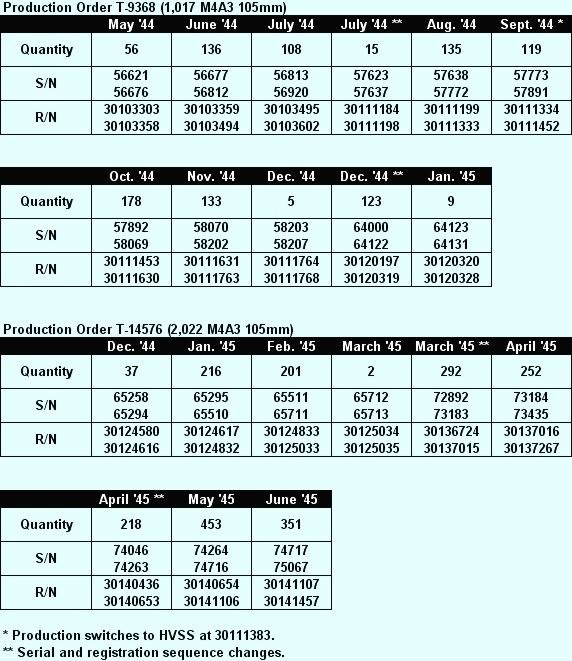

Chrysler also built 500 M4A3(105) Shermans with VVSS, and 2539 M4A3(105) Shermans with HVSS. The production started in May 1944 and ended in June 1945.

Production Order T-9368/1 : 300 M4A3(105) with VVSS manufactured: Serial Number 56621 / USA 30103303 through S/N 56920 / USA 30103602

Production Order T-9368/2 : 200 M4A3(105) with VVSS and 385 with HVSS manufactured: Serial Number 57623 / USA 30111184 through S/N 58207 / USA 30111768

Production Order T-9368/3 : 132 M4A3(105) with HVSS manufactured: Serial Number 64000 / USA 30120197 through S/N 64131 / USA 30120328

Production Order T-14576/1 : 456 M4A3(105) with HVSS manufactured: Serial Number 65258 / USA 30124580 through S/N 65713 / USA 30125035

Production Order T-14576/2 : 544 M4A3(105) with HVSS manufactured: Serial Number 72892 / USA 30136724 through S/N 73435 / USA 30137267

Production Order T-14576/3 : 1022 M4A3(105) with HVSS manufactured: Serial Number 74046 / USA 30140436 through S/N 75067 / USA 30141457

The original design of the

Sherman included a provision for mounting alternate main guns, including the

105mm Howitzer. In October, 1942, the Chrysler Corporation began work on the

development of a gun mount that could be adapted to the Sherman's standard 75mm,

D50878 turret. Above shows one of the two original pilots, designated “M4A4E1.”

This example, based on M4A4 Serial Number 5868 was photographed at Aberdeen

Proving Ground, Maryland in January, 1943. The pilot 105mm gun mount was

designated “Combination Mount T70.” Tests at APG and Ft. Knox found that the

gun mount’s internal configuration was nearly unworkable for the loader. The

M4A4E1s included the power traverse and gyrostabilizer systems of the original

Sherman design, but the large and heavy cast rotor shield (1) so unbalanced the

turret that the power traverse became overloaded and could not rotate the

turret while the tank was operating on slopes of 30 degrees or more.

In early 1943, the Armored Board found the “Combination Mount T70” unacceptable, and mandated a redesign which resulted in the “Combination Mount M52.” This configuration shortened the breechblock and introduced other changes which made it easier for the loader to service the piece. The M52 mount featured a new rotor shield casting (1), which was more like the 75mm M34A1 shield. This enabled the elevation range to be increased to +35 to –10 degrees as opposed to the +33 to –4 range of the earlier configuration. All Sherman turrets were somewhat unbalanced in the front, but the new and lighter combination mount improved the situation to a workable level. The Armored Board decided not to equip 105mm Shermans with gyrostabilizers. This omission was of little consequence, as the gyro was “in the way,” overly complicated and seldom used by the tankers. However, the Sherman had an excellent power traverse, and the Board’s decision to omit it on the 105s became the subject of many complaints, as crews were limited in combat by the much slower hand traverse. Above shows Pressed Steel Car M4, Serial Number 11435, one of the two pilots that incorporated the changes. These tanks were designated “M4E5,” and delivered for testing in August, 1943. The new features were determined to be acceptable for combat, provided that additional changes were made to production models. For instance, the M4E5s were based on 1st Generation small hatch M4s, while production would utilize 2nd Generation, large hatch M4s and M4A3s, whose designs were not finalized until early 1944.

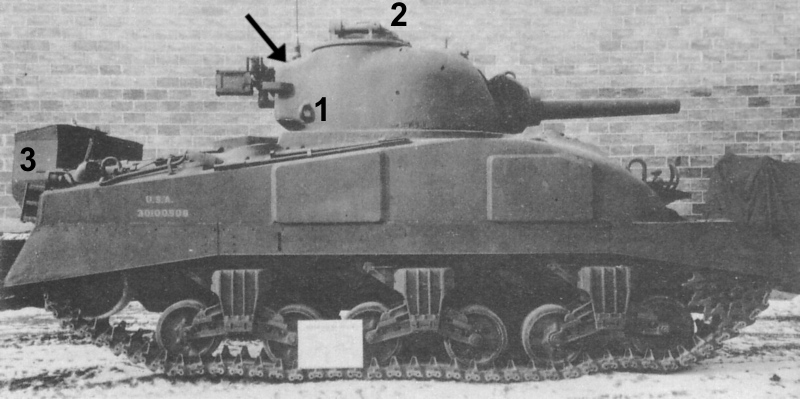

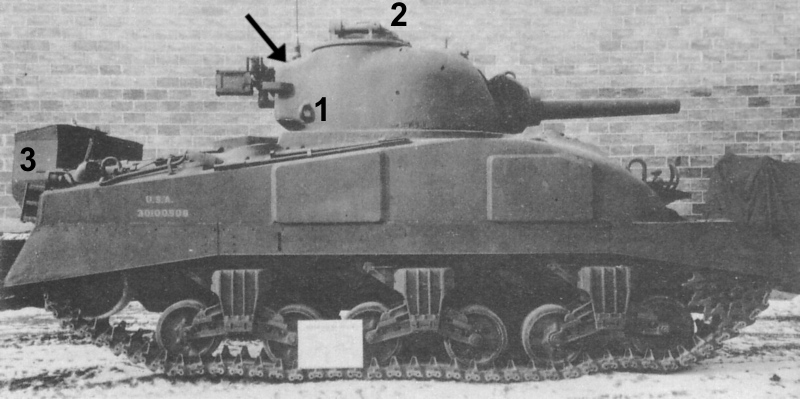

In the summer of 1943, the Ordnance Department embarked on a program to improve the original Sherman design with a number of new features. The most important were larger drivers’ hatches, an additional hatch in the turret for the loader, and more secure ammunition stowage. At the same time, two new gun types, the 76mm and 105mm, were to be introduced. It was anticipated that the “Ultimate Design” or “2nd Generation” series of Shermans would enter production in late 1943 or early 1944 at the latest. Two of the new 2nd Generation models, the M4 and M4A3 would be armed with 105mm howitzers, using the M52 Gun mount system developed for the M4E5. The photo above shows the M4(105) pilot photographed at the Detroit Tank Arsenal in early 1944. This unit was converted from USA 30100506, a September 1943 production M4 Composite, which we think may have been one of the first assembled with the E6289 front casting with large drivers' hatches. The Sherman’s original D50878 turret was redesigned for the new 75mm and 105mm models, most importantly by the addition of a “hatch over loader.” With only the single commander’s hatch in the original design, the loader lost precious seconds as he tried to work his way past the gun breech in emergency escape situations. The turret bustle was raised (arrow) on the new turret casting (Part Number D78461) so that it would clear the protuberances of the large drivers’ hatches. For future reference, note that this early version of the turret had the rear lifting rings (1) cast in in what we think of as the “low” position. 2nd Generation Shermans were to be equipped with the commander’s all round vision cupola (2) as seen here. All of the “Ultimate Design” pilots were test fitted with deep water fording equipment (3), but problems were encountered, and the fording development work was “carried on under a separate project.” The M4(105) pilot was unique, since all of the production M4(105)s and M4A3(105)s were made with welded hulls

There is an M4 Composite with 105mm turret on display at historic Ft. Wayne in Detroit, Michigan. The serial number of this tank as recorded from the rear tow lugs is 44272, which is an exact mathematical match to USA 30100506. Thus the M4(105) 2nd Gen pilot has managed to survive. However, we would observe that the original 105mm turret appears to have been replaced as the rear lifting rings (1) are somewhat higher than those seen in the period photo of the previous caption. The Chrysler Engineering “Ultimate Design” Report mentions that only one 105mm turret was available when the document was published on March 11, 1944, and states that the other turret would “be handled under a new project.” For this report, we gather that both the M4 and M4A3(105) pilots must have been photographed and weighed using the same turret with the “low” turret lifting rings. Unfortunately, we don’t know of any photos of the M4A3(105) pilot, which is stated to have been USA 3054283, a small hatch M4A3(75) built by Ford in May, 1943. As with the other pilots, the front of the tank would have been altered to include the larger drivers’ hatches. In any case, it seems possible that the turret currently on SN 44272 might be the one which was “handled under a new project.” At the least we would note that the rotor shield is the later iteration that included a shutter (2) to protect the telescopic sight. All of the 2nd Generation Shermans were ordered to be installed with the last type of Transmission and Final Drive Assembly. This featured a sharp nosed differential housing (Part Number E8543) that had been “heavied and streamlined.” Early versions had cast in steps (3), but because of interference issues, these were soon replaced with metal strip steps. As best we can determine, Chrysler only manufactured and installed the final, metal strip version of the E8543 differential housing on the Shermans the Company built from the Fall of 1943 to the end of production in mid 1945. Photo courtesy of Lorén and Paul Hannah.

In the absence of any known photos of the M4A3(105) pilot, we will substitute the M4A3(75)W pilot, USA 3054578. This tank would have been accepted at Ford in July, 1943. The weld seam indicated by the white arrow shows how the original front of this tank with the protruding drivers hoods and small hatches was removed and replaced with a 47 degree glacis with large drivers’ hatches in the “roof” of the hull front. This particular large hatch configuration was referred to as “the Fisher Front End,” and was the pattern used on all welded hull 2nd Generation Shermans, as it was found to be superior to the large hatch casting used on most M4 Composites and referred to as “the Chrysler Front End.” Note that the bullet splash (black arrow) seen on the forward engine deck, was typical of Ford built M4A3s. 2nd Generation M4A3s used a simpler forward engine deck configuration. A few standard 2nd Generation features installed on this pilot include the Anti Aircraft Machine Gun stowage fittings (1), spare track holders (2), and blanket roll rack with fittings on the bottom for the cleaning bore and staffs (3).

Chrysler produced its first 2 M4(105)s in February, 1944 and had completed 211 units by the end of April. (M4A3(105) production did not commence until May, 1944.) The Army wanted to get some 2nd Generation Shermans, particularly those with the new 76mm and 105mm guns, into the hands of US combat troops as soon as possible. Consequently, 160 M4A1(76)s and 210 M4(105)s were shipped to Great Britain in the weeks and months leading up to D-Day, June 6, 1944. These were made available, but there appears to have been a reluctance on the part of armor commanders to adopt them into the Table of Organization and Equipment (TO&E) before the Invasion, since the troops had not trained with them. At present, we don’t find evidence that any M4(105)s landed and fought on D-Day. The photo above provides an overhead view of USA 30103605. This unit would have been accepted in March, 1944, and would have been only the third M4(105) produced. USA 30103605 was used as a “model” in the M4(105)/M4A1(76) Technical Manual, dated June 23, 1944. Perhaps the most important feature of the new high bustle, D78461 turret was item V, the “loader’s escape hatch.” During 105mm pilot testing, it was found that an additional ventilator (1) would be required on the rear of the turret roof. All 2nd Generation Shermans were to be equipped with the “Commander’s Vision Cupola,” but 30103605 can be seen with the older Commander’s Split Hatch (2) instead. In early 1944, supplies of the new Commander’s Vision Cupola were limited, and 76mm Shermans were given first priority. Chrysler stated that the Vision Cupolas would "be installed at 215 Medium Tanks M4-105MM, and on No.1 M4A3-105MM." This equates to an introduction in early May 1944, and is confirmed by our counting heads method. Other 2nd Generation features missing from early production M4(105)s like 30103605 were the Anti Aircraft Machine Gun pintle and stowage fittings intended to be placed on the rear of the turret.

The Signal Corps photo above includes the not very informative caption, "With their 105 mm guns, a line of Yank M4 Sherman tanks lays down a barrage from a French wheat field. France, 7/13/44." We would observe that the description as "Sherman tanks" is rarely encountered in period American documents. No doubt these would have been some of the first M4(105)s photographed "in action," and the scene may well show the combat debut of the type. Note that the crews have "already" painted out some of the white stars that were thought to have provided excellent aiming targets to the enemy. Six tanks are visible, which would represent the total number of "Assault Guns" authorized to a Tank Battalion. In some Battalions, the 105mm Shermans were removed from the 3 Medium Companies, because they were not considered "suitable for employment with other tanks because of lack of power traverse." Instead, all six Assault Guns were grouped into one platoon under the control of the HQ Company, where they formed a fairly powerful artillery battery. Perhaps this is the arrangement represented in this scene? In the photo, the crew of USA 30103696 (April 1944 production) have opened the armored air intake cover on the engine deck, affording a rare view of the "pyramid turning vanes" of the Barber-Colman air flow system, a modification introduced on M4s and M4A1s in January 1944.

The French were not issued any 105 Shermans as official Lend Lease, but since their units served under US Army command, additional equipment (including tanks) was provided as requested or needed from US Army stocks. The French 2nd Armored Division (2ème Division Blindée) was an early recipient of the type, and received a few M4(105)s at the end of July, 1944 while in the UK. The photo above is dated 1st August, 1944 and symbolizes the long anticipated return to "la terre sacrée de France." “Moghrane” of the 2ème Escadron, 12ème RCA (Régiment de Chasseurs d’Afrique) is seen here coming ashore on Utah Beach. In general, French units painted out the USA Numbers, and replaced them with their own system of "matricule" numbers. However, although a number of French tactical markings are visible on “Moghrane”, "USA 30103764," and the "GLUE" shipping stencil had not yet been overpainted. “Moghrane” was another April, 1944 production M4(105), and as such, features the early glacis pattern with “inboard” lifting rings (1) and long bullet splashes (2). Note that the ventilator between the drivers' hatches (3) is "open." Counting heads suggests that a sheet metal cover was introduced into production at Chrysler in July, 1944. The Gunner's Periscope (4) is protected only by a wire guard. "Armor Protection around Gunner's Periscope" was considered to be an essential component of 2nd Generation Shermans, but for some reason, this was not incorporated on 105mm Shermans until very late in production. The dust cover for the bow machine gun (5) was a standard item of equipment introduced on the Sherman series in the Fall of 1942. A similar "canvas seal between gun shield and turret" was wanted for the main guns of 2nd Generation 76mm and 105mm Shermans. However, while the fittings were installed on 105mm Shermans from the start, the canvas covers themselves do not show up on 105mm Shermans overseas until the Fall of 1944.

This well known photo is dated August, 1944, and shows an early M4(105), most likely photographed in the US. The Signal Corps appears to have published this image for propaganda purposes. The caption reads in part, "Some of the General Sherman tanks (medium tank, M4) in action in Normandy and Brittany are armed with 105-mm howitzers. This is the first time that a field artillery piece with the punching power of a 105-mm howitzer has been successfully installed in a medium tank. It represents the maximum firepower thus far achieved in the fast moving, highly maneuverable vehicle. The new General Sherman is the master of any German tank in the field today." This unit can be identified as an M4(105) by the air scoop (arrow) just visible in the rear. (M4A3(105)s did not require these.) From the start, Shermans were equipped with sirens (1). These were replaced in production with automobile style horns in the summer of 1944. It is thought that US armor units gradually added 105mm Shermans to their TO&Es. For instance, the 743rd Tank Battalion, which was part of the initial landing on Omaha Beach on D-Day, reported that on July 3, 1944 "Assault Gun platoon received six M-4 105 Howitzer tanks." The Battalion appears to have chosen to allot all 6 M4(105)s to Headquarters Company. Their first combat appears to have occurred on July 10, near St. Jean De Daye, France..."The Assault Gun platoon in support of Company "A" fired from battery position at 466737." With thanks to Mike Canaday.

The 7th Armored Division arrived in Normandy in mid August, 1944 and immediately entered combat as part of the U.S. Third Army. The photo above was taken at that time in the vicinity of Chartres, France. The M4A1(75) on the left is named "Battling Bitch.” A magnifying glass examination of the Archives print revealed that the M4(105) has the tactical markings, “7 Δ - 31 Δ” painted on the [tank’s] right side differential housing, identifying it as 7th AD, 31st Tank Battalion. “B-19” is painted on the left, signifying the 19th vehicle of B Company. The Signal Corps shot some movie footage of this scene, where B-19 is noted with the name "Big Boy," which follows the convention of having tank names begin with the letter of the Company. We recorded the Registration Number seen in the footage as USA 30103800, indicating that it was one of the last M4(105)s accepted in April, 1944. From all of this, we might assume that the 31st Tank Battalion followed the prescribed TO&E, and allocated one "Assault Gun" to each of its 3 Medium Tank Companies, with 3 more assigned to Headquarters.

By the second half of 1943, Ordnance Department tests had determined that the 500 HP Ford V8, as installed in the M4A3, was the best tank engine for the Sherman. If industrial conditions had permitted, all future Sherman production would have utilized the Ford V8. However, supplies were limited, so that it was necessary to continue to produce 2nd Generation M4s and M4A1s with Continental Radial Engines, along with M4A2s with GM Twin Diesel power packs. It became government policy that M4A3s would be reserved for US Forces up to the limit of availability. The military was anxious to get some of the 2nd Generation M4A3s into the hands of combat troops, and they began to arrive in both the European and Mediterranean Theaters starting in July, 1944. The earliest M4A3(105)s in the ETO that we have found were 19 units shipped to Great Britain, which were then discharged over the Normandy Beaches on September 17, 1944. The photo above is dated October 6, 1944 and shows members of the 25th Ordnance Battalion driving new AFVs through a Belgian village in the "Eupen Sector." We identify the lead Sherman as an M4A3(105) due to the absence of the rammer staff fittings (arrow) on the left rear. For whatever reason, these fittings, installed on M4(105)s from the start, were NOT installed on M4A3(105) models until very late in production. At least 3 of the Shermans can be seen with commander's vision cupolas (1). The newly arrived M36 Tank Destroyers parked under the trees appear to be in the process of being combat equipped from the On Vehicle Material crates (2) lying around. The vehicle in the foreground is an open top M8 75mm Howitzer Motor Carriage (3). The 105mm Shermans replaced these in many Tank Battalions.

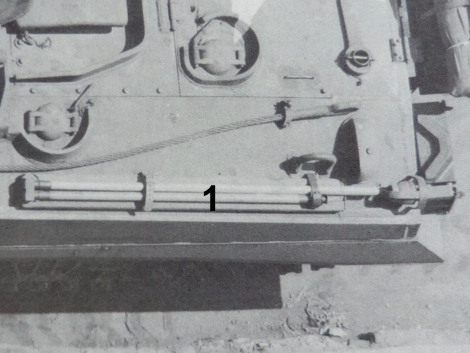

This overhead view from the 1954 M4A3 Technical Manual can be compared to the similar view of the M4(105) shown earlier. The 105 Shermans are virtually identical when viewed from the front. In the rear, large "top grille doors" dominated the engine deck of the M4A3. 2nd Generation M4A3s were installed with "door stops" (1) to hold the heavy doors when they were opened for servicing of the engine. If they can be seen in photos, these stops provide a positive identification of an M4A3. M4s and M4A1s had some overheating issues and were installed with a pair of air scoops over the grouser compartments to increase the air flow. These were not necessary on M4A3s, so the presence or absence of the scoops in photos is another way to distinguish between types. M4A3(105) production started in May 1944, and this particular example was one of the first units accepted. Note the "early" location of the forward cable clamp (2) and the one-piece rear most engine deck plate (3). It is thought that the M4A3(105)s were equipped with the Commander's Vision Cupola (4), the Machine Gun stowage fittings on the turret bustle (5), and the automobile type horn (6) from the start. Note the absence of the rammer staff fittings on the left rear sponson. Counting heads suggests that these were not installed on M4A3(105)s until October, 1944. Chrysler had completed the transition to HVSS suspension a month earlier, so it is our theory that any 105 Sherman with VVSS seen in a period photo with the rammer staff fittings would be M4 based.

Depending on the variant, 75mm armed Shermans could carry between 90-104 rounds of main gun ammunition. Larger ammunition lowered the capacity of 76mm Shermans to 71 rounds, and the even larger 105mm shells limited the Assault Guns to 66 rounds. One of the most important safety features of the 2nd Generation “redesign” of the Sherman was the relocation of the main gun ammunition from its original more exposed positions “up high” on the hull sponsons, to a more protected location in bins on the floor of the hull. In the 105mm Shermans, only 45 rounds could be stowed on the hull floor; another 21 rounds were carried in two armored racks in the right sponson. Commanders on the fighting fronts were insistent on “the maximum ammunition stowage that can be obtained” in the Sherman, or its proposed replacement, the T20 (Pershing) series of tanks. They gave the “minimum stowage” acceptable in any design as 70 rounds, so the 105mm series came up a little short. To compensate, the Army authorized the use of the M10 Ammunition Trailer, which according to a "Loading Instructions" plate attached to the body, had the capacity to carry an additional 44 rounds of 105mm ammunition "in boxes", or 54 rounds "in bundles". The photo above shows an M4A3(105) of the 10th Armored Division towing an M10 trailer near Trier, Germany, on March 7, 1945.

In the Italian Theater, the 1st Armored Division underwent a major reorganization at the end of July 1944. The Division received some of the first M4A3(76)s along with a few M4A3(105)s at that time. One of those listed as having been issued to the 1st Tank Battalion was USA 30103307. This unit would have been accepted in May 1944 and would have been only the fifth M4A3(105) built by Chrysler. We maintain a list of surviving Shermans with known good serial numbers here. Pierre-Olivier has personally examined the M4A3(105) on display at the 1st Armored Division and Fort Bliss Museum at Ft. Bliss, Texas. He was able to confirm from the dataplate and hull stamping that this unit is Serial Number 56625. That is an exact mathematical match to USA 30103307, so barring a typo in the period doc, it would appear that this tank survived service in Italy and was repatriated back to the US. At present, it is the only surviving Sherman of which we are aware, that was built as an M4A3(105) VVSS and has remained so. (There are a few surviving examples with M4A3(105)VVSS Serial Numbers that were converted to M4A3E4s in the early 1950s.) The great majority of WW II era vehicles that continued in US Army service in the post war years were modified to some extent, but 56625 appears to be nearly as built. Most of the surviving Shermans in the US survived because they were used as training tanks, and as such, never left the country. "Bring backs" are very rare, so if any readers know how this Sherman came to be at Ft. Bliss, we would be pleased to have a report.

For the 1945 Spring Offensive, Fifth Army reported that the 751st, 752nd, 755th, 757th and 760th Tank Battalions, along with the 1st, 4th and 13th Tank Battalions of the 1st Armored Division were "all...equipped with 6 of the M4A3 w/105mm Howitzers." The three Armored Infantry Battalions of the 1st Armored Division are also reported to have received some M4A3(105)s. The Assault Guns served mostly as artillery support during the Offensive, and casualties were light compared with those suffered by the Sherman gun tanks. From April 5 to May 2, 1945, 3 M4A3(105)s were reported destroyed and 1 damaged/repairable. In what may be the only recorded combat use of Shermans with HVSS during the Italian Campaign, the records of the 755th Tank Battalion state that, "The M4A3 with 105mm How. and wide steel tracks and all around vision cupola is especially good. The rolled armor plate of one of these took two hits of 75mm and deflected both...and destroyed the enemy gun...This tank should be used in close support or with the assault platoons, for its much greater destructive effect is useful against houses, road blocks or concrete blockhouses." Of course, there was the almost universal complaint, "Lack of power traverse...is a definite disadvantage." At present, we don't know of any combat photos of M4A3(105)HVSS Shermans in Italy. Above shows an M4A3(105)VVSS of the 752nd Tank Battalion in Bologna, April 21, 1945. Note the extended end connectors (arrow) which were installed on many of the Shermans with VVSS that took part in the Spring Offensive.

We don't find evidence that US armored units in Italy received anything other than M4A3(105)s. The build up appears to have been gradual with a number of the independent Tank Battalions reporting that they had received 6 M4A3(105)s in December, 1944. These replaced the M7 Priests that had been employed in their Assault Gun Platoons prior to that. Several units mentioned that, overall, they preferred the open topped M7s for carrying out the types of fire missions most often required by the conditions in Italy. Above shows an M4A3(105) of Company C, 13th Tank Battalion, 1st Armored Division, engaged in a typical artillery support mission in the mountains near Silla, circa December 30, 1944. October, 1944 to the Spring thaw in 1945 was a period of relative quiet on the Italian Front, but the 5th Army reported a significant expenditure of 75, 76 and 105mm ammunition, as every type of Sherman was used as mobile artillery. This tank can be seen with a canvas mantlet cover (1). The "donkey sight" (2) observed on many 1st AD tanks was manufactured and installed by the Division's 123rd Ordnance Maintenance Battalion. The T48 rubber chevron tracks (3) were the overwhelming preference of armored units in Italy, and are the type most commonly noted on both M4 and M4A3(105)s with VVSS.

The British did not really want any 76mm or 105mm Shermans as Lend Lease. They were more or less compelled to accept them due to the unavailability of the 75mm Shermans that they preferred. Their 1944 and 1945 requirements amounted to 1000 105mm Shermans, but in the end, US Goverment Lend Lease documents state that they received 593 units, all of which were reported to be M4(105)s. Of this total, 276 were allotted to the "U.K. & N.W. Europe" (ETO), with the other 317 set aside for "N. Africa & A.A.I." (MTO). These were allocated May through October, 1944. Chrysler completed the transition to HVSS suspension by the end of September, and we would surmise that the 100 M4(105)s assigned to the Commonwealth in October 1944 would have had HVSS. Some may have been shipped to Europe in time to be distributed before VE Day, but we don't know of any combat "shots" of them at present. As of December 31, 1944 it was reported that there were 24 M4(105)s in the UK with training and experimental establishments, and that there were NONE in Northwest Europe with the 21st Army Group, likely reflecting Field Marshall Montgomery's dislike for the type. Starting in October 1944, M4(105)s were distributed by the 15th Army Group in Italy, and at the end of the year, 100 were reported on strength with British, Canadian, South African and Polish units, with another 46 in reserve. The above shows 4 M4(105)s of the Pretoria Regiment, 6th South African Armoured Division engaged in a fire mission, February 18, 1945. By the time of the Spring Offensive, 3 of the 4 squadrons of the Regiment are reported to have been equipped with 3 M4(105)s, along with 8 M4A1(76)s and 3 "M4A4 w/17 Pounder Gun" (Fireflies).

A front view of another South African M4(105), or "Sherman IB" according to Commonwealth nomenclature. The crew’s cap badges and the circle tactical marking suggest that this was a Sherman of C Squadron, Prince Alfred's Guards. This tank can be seen with the early glacis pattern with “inboard” lifting rings and long bullet splashes. The ventilator between the drivers' hatches is "still" open. However, the "later" commander's vision cupola and the automobile type horn suggest that this unit was accepted in May or June, 1944. At present, we don't have any evidence that ANY Commonwealth 105mm Shermans were shipped with the earlier commander's split hatch. Note the installed canvas mantlet cover, also seen on the tanks in the previous photo. While the T48 rubber chevron tracks are the most common type noted on 105mm Shermans, the T54E1 steel chevron tracks seen here have also been observed. The track attaching tool (arrow) hints that the crew may have done some recent repairs. The small fitting that we have circled held a "Sun Compass," a disc type navigation tool. We could not find a single photo of a Sherman with the compass actually in place on the bracket, but the inset shows it on Monty's Grant. Despite the questionable utility of such a navigational aid in Europe, starting around mid 1943, the British prevailed on the US to have the fitting welded on to all Commonwealth Lend Lease Shermans processed for export at US Depots. We would assume a Sun Compass was also provided as "On Vehicle Materiel." Counting heads suggests that the 593 Lend Lease M4(105)s were assigned British War Department Numbers within a range set aside for 2000 "M4/M4A4" running from T-269094 through T-271093. Our subject appears to be T-269533.

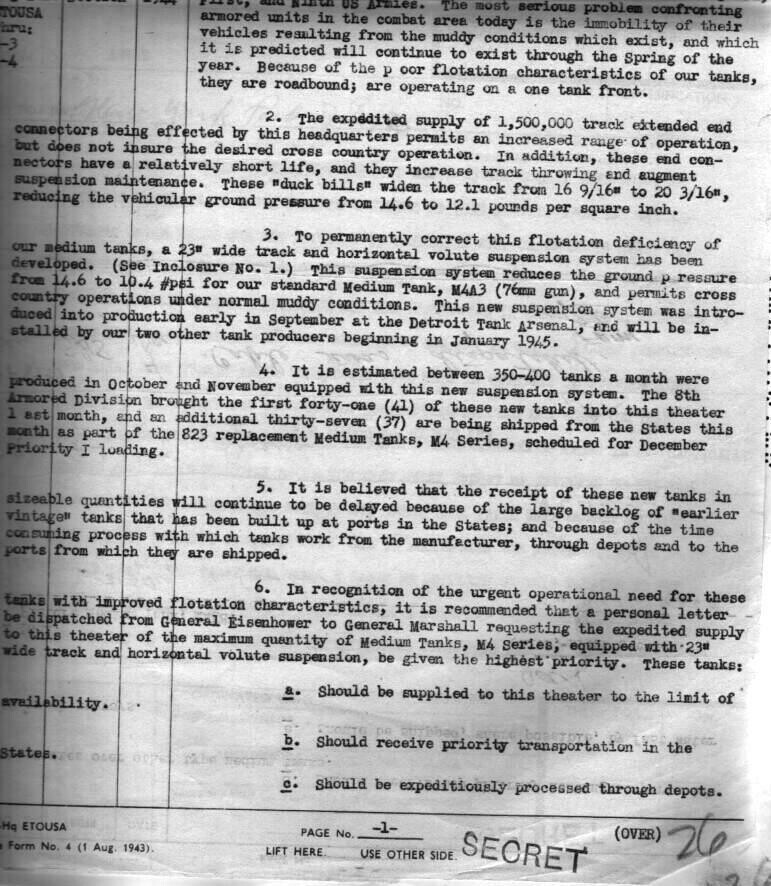

In December, 1944 the Armored Fighting Vehicle & Weapons section of the US Army in the European Theater of Operations (ETOUSA) circulated a Memo regarding the "urgent operational need" for Shermans equipped with Horizontal Volute Spring Suspension (HVSS). We've reproduced the document since it provides a fairly thorough background of the flotation problem. The average shipping time for a new tank to get from factory to fighting troops was between 4 and 5 months, and paragraph 5 explains some reasons for the "time consuming process." Thus by the time this Memo was written, it was more or less too late for a rush order or "redball" of only HVSS Shermans to affect the war in Europe. In any case, the Memo has it that the 8th Armored Division brought the first 41 HVSS Shermans into the ETO. These appear to have been all M4A3(76)s, and we would note that the Division arrived in the UK on November 19, 1944, but did not land on the Continent until January 1, 1945, and didn't enter combat until January 19. In the meantime, records indicate that some M4A3(76)HVSS Shermans were distributed to US combat troops during the last few days of December, 1944. In truth we cannot pinpoint the ETO combat debut of the 105mm Sherman with HVSS any more accurately than "around February or March, 1945." The "Assault Guns" did not suffer heavy attrition, so there aren't many listed in casualty reports. The earliest M4A3(105)HVSS we have noted at present is USA 30111426 of the 777th Tank Battalion, which was recorded as suffering repairable artillery fire damage on March 3, 1945.

An ETO Informational Memo states that "Every effort is being made to expedite the shipment of Medium Tanks, M4A3 (76mm gun and 105mm Howitzer) equipped with 23" wide track to the limit of availability. A total of three hundred and twenty eight (328) 76mm gun tanks and one hundred forty three (143) 105mm Howitzer Tanks with this improvement are scheduled for December lift to Northern France." As they arrived, the M4A3(76)HVSS's were distributed evenly among the various Armies with the object of replacing as many 75mm Shermans as possible. Services of Supply in the US had suggested that 105's with HVSS might also be used to replace 75mms. However, ETO rejected the idea, "additional 105mm howitzer M-4 series medium tanks with wide tracks in lieu of 75mm gun tanks not acceptable. There is a reluctance to substitute the 105mm howitzer tank in the tank platoon because of the lack of power traverse mechanism." In any case, it would have taken several weeks for these to arrive at the ports, get unloaded, get processed for issue, and finally get distributed to combat troops. On February 4, 1945 the First (US) Army Group allocated 20 "M4A3 (105 how with 23" track)" to the Ninth Army. This is the first instance we have found that specifically mentions the type. The Signal Corps photo above is dated January 25, 1945. While not a “combat shot,” it is the earliest example we have encountered that shows an M4A3(105)HVSS “in theater.” The caption has it that a pair of Ninth Army officers are "examining one of the new M4A3 tanks," so perhaps it was one of the 20 units allocated to the Ninth Army on February 4. This tank appears to be nearly "Ready For Issue.” The shipping brackets (arrow) on the front and rear bogies were directed to be removed upon final delivery. "Failure to remove this bracket when unloading the vehicle from the freight car often results in damage to the tracks when operated over rough terrain." No location is given, but the shipping destination code is "HAIL," indicating the port of Antwerp. The last 3 digits of the Registration Number can be seen as "413, leading us to speculate that it is USA 30111413, accepted in September, 1944, the month that Chrysler began the transition from the production of VVSS to HVSS Shermans. Note that this tank has Chrysler's original design, single pin T66 track, while the Sherman in the foreground, which we take to be another M4A3(105), has the superior, double pin T80 track, as evidenced by the larger side profile of the end connectors.

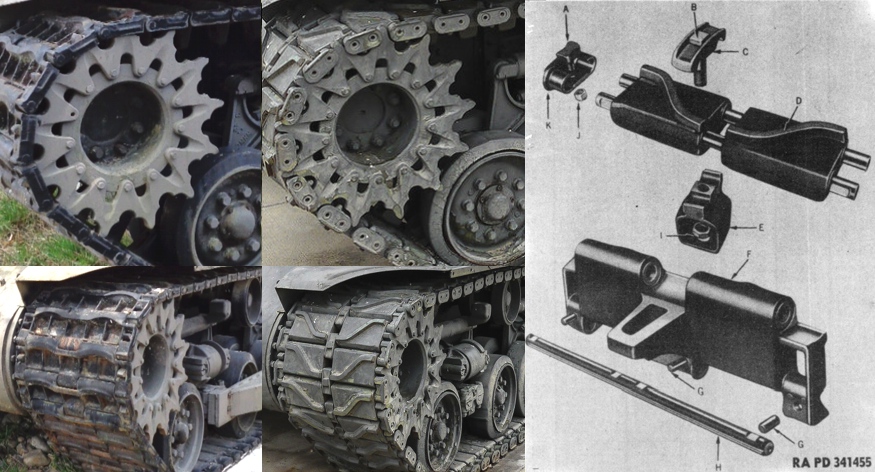

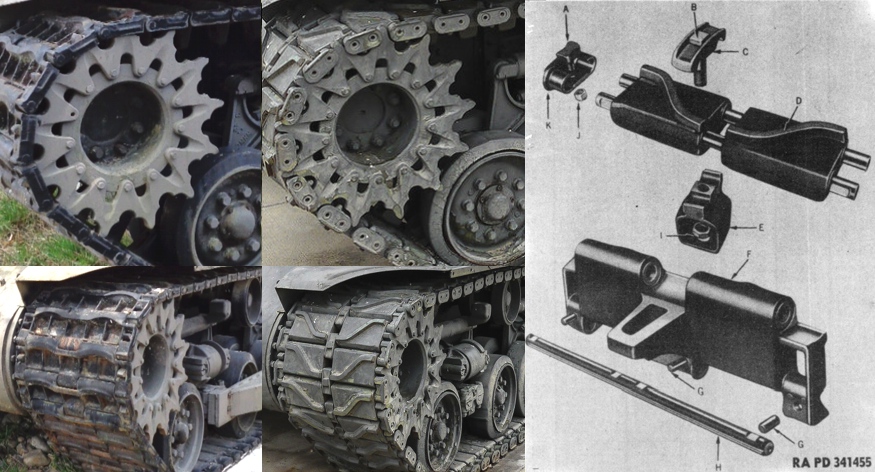

The photo above is dated April 10, 1945, and shows an M4A3(76)VVSS and an M4A3(105)HVSS advancing through the town of Altenhundem, Germany "as the noose tightens on trapped Nazis in the Ruhr Pocket." The men and tanks are identified as with the 99th Infantry Division, and we would observe that the 786th Tank Battalion was attached to the 99th at that time. From this angle, the 105mm Sherman could be mistaken for a 2nd Generation Fisher built M4A3(75)HVSS, except that the 105mm gun was noticeably "thicker" than the 75mm. A secondary clue would be the Chrysler type drive sprocket. Of course, the suspension components were frequently replaced in service, but "in general," Chrysler built Shermans (M4(105), M4A3(105) and M4A3(76)) will be seen with the Chrysler type sprockets, whereas Fisher built units (M4A3(75), M4A3(76), M4A3E2) were factory installed with a much plainer style of drive sprocket. HVSS Shermans overseas during WW II are noted with either the original T66 track seen here, or the improved T80 track. While HVSS suspension was considered as the permanent solution to the "floatation deficiency of our medium tanks," it was developed somewhat late. Extended End Connectors (EECs) were designed as an expedient in an attempt to improve the floatation properties of Shermans with VVSS, which, ultimately, were used on the fighting fronts in much greater numbers than HVSS. Note that the tracks on the M4A3(76)VVSS in the background appear wider than the standard 16 9/16 inches, because EECs are installed.

Above is a nice quality snapshot showing a GI "taking refreshment" in front of his M4A3(105)HVSS in the Spring of 1945. PFC John Sublett was a loader in the Assault Gun Platoon, HQ Company, 745th Tank Battalion. Chrysler painted the Registration Number in blue drab on many of its Shermans, and it can be seen here (circled), although it is partially obscured by a field repair of a damaged rear fender section. The Number is also painted on in the middle of the tank, larger and in white as per an Army directive. USA 30111471 would have been accepted in October, 1944. This tank is equipped with T80 tracks, which were considered a great improvement over the original T66 design. T80 tracks were heavier and consisted of many more parts than the T66. They included steel chevron grousers as seen here (1). The inside surface was rubber backed, which increased the life of the track, and also cut down on the wear and tear of the HVSS suspension wheels. Unlike T66 tracks, T80 tracks were joined together by separate end connectors (2). When viewed from the side, T80 tracks can be distinguished from T66 by their much "thicker" profile. Photo courtesy of Mattie Waldstein via Bill Brewster, http://www2.needham.k12.ma.us/nhs/cur/wwII/06/p2/MW/Sublett.html

Documentary and photographic evidence indicate that a handful of 105 Shermans with HVSS were received by French forces in late April, 1945. The photo above, taken around April 21, 1945, is part of a series that shows train cars of replacement tanks assigned to the 2ème Division Blindée just before it began its final push into southwest Germany. Most of the vehicles seen in this series are US remanufactured M4A1(75)s. Some are noted with the E9 suspension, a modification that only became available in early 1945. A (105)HVSS of indeterminate type is seen on the far left. The On Vehicle Materiel boxes on the engine decks indicate that these tanks have not yet been processed and made “Ready for Issue.” While there is a “combat shot,” taken on April 29, 1945, showing an M4A1E9 of the 2ème DB, at present, no such photos of French 105 HVSS Shermans have been found. As for the other French Armored Divisions (1ère and 5ème Divisions Blindée), it is thought that they were not equipped with any 105’s until April, 1945. Documents from the French Archives in Vincennes report that 18 "M4A3 105mm" were listed as “authorized” starting late January, 1945, but it is only from April 29 through May 5, 1945 that they become listed as “on hand.” We would observe that period photos from the Summer of 1945 suggest that most of these tanks were M4(105)HVSS, although "La Marne III" [photo’d during a parade in Paris on 18 June, 1945] can be seen clearly as an M4A3(105)HVSS. Photo courtesy of Musée de la libération-Jean Moulin-Ville de Paris.

While there is ample evidence of the WW II combat use of M4A3(105)HVSS Shermans in Europe, the only hint we have found so far of the combat use of M4(105)HVSS’s in the ETO comes from the 20th Armored Division. The 20th was alerted for overseas movement in the Fall of 1944, and “was scheduled to go over carrying more of its organic equipment than had ever been attempted.” That is, they brought their AFVs with them, whereas most armor units in Europe drew their equipment upon arrival. At that time, the TO&E of an Armored Division would have included 168 75mm or preferably 76mm Shermans, along with 27 with 105mm Howitzers. What is unusual at this late stage, is that the 20th’s Tank Battalions appear to have been equipped almost entirely with M4 and M4A1 Shermans with Continental Radial engines, as opposed to the preferred Ford V8 powered M4A3s. The Division arrived in Le Havre, France in February, 1945, and the available period photos show remanufactured M4 and M4A1(75)s, M4A1(76)s with VVSS, and a few M4(105)s with both VVSS and HVSS. It was the Army’s practice to issue new tanks to units slated for combat, so it is thought that all of the 20th AD’s Shermans would have been new production or newly remanufactured, issued in the months preceding the unit’s deployment to the ETO. From northern France, the Division convoyed across Europe until it arrived in Würzburg, Germany on April 23, 1945, where it was assigned to the US Seventh Army. It saw action the next day and was officially credited with 8 “Days in Combat.” While we can’t offer a “combat shot” at present, it is our contention that the Division’s M4(105)HVSS Shermans would have served. The photo above shows M4(105)HVSS, USA 30112141 (Nov. 1944 production) in the Austrian Alps in late May, 1945. Courtesy of Mary-Ann Dahlquist-Downs, the daughter of Sgt Henry Dahlquist (2nd from left) of HQ Co, 65th Armored Infantry Battalion, 20th Armored Division.

As best we have been able to determine, combat use of the 105 Sherman series in the Pacific Theater of Operations was limited to the US Army (not Marines) in two 1945 campaigns - the Philippines and Okinawa. Units that have been noted to have had 105s in the Philippines include the 44th, 716th and 775th Tank Battalions. The Assault Gun Platoon of the 716th TB seems to have been the first unit to use its 105s in combat when it took part in the January 9, 1945 assault landing in Lingayen Gulf in northern Luzon. From photographs, it would appear that all of the Assault Guns used in the Philippines were M4(105)s with VVSS. These Signal Corps photos are the earliest we could find that show a 105 Sherman in the PTO. They were taken on November 16, 1944 at the Base Ordnance Depot in Oro Bay, New Guinea, and document the premature shell burst of a H.E.A.T. round that destroyed the howitzer gun. The USA Number is partially visible as 30104XXX, indicating June, July or August 1944 acceptance. Note the (damaged) sheet metal cover (1) over the ventilator between the drivers' hatches, as well as the rear view mirrors (2). "Counting heads" suggests that these were introduced in July. We would assume that the elongated smoke mortar sleeve (3) was factory, not depot, installed. If so, this would be the earliest instance of this item that we have noted on a 105mm Sherman. The armored periscope cover (4) is of interest, in that these are not seen on overseas WW II Assault Guns except on a few examples photographed in the Philippines. Perhaps they were retrofitted at Oro Bay? The 775th Tank Battalion arrived at Oro Bay on June 20, 1944, and set up their camp at a race track. They report that they drew their tanks on Sept. 1, no doubt from the Base Ordnance Depot. They departed Oro Bay for the M1 [Luzon] Operation on LSTs on Dec. 22, 1944.

Most of the 775th Tank Battalion came ashore in Lingayen Gulf on "D plus 2" - January 11, 1945. The Battalion’s records are very generic, and simply describe their tanks as "Medium," "Light" and "Assault Guns." From photos, we would surmise that each of their Medium Tank companies was equipped with 17 M4 Composites and 1 M4(105)VVSS. US Army Tank Battalions in the Pacific frequently mentioned that they were not supplied with Tank Retrievers, as per the standard TO&E. Consequently, their losses were more severe than necessary, as the Japanese placed a high value on the destruction of disabled and abandoned tanks. The Battalions often used other tanks as recovery vehicles, such as shown in the scene above. This photo is dated 22 April, 1945, and the caption reads, "A bulldozer of the 117 Engr Bn, 37th Div and a Sherman tank of Co B, 775th Tank Bn pulling a Sherman tank just after it had hit a road mine, near Baguio, Luzon, PI." Note the WW II use of "Sherman tank" in this caption. The Assault Gun appears to be named "Baby Boy," and can be identified as an M4(105) by the configuration of the engine deck (1). This example features the earlier commander's split hatch (2).

The scene above documents an incident that occurred in the Cagayan Valley on June 13, 1945. The Japanese infiltrated miles behind the 37th Infantry Division's lines and ambushed an "American column." We believe that the tank in the foreground may be the same Company B, M4(105) as shown in the previous caption. This unit features the first smoke mortar configuration (1) with the hole mounted flush with the surface of the turret. Counting heads suggests that Chrysler transitioned to the mid glacis pattern, the sheet metal vent cover (2) and the rear view mirrors (3) (fittings only seen here) in July 1944. We can confirm that the transition to the commander's vision cupola began in May 1944. Most transitions took about a month to complete, so the presence of the split hatch on this tank is somewhat unexpected. However, in a Pacific Warfare Board Report dated July 18, 1945, and based on interviews with officers of the 44th, 754th and 775th Tank Battalions, it was stated that, “The only vision cupolas received in this theater have been on a few tanks equipped with 105mm howitzers. In all cases the cupolas were transferred to command tanks.” Thus, it would seem, the 105 Shermans’ vision cupolas were considered better used on the Battalions’ command tanks. The armored periscope cover (4) is also unexpected, and at present, has only been noted in a few photos of the 775th Tank Battalion's Assault Guns. The M4 Composites of the 775th are fairly well represented in the photos of the Signal Corps collection, and the spare tracks seen on the sides of the turrets in this and the previous image are typical of their Shermans.

The only other use of 105 Shermans in the Pacific that we have been able to document took place on Okinawa, site of "The Last Battle." The records of the various Tank Battalions provide fairly accurate information about the units' Shermans, including the USA Registration Numbers of combat casualties. The 763rd Tank Battalion did not list any Assault Guns on strength during the Leyte Campaign, but noted that "6 Medium Tanks M4 (105mm)," were transported to the Okinawa beachhead on a single LSM. For neutralizing caves and other strongpoints, the 763rd employed "Tank, Flamethrower and Assault Gun teams" that consisted of one platoon of standard tanks (2-3 M4 Composites to start), 2 flamethrowers (M4 Composites of the 713th Tank Battalion, Armored Flame Thrower, Provisional which had their 75mm guns replaced with flame throwers), and 2 assault guns. "Assault guns and flamers would be kept well behind the standard tanks until suitable targets were located." The Flame Thrower Shermans are described in a number of reports as the most important weapon used during the campaign, while the Assault Guns were valued for the destructive power of their 105mm guns. During the course of the campaign, the 763rd reported the total loss of 2 of its Assault Guns, both described as "M/4 w/105mm." USA 30111886 was hit and burned by artillery fire on April 7, while USA 30111876 was destroyed by a mine on May 21, 1945. The USA Registration Numbers of both of these indicate that they were accepted in September 1944, and were among the first M4(105)s to be built with HVSS. It is not known if all 6 of the 763rd's Assault Guns had HVSS, but the photo above shows an M4(105)HVSS, reportedly of the 763rd TB. Another appears in the background, directly behind it.

Unit Reports suggest that, at the start of the Okinawa Campaign, the Assault Guns of the 706th, 711th & 763rd Tank Battalions consisted entirely of M4(105)s (as opposed to M4A3(105)s). Moreover, all of the Registration Numbers listed in combat casualty records correspond to M4(105)HVSS Shermans produced in either September or October, 1944. The photos above were taken in June, 1945 shortly before the end of the Okinawa Campaign. They show M4(105)s with HVSS, along with some Flamethrower Shermans of Company A, 713th Tank Battalion. The Signal Corps photo captions provide no useful information, and some authors have assumed that the Assault Guns were HQ Company of the 713th, but records reveal that the specialized 713th was entirely and only equipped with 54 M4 Composites that had been converted in Hawaii to Flamethrowers, and given the nomenclature "POA-CWS-H1." Note the M4A3(75)W with Speed Number 43 (1). A close examination of the original print revealed that this tank was USA 3082598, and carried the name "China Clipper." This could be cross referenced to the records of the 711th Tank Battalion, which leads us to speculate that the photo shows the Assault Guns of the 711th. The unit with a camouflage pattern on the turret (2) is a popular modeling subject. It can been seen to have Speed Number 6 on its wading trunk. This cross references to USA 30111892 (Sept. 1944 production) of HQ Company, 711th. This tank was reported damaged, but repaired when a piece of shrapnel entered the gun barrel.

As mentioned previously, the US Government had wanted to provide its troops with late model M4A3 Shermans with the superior Ford V8 engine. For the "Last Battle," the only unit entirely equipped with 2nd Generation M4A3s was the ill-starred 193rd Tank Battalion. The details are somewhat obscured in the Battalion's After Action Reports, but the 193rd suffered heavy losses in its combat debut around Kakuza Ridge on April 19th. Losses continued to mount, until on May 1st, "Tenth Army ordered all serviceable medium tanks turned over to other combat units as follows: 711th Tank Battalion - eleven (11) tanks, 706th Tank Battalion - nine (9) tanks, 763rd Tank Battalion fourteen (14) tanks." Losses had been heavy in all of the Army's Tank Battalions, and because of shipping shortages and poor planning, no replacement tanks were available. Thus the 193rd's Medium Tanks became replacements. Three of the 193rd's six Assault Guns were lost to AT Mines on April 19th, and the "after the battle" photo above shows "Big Boomer," USA 30103524 (July 1944 production). In order to ensure its complete destruction, Japanese troops satchel charged this tank after it had been abandoned. M4A3s had large engine deck doors with debris catching chutes (1), officially known as "splash shields," on the bottom. When opened, the engine doors were supported by a "stop" (2) as seen here.

USA 30111207 (August, 1944 production) was another of the 193rd's M4A3(105)s which was reported lost on April 19, 1945. It was damaged by an "AT mine" and satchel charged by "later enemy action." As the fighting moved on, battalion maintenance was able to recover and repair many of the 193rd's KO'ed Shermans so that they could be provided as replacements to the other Army Tank Battalions. Of interest is that USA 30111207 was reported recovered, "and was converted to M4A3-75mm, by use of 105mm How Hull and repairable 75mm turret." This tank is featured in several Signal Corps photos dated July 6, 1945. It was used to demonstrate a modified configuration of the "Backscratcher mines" which had been installed in Hawaii on some of the 193rd's Shermans. In theory, these would be triggered from inside a buttoned up tank with the explosions intended to defeat Japanese tank swarming attacks. Backscratchers were reported to have been used a few times in combat on Okinawa, but the effect "was hard to determine." In any case, we've pointed out some of the features of this 105 to 75mm conversion in the photo. The 706th Tank Battalion used three digit Speed Numbers that began with 7, so the "734" seen on the turret suggests that 30111207 may have been provided as a replacement to the 706th. The 193rd reported 30 tank casualties between April 19th and April 28th 1945. However, in the end, the 193rd's battalion maintenance reported a "net loss after salvage and repair operations" of only 3 75mm and 2 105mm Shermans.

The capture of Okinawa provided an essential base for the invasion of Japan. General Douglas MacArthur's planners scheduled an assault on the southern island of Kyushu for November 1945, to be followed by an invasion of the main island of Honshu in March 1946. It was intended to outfit each participating Army Tank Battalion with the latest model tanks including M26s, M4A3(76)s and M4A3(105)s with HVSS, along with M24 Light Tanks as shown in the proposed July 1945 TO&E reproduced above. The Marines continued to prefer the 75mm Sherman over the 76, and their plans included the use of M4A3(75)s and M4A3(105)s with HVSS. It was stressed that all of the M4A3(105)s taking part must be equipped with power traverse. For the Army and Marine Armored units to be equipped for the operations, approximately 300 M4A3(105)HVSS Shermans including reserves would be required. Document courtesy of Trent Telenko.

The Chemical Warfare Service in Hawaii converted 70 75mm and 105mm M4A3 Shermans to POA-CWS-H5 Flame Thrower tanks at the request of the Marine Amphibious Force. The "H5" addressed the primary complaint regarding the "H1" as used on Iwo Jima and Okinawa. It retained the tank's main gun in order to "afford the armored flame thrower some means of self-protection, [and making] the armored flame thrower units less dependent on standard tanks for over-watching support, in that their sections could cover each other as they attacked sheer flame thrower targets." A disadvantage of the design was that the flame gun (1) in combination with the main gun created a distinct silhouette that easily identified the tank to the enemy as a flame thrower. The H5 had the same flame fuel capacity as the H1. However, in order to achieve that, the number of rounds carried was reduced to 40 for the 75mm and only 20 for the larger rounds of the 105mm howitzer. The exact breakdown of H5 types is not known, but it is thought that the majority were converted from M4A3(105)HVSS Shermans, some of which the Marines later used in Korea. The photo above shows what is thought to be the 35th production POA-CWS-H5 undergoing a shakeout on Oahu in July, 1945. We suspect that this is a Spring 1945 production M4A3(105)HVSS with factory installed armored periscope cover (2), the revised turret casting with “bump out” (3) for the commander’s cupola, and the improved T-shaped towing shackles (4), which provided for the "quick release" of a tow cable, since the cable could be hooked or unhooked without having to remove the shackles as on the earlier type.

As has been mentioned previously, the Sherman had an excellent power traverse, and the decision to omit it on the 105s was the subject of many complaints from the using arms. "It was anticipated that the 105mm howitzer tank would be equipped with a turret power traverse mechanism and would be employed as a "fighter" tank, similar to gun tanks. However, the employment of the 105mm howitzer tank has been largely restricted to the support of gun tanks, and losses have been relatively low." It was agreed that power traverse would be included in future production, but it came too late for WW II. An AFV&W, ETO Memo dated March 31, 1945 states that "Howitzer tanks equipped with turret power traverse mechanism should become available at the port in April." We would note that this suggests an introduction date of March, 1945. Our counting heads method suggests that the transition began in mid March at around Serial Number 73000 for the M4A3(105)HVSS. M4(105)HVSS production was terminated at the end of March, and we suspect that a small number of these were built with power traverse. A mid 1948 inventory singles out power traverse, and lists 28 M4(105)s along with 1369 M4A3(105)s, all with HVSS, in the US at that time. In any case, in the Spring of 1945, there was a 71% reserve of howitzer Shermans in the ETO (1082 on hand vs. a T/E requirement for 633). It was considered "undesirable to introduce large additional quantities [with power traverse] into the theater solely for the substitution of tanks now in the hands of troops." Consequently, it was recommended that further shipments, even with power traverse, be cancelled. We would observe that the power traverse mechanism was not installed at the front as on other Shermans, but was shoe horned in in the rear as shown in the TM illustration above.

After looking inside a number of surviving 105mm turrets over the course of the years, one of the authors, Pierre-Olivier Buan, finally found an example that still has the power traverse mechanism “shoe horned in in the rear,” almost exactly as shown in the Tech Manual illustration above. Had power traverse been installed from the start, the 105 mm Shermans may have been used more aggressively, and merited the name “assault gun.” However, we can’t help but think that the addition of this item, particularly in the rear, only exacerbated the already cramped crew conditions inside the turret. Other objects seen here include the radio shelf (1), part of the ducting for the rear ventilator (2), and the support for the commander’s seat (3).

An interesting "sidebar" concerning power traverse was mentioned in a November 1944 Status Report issued by BG. Joseph A. Holly, Chief of the US Army's Armored Section. "Service Test of a 105mm Howitzer installation in the larger 76mm gun type turret has been completed. This turret provides 1/2" more armor protection and a power traverse mechanism. Approximately four (4) months will be required to introduce this installation into 105mm Howitzer tank production." Obviously, this was never implemented, and unfortunately, we could not find a Report or any photos of the test installation. It is thought that this configuration, along with providing power traverse, would have ameliorated the cramped and smoke filled working conditions inside of the smaller turret. We have substituted a photo of a similar installation as designed for the T26E2, later standardized as the "M45 (105mm Howitzer)." Chrysler initially received orders for 1851 units as part of the 1945/46 Army Supply Program. Ultimately, only 185 were produced from July through September 1945 before the contract was terminated with the end of WW II. Had they been available in time, the T26E2 would have replaced 105 Shermans. As it was, Army planners called for the use of M4A3(105)s with HVSS and power traverse for the invasion of Japan. The photo above shows an M45 fording the Kumho River on 18th September 1950. This tank, which is named "Helen," is thought to be one of six M45s that equipped the Assault Gun Platoon of the 6th Medium Tank Battalion, 24th Infantry Division during the early months of the Korean War.

Another interesting diversion we might mention is shown above. In the Summer of 1944, Chrysler Engineering mounted a T26E3 (M26) turret on a June 1944 production M4(105)VVSS hull, USA 30103950. This was possible since both the Sherman and the Pershing had 69 inch diameter turret rings. On a trip to the US in July, General Holly had been informed that there was no possibility of getting ANY T26E3 Heavy Tanks overseas "during the current calendar year." He looked at the M4 with T26E3 turret shown above as a potential alternate path to deploying 90mm gun tanks overseas in 1944. "All factors considered, had we been able to get immediate deliveries, it would have presented tempting possibilities. It was estimated, however, that deliveries could not be made prior to January, and any cobbling program would interfere with the production of the T26. There was no net gain in selecting the cobbled M-4. Decision was made not to proceed with any cobbling of M-4, and to devote all facilities available towards furthering T-26 production." General Holly went on to state that, "We were more fortunate in immediate results obtained towards delivery of the 90mm Tank Destroyer, M-36." He reported that the first 50 M36s destined for the ETO had been shipped to port on July 9, 1944, with a total of 446 to be made available through September, 1944. No doubt some of the M36s seen in Belgium in the October 1944 photo featured earlier in this piece were some of the first arrivals.

We find no evidence that the US Marine Corps used any 105 Shermans in combat during WW II. They are reported to have received 289 M4A3(105)HVSS’s during the final days of World War II. The photo above shows a good many of them processed for overseas shipment at a West Coast Depot in July, 1945. The figure of 289 is somewhat baffling, since it represents approximately four times as many such units, even assuming 100% reserves, as Marine Tank Battalions would have needed for the Invasion of Japan. One possible explanation is that perhaps, at the last minute, USMC planners decided not to use 75mms, but opted instead to equip their Tank Battalions entirely with M4A3(105)HVSS Assault Guns (assuming with power traverse) for the Invasion? In any case, it is thought that most or all of the M4A3(105)s received by the Marines would have had power traverse simply because it was required by the planners. Thus, for all intents and purposes, 105s without power traverse were rendered obsolete. As a matter of fact, at a Flame Thrower Design Conference in Washington D.C. in June, 1945 it was "suggested that a number of M4A3-105 mm. Howitzer tanks without power traverse were considered obsolete and should be available for the T33 project." The USMC had its own registration number system, which towards the end of the War, consisted of 6 digits, beginning with "10" (circled). As with British WD Numbers, USMC Numbers have no correlation to the tanks' Serial and USA Registration Numbers, and so are useless for determining production dates. However, the US Army Registration Number was commonly stenciled on the OVM boxes, and we've pointed out USA 30137154, which would have been accepted in April, 1945 after power traverse was introduced in mid March. By April, the turret smoke mortar would have been eliminated, and the armored exhaust deflector would have been factory installed. Note the new deflector's tell tale hinge. Furthermore, it is our theory that the armored periscope covers seen on these tanks were introduced by Chrysler in March, 1945, at about the same time as the introduction of power traverse.

Click on the image for larger size

A "Report of Modifications Entering Production at Facility (sic)" dated February 15, 1945 has it that the "Armor Plate Exhaust Deflector" (1) was installed on Chrysler M4A3(105)s starting January 1, 1945 at Serial Number 65303. We cannot verify that through "counting heads," since this item was retrofitted to large numbers of Ford engined AFVs by a Modification Work Order Kit that became available in April 1945. The undated photo above shows M4A3(76)HVSS and M4A3(105)HVSS Shermans at the Detroit Tank Arsenal with the new deflectors mostly in the "up" position. The "Cross Bar Towing Hook" or "T-shaped towing shackle" (2) was reported to have been introduced in early December, 1944 at SN 64212 on the M4(105) and SN 64040 on the M4A3(105). In January 1945, the Ordnance Department ordered that the 2 inch smoke mortar be eliminated from the Sherman. It would take a month or two for the factories to implement this change, and we would note the Shermans seen here "still" have the mortar sleeve installed (3). To us, this would tend to date this photo, January, February or perhaps March, 1945 at the latest. The rammer staff fittings on the left rear sponson (4) are present, and counting heads suggests that they were not factory installed on M4A3(105)s until October, 1944. The reason for this omission remains a mystery, since they were installed from the beginning on M4(105)s. Another mystery omission involves the "Armor Protection around Gunner's Periscope." M4A3(76)s incorporated this item (5) from the start, but unlike the USMC Shermans in the previous image, note that it is "still" not installed on the M4A3(105)s in this photo (circled).

It was planned that the tanks that the US Marines would use for the invasion of Japan would be M4A3(75) and M4A3(105) with HVSS. For the sake of "maximum interchangeability," the USMC requested 50 Tank Recovery Vehicles based on new production M4A3s with HVSS. As originally designed, M32 series conversions had been approved only for VVSS Shermans. The standard tank retriever had a lifting drum attached to the right drive sprocket to raise and lower the boom. At the time, it was not known if the standard sprocket lifting drum configuration would work with the wider 23 inch HVSS tracks, so engineers created a pilot model (shown above), and modified the original design by replacing the lifting drum with a "boom raising sheave" (1). In February, 1945 Army Service Forces authorized procurement of 50 units, and since this conversion did "not correspond to current production Tank Recovery Vehicles, M32B3," it was assigned a separate designation of "Vehicle, Recovery, Tank, T14E1." In April 1945, Chrysler was ordered to divert an additional 30 M4A3(105)HVSS Shermans from its lines for conversion to T14E1 at Baldwin Locomotive Works. Ultimately, according to the December 1945 "Summary Report of Acceptances," 80 T14E1s were produced during the year 1945 - 30 by Baldwin Locomotive and 50 by International Harvester. Since these were done specifically for the USMC, it seems possible that they and any M4A3(105) based POA-CWS-H5's were included in the total of 289 M4A3(105)HVSS Shermans reported to have been distributed to the Corps during WW II.

Above shows another view of the West Coast Navy Depot in July, 1945. We've labeled the T14E1 in the middle distance, and would note that there are quite a few additional tell tale boom raising sheaves protruding in the background of the photo. We've also labeled an M4A2(75)VVSS and M4A3(75)VVSS. Most likely these were unallocated from the Marines 1944 or earlier Sherman requirements, and without HVSS, would not have been wanted for the planned Invasion of Japan. Indeed, due to the Japanese surrender agreement on August 14, 1945, it seems unlikely that any of the AFVs seen here were shipped overseas before that. While they were “too late” for World War II, some of the T14E1s, M4A3(105)HVSS’s and POA-CWS-H5's performed valuable service with the Marine Corps during the Korean War.

An August 1948 "Medium Tank Status" Report provided an inventory of remaining M4(105) Shermans. It indicated that, out of a total production of 841 M4(105)HVSS, there were 594 units "still" present, only 28 of which had power traverse. 546 were in Depot storage in the US, "NRFI" (Not Ready For Issue). 39 were in Depots, "RFI." Only 9 units M4(105)HVSS were reported with Troops in the US or Overseas. Out of the total production of 800 M4(105) with VVSS, only 182 were listed in the inventory, all in Depot storage, NRFI. In the greatly downsized post war US Army, these tanks would not have been considered as acceptable assets, because of their radial engines. Many were distributed to Allies as part of the Mutual Defense Assistance Program of the early 1950s. France appears to have been the largest recipient of the M4(105) at 230 units, divided about evenly between VVSS and HVSS models. The photo above is dated April 26, 1951 and features some units of the French 2nd Army Corps (possibly the 30th Dragoon Regiment) parading in Marburg, Germany. The lead tank still has the "TILE" shipping code stenciled on the differential housing. "TILE" was the post war destination code for the port of Cherbourg. Counting heads suggests that the second type of canvas mantlet cover (1) was introduced after M4(105)VVSS production ended in September, 1944. This would suggest that the original turret was replaced, or more likely that the newer dust cover was retrofitted as a modification. The presence of the armored aperture cover for the gun sight (2) suggests that the original rotor shield, or the entire 105 Gun Mount, was replaced when this tank was processed for MDAP shipment. Another post war modification seen here is the single piece locking arm on the gun travel lock (3).

The August 1948 "Medium Tank Status" reported that there were 1398 M4A3(105)s with HVSS and Power Traverse in the Army's Inventory. An additional 521 M4A3(105)s with HVSS, but without Power Traverse were also listed. All of the M4A3(105)HVSS Shermans were classified as "Good Resource." Most were in US Depots, but 31 were reported as overseas. There were 455 M4A3(105)s "wo/HVSS" in the Army's inventory, with the note, "The possibility of converting these into a combat resource if necessary should be investigated (possibly using horizontal volute springs in stock or from other tanks not necessary for training." The 105mm Shermans had been greatly overproduced, and these totals were far more than the post war US Army would have required in its armored units. Because they were considered a "Good Resource," many of these tanks were "cocooned" in Depots in the event of emergency. One of the units listed as overseas, is shown above in Seoul, Korea, January 2, 1948. At the end of WW II, Korea, which had been a Japanese colony since 1910, was divided by the Allies along the 38th Parallel. The Soviets joined the war against Japan in August 1945, and it was agreed that they would take the surrender of Japanese Forces and administer the northern part of the country, while the US would do the same in the south. The situation unraveled from there, with reverberations felt to this day. The US 7th Infantry Division was part of the Occupation Force in the south, and the photo shows one of the Assault Guns of the Tank Company of the 31st Infantry Regiment. Of interest is the large and "open in the rear" armored periscope cover (arrow). This appears to have been factory installed by Chrysler on M4A3(105)HVSS's starting around March, 1945, possibly as part of the introduction of the M10D gunner's periscope.

In the immediate post World War II years, the US Army used "lessons learned" through hard fought combat experience to organize its force structure more effectively. In order to improve Tank-Infantry cooperation, the independent Tank Battalion concept was shelved, and instead, each Infantry Division was enlarged by being provided with a permanent Tank Battalion as part of its Table of Organization. Furthermore, and further emphasizing the Tank-Infantry team, a Tank Company of 148 men and 22 tanks was made organic to each of the three Regiments of the standard Infantry Division. According to FM 7-35, "Tank Company, Infantry Regiment," dated June 1949, each Company would be "heavy" in the sense that it employed 4 more tanks than a WW II Tank Company. The headquarters section was to be composed of "two M45 [Pershing] tanks, mounting 105-mm howitzers." The rest of the Company was divided into four platoons, each consisting of five M26s, as shown in the chart above. At the time, this Field Manual assumed that a sufficient supply of M26s and M45s would be available, but that did not prove to be the case. One reason for this has to do with the fact that, as built, the M26 was not completely "combat ready." It used the same 500 HP V8 engine as the M4A3, although it was over 10 tons heavier. Consequently, it suffered from mobility and reliability issues. A rebuilding program that commenced in November 1949 introduced a number of upgrades including an 810 HP engine, new transmission, new gun with bore evacuator, and suspension improvements. The changes were so extensive that the modified M26 was given a new designation - the M46 Patton. A September 1953 revision to FM 7-35 retained the 22 tank company, but replaced the M26s and M45s entirely with M46 Pattons. It is important to note that this revision eliminated the use of tanks mounting 105-mm howitzers. As it was, the M46 itself had a number of teething problems, and the old reliable Sherman continued to play an important part in the US post war Armored Force, at least through to the end of the Korean Conflict.

During its occupation of northern Korea, the Soviets helped form, arm and train the North Korean People's Army. The North invaded the South on June 25, 1950, and quickly overwhelmed the lightly armed Republic of Korea (ROK) troops. US Government officials had publicly declared that Korea was "outside of the United States defense perimeter," practically inviting the North's attack. However, when it occurred, President Harry Truman reversed policy, and made the decision to come to the aid of the South Koreans. All told 6 US Infantry and 1 US Marine Division, along with contingents from various member countries fought under the banner of the United Nations. The tables above are taken from a 1951 Operations Research Office Report entitled "The Employment of Armor in Korea," and show "Allied Tank Losses and Tanks Issued 1 July 1950 to 21 January 1951." These were the most active months of the Korean War, and it can be seen that US Medium Tank issues amounted to 252 M26s, 173 M46s and 516 M4A3s. Unfortunately, the M4A3s are not broken down by type, although it is obvious from photos that nearly all of the Shermans that fought in Korea were M4A3(76)HVSS. A few 105mm Shermans are seen in period photographs, but we would judge that these were not present to the full Table of Organization numbers for US Army Tank Battalions and Companies. Note that the Pershings were delineated in the chart above, as it was reported that along with the 252 90mm M26s, there were 8 M45 (105mm) issued. It is thought that all of these served with the 6th Medium Tank Battalion, and that along with all of the M26s, they were withdrawn from the theater by mid 1951.

Starting in July, 1950, US Forces were rushed to Korea in an initially shaky, but ultimately successful attempt to halt the North Korean blitzkrieg. On August 1, Company A of the 8072nd Provisional Tank Battalion deployed from Japan, and became the first unit with Shermans to arrive in Korea. The hastily trained outfit entered combat the next day near Masan. The bulk of the Battalion arrived by August 4th, and was redesignated the 89th Medium Tank Battalion a few days later. The photo above is from a series dated August 3rd, which shows a group of Shermans and other AFVs recently "landing from LSTs in Pusan." Most of the tanks seen are M4A3(76)HVSS's, but this photo shows that the tank with sand shields is an M4A3(105)HVSS. We recorded the Registration Number from the original print as USA 30140502, indicating April 1945 acceptance (inset). It was reported that 54 “WW II M4A3s” had been collected up and rebuilt at the Tokyo Ordnance Depot in a hurried effort to equip the Battalion, which had been activated in Japan only on July 17th. Early Tokyo Ordnance Depot Shermans have a distinctive appearance with additional track links, sprockets and idler wheels attached to the hull and turret as indicated in the photo. It is unclear if the 89th Medium Tank Battalion ever had a full TO&E compliment of 105mm tanks, but judging by the lack of period photos, we would guess not.

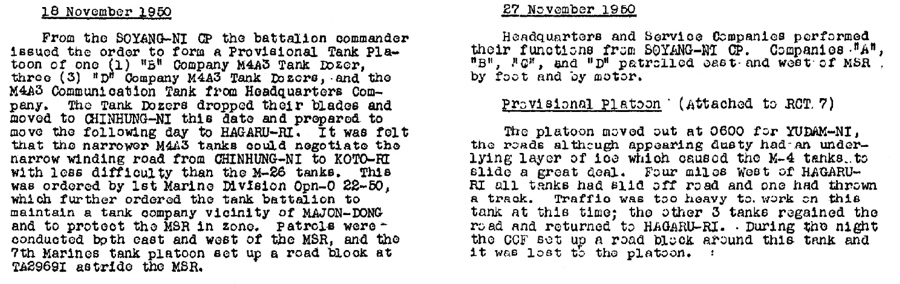

Like most US Army armor units just before the start of the Korean War, the 1st Marine Tank Battalion had been "demobilized" down to a single company. Upon alert for overseas movement in early July, 1950, A Company appears to have been equipped with 18 M4A3(105)HVSS Shermans, including a dozer, along with a single "M32B3" (probably a T14E1). Shortly before this, the USMC had requisitioned 102 M26s, but "it was not known whether the company would be equipped with the M-26 tank or embark with its present M4A3 tank." The decision was made for the M26, and the Company sailed for Korea on July 12 with 17 M26s, an M4A3 Dozer and an M32B3 (or T14E1) retriever. As part of the First Provisional Marine Brigade, A Company arrived at Pusan on August 3, 1950 and convoyed up to Chingdong-Ni, where it first entered combat on August 7. Unit records specifically mention that the "M4A3 Bulldozer" was "Tank number 43," and that the crew "drew first blood for the company" using one of the tank's machine guns. The Signal Corps photo above is dated August 3, 1950, and shows M4A3(105)HVSS, #43, USMC 103247 not long after it had been unloaded from "Navy Ship PA 45 (seen in the background) that brought them to Pusan, Korea." The 1st Marine Tank Battalion was intrinsic to the 1st Marine Division. Fully equipped, the Battalion was composed of Companies A through D, with each Company having 17 M26s, 3 M4A3 Dozers and 1 M32 (retriever). The Battalion also included a Flame Platoon of 9 "M4A3s." Furthermore, each Regiment of the 1st Marine Division included a Tank Platoon of 5 M26s. While the Dozers and Flamethrowers are described generically as "M4A3s," other unit records and photos suggest that all were based on M4A3(105)s with HVSS.

Tank #43, USMC 103247 is shown again in the photo above, taken shortly after one of the few "tank vs. tank" battles of the Korean War. The “Operational Report” of A Company for August 17, 1950 describes the action as having taken place near Obong-ni in the western sector of the Pusan Perimeter. Two M26s of the third platoon (Numbers 33 & 34) ambushed three T-34/85s, which were reportedly destroyed in quick succession from 100 yards out as they came around a blind curve in the road. By late August, the tide was beginning to turn as the all out North Korean attacks failed to break through the Pusan Perimeter. The photo illustrates one of the uses of the Dozer Sherman - road clearance. Unit records mention that the Dozer was used to prepare defensive positions for the Company's M26s, and that #43 fought as well, firing 60 rounds of High Explosive and 40 of White Phosphorous during the month of August. In his “Marine Corps Tank Battles in Korea,” author Oscar Gilbert details another use of the dozer Sherman. The transmissions of the M26s would slip on steep hills, and tank commander Eugene Viveiros explained that “he was called upon “to pat them on the butt end with the blade of the ‘dozer tank to shove ‘em up and get ‘em going again.” The armored first aid box (1) is seen on some, but not all of the Korean War M4A3(105)s. We believe that the Assault Guns received by the Marines in 1945 were produced in March, April or May, and that none of them had the first aid box factory installed. While that was a post production retrofit, the rammer staff fittings (2) and the armored exhaust deflector (3) would have been factory installed by Chrysler.

The rest of the 1st Marine Division (including Companies B through D of the 1st Tank Battalion) was brought up to authorized strength in the US, and was chosen to lead Operation Chromite - the Invasion at Inchon. The Marines landed on September 15, 1950, and quickly moved inland, threatening to cut off the masses of NKPA troops far down the peninsula fighting at the Pusan Perimeter. The 7th Infantry Division landed a few days later and proceeded south toward Suwon, protecting the right flank of the Marines. The photo above is dated September 28th, and shows an Assault Gun of the Tank Company of the 32nd Infantry Regiment, 7th ID in the South Korean Capital of Seoul, the day after it was retaken by the USMC with assistance from the 32nd. This tank may well be an M4(105)HVSS as opposed to the prescribed M4A3. A photo of the same Tank Company taken 3 days earlier shows two 105mm Shermans in the mix, one of which can be seen with the upper rear hull plate and air cleaners indicative of an M4 (inset). Note the stowage configuration typical of a Tokyo Ordnance Depot rebuild. In the opening months of the war, not all of the Shermans were M4A3s with HVSS. "The Employment of Armor in Korea" explains, "The type of tanks assigned have varied because of the limited supply of the authorized types in the Far East."