Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

We would like to thank Daniel Reed, who for nearly 20 years, has been providing us with photos and information about Shermans in the Upper Midwest. Pierre-Olivier (left) and Dan met up for an epic Sherman-spotting tour in 2018. Here they are in Waconia, Minnesota.

First of all, you have to

identify the tank as being an M4A3(75) "small hatch" Sherman tank.

Please visit this

page to do so.

The Ford Motor Company was the

exclusive manufacturer of the “First Generation” or

“small hatch” version of

the M4A3(75). 1690 units were made from June 1942 to September 1943.

There were two Ford M4A3

Production Orders:

P.O. T-3034: 350

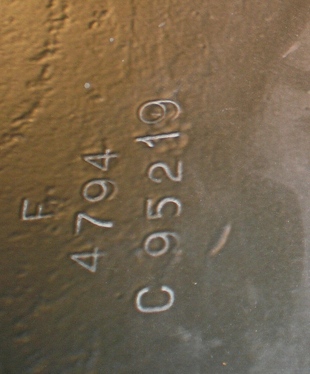

units produced June 1942 thru January 1943 : Serial Number 2655 / USA

3055615 thru SN 3004 / USA 3055964

P.O. T-3334: 1340

units produced November 1942 thru September 1943 : SN 11460 / USA

3053615 thru SN 12799 / USA 3054954

In

late 1941, Ford was contracted to manufacture Medium Tanks powered by

an in house designed 500 HP V8 engine. Since the engine was new and

untested, at first M4A3s were only authorized for use as training tanks

in the US, giving Ford engineers the opportunity to "iron out the

bugs." In comparison tests, the Ford GAA engine was found to be

"superior to any other medium tank power plant now available" and in

June 1943, it was "recommended that the Ford-powered medium tank be

declared suitable for overseas supply and placed in active theaters at

the earliest practicable date." Further recommendations included "Build

a pool of M4A3 medium tanks in all theaters where armored units are

stationed, and replace the M4A1 with the M4A3 as fast as the tactical

and supply situations will permit." Additionally, "reserve Ford-powered

combat vehicles for United States troops." While Ford left the Sherman

program in September 1943, the company continued to supply engines to

Chrysler and Fisher Body for the 1944/45 production of M4A3s and M26s.

During WW II, Ford's Lincoln plant produced 26,954 V8 tank engines

(above). Most of the M4A3s that served in combat were of the 1944/45

production "large hatch" or "Second Generation" type, but period photos

and documents show that a small number of Ford built M4A3s fought in

the final campaigns in Northwest Europe, as well as on Okinawa.

The photo above shows the M4A3 pilot, rolled out on 13 May 1942. The pilot's hull appears to have been based on the shape of an early M4A2. It seems likely that it was assembled using components that were available at the time or perhaps the hull was taken from the assembly line at either Fisher Body or Pullman Standard, both of whom had commenced M4A2 production the month before. Note the odd "bump" (1) on the glacis, a feature observed on some early Pullman, Fisher and ALCO M4A2s. The "bump" was a casting that included fittings on the inside surface for the twin fixed machine guns that were part of the original Sherman design. This casting also included the bow machine gun socket (2). For some reason, the weld seams were ground down or smoothed out on this and some other early Ford M4A3s, which makes it difficult to determine their glacis patterns. The antenna bracket (3) appears to be the early Ford casting, although it has a non-standard extension (4) attached to it, which was also seen on the T6 [Sherman] pilot. This unit is equipped with M3 type bogies (5). As part of its contract, Ford took up the manufacture of M4 bogies, so production M4A3s were outfitted with them from start to finish. The drive sprocket (6) seen here is curious in that it appears to be the type used by Chrysler, although counting heads suggests that it was not introduced on M4A4s until October 1942, 4 months after the date of this photo. As we shall see, Ford made its own drive sprockets which have a very distinct appearance. The odd shape of the engine deck doors (7) can just be discerned behind the legs of the man standing on the vehicle. The standard "chute" or "splash shield" attached to the inside of the doors is not apparent in this case. Ford also produced its own transmissions, and their M4A3s were equipped with 1-piece differential housings from start to finish. Indeed, one of the captions from this photo series states, "The Ford designed, one-piece, final-drive casting was stronger, smoother and eliminated flanges and projectile pockets."

Here we have another photo dated 13 May 1942 showing a rear view of the pilot. The tank was presented at the Ford plant in Highland Park, Michigan where production lines were set up for final assembly of M4A3s and M10A1 Tank Destroyers. Ford had not yet built a tank test track, so the pilot and the next 24 units were driven around a field at Greenfield Rd and Airport Drive while a full-service test track with garage was constructed on Oakland Avenue. Note the "M4A2 angle" of the upper rear hull plate (1) which was much steeper than the angle of the standard M4A3. The single, rectangular engine access door (2) in the lower rear hull appears to be standard, but we believe that this and the second pilot were outfitted with non-standard exhaust stacks (3). We lightened the photo, but it is too high contrast to show them in detail. The fire extinguisher pull housing can be seen protected by 3 plates (4) welded together, an odd but standard feature of Ford M4A3s. Production models had three armored fuel filler caps just in front of the engine doors, but they are not apparent here. If item 5 is a turret splash, it appears to have been mounted pretty far back, so may have been affixed to the hull as opposed to the standard mounting on the forward engine deck panel. This tank was shipped the 40 miles to the General Motors Proving Ground in Milford, Michigan, where it was the subject of "Engineering Test of Medium Tank, M4A3, #1, Ford" curiously dated 27 February 1943. It is listed as GMPG Project Number 8067, and the Ordnance Serial Number is given as 2655. A digest of the report notes some deficiencies, but recommendation was made for approval of the vehicle. However, an "Ordnance representative considered the recommendations questionable because of the brevity of the test." "This 156-page report contains 17 photographs showing various views of the test vehicle and the condition of components after operation." Sorry to say, we have not been able to locate any of those photos, so SN 2655 seems to have "disappeared" (to us at least) after "Presentation Day" 13 May 1942. Officially, the tank was accepted a month later in June. In other words, despite the fact that it was a pilot and pre-production, it was accepted as the first Ford M4A3, SN 2655/USA 3055615.

Ford produced a second pilot which was shipped to GMPG and became the subject of "Test of Medium Tank M4A3 No. 2 Ford" dated 25 January 1943. This tank is listed as GMPG Project 8029 (1), but the serial number is given as "None." Note that the GMPG Number, 8029, is lower than GMPG 8067 assigned to the first pilot. This suggests that the second pilot might have been tested at GMPG before the first. At 459 pages, the report was much longer than that done for Ford #1 and included 12 photographs. Luckily, some of the photos such as the above were preserved. Importantly, they are dated 29 May 1942, which tells us that #2 was at GMPG about 2 weeks after # 1 was rolled out. We find it odd that the GMPG reports regarding Numbers 1 and 2 are dated in early 1943. By then, M4A3 production was in full swing, so any recommendations would have been somewhat useless. It seems likely that preliminary findings were submitted to Ford ahead of the final reports. In appearance, #2 looks nearly identical to the first pilot right down to the "bump" on the glacis and the smoothed-out weld seams. However, this unit was installed with M4 bogies with the original half round track skids, although curiously, the rearmost units were mounted backwards (2). The drive sprockets (3) on both sides are the standard Ford type characterized by little "dimples." Note the "padded" hull lifting rings (4) with which Ford began production. The headlamp plug holders (5) seen here are not present on the first pilot. They were mounted parallel to the glacis to start. The siren (6) seen here is non-standard. Counting heads suggests that Ford used the more common Federal type siren from start to finish. Counting heads also suggests that pilots 1 and 2 were the only Fords bult with the lifting rings on the turret in the "high" position (7).

We thought we would include this rear photo which we have lightened up somewhat so readers can better see the unusual, non-standard exhaust stacks (1) that equipped the two pilots. This unit was installed with the armored fuel filler covers (2) just in front of the engine doors. The outer ones were for the vertical fuel tanks, while the middle cover serviced the engine coolant expansion tank. The outer covers are seen oriented side to side, but they were installed front to back on production units. Again, the rear turret splash (3) appears to have been mounted pretty far back, suggesting it was welded to the hull in this case. For future reference, we would point out that the taillight guards (4) of pilots 1 and 2 completely encompassed the taillights. The trio of signal lights (5) were not part of the M4A3 design. They were added at GMPG and are often seen on AFVs tested there. Five engines were reported to have been used in the tests of this vehicle with "the last one operating for 2000 miles." Keeping the 25 January 1943 date of the report in mind, it was recommended that the M4A3 be accepted by the Ordnance Department but that "further development be undertaken to improve the durability of fan belts, magnetos, tracks and bogie wheels."

This overhead view shows the unusual shape of the engine deck doors (1) observed on pilots 1 and 2. They were "jogged in" at the front to make room for the fuel fillers. The pilots appear to have been the only Ford M4A3s built with the handles of the drivers' hatches mounted towards the rear and on an angle (2). Additionally, these two were produced without grab handles on the commander's cupola hatch (3). Production Ford M4A3s were assembled with so called "wide" drivers' hood castings made by Ford at their River Rouge plant. We have studied the photos of the pilots and think we can see telltale traces of weld seams between the drivers' hatches, but the fact that the seams were smoothed out make it difficult to tell for certain. For future reference, note the straight to the rear orientation of the drain holes (arrow) on the turret's ventilator.

Here we have a photo of GMPG Number 8037, dated 13 June 1942. This tank has been the source of some confusion. It was the subject of "Supplementary Report on Medium Tank M4A3 - Ford" dated 15 May 1943. Again, the tank's Serial Number is listed as "None", but the Registration Number USA 3055616 is clearly visible in the photo. This corresponds to Serial Number 2656, so this would have been pilot number 2, renumbered from GMPG 8029 to GMPG 8037. A July 1945 "Project Summary" found in the library of the old Patton Museum at Ft. Knox, shows that the General Motors Proving Ground did reports on nearly 800 military vehicles during WW II. These projects were numbered GMPG 8000 through GMPG 8801. Some photos have obviously survived, but we have wondered if the full project reports might have been preserved, perhaps at the General Motors Archives, which is, we were told, not open to the public. In any case, the digest for GMPG 8037 reports that "six test projects were run on the vehicle [and] charts, photographs, logs, and repair records of these projects were accumulated into one report." A few changes were made such as the addition of the standard exhaust deflector (1) and a pair of mud flaps (2). The backwards mounted rear bogies were not corrected, but the front and middle welded spoke road wheels seen when it was GMPG 8029 were replaced with pressed spoke wheels (3) on both sides. Ford appears to have used both types throughout production. The protective armor around the fire extinguisher pull housing was altered, and a new rear turret splash (4) with a pair of angled side pieces was installed on the forward engine deck panel judging by its position. The orientation of the armored fuel filler caps (5) that served the vertical fuel tanks was changed from side to side to the standard front to back. It would appear that the engine deck configuration was still a work in progress when these photos were taken in June 1942. We try to record serial and registration numbers from period documents and photos. After its time at GMPG, this unit may have been rebuilt or reconditioned. It must have been sent to Army Ground Forces at Ft. Benning, since USA 3055616 was reported to have been transferred from there on 2 May 1945.

We "suspect" that the 2 Ford pilots would have been the only ones made with the "bump" on the glacis. However, without seeing photos of every Ford M4A3 produced, we really have no way of determining if that was the case. The undated photo above has a generic caption about "Installing the tracks on an M4 tank in Final Assembly." It shows a Ford with "bump" (1) ready to roll off the line at Highland Park. Aside from the bump, this unit shares a couple of other features noted on the pilots. The handle of the bow gunner's hatch can be seen mounted towards the rear and on an angle (2) and the antenna bracket is fitted with the non-standard extension ring (3). This may be a new tank, but our guess would be that it is one of the pilots returned from the General Motors Proving Ground in order to retrofit it with the latest modifications and/or bring it up to current specifications. We tend to think it might have been pilot 1 since the GMPG report digest mentions "the brevity of the test" whereas pilot 2 was said to have been used to test 5 engines which probably took some time. Also, it appears to have the number "1" (circled) painted on the glacis and the hull side. (Other early Ford factory photos show what we assume was a build sequence number painted on in a like manner.) Just visible are M4 type bogies (4), which would have replaced the M3 bogies, assuming this was pilot 1. If our theory is accurate, other additions would have been the Ford type sprocket (5), pressed metal road wheels (6), M34 gun mount with "outboard" lifting rings (7), and the gunner's blade sight (8). Counting heads suggests that the machine gun dust cover fitting (9) didn't enter the Sherman production pipeline until late September/early October so that may tend to date this photo.

This photo is part of a series taken at the Ford plant on 20 July 1942. The Registration Number, USA 3055617, would indicate that it was the third M4A3, and indeed, the Number 3 can be seen painted on. Similar to pilot # 2, USA 3055616, the Registration Number appears to be painted on in black, or at least a darker color than blue drab. Counting heads suggests that Ford started painting their Registration Numbers in blue drab a month or two later. As the first production M4A3, Ford and the Ordnance Department used 3055617 to model the interior and exterior layouts, including the stowage items the parties had agreed would equip subsequent production. Unlike pilots 1 and 2, the hull of 3055617 was assembled with the standard M4A3 angle (1) of the upper rear hull plate, achieved by lengthening the hull by a few inches when compared to the M4A2. As a consequence, the mud flap (2) can be seen positioned further back from its location on USA 3055616, GMPG 8037. Again, the weld seams are conspicuous by their absence. The engines decks were not installed when this photo was taken, and it can be seen that the white interior paint over sprayed a bit. Earlier we wrote "Counting heads also suggests that pilots 1 and 2 were the only Fords built with the lifting rings on the turret in the "high" position." However, here we have another such turret. In addition, the inset shows that the tank had the earlier type of M34 gun mount with the lifting rings mounted very close to the rotor shield. Unlike pilots 1 and 2, the right hatch of the commander's cupola was equipped with a handle (3), although the handles are seen positioned closer to the edge on subsequent Fords. Another item not present on pilots 1 and 2 is the gunner's blade sight (4). Even so, we suspect that the turret and gun mount seen on 3055617 in the July series of photos was not processed at Ford but provided by an outside supplier. At the bottom left, the return roller (5) shows that the rear bogie was mounted correctly on this example. An antenna (6) is installed on the right front which would suggest that the vehicle was configured as a command tank with an additional radio. However, an interior photo taken on that day shows the usual 17 round 75mm ammo bin on the right front sponson, so perhaps the antenna was placed there for show? Oddly, the taillight guards, which completely encompassed the taillights on the pilots, are seen incorrectly installed or "out of spec" (7) on this and other early production Fords. "Product Correction Reports" were submitted by units as they trained. PCRs often resulted in change orders, such as..."The present guard on all M4 welded hull tanks is being moved back to protect the taillight. Starting with Ford Motor Company tank Serial No. 11525, the guard will be properly placed." The tracks are the familiar T51 flat block rubber type.

The photo above shows USA 3055617 at Ft. Knox, Kentucky. While this tank was photographed at Ford in June and July, it would not have been officially accepted until August 1942. The identification panels on the Armored Force Board photos are a bit miserly in their details including dates, but a Road Test Inspection Report (inset) for USA 3055617 is dated 7 August 1942, which suggests that it was shipped from Ford to Ft. Knox immediately. For counting heads, the doc also very helpfully provides the tank's Serial Number - 2657. This side view clearly shows the standard M4A3 angle (1) of the upper rear hull plate. The "dimpled" drive sprocket (2) was the standard used by Ford from start to finish. The bogie wheels (3) on both sides are the pressed metal type. The handles (4) on the drivers' hatches are mounted in the standard location. The simple gunner's blade sight (5) was a standard feature of Sherman turrets until it was replaced in the Fall of 1943. The lifting rings on the turret (6) can be seen in the "low" position. We suspect that the "high" lifting rings turret seen in the June and July photos was replaced with a Ford processed turret before the tank was shipped to Knox. USA 3055617 was Armored Board Project 267 and was used in an M4A3 Engine Endurance Test at least until November 1942. It was reported to have been named "Green Hornet."

When

compared with the pilots and the July photos of 3055617, this front

view shows the later, typical Ford produced M34 gun mount configuration,

with outboard lifting rings (1) on the gun shield, and the protective

side extensions (2) on the rotor shield. As production ramped up, Ford

became a supplier of gun mounts to other builders. The side extensions

were carried over in the design of the M34A1 gun mount which Ford

introduced into production in March 1943. Ford made its own power trains

(inset), and it is reported that, in September 1941, a Ford executive

named Laurence Sheldrick took one look at the M3 Medium's 3-piece

differential housing, and had his engineers design a one-piece unit.

Ford used the one-piece throughout M4A3 production, and indeed, the

Ordnance Department would have immediately and completely replaced the

3-piece if industrial conditions had permitted. The differential

housings of some early Fords are noted with the Part Number E4186 cast

right in the middle as seen here (3). The siren most commonly used on

the M4A3 was the Federal Electric Type 160 with the "V for Victory"

grill (4). Note the exposed electrical conduit (5). Unlike some other

Shermans, the siren remained mounted and unprotected on the left front

fender throughout Ford M4A3 production. The weld seams on the hull certainly

appear to have been smoothed out. We've studied this photo and think we

can see a weld seam (arrow) in the upper center of the glacis. If so,

this would suggest that the drivers' hoods were the standard "wide"

castings used by Ford and Chrysler. The bow machine gun socket appears

to be part of a casting that comprised at least part of the lower glacis

plate. The roughness in the area around the number 6 might hint that

this was a recasting that used a "bump" casting as its pattern. Again,

the "invisible" weld seams make it difficult to tell the width of this

piece. Counting heads suggests that Fords used variations of this

casting up through September 1942, but by October, the company had

settled into a standard pattern that featured a lower glacis of armor

plate into which was welded a small bow mg casting. The fittings (7) for

the driver's foul weather hood are just visible here, and the hood

itself is present on its shelf atop the transmission in one of the 20

July interior photos. So, we might assume that the foul weather hood was

standard equipment from the start or at least early on. On the other

hand, we would judge that the bow machine gun dust cover fitting (8) was

not factory installed until around October 1942, so was likely

retrofitted at Ft. Knox. Recall that this tank had rubber tracks in the

July photo, whereas it has steel tracks, possibly the T49 "cast parallel

grouser" type here. A 1994 article in The Dearborn Historian has it

that "Steel tracks (9) for the tank were manufactured by Ford at the

Rouge [plant], whereas rubber tracks were purchased. Ford supplied one

extra set of tracks for each tank produced."

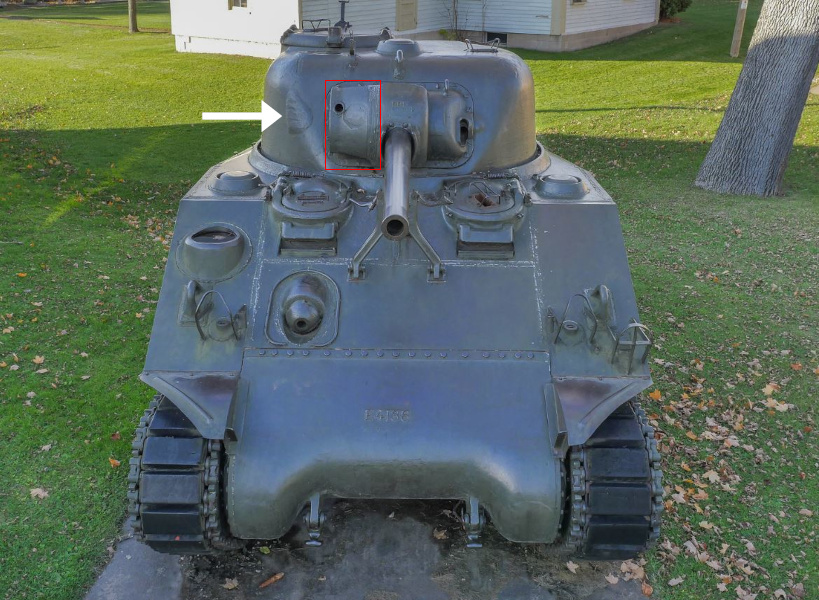

At

this point, we would like to explain what is meant by the terms "wide"

and "narrow" drivers' hood castings. "Narrow" drivers' hood castings

were about 18 1/2 inches wide and were welded directly into the

surrounding armor. As a consequence, the weakest spots were at the weld

joints (in red) at the sides and front of the hoods as seen in the

photo on the left. Wide drivers' hood castings attempted to improve the

situation by eliminating the weak spots on the sides of the hoods by

moving the weld joints away from them as seen in the photo on the

right. Note how the inner sections of the "wide" castings were joined

together at the center to form part of the upper glacis and even a bit

of the turret splash. Chrysler used "wide" drivers' hood castings on

its M4A4s from the very start, including the pilot

model, which was completed on 9 May 1942, a few days before

the pilot M4A3. Most likely Ford communicated with Chrysler or at the

least took a cue from them and adopted the use of wide drivers' hoods.

On M4A3s and M4A4s, possibly because of the use of wide hoods, the

antenna bracket was positioned very close to the edge of the glacis,

whereas it was mounted further inboard on M4s and M4A2s.

Regarding the 2 Ford pilots and perhaps some of the earliest production units, we would guess that their glacis patterns were similar to what is seen on the first ALCO built Sherman, M4A2 Serial Number 1405, which was accepted in September 1942. However, we suspect the Fords, including the pilots, were built with wide drivers' hood castings as explained in the previous caption. SN 1405 was on display for many years at the Ordnance Museum at Aberdeen Proving Ground in Maryland. When the Museum closed, it was moved to storage at Ft. Moore, Georgia, where it is no longer accessible to the general public. SN 1405 is another example where all of the weld seams were smoothed out. The Restoration Staff at APG completely stripped the paint from 1405 which revealed the glacis pattern. The Military Characteristics of the M4 series were revised to eliminate the two fixed machine guns on 5 March 1942, right before series production got underway. However, some hulls had already been assembled and in most cases, the fixed mg holes were simply sealed up by welding as seen here, just below the "bump." Of course, SN 1405 was built with a standard D50878 75mm turret. The 17 pounder Firefly turret was provided by the British and tested at APG and Ft. Knox, and later installed on this tank by the Ordnance Museum to create a faux Firefly display. Photo courtesy of the APG Restoration Staff.

This undated photo shows what we assume was the 5th Ford built M4A3. This

tank may not as yet have been accepted since it lacks the drivers'

hatches and commander's cupola. Perhaps it was undergoing its test drive

before finishing and final acceptance? The

Ft. Knox photos of the third Ford, SN 2657, show the later M34 gun

mount, while here Number 5 has "reverted back" to the earlier type with

inboard lifting rings on the gun shield, and without the protective side

extensions on the rotor shield. We think it likely that Ford received a

small supply of these from another manufacturer while their facilities

tooled up to produce their own gun mounts. Additionally, we see the

reversion of the rearmost bogie unit to backwards mount as on pilot 2,

SN 2656. We can't help but think that Chrysler, who designed the M4

bogies, would have provided Ford with drawings and advice about these,

since part of the Ford contract was for the production of M4 bogies.

Chrysler M4A4s, including the pilot, had the bogies mounted in the

"standard" orientation from start to finish as did the 109 M3A4 Lees

produced from June through August 1942. Chrysler hulls were made 11

inches longer than the standard Sherman hull in order to accommodate the

massive multi-bank engine. Perhaps the Ford people thought that the

backwards orientation offered some advantage on the standard hull? The

1942 and 1943 M4A3 Technical Manuals include photos and illustrations

that show the bogies mounted in the "normal" way, but an illustration in

the Lubrication Chart shows the rears mounted backwards as seen in the

inset. In any case, we suspect that the backwards mounting was corrected

before the tanks were shipped to their assigned stations. Observe that

the backwards mounted bogie has welded spoke wheels while the others

have pressed metal wheels. Some of the wheels look as if they had been

used. This unit can be seen with the "C-H" logo of Continental-Hubbard

(arrow) cast in the middle of the differential housing. While Ford

claims to have designed the one-piece differential housing, the evidence

observed on surviving examples suggests that they did not cast them,

say at River Rouge, but rather subcontracted them from firms like

Continental Foundry and Machine, who had the capacity to produce large

castings like diffs, turrets and hulls. Ford Number 5 would have been SN

2659. We mention in passing that SN 2659 is listed as the first of 7

M4A3s supplied to the British for evaluation. It was assigned War

Department Number T-146190 and was used in tests at the Mechanical

Warfare Experimental Establishment in the UK. If any readers have any

photos of T-146190, we'd be curious to know if it had backwards mounted

rear bogies.

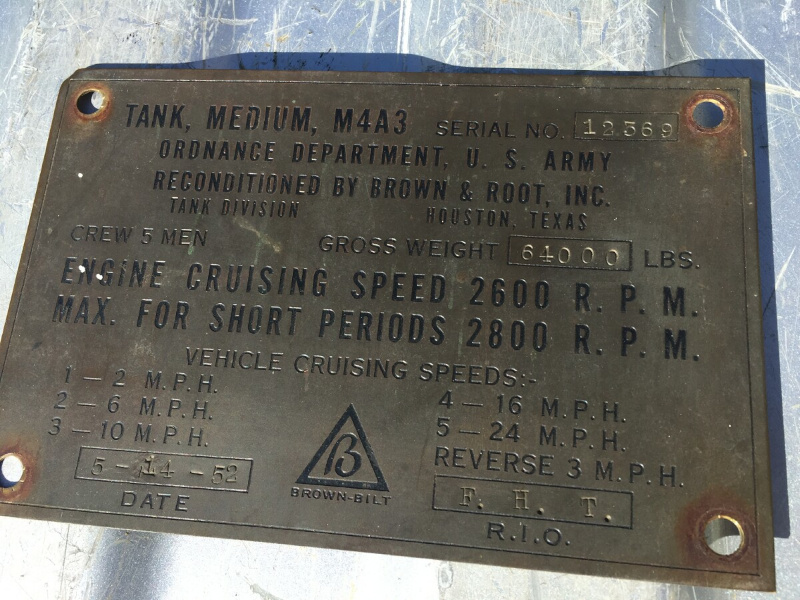

This photo shows the earliest known surviving M4A3, Serial Number 2662 on display at the VFW Post in South Boardman, Michigan. This would have been Ford's 8th unit and would have been accepted in August 1942. SN 2662 was obviously heavily modified. It strikes us as an example that was remanufactured once during WW II and again in the early 1950s. Wartime remanufacturing programs generally required the installation of the M34A1 gun mount (1) which did not enter production until early 1943 well after 2662 had been produced. Jim Goetz took this photo on a nice sunny day, and we would point out how the weld seams are nearly invisible. The bow machine gun appears to be part of a larger casting, but without weld seams as reference, it is hard to determine the size of it.

Jim took some photos of the "early" antenna bracket on SN 2662. Internal correspondence labels this as "Radio Bracket, [Part Number] B 50112." Note the lack of a "flat" or flange at the base, and the little square protuberance (circled) at the front. It is obvious that Ford started production using this casting.

This factory photo shows what we take to be the 20th Ford (August

1942). There should be a prominent weld seam where the glacis plate is

joined to the side plate (arrow), but instead the welds were smoothed

out. Consequently, we have no weld seams to use as reference in regard

to the size and shape of the bow machine gun casting. The weld joints

were acknowledged as some of the weakest points in the assembly process,

and we can't see how grinding them down to smooth them out would have

improved the situation. Perhaps it was the impulse of an automaker to

make everything look smooth and pretty? Again, we see the little

rectangular "protuberance" (circled) at the base of the early Ford

antenna bracket. This photo provides a good view of the Federal Electric

Type 160 siren with the "V for Victory" grill. As mentioned, Ford

produced armor plate and armor castings at its River Rouge complex. The

inset shows the casting marks that can be seen here on the gun shield.

The Part Number of the M34 gun shield was "D50880" and Ford used "GAD"

for its caster's logo. After a while, it would appear that Ford

contracted with outsides foundries to produce the gun and rotor shield

castings. The Government contracted with Ford to assemble complete gun

mounts, and it is reported that they produced a total of 19,985 M34 and

M34A1 Gun Mounts. The Government supplied those not needed by Ford to

the "railroad" companies that produced Shermans (Pressed Steel Car,

Pullman, ALCO, Lima Locomotive and Baldwin) as either primary or

secondary sources. "Every assembled Mount was...sent to the Erie

Ordnance Division for test firing" before distribution.

The

factory floor photo above appeared in newspapers in November 1942. The

caption identifies these Shermans as "Ford Steel M4's rolling down the

assembly line." It gives the location as "Dearborn, Mich", the

corporate headquarters of the Ford Motor Company. The photo

was obviously taken at the plant not far away in Highland Park, the

world's first to produce automobiles (the Model T) on a moving assembly

line. Many contemporary captions were more security conscious

and did not provide the manufacturer's name or location,

instead describing the scene as something like "a factory in the

Midwest." Nonetheless, some security was used on this photo, with

certain things censored out including the paper sticking out of the

pocket of the man leaning against the differential housing. On

the tank itself, the number "28" was censored (inset). We take this to

indicate the 28th Ford M4A3 which would have been accepted in September

1942. The caption was likely provided by Ford's Public Relations

Department and explains that the tanks were "constructed almost wholly

from equipment and material manufactured in Ford plants...A new method

of manufacturing non-buckling armor plate, increased accessibility of

vital parts, and simpler designs are a few of the Ford plant

revolutionary improvements." To our eyes, the weld seams look like they

were still smoothed out on Number 28, but it would be hard to say for

certain. Note that the bow machine gun dust cover fitting is not

installed, and that the headlamp plug holders are in the

initial orientation, mounted parallel to the glacis. The 3 tanks behind

Number 28 all appear to have the early type of antenna

bracket. Although

there is no mention in the caption, we suspect that the man in the suit

might have been the President of the Company, Henry Ford's son, Edsel,

who died of cancer in May 1943.

The second earliest known surviving M4A3, Serial Number 2703 is on display in Papineau Square in New Bedford, Massachusetts. This unit would have been accepted in September 1942, and would have been the 49th M4A3 produced. The weld seams are clearly visible on SN 2703, so we might theorize that the practice of smoothing them out was discontinued in September. At least we can observe that every other surviving Ford with a higher serial number (not to mention almost every Sherman produced) is seen with weld seams that stand "proud" of the armor surface. However, there should be a prominent weld seam right in the middle of the glacis between the drivers' hoods. Most likely it was smoothed out. Either that, or perhaps Ford was experimenting with a single casting that included both drivers' hoods? In any case, SN 2703 was obviously modified, but the absence of applique plates on the hull sides and in front of the driver's hoods, suggests that it was not remanufactured during WW II. This is the only instance of a surviving Ford we have encountered that is seen with a small rectangular bow machine gun casting (inset). The bow mg socket is positioned a bit off center, and "buttons" are present on 3 of the 4 corners of the casting. A similar but trapezoidal shaped bow mg casting is noted on some surviving M4A2s. The differential housing is one of a number of surviving examples observed with Part Number "E4186" cast in the middle of it. Pierre-Olivier stuck his camera under the diff and noted the C-H logo in the area indicated by the circle. A couple of period documents suggest that SN 2703 spent its time at Ft. Knox, Kentucky during WW II. It was listed as "deadlined" [out of service, awaiting repair] there on 15 December 1942 and transferred from the Armored Replacement Training Center (Ft. Knox) on 25 June 1945.

Speaking of Ft. Knox, here we have a period photo on an M4A3 of the Armored School, Gunnery Section. This unit likely reflects the appearance of SN 2703 at Papineau Square when it was built. That is, before it was modified/upgraded/reconditioned, and installed with a "no pistol port" turret with M34A1 Gun Mount and so forth. The inset shows the rectangular bow machine gun casting with the "buttons" on the corners. We don't think this is the same hull as SN 2703, since that one is missing the "button" on the upper left. So, Ford must have produced more than one M4A3 with the rectangular bow machine gun casting. Judging by the foliage, we would guess that this photo was taken in late 1942. Photo courtesy of Judith Gordon and Lawrence Banka.

Starting with SN 2756 (October 1942) in Clintonville, Wisconsin, every subsequent surviving M4A3 is seen with what we think of as the "standard" bow mg casting. This was a small oval shaped casting welded into a rectangular piece of armor plate that formed the lower section of the glacis. In addition, SN 2756 is the first surviving M4A3 observed with what we think of as the "standard" Ford antenna bracket. Note the "flange" around the base. Again, every subsequent surviving M4A3 is seen with this particular antenna bracket with the exception of SNs 2785 (Oct. 1942), 2925 (Nov. 1942) and 11550 (Dec. 1942). Casting imperfections were often corrected by welding, and the arrow points to a rather large patch job on the turret. For future reference, we would like to point out the modified M34 Gun Mount (outlined) which is seen on SN 2756 and 33 more surviving Ford M4A3s. Photo courtesy of Paul and Loren Hannah.

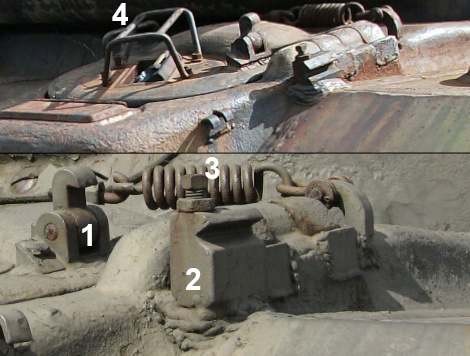

Lawrence Banka sent us this photo with the explanation, "My father, Edmund A. Banka, Tec 5, was stationed at Ft. Knox during WWII working in the Reproduction Department of the Armored Force School. This department took professional photos of armored vehicles on the base." The Banka family donated many of their father's collection of photos to the base historian years ago, but Lawrence recently found some new images and generously shared a couple with us. The photo shows USA 3055868 which would have been SN 2908 accepted in November 1942. We have a textual listing that has it that 3055868 along with 3055864, 3055866 and 3055869 were shipped from the Toledo [Ohio] Tank Depot to Ft. Knox on 8 November 1942. It can be seen that the Registration Number is painted on in what we take to be blue drab as opposed to the darker color noted on some of the earlier Fords. The tactical markings indicate that the vehicle was assigned to the Armored School's Tank Department where student troops were trained in the care and maintenance of AFVs. Judging by the condition of the road wheels, this tank had been used a bit, and we would guess the photo was taken in early 1943. "Tanner" can be seen with the early pattern M4 bogies with the asymmetrical track skids (1). Note that the bogies have received the "Roller Bracket Spacer" modification (inset). The use of steel tracks created a friction problem involving the track skid, which was remedied by the addition of a spacer that elevated the return roller by about an inch. The spacers don't appear to have become available to production until January 1943, so these were likely retrofitted at the school. Only the rearmost bogie looks to be a Ford casting, and we would guess the others were installed by the students as part of their instruction in assembly and disassembly. We do think that by November Ford would have been factory installing the MG dust cover fitting (2), the little step for traction (3) and the "Spot and Signal lamp" (4) whose fitting is visible here. This tank has what we consider to be the "standard" bow machine gun configuration, but unlike SN 2756 of the previous caption, it has reverted back to the earlier antenna bracket. The headlamp plug holders (5) are in the first position, mounted parallel to the glacis. The evidence suggests that these were changed to a vertical orientation in November, a few units after this tank had been accepted.

We would characterize the casting shown above as the "standard" or "typical" Ford antenna bracket. This bracket has also been observed with part number B50112 stamped in or cast on, the same PN as the earlier one. On this example, the Part Number is cast in just below the asterisk. So, for whatever reason, the shape was changed, but not the part number. To give readers an idea of the counting heads process, as mentioned, this bracket makes its first appearance on surviving Fords on Serial Number 2756. The next survivor, Serial Number 2779 is also noted with this bracket. The next, Serial Number 2785, reverts back to the earlier bracket. All three of these would have been accepted in October 1943. After that, we have seven additional surviving October M4A3s with the typical bracket, but then the earlier bracket "reappears" on a few more units. This provides an illustration of the transitional nature of the introduction of changes. This particular bracket was photographed on SN 2980 (Nov. 1942), one of the Shermans featured at the annual Open House of the Virginia Museum of Military Vehicles. Speaking of transitions, 2980 can be observed with the elongated drivers' hoods that replaced the original direct vision hoods. We would judge that this tank was built at about the point where Ford had completed the transition to the later drivers' hoods. That is to say, there are no further "sightings" of surviving direct vision M4A3s with higher serial numbers.

So far, most of the M4A3s

we have featured have been noted with the original drivers' hoods with

direct vision slots. These were found to be ballistic weak points in

the Sherman design, and the Ordnance Department ordered them eliminated

from welded hulls on August 13, 1942. Some lead time was needed to

design and mass produce the new driver's hood castings. The

reconfigured hoods were elongated in the front, where an additional

periscope was provided. The first surviving M4A3 we have encountered

with the new hoods is Serial Number 2893 on display as part of a Korean

War Memorial in Long Prairie, Minnesota. This unit would have been one

of the last accepted in October 1942. Note that the Ford castings have

a sort of undercut (1) at the front. Many surviving Ford M4A3s have

drivers' hood applique plates installed, but on those that don't, such

as SN 2893, the undercut appears to be the same size on both hoods. We

mention this simply because the undercuts observed on M4A4 drivers'

hoods appear to have been asymmetrical with the driver's hood having a

smaller undercut than the bow gunner's hood. In any case, SN 2893

implies that Ford began to replace the old hoods in October 1942.

Counting heads suggests that the transition to the new hoods was

completed a month later. In general, the introduction of changes was

"with obsolescence." As the new parts began to enter production, the

manufacturer continued to use the old parts until the supply was

exhausted. For instance, the next surviving unit, SN 2894 is in

Waconia, Minnesota. It would have been the last M4A3 accepted in

October 1942, and it "reverts back" to direct vision. The "final"

direct vision Ford M4A3 we have visited is SN 2930 (Nov. 1942) in

Stowe, Ohio. As with most surviving Fords in the US, the Long Prairie

has been extensively modified. For instance, note the final type of

1-piece differential housing (2). The E8543 diff was not introduced in

production until mid 1943, so for whatever reason, the original E4186

housing was replaced. This particular E8543 diff represents the "final"

configuration with welded on steps (3), one of which is missing. The

muzzle brake (4) is a somewhat unusual modification. One might assume

that this is one of those clueless, dumb things added to display tanks

to make them look more fearsome, but SN 2893 is not the only surviving

example with this exact same muzzle brake. SN 2800 on display in

Aitken, Minnesota and shown in the inset is another. We think these may

have been functional and retrofitted at Camp Ripley, Minnesota to a few

M4A3s used as gunnery training tanks in the early to mid 1950s.

This period photo shows USA 3055877, which would have been Serial Number 2917, accepted in November 1942. From our standpoint, this M4A3 is interesting in that it can be seen with the elongated drivers' hoods and the earlier type of antenna bracket. Note that an antenna base with spring is installed on the bracket along with a round extension piece such as seen on some early Ford M4A3s. Perhaps the extension was provided with units that were outfitted as command tanks? Like "Tanner" USA 3055868, this tank is equipped with the little "step" between the drivers' hoods. Unlike "Tanner" the headlamp plug holders are in the final, upright position. USA 3055877 was probably pretty close to "patient zero" for this change. This M4A3 was the pilot conversion of the Engineer Armored Vehicle done at Ft. Belvoir, Virginia in late 1943. According to Training Circular Number 46, dated 18 July 1944, the EAV would have had a crew of six, "four demolition men in the turret, a driver and an assistant driver." Harking back to the M3 Medium, armored doors were provided on both sides of the hull. The EAV would have been equipped with a rocket launcher and a dozer blade and carried 2000 pounds of explosives. A “Doozit” frame attached to the dozer blade would have been "used to place large explosive charges against anti-tank walls to make a passable gap for tanks." Author Richard Hunnicutt states that "Although 100 conversion kits were authorized for procurement, only two engineer armored vehicles with crews and instructors were at a port of embarkation on VJ-day."

The photo above shows "Field Tests of a Pressure Ventilated M4A3 Tank Equipped With Air Purification System." These trials were conducted at Edgewood Arsenal, Maryland in August 1943. The tank in the foreground, which is listed as USA 3055653 (SN 2693, September 1942) was extensively sealed and equipped with an air purification system. The idea was to determine if it would be possible to provide "collective protection" to a tank crew against chemical attack. The results were inconclusive with more testing and development recommended. In any case, SN 2693 can be seen with direct vision and the first type of antenna bracket as one might expect of a September 1942 production Ford. The gun shield features the outboard lifting rings, but the rotor shield is the earlier type without the protective side pieces. The headlamp plug holders are in the first position, parallel to the glacis. Note that an MG dust cover fitting is installed. Of interest is that 2693 has been retrofitted with what appears to be a "door stop" (arrow) such as was used on Second Generation M4A3s. The unit in the background has its serial number painted on - 2936 indicating November 1942 production. This was the "control tank" and the hatches were left open as the sealed tank was blasted with "CC agent" from a modified flamethrower. While SN 2936 "still" has direct vision, it can be seen with the later antenna bracket, headlamp plug holders in the upright position, an MG dust cover fitting, plus the little "step" between the drivers' hoods. Just visible on the turret is the fitting for the "Spot and Signal lamp." The inset photo shows the spotlight prototype on a Lee at APG and is dated 7 August 1942. We don't have a lot of counting heads material to work with, but would judge that the MG dust cover, the step and the spotlight were all added to Ford production starting, shall we say, in "the fourth quarter of 1942."

Here we have another interesting example, Serial Number 2925 made in November 1942, a few units after the EAV and a few units before the "control tank." Of course, this M4A3 was converted to an M32B3 Tank Recovery Vehicle. It serves as a roadside attraction in the parking lot at Smith and Edwards Military Surplus in aptly named Pleasant View, Utah. Pierre-Olivier noticed that the M32B3 Registration Number was still painted on as well as stamped into the glacis plate. It is USA 40155174, indicating that it had been converted by Pressed Steel Car in October 1944. PSC was originally contracted to "remanufacture and convert" a total of 450 used Ford M4A3s to M32B3s. However, "due to the inability of Pressed Steel Car Co. receiving from camps, posts and stations 155 Medium Tanks M4A3" the number of M32B3 conversions was reduced to 295 units. As it turned out, 3 more M4A3s were "found" so that the final number of M32B3s converted by PSC from March through December 1944 was 298. This retriever appears to have had its original power train changed out for one with a 3-piece differential housing. Like the EAV, it can be seen with the elongated drivers' hoods and the earlier type of antenna bracket.

The only other surviving M4A3 we have noted with the earlier antenna bracket is a December 1942 production M4A3, S/N 11550, on display at the VFW in Winooski, Vermont. With the exceptions cited, most surviving units before this and all of them after have the typical Ford antenna bracket. Thus, we can observe that on the 100 plus surviving Fords, the typical bracket first appears in October 1942, and the earlier bracket seems to completely disappear after SN 11550 in December.

A subtle feature noted on surviving Ford M4A3s is that the side armor plates have neatly beveled top edges, such as seen on the left on SN 11603 (Dec. 1942) in Philipsburg, Pennsylvania. On most Shermans, including all of the Second Generation 47-degree welded hulls, the side armor plates were straight cut, so that the top edges were not beveled. Evidence indicates that Ford did not provide engine deck door "stops" (outlined in red), while they were standard on large hatch M4A3s. Note that an oblong opening (1) is present on the Ford M4A3 but not on the large hatch model.

Ford M4A3s were built with grouser compartments with oblong cover plates (1). Overheating within the engine compartment was not an issue on M4A2s and M4A3s, so that they did not require the use of air scoops as did the M4, M4A1 and M4A4. Thus, the grouser compartments on these models simply held grousers, likely 13 to a side. While large hatch, 47 degree hull M4A2s continued to include grouser compartments with access plates, late production M4A3s did not. Chris Hughes was able to remove one of these covers from Ford M4A3 Serial Number 2779 (Oct. 1942) in order to photograph the inside. It can be seen as a casting not an armor plate. The bar (2) was pivoted 90 degrees and tightened to secure the cover to the hull. The square protrusions (3) would have served to maintain the position of the cover within the opening. The raised pad (4) is observed on many Ford castings and is noted with information such as the part and heat treatment numbers stamped into it. We have only seen two examples, but assume that Ford used these castings throughout production. Note that grouser covers were mounted flush with the armor surface on the Fords, whereas they were mounted on top of the armor on some other Shermans such as Fisher built M4A2s. We have not had the opportunity to measure a Ford grouser cover. On other types of Shermans, the dimensions of the covers vary slightly, but are in the "neighborhood" of 10.25 inches long by 5.25 inches wide. Right side photo courtesy of Chris Hughes http://

This photo shows the engine deck of S/N 12306, a June 1943 production M4A3 that is on display at the National Guard Armory in Denver, Colorado. As best we can tell, it is the only surviving example in the US that has retained the original engine deck configuration. Unlike all of the others, we would conclude that 12306 was not remanufactured in the the early 1950s, and so was NOT retrofitted with the torsion bar hinge modification. The forward engine deck panel held the armored filler covers for the left and right vertical fuel tanks (1), as well as a middle cover for the engine coolant expansion tank (2). The edges of the forward panel were built up with armor plates to protect the filler caps from shrapnel and bullet splash damage. The plate at the front of the panel (3) served as bullet splash protection for the turret race. A three-piece splash guard (4) was also positioned in front of the housing for the fire extinguisher pulls. Note the little drainage hole (5). There are no drainage holes in the rear panel (6). Rather, drainage was provided at the rear of the side panels (circled). Pierre-Olivier photographed this on a rainy day, and it can be seen that water has built up at the rear of the enclosure. It strikes us that this could threaten to contaminate the fuel tanks. So, perhaps the side drainage was inadequate. Air intake was provided by the engine deck doors (7) with tightly spaced grill work. For security, the doors were bolted down at the front and rear, although the bolts (circled) are no longer installed on this example. The rearmost engine deck panel (8) was a single plate with two lifting handles welded on to it.

The

engine deck doors were extremely heavy. They included the "chutes" (1)

shown here on the underside that, upon personal examination, appear to

have been constructed of 1/4-inch armor or steel plate. We have heard

these described as "air deflectors," however, an Ordnance Department

drawing labels them "Splash Shields," suggesting that they served to

protect the engine from any shrapnel or other debris that might get

through the air intake grates (2) of the engine deck doors. (In the

photos, note that the doors are shown upside down, so the splash shields

are on the top.) We were able to observe on a surviving M4A3 that when

the doors were closed, the splash shields practically touched the top of

the V8 engine. Only the left side door is noted with a "shielded" hole

(3) in the assembly. If any readers can document its purpose, the

authors and the owner would be interested to know. In

November 1942, a request for a "heavy door" fix was submitted to the

Manufacturing Branch of the Tank-Automotive Center. It was rejected...

"It is thought that any mechanical assistance to facilitate door opening

would only result in much complication, interference with cooling, and

reduced accessibility to motor. Two men can easily raise and close these

doors where on previous tank models a crane was required."

This APG photo dated 25 June 1943 provides a view inside of the engine compartment of "M4A3, #12099." Note how the engine just squeezes in between the vertically mounted fuel tanks (1). A pair of horizontal fuel tanks were located at positions 2. Combined, these held 168 gallons of 80 octane gasoline, giving the vehicle a cruising range of about 100 miles. Earlier, we pointed out the armored fuel filler cover mounted in the middle of the forward engine deck panel. Here we see the engine coolant expansion tank (3) that it serviced. This was the only non-gasoline filler point on the M4A3, but as best we can tell, Ford M4A3s were not provided with little pressed metal labels besides the filler caps to help the crews avoid contaminating the tanks with the wrong solutions. Second Generation M4A3s were installed with such labels. On those, the filler point for the engine coolant expansion tank read "WATER" while the rest read "GASOLINE." A pair of shrouded fans (4) cooled the water in the large radiator mounted just behind them. Serial Number 12099/USA 3054254 which would have been the first M4A3 accepted in May 1943, was used 2 months later at APG in comparative trials against a British Centaur and a Cromwell. Some film footage from the trials was shot and what caught our eye was that 12099 can be seen with a welded-up pistol port (inset). In mid-April, the Ordnance Department ordered the elimination of the pistol port as a ballistic hazard. We assume that 12099 had its original, factory turret, and if so, May 1943 production is the earliest instance we've seen of a welded PP. As an aside, we would note that the APG Report mentions that the Centaur had a "500 horsepower Ford GAY, 8-cylinder, V-type water cooled engine." We thought this might have been a misidentification since, officially, the Centaur was powered by a 340 HP Nuffield/Liberty engine. Plus, we could not find any online reference to a "Ford GAY engine" until we thought to search David Jackson's fine "US Auto Industry in WW 2" website. Sure enough, there is an APG photo dated 25 September 1943 that shows "GAY engine #6," and David comments, "This WW Two era photo shows one of 26 GAY tank engines built for possible use in a British tank." Given the recommendation cited earlier, "reserve Ford-powered combat vehicles for United States troops", we are somewhat surprised that the Ordnance Department undertook a project like this considering the great demand for the Ford GAA by the US Army.

The lower rear hull configurations of Ford M4A3s and the Second Generation models are similar, with a single engine access door bracketed by a pair of heavy exhaust stacks. However, Ford used a rounded casting to join the lower rear hull plate to the belly plate, while the Second Gens used an angled plate. Note the "GAD" caster's logo in the left side photo (outlined in red) and a close up in the inset. M4A3s were equipped with sheet metal exhaust deflectors. The original version is shown on the left. The later featured a "prop up" rod which could support the deflector when in the up position as on the right. However, counting heads evidence would lead us to conclude that Ford did not factory install the later deflector with prop up rod. We would guess that in the case of SN 2846 (Oct. 1942) in Island Pond, Vermont, the later exhaust deflector was recycled from a Second Generation M4A3 when 2846 was rebuilt in the early 1950s. According to an Ordnance Department "Effective Points of Modification M4 Series Medium Tanks" document, Ford M4A3s were not factory installed with trailer towing pintles. However, some surviving examples are noted with the original, "long" or "first design" pintle mount (1), such as SN 12390 (June 1943) in storage at the Musée des Blindés at Saumur. On the other hand, far more are seen with the "short" or "second design" pintle mount (2). The long pintle could get bent up in service causing a misalignment of the rear engine mount and/or making it impossible to open the engine access doors. As a result, the pintle was shortened and the redesigned item was ordered to be factory installed as standard equipment on Second Generation Shermans. A Modification Work Order for the "second design" pintle was released in November 1943, and as supplies became available, Tank Depots were directed to install the mod to any M4, M4A1 or M4A3 "not equipped with towing pintles" or in cases where the "first design" pintle had "been damaged due to its length."

The Ordnance Department directed the installation of trailer towing pintles on Shermans starting around mid-April 1943, so it is kind of a mystery to us as to why "Effective Points" has it that the "long" or "first design" pintle was "never applied" at Ford. A few period photos seem to indicate otherwise. Most surviving Fords had the short pintle installed at some point, but we might safely assume that Ford M4A3s produced before the mandate in mid-April, say around SN 12020, would not have had pintles factory installed. SN 12099, which was the M4A3 used in the comparative trials against a pair of British tanks, was installed with the long pintle (1) as shown above. In one segment of the film, it is seen backing down a 3-foot barrier wall, and the pintle is the first thing that hits the ground with the entire weight of the tank on it. So, it becomes perfectly understandable why the long pintle was replaced with the short pintle on Second Generation Shermans. The long pintle problem manifested itself almost immediately on Chrysler M4A4s to the point that installation was suspended, and it was ordered that the pintle be removed from "as many new tanks M4A4 as possible." This does not appear to have been the case with Ford M4A3s. The APG photo above is dated 22 May 1943, and as mentioned previously, SN 12099 would have been the first M4A3 accepted in May. "Effective Points" has it that "Sand Shields" were introduced at Ford on 15 May 1943 at exactly SN 12219. We suspect that this was a case of wishful thinking. The Ordnance Department had set a cutoff date for the so called "universal" sand shields and directed that "No tanks without this item be accepted after 5/15/43." However, although 15,000 sets had been requisitioned in early May, there appears to have been a delay in production that wasn't resolved until mid-June. These sorts of mandates generally included an "escape clause" relating to the manufacturer's ability to obtain the necessary components on time. At any rate, before that, Ford M4A3s are seen in the configuration shown above with the rather awkward looking placement of the rear mud flaps (2). We would also observe that we have not encountered any period photos or surviving Fords with aircraft cowl type fasteners running along the bottom, such as were used by other makers to attach an earlier version of sand shield which was ultimately dropped partly because only the forward section was "common to all vehicles." A modification that can be seen on SN 12099 is the "Disc Type Idler Wheel, C85164."(3) This was reportedly installed starting on 12 May 1943 at SN 12189, so 12099 was a little ahead of the game. A positive hatch lock (4) can be seen on the commander's cupola and similar fittings are observed on the driver's hatches in the film. These important safety features were said to have been introduced in early April 1943, 5 April at SN 11998 in the case of the commander's hatch. Previously we noted that as a May production Ford, 12099 was the earliest instance we have seen of a welded pistol port. In this view, notice that the turret was not installed with the "thin spot" patch on the right front. This was reported to have been introduced at Ford in late April 1943, but strikes us as more wishful thinking. This was released as a modification kit on 14 June 1943 and was ordered to be applied to all Shermans "now located in theatres [sic] of operations and to all...now located at depots and in the field that are designated for shipment to theatres of operations." It was reported that approximately 900 of the first of these kits were shipped to the Mediterranean Theater of Operations and arrived in September 1943. Consequently, they were not immediately available to the manufacturers. We can do no more than guess that while some turrets had the pistol ports welded up, the patches were never installed at Ford.

SN 12099 was used in a number of test applications at APG. The original welded spoke road wheels seen in the previous photo and in the trials film footage were likely replaced, perhaps more than once, during the course of the tank's service. Here we see 12099 installed with a mine exploder that has "T1E6" chalked on it. However, this looks nothing like the T1E6 pictured on page 460 (inset) of Richard Hunnicutt's "Sherman." Indeed, Mr. Hunnicutt identifies this device as "a T1E3 fitted with discs having serrated edges to improve the traction." He goes on to add, "In some sources, this equipment has been incorrectly identified as the T1E6" which may be an allusion to this photo? The tank can be seen with "MCV 251" chalked on, and the mine exploder with "MCV 251A." We associate "MCV" numbers with AFVs that were assigned to the APG Ordnance Museum for historical reference, so this photo may have been taken years after WW II, but before the 1950s when many of the Museum's "historic reference" AFVs were scrapped. The M34A1 gun mount would have been a recent introduction when 12099 was accepted in May 1943, and note the lifting ring (circled) on the gun shield.

Not long after Sherman production commenced, it became clear that the original periscope gun sight was inadequate, so the Ordnance Department designed a new gun mount that incorporated a direct sight telescope. A mockup was photographed at APG on June 22, 1942. The sides of the rotor shield were extended to protect the telescope (1) as well as the .30 caliber coaxial machine gun (2). The new configuration was heavier and required "a breach counterweight to balance the new [gun] shield." Designated "Combination Gun Mount, M34A1," the design was released for production on 16 October 1942. Most changes to the Sherman were introduced "with obsolescence." This permitted the manufacturer to use up supplies of the old parts, in this case, the M34 Gun Mounts, even as the new parts were introduced into production. The addition of the direct sight telescope was deemed so important that the M34A1 was initially released "without obsolescence," with a cutoff date of 15 January 1943. The manufacturers could not obtain all of the parts necessary to meet such a rigorous deadline, and ultimately, the M34A1 did not completely replace the M34 gun mount in Sherman production until the end of April 1943. "Effective Points" has it that the M34A1 Gun Mount was introduced at Ford on 15 March 1943 on Serial Number 11914. It is assumed that the driver's hood casting (3) was included to offer some sort of scale to the display. Of course, this is an example of the "narrow" 18 1/2-inch-wide driver's hood used on many M4s and M4A2s. The inset, courtesy of Brian Branson, shows a Ford M34A1 Gun Mount Identification plate, Serial Number 5754. For future reference, note that "ABQ" is stamped into the box at the upper right.

The photos above provide comparative views of the early and late type M34A1 gun shield castings. The early version had an exposed bolt flange on the right side and lifting rings welded to the top of the gun shield. (Please keep in mind that, on a tank, right and left are determined as if one were sitting in the driver's seat.) These features were eliminated on the later version, which appears to have completely replaced the earlier mount by the end of July 1943 at Ford. Of course, the later gun mount was carried over to Second Generation M4A3(75)s.

It is thought that the lifting rings were eliminated from the later version of the M34A1 gun shield because it was found that they interfered with the full elevation of the gun. Instead, the gun shield was drilled with a pair of threaded holes in which users could insert screw eyes for lifting. On surviving Shermans, these holes are seen plugged with slotted bolts (circled). It is assumed that a pair of screw eyes were included with the specialized tank tools provided as On Vehicle Materiel, although we can't say we've ever seen a photo of the screw eyes in use. This particular gun shield is interesting in that it is stamped with an always useful date - 7-17-43 [July 17, 1943]. The top line provides the Part Number of the piece: E5721. On the second line, we interpret "713" to be the serial number of the gun shield casting, "V" to be shorthand for the casting firm, and 440 to be the Heat Treatment Number. (We won't even guess about the other visible numbers.) Some of the same info is seen cast in on the side of the gun shield as shown in the inset. The "V" appears to be the incompletely formed logo of the National Roll and Foundry Co. We wouldn't be surprised if the date was stamped on at Ford as they assembled the various pieces of the M34A1 Gun Mount.

The factory photo above is dated 5 April 1943 and is headlined "Bad News for the Axis." It shows M4A3s and M10A1s being assembled on parallel production lines "in Building 4" at the Highland Park plant. We've included it here because it is one of the only factory or Ordnance type photos we know that shows Ford M4A3s with the early version of the M34A1 gun shield with the lifting rings and exposed flange. The positive hatch locks were stated to have been introduced in early April, but they don't seem to be present on these examples. Early production Fords are seen with what we have assumed were build sequence numbers stenciled on the glacis and sides. Ford appears to have dispensed with that practice, but we suspect that the chalked-on number indicated by the arrow was the tank's serial number, although try as we might, we could not read it on the glossy print at the US Archives. As we shall demonstrate later, surviving Fords are noted with the serial number stamped in this same area, directly below both of the front lifting rings.

Our goal has been to provide an Ordnance Department or factory photo of a Ford M4A3 from every month of production. Here we have a June 1943 entry - SN 12293. Unfortunately, the photo is not very informative due to the angle and the nature of the project for which the tank was used. The lack of visible hinge (black arrow) on the pistol port casting suggests that the pistol port was welded up on this example. It can be seen that the turret was not installed with the "thin spot" patch. The presence of the bolt (red arrow) would indicate an early version of the M34A1 gun shield with exposed bolt flange on the right side. SN 12293 was installed with the attachment strips typical of the universal sand shields. This was the only photo of 12293 we came across. It was General Motors Proving Ground Project 8270 and was used to test the feasibility of producing a heavier Sherman powered by the Ford V8 engine. The “12th Army Group Report of Operations” published in July 1945, explains the matter... “Early in January 1944, a theater requirement was submitted for 250 heavy assault tanks for operational purposes, it then being assumed that the tank in question would be of the T26E1 type (M26). When it appeared that the production of this tank would not make it available for early use on the Continent, the War Department inquired, on or about 15 April 1944, whether our operational requirement was such as to make it desirable that they fill our requirement with a specially up-armored M4 series tank. The reply was that the extra heavy tank was required for assault purposes. It was hoped that the tank would be available on or shortly after D-Day.” The Ordnance Department appears to have put the wheels in motion on the "extra heavy" Sherman project starting on December 17, 1943, when it directed the General Motors Proving Ground to operate an M4A3 with a test weight of 82,600 pounds. After 500 miles over a standard endurance course, it was found that "no abnormal failures were encountered...It, therefore, appears feasible to convert a Medium Tank into an Assault Tank with a weight of 82,600 lbs. if only limited operation is to be encountered." SN 12293 was installed with additional "ballast" and photographed on January 18, 1944, before commencement of the 500-mile endurance test. Note the use of the recently developed extended end connectors, which reduced the ground pressure to 14.2 pounds per square inch. Ultimately, 254 M4A3E2 (Jumbo) Shermans were produced from May through July 1944.

Here we have another June 1943 production M4A3, USA 3054514. This tank was an APG asset that was used in Winterization Tests in Minneapolis in February 1944. The above is a color photograph taken at Edgewood Arsenal in Maryland that was not released by the Public Information Department until September 1947. However, we suspect that it was taken during or shortly after WW II. It demonstrates the Chemical Warfare Service's use of "prearranged smoke codes, by color or pattern, [to] make known to fliers the needs of ground troops and tank crews." Our color scan showing pink and yellow smoke came out a little poor, so we have substituted the black & white. This tank appears to be "as built." Readers can better see the welded-up pistol port compared to the previous photo. On this example, the hinge section (arrow) on the turret was ground off. The middle and rear bogies feature raised "lines" running across the upper face of the bogie brackets. These are typical of GAD castings.

We count 13 welded up pistol port turrets on surviving Fords. The "window" for these was brief and primarily limited to the months of May and June 1943, at which point the no pistol port turrets entered the production pipeline at Ford. Based on the survivors, we can observe that the pistol port "door" was used as the blank off and in all cases, the door's hinges were cut or burned off. It's not saying much due to the small sample, but six are seen to have had the center hinge that was part of the turret casting removed before the whole thing was welded up. The example in the photo on the left, courtesy of Mike Haines, is on a turret with a casting date of 4-43-C (April) and what we take to be a machining date of "5-1-43" (May). This is the configuration that can be seen on USA 3054514 in the previous caption. On seven of the survivors, the center hinge was not removed. The example on the right is on a Buckeye Steel turret dated 3-43 (March) and is the only one from our sample that does not have a GAD pistol port casting. ("ARSS" = American Radiator and Standard Sanitary Corporation.) "With center hinge" is the configuration that can be seen on Serial Number 12099 in the APG film footage. Unlike SN 12099 as filmed in mid 1943, all 13 of the surviving examples are noted to have been retrofitted with the "turret armor reinforcement" modification.

Here we have an unusual photo of SN 12506/USA 3054661 (July 1943) undergoing a "Power Train Efficiency Test" at APG on 30 September 1943. On 24 July, this tank was reported to have been shipped directly from the Ford plant to APG, so we believe it is shown "as built" since it did not pass through a Tank Depot. Again, the long trailer towing pintle, which was supposedly "never applied" is present. Sand shields have been installed, and they can be identified as the mandated "universal type" by the vertical slit (1) in the center section. Note that the oddly positioned mud flaps were eliminated with the introduction of the sand shields. The inset shows the front of the tank inside the building and hooked up to a dynamometer. Ford is reported to have introduced the gun travel lock (2) in production on 31 July 1943 at SN 12555, so 12506 was a little ahead of its time. This tank can be seen to have a no pistol port turret. We have not been able to collect much counting heads evidence, but suspect that the revised turret castings, with no pistol ports and "cast in thickened cheeks" began to enter the production pipeline at Ford around June 1943. We estimate that the last 600 or so M4A3s were produced with either "no pistol port" turrets, or earlier turrets with welded up pistol ports.

SN 12527/USA 3054682 would have been accepted in July 1943 a few units after 12509 of the previous caption. It was the subject of an Inspection Control Test at APG shortly after it arrived. Note that, unlike 12509, it is not equipped with a gun travel lock, but recall that "Effective Points" has it that the effective point for the introduction of the gun travel lock was SN 12555. This perhaps provides another illustration of the transitional nature of the introduction of changes. The photo offers a good view of a full installation of the universal sand shields. These were not popular with tank crews and the vast majority were removed in service. Unlike SN 12099 and SN 12506, SN 12527 can be seen equipped with pressed metal road wheels (1). Ford used both types, although there is no evidence that the wheels were mixed and matched at the factory. That is, we believe the tanks were built with all one type on each single unit. The effect is subtle, but the shadows (arrows) on the right front of the turret indicate a so called "cast in thickened cheek." Thus, this turret is one of the revised castings made without a pistol port. These would be almost a given on a Ford made from June to the end of production in September 1943. We write "almost" because a small number of welded up pistol port turrets appear in the mix during that time frame. We have outlined a bit of Sherman minutia that is seen on the bow gunner's hatch.

From the examination of surviving examples, we would theorize that it was intended that the Ford drivers' hood castings, both direct vision and elongated, would have a little "jog-out" at the hinge points as seen in the photo on the left. However, in many cases, the jog-out did not fully form. In some instances, the deformity was minor and was fixed with welding, but more often it was corrected with little square patches, some applied more subtly than others as seen in the photos on the right. These photos show the positive hatch lock mechanisms (1 & 2) along with the equilibrator springs (3) that made it easier for the drivers to open and close the heavy hatch doors. These were reported to have been introduced at Ford in early April 1943. Just about every surviving Ford has these, no doubt installed at a Depot or in the field or during a remanufacture since this was an important safety modification. Far fewer survivors also have the periscope guards (4). These were reportedly introduced at Ford on 30 August 1943, which, if accurate, suggests that only about 100 of the final units would have had them factory installed. However, starting in late 1943, they were ordered to be installed at Tank Depots and during remanufacturing programs.

SN 12580, another APG test tank, takes us into August 1943 production. At this point, we might have expected this unit to have been factory installed with the drivers' and side applique plates, but it differs from 12527 only in that it has a gun travel lock and another "new" item that was reportedly introduced at Ford at the end of July, the final type of differential housing, Part Number E8543. The sharp-nosed shape improved the ballistic properties when compared to the original E4186 1-piece housing. Indeed, it was directed that all new Shermans produced in the US be equipped with E8543 diffs before the end of September. SN 12580 shows the "early" version of the E8543 that featured cast-in steps (circled). Hand in hand with the E8543 came the introduction of the quick release towing shackle pins with handles (1). These were designed in such a way that the pin could be inserted or removed quickly. They did away with the front towing shackles, so that the tow cable was attached directly to the pin. A bit of chain (2) kept the pin from getting lost when removed. Counting heads using period photos and surviving tanks seems to hint that Ford M4A3s may have been installed only with the cast-in steps version of the E8543 differential. Ordnance documents mention that the cast-in steps interfered with the crew's ability to work the quick release towing shackles. Consequently, the castings were altered to eliminate the cast-in steps, and metal strip steps were welded on instead. It can be seen that SN 12580 is "still" equipped with the original gunner's blade sight (3). The evidence suggests that, from start to finish, Ford M4A3s were installed with a siren mounted unprotected on the left front fender, but it is missing in this case.