Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

The

American Locomotive Co. manufactured 150 M4A2(75)s from September 1942 through April

1943, as well as 2150 M4(75)s from February 1943 through December 1943. Evidence

from surviving examples has recently come to light which confirms that ALCO

manufactured some M4s with Composite hulls. So far, the

data suggests that some or possibly even all of the 300 tanks of the final

Production Order were built as large hatch Composites.

Interior and exterior views of the "bump" show that this particular glacis casting was made to hold the twin fixed machine guns that were part of the original M4 design. The fixed MGs had been eliminated months before ALCO began producing Shermans, and one can see that the holes were simply sealed up by welding. Also evident is the repair by welding of imperfections in the differential housing and rotor shield castings. (Photos courtesy of the APG Restoration Staff).

Photos showing the "bump" on a pair of Commowealth M4A2s, and two US Army M4s. Note that in the few period photos showing the "bump" on M4A2s, as well as on the two known surviving examples, the tanks have direct vision. On the other hand, the two M4s, which are presumed to be ALCO built, are seen to have the later type of drivers' hoods. There are no known surviving examples of M4s with the "bump."

The left-side photo shows the construction of the front glacis on earlier ALCO built Shermans. The red lines indicate the weld joints. Note that the "plate" that includes the bow MG was actually a casting, whereas the other sections of the glacis were armor plates. "With the bump" would be a variation of this early glacis pattern. In the right-side photo, the front glacis is made of a single armor plate, and the bow MG, hull antenna bracket and drivers' hoods are welded into it. Left-side photo courtesy of http://wra-tanks.blogspot.fr/

ALCO built Shermans have been seen with two variations of the bow MG socket. On the earlier configuration (left side photo), the bow MG is actually part of a cast "plate," while on the later one (right side photo), the bow mg is a small casting that is welded into the front hull armor plate.

The typical cast antenna bracket seen on ALCO built Shermans. Note how the bracket is welded flush with the glacis, a useful clue when trying to identify an ALCO Sherman.

ALCO Shermans were equipped with the cast type of head lamp sockets used by most of the small hatch Sherman manufacturers. In the above photo of Serial Number 1405, one can see that a plug is partially installed into the head lamp socket. When not needed, the head lamps were stored inside, and plugs were provided to seal the sockets. Note the plug holder welded to the head lamp guard, which held the plug when the head lamps were installed. The plug holders were initially oriented parallel to the glacis, but later were repositioned to vertical, most likely to keep them from falling out. "Counting heads" evidence suggests that ALCO repositioned the plug holders to vertical about mid 1943. Also seen to good advantage in the above photo is what the authors informally refer to as the "bent rod" lifting ring as seen on many early Shermans.

All Serial &

Registration Number ranges given are interpolations. The authors would

welcome more data concerning ALCO built Shermans.

Production Order T-1480: 500 units, 150 M4A2(75),

350 M4(75): Serial Number 1405 / USA 3065484 through S/N 1904 / USA 3065983

Production Order T-3157 : 500 M4(75) tanks: S/N 3931 / USA 3065984 through S/N 4430 / USA 3066483

Production Order T-3646 : 1000 M4(75) tanks: S/N 24705 / USA 3033235 through S/N 25704 / USA 3034234

Production Order T-4305 : 300 M4(75) tanks: S/N 40305 / USA 3072902 through S/N 40604 / USA 3073201

Production Order T-3157 : 500 M4(75) tanks: S/N 3931 / USA 3065984 through S/N 4430 / USA 3066483

Production Order T-3646 : 1000 M4(75) tanks: S/N 24705 / USA 3033235 through S/N 25704 / USA 3034234

Production Order T-4305 : 300 M4(75) tanks: S/N 40305 / USA 3072902 through S/N 40604 / USA 3073201

A late

1940s, along with a modern view, of the very first ALCO built Sherman, M4A2,

Serial Number 1405 / USA 3065484, accepted in September, 1942. This tank was on

display for many years at the Ordnance Museum at Aberdeen Proving Ground in

Maryland. When the Museum closed, it was moved to storage at Ft. Benning,

Georgia, where it is no longer accessible to the general public. Of course, SN

1405 was built with a standard D50878 75mm turret. The 17 pounder Firefly

turret seen in the photos was tested at APG & Ft. Knox, and later installed

on this tank by the Ordnance Museum to create a Firefly display. SN 1405 was

delivered to APG with a one-piece final drive housing, but the tank was used to

test "final drive protective shields." Presumably its original

differential housing was tested to destruction, and it now has the three piece

differential from the very first Pacific Car & Foundry M4A1, which was also

a test tank at APG. In any case, ALCO Shermans used both three piece & one

piece housings interchangeably up until about September, 1943. Color picture

courtesy of Neil Baumgardner.

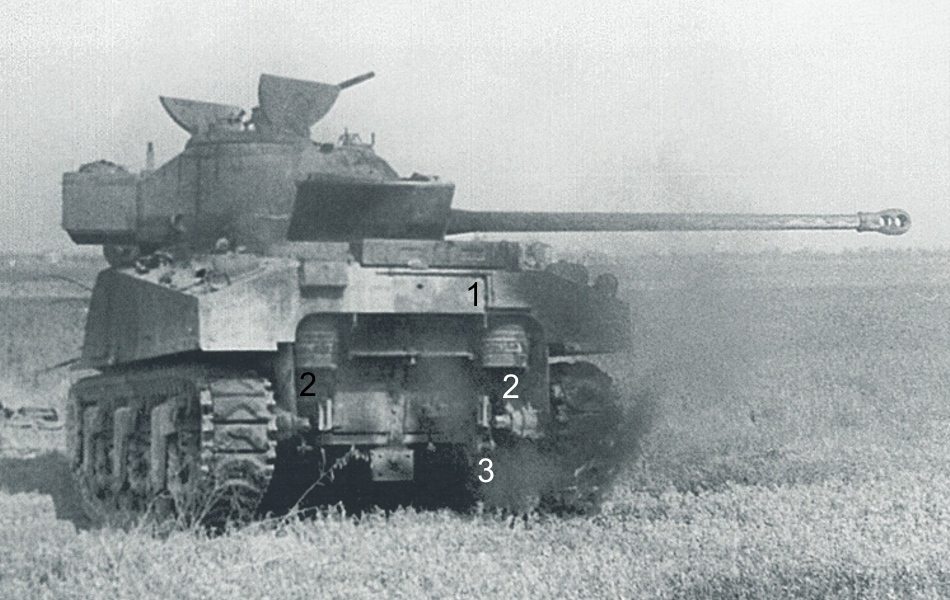

Two

January 1943 views of the third ALCO M4A2 Serial Number 1407. Of note

is the very early type of E4186 one piece differential housing, and the

"bent rod" hull lifting rings. The M4 type of bogie units certainly

appear to have been installed on ALCO Shermans from the start. ALCO

began Sherman production relatively late, and these photos suggest that

none of their turrets had lifting rings mounted in the "high" position

(see the 75mm turrets page for

further information). M4A2s were provided with rather simple exhaust

deflectors (1) made up of pieces of formed sheet metal supported by a

pair of brackets on the ends. The brackets are missing on this example,

and the deflector is somewhat distorted. Note that the grouser cover

blank off plate (2) is mounted flush with the armor. An

interesting curiosity that is seen on both 1405 and 1407, and on a

small number of other Shermans, is the cast in "bump" next to the bow

machine gun (3).

Interior and exterior views of the "bump" show that this particular glacis casting was made to hold the twin fixed machine guns that were part of the original M4 design. The fixed MGs had been eliminated months before ALCO began producing Shermans, and one can see that the holes were simply sealed up by welding. Also evident is the repair by welding of imperfections in the differential housing and rotor shield castings. (Photos courtesy of the APG Restoration Staff).

Photos showing the "bump" on a pair of Commowealth M4A2s, and two US Army M4s. Note that in the few period photos showing the "bump" on M4A2s, as well as on the two known surviving examples, the tanks have direct vision. On the other hand, the two M4s, which are presumed to be ALCO built, are seen to have the later type of drivers' hoods. There are no known surviving examples of M4s with the "bump."

A

front view of the only other known surviving M4A2 with the "bump," as

photographed by Jim Goetz. This tank, which was named "Sultan," served

with the Polish Skorpion Regiment, and was assigned the British War

Department Number T-145501. It was reported that on May 12, during the

4th Battle of Monte Cassino, T-145501 veered into a pile of anti-tank

mines that had been hastily removed to the side of the road. This set

off an explosive chain reaction which utterly destroyed the tank and

killed the entire crew. These were the first combat fatalities suffered

by the Skorpion Regiment, and in the action from the 12th to the 18th of

May, the unit recorded the loss of 5 officers and 8 enlisted men KIA, 8

officers and 27 enlisted men WIA, with 3 Shermans totally destroyed and

8 damaged. Shortly after the battle, it was decided to leave T-145501

in place, and in May, 1946, the tank became the basis for a monument to

the 4th “Skorpion” Armoured Regiment. In our view, it is one of the most

unusual and poignant tank monuments in the world. Both Jim and our own

Pierre-Olivier have closely examined this tank, and we can only conclude

that its serial number has been lost to time. So who made this tank?

Note the "bump" (1) along with the filled in holes for the fixed machine

guns (2). As mentioned earlier, "the bump" has been seen on a few early

production Shermans made by Pullman, Fisher, Ford and ALCO. An

interesting anomaly seen on T-145501 is that the weld seams (arrows)

have been ground down, so that they would disappear under a coat of

paint. The only other surviving example we have seen with ground down

weld seams is the first ALCO Sherman, Serial Number 1405 featured

earlier. This practice would have been strictly cosmetic, completely

unnecessary and wasteful of labor, so we had assumed it would have been

very limited. For instance, photos of the third ALCO, SN 1407, also

accepted in September, show the bump, but the weld seams stand proud of

the armor, as was obviously the case with almost every Sherman made. So

could T-145501 have been the second ALCO M4A2? Perhaps, but the machine

gun dust cover fitting (3) suggests that this tank was made in October,

1942 or later. Also, although not apparent here, the little step between

the drivers' hoods can be seen in period photos of T-145501, and

counting heads suggests that the step was introduced in Sherman

production in "late 1942." Also of note is that this tank has fittings

for the foul weather hood (circled) on both the driver's and assistant

driver's hatches. In any case, our best guess is that this M4A2 was

produced by ALCO in late 1942.

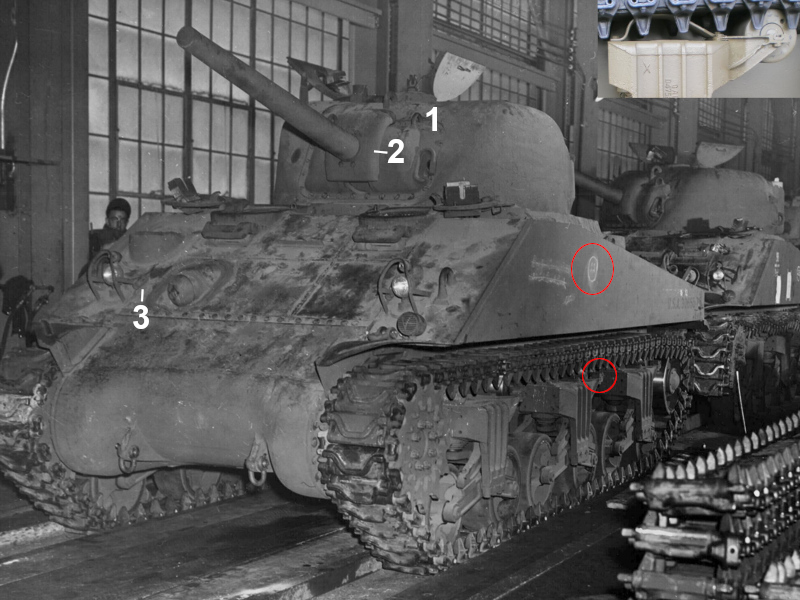

This

Office of War Information photo is part of a series taken at the ALCO

plant in Schenectady, NY, and dated January, 1943.

While described as "new M4 tanks," we believe "M4" was being used

generically in this case, and would judge that these are actually

M4A2s, since ALCO did not begin M4 production until February, 1943. Of

interest is the mix of 1 and 3 piece differential housings, as well as

metal and rubber tracks, suggesting the company received supplies of

these components from more than one source. Note the factory

installation of the bow machine gun dust cover fitting (1), an item

that appears to have entered the Sherman production pipeline in

October, 1942. The little step bracket (2) was

introduced in "late 1942." These are not present on SNs 1405 and 1407

shown earlier, although the fittings for the driver's foul weather hood

can be be seen on them, and oddly, on both the driver's and assistant

driver's hatches. Double fittings (3) can also be seen in 3 of the

tanks in the OWI photo. Perhaps ALCO mistakenly thought that a

foul weather hood was going to be provided for the assistant

driver as well? In any case, while the fittings were installed at the

outset, it is thought that supplies of the foul weather hoods

did not become available until late 1942. The tank furthest from the

camera can be seen with a foul weather hood (4) partially

installed on the driver's hatch. That same tank has the "bump," as

evidenced by the rise in the dust cover fitting. ALCO appears to have

chalked build numbers on its Shermans, and we suspect that the "117"

seen on the unit with the 1-piece diff might be such, indicating

December, 1942 acceptance. Current evidence suggests that most or all

of the 150 ALCO built M4A2s had direct vision. On the other hand, the

authors have yet to come across a period photo or surviving example of

a direct vision M4 that can be identified as ALCO.

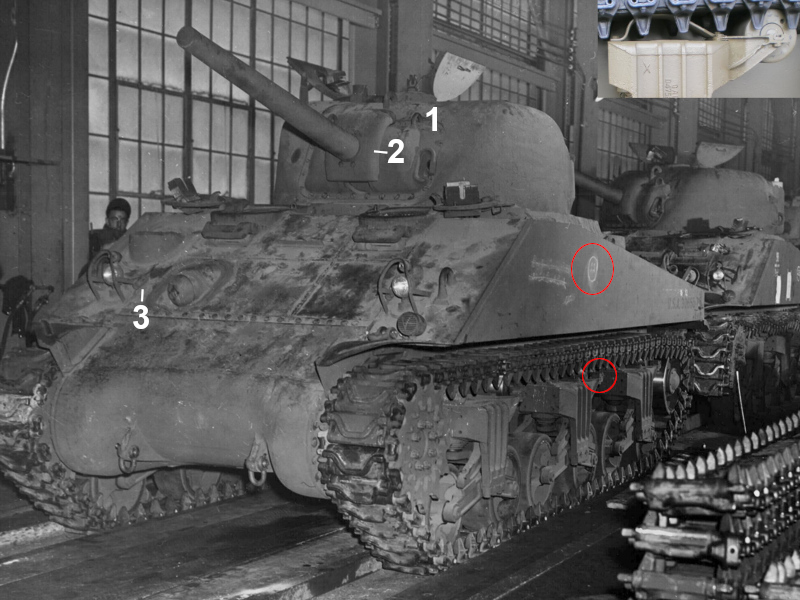

Period

photos of M4A2s known to have been built by ALCO are rare, and our

final example shows USA 3065575 about to roll off the assembly line.

This OWI photo was likely taken by Howard Hollem on the same day as the

previous image. By the Registration Number, this tank would have been

accepted in December, 1942, and would have been their 92nd unit. We

couldn't get a definitive read from the original 8 x 10 glossy print,

but suspect that the number chalked on the side and circled might be 92.

The M34 gun mounts seen on this and the unit behind, are the same as

what is on Serial Number 1407 - "outboard" lifting rings (1) on the gun

shield, and the first type of rotor shield (2) without the cast in

"wing" pieces. The head lamp plug holders (3) are mounted parallel to

the glacis. The bogie units feature the second or asymmetric type of

track skid (inset), and the return rollers have been raised up an inch

by the addition of spacers (circled).

The left-side photo shows the construction of the front glacis on earlier ALCO built Shermans. The red lines indicate the weld joints. Note that the "plate" that includes the bow MG was actually a casting, whereas the other sections of the glacis were armor plates. "With the bump" would be a variation of this early glacis pattern. In the right-side photo, the front glacis is made of a single armor plate, and the bow MG, hull antenna bracket and drivers' hoods are welded into it. Left-side photo courtesy of http://wra-tanks.blogspot.fr/

ALCO built Shermans have been seen with two variations of the bow MG socket. On the earlier configuration (left side photo), the bow MG is actually part of a cast "plate," while on the later one (right side photo), the bow mg is a small casting that is welded into the front hull armor plate.

The typical cast antenna bracket seen on ALCO built Shermans. Note how the bracket is welded flush with the glacis, a useful clue when trying to identify an ALCO Sherman.

The

direct vision slots were considered ballistic weak points, and it is

thought that ALCO dispensed with them when they transitioned from M4A2s

to M4s in early 1943. The modified drivers' hood casting featured an

additional periscope in front of the hatch. Positive hatch lock

mechanisms (1) with equilibrator springs (2) were factory installed on

ALCO Shermans starting around May, 1943. These made the hatches easier

to manipulate, and insured that they were locked in the open position,

thereby avoiding injury to the crew. Tank Depots also retrofitted this

modification to many Shermans. The drivers' hoods are what are

informally labeled "narrow" hood castings. The castings were about 18

1/2 inches wide, and were mirror images of each other with Part Numbers

D77160A and D77160B, respectively. Note how the front of the castings

were rounded at the top. Although somewhat obscured by the applique

plates on this and every other of the 24 surviving ALCO M4s we know of,

the shape was tapered in such a way that it was "square-ish" where it

was welded to the glacis.

As a

matter of minutia, we would observe that we have been able to "climb

on" at least 7 surviving ALCO M4s to find hood castings

with the stylized "PL" logo indicating that they were cast by

Pratt and Letchworth, a foundry in Buffalo, New York. Of interest

is that the casting marks include "RECON" and below that a date

"11-16-42." We have also seen these same casting marks on 2 M4A2s

thought to have been made by Federal Machine & Welder. All have the

same date, which would lead us to guess that RECON was not a foundry,

and 11-16-42 was not a casting date, but that the symbols might

indicate that the drivers' hood castings were "reconfigured" from

direct vison to the elongated type by Pratt and Letchworth on November

16, 1942.

The photo above provides a close up of the little bullet splash that

protected the drivers' hood hinge knuckles (outlined in red). At

present, these pieces have been noted only on some ALCO M4s as well as

some Fisher M4A2s with welded drivers' hoods. They were official parts

that appear to have been introduced on ALCO M4s starting in April 1943.

An ALCO drawing labels them "Guard, Hinge" and shows that they were

welded assemblies made from "1/2 Armor Plate" with Part Number 8673287

for the right-side piece and 8673288 for the left. We have not been able

to document the reason that these were not added to other

manufacturers' Shermans.

ALCO Shermans were equipped with the cast type of head lamp sockets used by most of the small hatch Sherman manufacturers. In the above photo of Serial Number 1405, one can see that a plug is partially installed into the head lamp socket. When not needed, the head lamps were stored inside, and plugs were provided to seal the sockets. Note the plug holder welded to the head lamp guard, which held the plug when the head lamps were installed. The plug holders were initially oriented parallel to the glacis, but later were repositioned to vertical, most likely to keep them from falling out. "Counting heads" evidence suggests that ALCO repositioned the plug holders to vertical about mid 1943. Also seen to good advantage in the above photo is what the authors informally refer to as the "bent rod" lifting ring as seen on many early Shermans.