Most of the information on this page is courtesy of Joe DeMarco. Note: some of the information on this page was compiled using a technique informally referred to as "counting heads." It is based on the ongoing study of period documents and photographs, as well as surviving Shermans. Due to the limited nature of available reference sources, some of the information presented here must be considered as "educated guesswork."

Many thanks to Mike Haines,

Peter Brown, and Steve Zaloga for their assistance!

First of all, you have to

identify the tank as being an M4A1(75) with small hatches. Please visit

this

page to do so.

The Lima Locomotive

Works produced 1655 M4A1(75) Shermans from February 1942 to September 1943.

Production Order T-4154, Block 1: 28 units: T-25189 through T-25194 for the first 6 units, the rest unknown (interpolation that no US Serial and Registration Numbers were assigned)

Production Order T-4154, Block 2: 100 units: Serial Number 25705 / USA 3058972 through S/N 25804 / USA 3059071

Production Order T-4154, Block 3: 272 units: Serial Number 25805 / USA 3067630 through S/N 26076 / USA 3067901

Production Order T-3208: 655 units: Serial Number 6805 / USA 3058317 through S/N 7459 / USA 3058971

Production Order T-3606: 600 units: Serial Number 29605 / USA 3038135 through S/N 30204 / USA 3038734

Introduction

Despite US neutrality before December 7, 1941, the British Government, which had been at war since September 1939, was permitted to contract with US firms for war materiel produced on a strictly "Cash and Carry" basis. One of the last contracts let before British dollar and gold reserves were depleted came in February, 1941. The Lima Locomotive Works of Lima, Ohio was engaged to produce 400 Grant Medium Tanks. The contract included funds for the construction of a 125,000 square foot assembly hall, along with the purchase of machine tools and other equipment necessary for the production of 50 tanks per month. The plant was not scheduled to come on line until late 1941. In the meantime, the Lend Lease Act was signed into law on March 11, 1941. The survival of Great Britain was considered a matter of vital national defense to the United States, and Lend Lease was a contrivance which permitted supplies to continue to flow to the beleaguered country despite its inability to pay for them. The Ordnance Department took over all of the existing British contracts in the US, so that the materiel could be provided and shipped "free" as Lend Lease. In partial exchange, British purchased plant and equipment was transferred to the US as Reverse Lend Lease. In the midst of this was Lima Locomotive, under contract with the British, but not yet producing tanks. Because the new facility, shown above under construction in April 1941, would not be ready to come on line until the end of the year, it was decided to terminate the Grant Contract, and tool up the plant for production of the newly designed cast hull M4A1 Sherman instead.

The T6 Pilot along with Lima's first Sherman do not appear to have been preserved by the US Army. The British, with perhaps a greater sense of history, saved the second production Sherman for posterity. It is now on display at the Tank Museum at Bovington. It was named in honor of Michael Dewar, chief of the British Tank Mission in the US. "Michael" plates were affixed to each side for photo opportunities in both the US and UK. The tank is shown above on the Lima factory floor at the outset of production. It was rather crudely sealed, and we would be curious to know if it was actually shipped with the hull machine guns installed as shown here. The "5190" that can be seen painted on directly behind the "MICHAEL" plate is the British War Department Number T-25190. Just above that is "LINK" and just below is "1 of 2", which we take to be part of the shipping codes. It was intended to equip the new Shermans with the longer M3 75mm guns, but they were not yet available, so that Michael was originally outfitted with the earlier M2 gun counterweighted for balance.

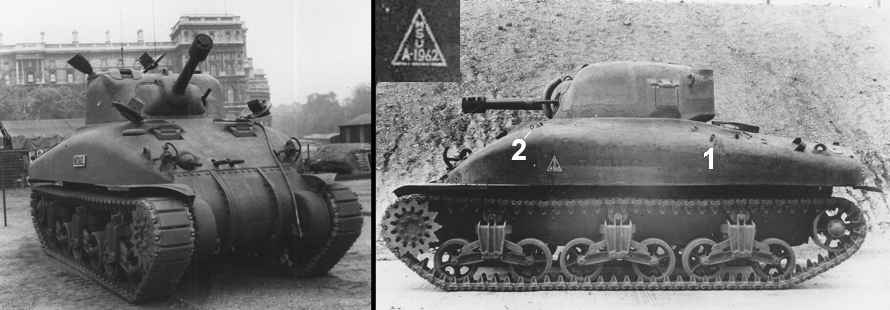

The first mention of the Sherman in British Purchasing Commission Export documents comes on 31 March 1942. The model is listed generically as "M4" with a total of 400 "On Contract or Requisition." One unit is stated to be "On Ship Awaiting Sailing." The destination is not revealed until 3 April when it is shown to be "United Kingdom." For a little context, 10 Grants and 94 Lees had been exported to the UK by that date. On 1st May, the export docs have it that one "M4" was in the UK, with 3 others "In Transit." The photo on the left is of "Michael" and is captioned "The first Sherman tank delivered to Britain, on display at Horse Guards Parade in London, 8 May 1942." On 15 May, two "M4s" are listed in the UK. The photo on the right shows the next arrival, the sixth Lima M4A1, T-25194. Again, we see "LINK 1 of 2." The other two "In Transit" were heading for the "Middle East" and had arrived by 26 June 1942. At that point, the nomenclature for these four Shermans had been changed from "M4" to "M4A1 (BR.) Gas." In any case, both "Michael" T-25190 and T-25194 remained in the UK and performed service as test vehicles during the war years. The "MSU inside a triangle" seen in the inset is shipping code for Lend Lease AFVs destined for Great Britain. "Michael" does not have it, but some early production Lima M4A1s, such as T-25194, have been noted with an extra cable clamp in the center (1). This is one of those oddities of Sherman minutia that appears in a few period photos, and then vanishes. We know of two surviving Lima built examples that have the additional cable clamp and have not seen it on any of the other builders' Shermans. Note that on T-25194, but not on "Michael", metal "eyelets" (2), likely used to secure the open hatches with wire or a screen door type hook, were retrofitted next to the drivers' hatches. Hunnicutt Collection, Patton Museum.

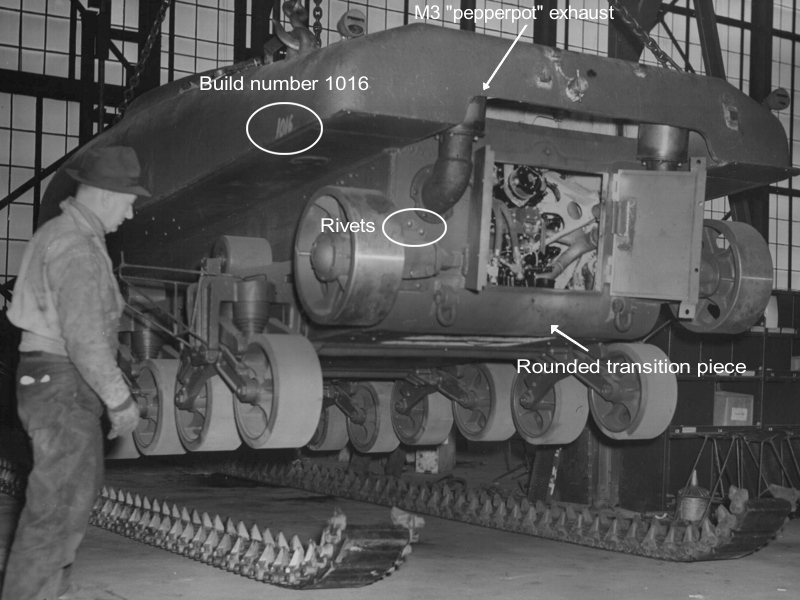

"Michael" does not have the E4153 casting information on the left rear side of the hull as on T-25189. It is cast in on the hull's underside in the area of the right pepperpot exhaust as shown above on the left. This casting is serial number 6. All of the few other Continental hull castings we have examined have the E4153 info cast in on the firewall facing the fighting compartment, as shown on hull serial number 20 on the right. Until late 1942, Continental cast all of the E4153 hulls. The cost to produce and machine an upper hull was listed as $4500. An Ordnance Department Memo mentions that some of the early castings had "drooped" slightly in the rear. Anxious to get the Sherman into production, rather than reject these massive castings, it was decided to grind down the turret splash to enable the turret to rotate, and cut the underside sponson plates so that they would fit. Over time US companies improved their techniques, and produced high quality cast and plate armor.

The first range of British War Department Numbers set aside specifically for the new Sherman models was for 400 units - T-74194 through T-74593. By June 1942, "Michael" had been assigned the second number within this range - T-74195. Above, shows that the tank was retrofitted with the new M3 75mm gun. However, a "Preliminary Report" noted that "lack of information," and defects in the gun mount and turret had delayed firing trials. The Americans and British were anxious to examine the new design, and rushed to get some tanks finished before all the bugs had been ironed out. Indeed, many of the Shermans produced in April 1942 and earlier were shipped back to the factories to incorporate improvements and fixes that had been made in the interim. The photo above was doctored in anticipation of the elimination of the rotor sight (1). The twin fixed machine guns were removed as well (2). There is no mention in the Lima records of the use of anything but armor hulls. However, "Michael" is listed in the Lulworth Camp Report as "Mild Steel," and a triangular warning plate with "UNARMOURED" (inset) was (and still is) affixed to the right side of the hull. Perhaps a Brinell Hardness test could determine the composition of the metal, but we suspect that the tank was labeled "Mild Steel" simply because it was not "combat ready." In any case, the Report concludes, "This tank, in spite of its defects, shows promise of being a much better fighting machine than the M3 [Medium]. The general layout is good, and the arrangement of the mounting is excellent." Significantly, it was around this time that the British first made the suggestion to US Ordnance that most of the main gun rounds be relocated from "up high" on the sponsons to the floor of the hull.

Based on the retrofitted "eyelets" (1) by the drivers' hatches, we believe that the early M4A1 with rotor sight turret shown above was T-25194, renumbered to T-74199. The photos appear in a "Protection Against Magnetic Grenades" Report dated 25 July 1944. These trials were carried out in the UK on Chobham Common. The letters represent various anti-magnetic patches that were applied to the armor with adhesive: A = Asbestos fabric, F = Felt quilted on hessian, P = Plastic, and H = 4 ply hessian packed with plastic. The tank ran for 29 miles through a "lightly wooded country" which did considerable damage to the patches, in some cases causing them to fall off. At about 20 miles, "it was observed that smoke was coming from the rear upper hull plate which is situated to the rear of the exhaust outlets. As far as could be ascertained it was caused by the adhesive which appeared to be smoldering." We would note that this tank was still running with its original R975-EC2 engine with the problematic pepper pot exhausts. In any case, it was concluded that while all of the materials prevented the adherence of magnetic grenades, none held up under "rough usage." Only the "Bituminous Plastic" was recommended for further testing. T-74199 probably met its end when it was later used in more lethal trials involving Teller Mines and "Flame Thrower attack." With thanks to Peter Brown.

We can document that one of the two "M4A1 (BR.) Gas" that were reported to have arrived in the Middle East by 26 June 1942 was T-25193 as seen above in a snapshot believed to have been taken at the US Middle East Training Center by its Director [then] Maj. George Burling Jarrett from Aberdeen Proving Ground. The school had been established in May 1942 to instruct members of the British armoured corps in the maintenance of US tanks and self-propelled guns. The "UFS" seen painted on T-25193 is shipping code used on Lend Lease materiel intended for the Middle East. The destination is often listed as "Suez", as in "New York (or Baltimore) to Suez." There was no caption or date with the photo, but it would have to have been sometime after the two tanks reportedly arrived in late June. The British repainted their Shermans for the desert, but T-25193 still appears to have been in its original olive drab paint at the time this photo was taken. It can be seen to have been retrofitted with locally produced sand shields and a Crusader tank type stowage box on the turret bustle. The Mechanization Experimental Establishment (Middle East) devised a suite of additional modifications that were applied to the Shermans as they were processed for issue before they had their combat debut at the Second Battle of El Alamein in late October. T-25193 is another example that can be seen with the extra cable clamp in the center. Unfortunately, at present we can't document the other early "M4A1 (BR.) Gas" that was shipped to Egypt, but, by process of elimination, would guess that it was T-25192. Jarrett Collection, Military History Institute, Carlisle, Pa. via Steve Zaloga.

The process had begun much earlier, but in April, 1942 the Ordnance Department formally took over the British Tank Contract at LLW. Lima's M4A1s were now to be procured on a retroactive basis under US Production Order T-4154 for 400 units. While the first few M4A1s can be seen with British T-Numbers, US Ordnance Serial and Registration Numbers were assigned after the fact. One might expect that the Serial Numbers assigned to the first Shermans would be very low, but because they were initially ordered on a British contract, no US Serial Numbers had been set aside. Based on historic documents and period photos that list or show Serial and/or USA Registration Numbers, we have "interpolated" that these M4A1s were assigned the numbers shown at the top of the page. One interesting Serial Number source comes from a "Thank You" letter, shown above, written to the employees of Lima by Sgt. L. Callet of B Squadron, 5th Royal Tank Regiment. He mentions that "25734 (Serial No.)...was "in it" and gave much more than it took right from Alamein to Tripoli." By our reckoning, Serial Number 25734 would have been Lima's 58th M4A1, and would have been accepted in July, 1942. A footnote to PO T-4154 states " 1 tank purchased by the British." No doubt, this was "Michael," the only Sherman the British Government actually paid for. The US ordered additional M4A1s from Lima, and provided funds to expand the facility for the production of 200 tanks per month.

The Sherman design was still being revised as the first tanks rolled off the assembly lines. Some early M4A1(75)s, and only M4A1(75)s, can be seen to have rotor sights as on the T6 pilot turret. The exact number is unknown, but a Lima memo dated Jan 21, 1942 provides a clue when it states "First 30 tanks using Rotor Device." It is thought that 10 or so of the early Pressed Steel Car M4A1s also had rotor sight turrets. "Michael" is the only surviving Sherman known to have this feature, and the photos above provide front and rear views of the turret's rotor sight casting.

Like the M3 Medium type "pepper pot exhaust", the rotor sight was not considered "battle worthy" and tanks so equipped were NOT to be shipped overseas to combat troops. However, at least one M4A1 with rotor sight turret "slipped through the cracks." The photo above depicts the recovery of a Sherman of the 751st Tank Battalion near Montemarano, Italy on 29 September 1943. The Sherman replaced the M3 Lee as the US Army's standard medium tank, but some M3s continued to serve overseas in support roles, such as Recovery Vehicles, Prime Movers, and Canal Defense Lights. Baldwin Locomotive converted 805 Gas and Diesel Lees to T2 (M31) Tank Recovery Vehicles, such as the example seen on the right in the photo. Many of these served with the US to the end of the war in both the Mediterranean & European Theaters of Operation.

An early D50878 turret, neatly machined, gets some finishing touches at Lima. Note the opening for the rotor sight (1). The "21" that can be seen cast on the side is the serial number, indicating it was the 21st turret casting accepted. ("Michael" has turret serial number 28.) The "serial number on the side" is typical of Union Steel turrets. During its time as a producer of the M4A1, Lima procured the majority of its turrets from this firm. Throughout much of 1942, it would appear that Union Steel, with a capacity of 300 turrets a month, split its production evenly between Lima and Pressed Steel Car. While the majority of D50878 turrets can be seen with the rear lifting rings mounted close to the lower edge, early production units had them mounted near the upper edge of the turret. About 400 Union Steel turrets appear to have had the "high" turret lifting rings (2).

On March 5, 1942, the Military Characteristics of the M4 series were revised to eliminate the two fixed machine guns. Twelve M4A1s had been accepted through the end of March, and we suspect that is close to the total built with the fixed MGs factory installed. The number of hulls in the production pipeline that had had the fixed MG holes machined out up to that point is unknown. The holes were ordered to be plugged and filled in by welding. The paint has burned away revealing the plugged holes seen on the lead Sherman hulk in the photo above. The distinctive tail lamp guard identifies this M4A1 as Lima built. These tanks were combat casualties of the 3rd Battalion, 1st Armored Regiment of the 1st Armored Division. They were knocked out in mid February, 1943 during the Battle of Sidi bou Zid. For a short time, the Germans controlled the battlefield, and appear to have rendered these tanks unrecoverable by the use of demolitions. It is likely that, after the Germans had retreated, they were collected up by US Ordnance units and placed by the side of the road for salvage.

The minutes of a conference held at LLW, 4/27/42 discuss a gap in the direct vision configuration that exposed the drivers to bullet splash. It is noted that engineers at APG had designed a solution which replaced direct vision with auxiliary retractable periscopes in a lengthened driver's hood. The Ordnance Department adopted this, and eliminated direct vision from the cast hull design on June 24, 1942. The Lima minutes may provide a clue as to the number of direct vision M4A1 hulls that were made... "However, inasmuch as there are approximately 250 hulls cast and in the process of assembly, it is absolutely essential that some modification be made to protect this point." The remedy proposed was the addition of a splash guard. We haven't found any evidence that the L shaped splash guards were ever installed on any direct vision M4A1s, but they appear to have been included almost from the start on many welded hull Shermans. Above shows the guards (asterisked) on the M4A4 pilot.

From a series of photos taken at the outset of production in early 1942, workers prepare to install the turret on what is marked as Lima's sixth M4A1. (We believe this would have been T-25194 shown in the UK in an earlier caption.) In combat, the perforated sheet metal around the turret basket (1) was found to isolate and trap the crew, and was eliminated from the design about a year later. Another item of interest is the "sloped" instrument panel (2 and inset). This appears to have been used on M4s and M4A1s until late 1942, when it was replaced with a "tombstone" shaped panel. At the outset of production, the grouser compartments were covered with oblong plates (3).

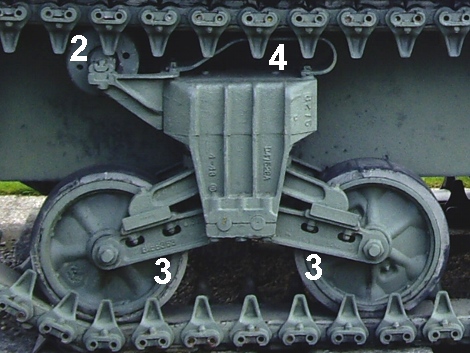

The weight of the Sherman overtaxed the original M3 Medium type suspension units. Chrysler designed new bogie assemblies with larger springs and trailing return roller arms. These were approved for production in January, 1942. For convenience, we refer to them as "M4 bogies," because, as quickly as they could be produced, they replaced the older M3 type bogies, and became standard on all M4 series Shermans. Counting heads suggests that Lima completed the transition to the heavier duty bogies by the end of October, 1942. The Lima factory floor photo above provides a good view of the appearance of the early M3 type suspension units. On the left, the complex bogie bracket casting can be seen with a slight hollow on the inside, and a notch at the top.

LLW and Pacific Car & Foundry assembled all of their lower hulls by welding as directed by the Ordnance Department. Up until the Spring of 1943, the lower hulls of Pressed Steel Car Shermans were assembled with rivets. In photos, the presence or absence of rivets can provide a clue as to the maker of early M4A1s. While the bogies units were attached to the hull with bolts, the idler wheel assemblies were "still" secured by rivets on some of Lima's first Shermans. Throughout production, both Lima and PCF used a rounded transition piece to join the lower rear hull plate to the belly plate. As can be seen here on their 16th tank, some early Limas were built with R-975-EC2 engines, which used 91 octane aviation gasoline and were configured with the M3 Medium "pepper pot" exhaust and internal air cleaners. An Ordnance Department document has it that it was “the first 56 tanks produced.” Field reports from users of the M3 Medium noted that the original exhaust system created a dangerous heat buildup on the engine deck, which, in some cases, melted the leather straps holding the pioneer tools. The Army determined to use "regular" gasoline for its vehicles, and, in May 1942, the R-975-C1, which was modified to run on 80 octane gas, replaced the R-975-EC2 in production. Lima documents mention that all M4A1s not built with the standard M4/M4A1 exhaust and external air cleaner configuration would be retrofitted with it before assignment to troops. We interpret this to mean that any M4A1s built with R-975-EC2 radials would have had them replaced with the R-975-C1 before they were released for issue.

One might assume that the number of lower hulls assembled with the pepper pot holes would have been limited to a small number of early M4A1s with direct vision. However, the LLW factory photo above is dated July 29, 1942 and, by our count, there are over 100 lower hulls with the pepper pot holes visible. This suggests that Lima M4A1s would have been built with "blanked off" lower hulls at least through the month of August, and some of them would have been on the later upper hull castings without direct vision.

A correspondent encountered a surviving Lima M4A1 with the holes blanked off, but with a later, non direct vision upper hull. The serial number of this tank is unknown, but we have interpolated that Lima used about 250 direct vision hulls, before transitioning to the later hulls in August, 1942. Right side photos courtesy of Maurice Donckers.

Early production M4s, M4A1s and M4A4s were produced with the grouser compartment holes blanked off. However, it was found that their fuel tanks suffered an excessive heat condition, which caused melted solder joints and other fire hazards. This was remedied by the addition of a pair grouser compartment covers with air inlet grills, which permitted greater air flow to the fuel tanks. Some early M4s and M4A1s were equipped with welded together "air scoops." These are thought to have been post production additions, fashioned at Tank Depots. They are seen in two shapes, half a triangle and quarter round. The shapes are not specific to a particular maker (Lima or Pressed Steel). A few period photos lead us to theorize that the triangular shape was fabricated and installed at the Toledo Tank Depot in Ohio, while the quarter round came from the Chester Tank Depot in Pennsylvania. The Lima built M4A1 on display in Dompaire, France is the only surviving Sherman we have encountered that is "still" equipped with the early welded air scoops. Two views are shown above. All of the air scoops were secured to the hull by means of a long bolt and clamp, as shown in the inset.

The standard air scoop castings entered the production pipeline at Lima around September 1942. They were made in left and right hand versions. The openings were machined in such a way that the air scoops were mounted inset. This was not the case with welded hull Shermans, where the pieces were mounted on top of the armor. The other item of interest shown is the tail light guard. Lima was the only builder that used 3 pieces to form the rear guards, so that they have a very distinctive appearance. They provide a good Lima recognition feature when they can be seen in period photos. While the head light guards were installed from the outset, the rear guards appear to have been introduced in July, 1942, and were used to the end of production in September, 1943.

The minutes of a conference at Lima on 24 February 1942 discuss various shortages including transmissions and final drives..."We have received 10 of the M3 type which have been converted and applied to tanks. Twenty of the M4 type are promised during the next week." The differential housing as designed for the M3 Medium consisted of 3 castings bolted together. The left-hand section was part number E1231, the middle or "carrier" piece, part number E1232, and the right-hand casting with a notch in the bolt strip (inset) was part number E1230. At the outset of production, it was necessary for Lima and some of the other builders to make do by welding an extension into the notch in order for the E1230 piece to fit the Sherman. The "twenty M4 types" mentioned in the memo would have been 3-piece differential housings with the E1230 piece replaced by a new casting, part number E4151, with an un-notched bolt strip. While "Michael" was built with the E4151 piece, the photo above shows the first Lima M4A1 with the E1230 section with filled in notch. The Sherman design was still undergoing revision, and on this example, the weld seams on the glacis indicate that both the bow machine gun (1) and the bow gunner's hood (2) were separate castings that were added in to the hull. Thus, it seems likely that the upper hull was originally cast without a bow gunner's hatch, like the T6 pilot.

Lima had a distinct diamond shaped logo that they used to identify their locomotives. They "branded" their Shermans as well by stamping their logo on the right front, as seen on the M4A1 in Dompaire. Stamped above or below the logo is a number, which, on most of the examples examined, works out to be an exact build sequence number, added to 1000. Thus, the "1022" shown in the inset suggests that this was the 22nd unit built by LLW, and would have been accepted in April, 1942. Surviving Shermans cannot be assumed to have all of their original components. Our counting heads method would indicate that this tank would have been built with M3 bogies and a rotor sight turret. Those items were obviously replaced at some point. The applique armor was also retrofitted post production.

The M4A1 in Dompaire has a Union Steel turret with serial number 1253. That would be over 1200 too high for the 22nd Lima, leading us to conclude that this turret was retrofitted from another Sherman. Turret 1253 would have been built with an M34 gun mount (1), but the commander's vision cupola, (2) the various machine gun stowage fittings (3) and the smoke mortar (4) would have to have been post production modifications. We've already discussed the welded air scoops, but another very early production clue regarding the hull, is the additional cable clamp (circled). It might be helpful to have a look inside this tank to see if it still has a dataplate, as we believe this is one of the Lima's that was NOT originally assigned a US Ordnance Serial Number. Update: In 2019, Pierre-Olivier was able to “look inside” this tank using his phone connected to a miniature camera on a telescoping stick. Unfortunately, there was no Lima dataplate, but instead, French “Char M4A1” dataplates, probably dating from the 1950s. The presence on the transmission of the hydraulic fittings for an M1 dozer blade was unexpected, since this vehicle shows no external signs of having been a dozer tank.

We would judge that the Dompaire M4A1 has retained its original 3-piece differential housing. Just below the painted on French flag, the plugged holes of the fixed machine guns are barely visible under the paint layers (circled in red). Indeed, Pierre-Olivier was able to capture the interior fixed MG fittings with his mini-cam (inset 1). The bow machine gun dust cover fitting would have been retrofitted at some point during the course of its service life. As best we have been able to determine, Lima built M4A1s never used the "standard" hull lifting ring castings which were introduced in early 1943, and equipped most Shermans to the end of production. Inset 2 shows the fabricated lifting ring used by Lima up until the last month of production. The distinctive weld pattern, with a sort of "swirl" is consistent throughout, so that we consider these rings to be a Lima recognition feature.

In this view, the drivers' hatch handles (1) can be seen to be in the "first" position, mounted towards the rear and on an angle. The positive hatch lock mechanisms and equilibrator springs (2) were introduced in the Spring of 1943, and could have been added as a field modification or during remanufacture. The driver's hood applique plates (3) obscure the direct vision slots. The Field Service Modification Work Order for these plates was published in late August, 1943. The modification did not apply to the M4A1 as it was thought that the cast armor in front of the drivers' hoods was better contoured, and not as vulnerable as the protruding hoods used on welded hull Shermans. However, based on a few period photos and surviving examples, it would appear that direct vision M4A1s received this mod during remanufacture, and, overseas "in the field" in some instances.

It is likely that this M4A1 was built with an R-975-EC2 engine with the odd "pepper pot" exhausts, and that, before issue, the engine was replaced with the standard R-975-C1 engine with its reconfigured exhaust and air cleaner setup. The pepper pot holes were no longer necessary and were blanked off (1). The "high" exhaust pipes of the C1 engine are no longer present, but they would have been located in the area indicated by the "2." Note that the retrofitted external air cleaners are missing their bottom sections. Earlier we mentioned that the idler wheel assemblies were "still" secured by rivets on some of Lima's first Shermans. The rivets can be seen on the assembly on the right. The one on the left has had the rivets replaced with bolts, the standard configuration for VVSS equipped Shermans. At some point during its service life, this tank was retrofitted with the Barber-Colman exhaust deflector. While the deflector is long gone, the "X"s indicate the parts that were added to hold it.

The earliest Shermans built by Lima were equipped with a pair of external fuel shut off valves on the engine deck, as seen on Michael above left. These were eliminated from production by July, 1942. On the Dompaire, the shut off valve holes have been filled in with welded discs. Early production Limas also had M3 Medium type fuel filler caps with tabs. In the interest of simplicity, the tabs were eliminated, and the center hinge barrels were welded directly to the armor plate.

On the occasion of the Horse Guards Parade on 8 May 1942, Prime Minister Winston Churchill closely inspected "Michael," and actually climbed in. About a month and a half later, on June 21, Churchill was at the White House when he got the news of the surrender of Tobruk. President Franklin Roosevelt asked if there was anything he could do to help, and without hesitation, Churchill replied, "Give us as many Sherman tanks as you can spare and ship them to the Middle East as quickly as possible." Soon after, Roosevelt ordered the shipment of 300 Shermans and 100 M7 Priests. This would have been pretty much the entire production of Shermans up to that point. Indeed, a British description of the "special shipment" Shermans describes them as "from May June and July production." The tanks were collected up from the factories, as well as from US units that had just begun training with them. The "5185 Opportunity" convoy sailed on 15 July 1942 with 302 Shermans and 100 Priests. The Shermans break down to 212 M4A1s and 90 M4A2s. The S.S. Fairport with 51 M4A1s and 32 Priests on board was sunk by a U-Boat the next day. The Seatrain Texas sailed unescorted two weeks later with replacements of 52 M4A1s and 25 Priests. Hunnicutt Collection, Patton Museum.

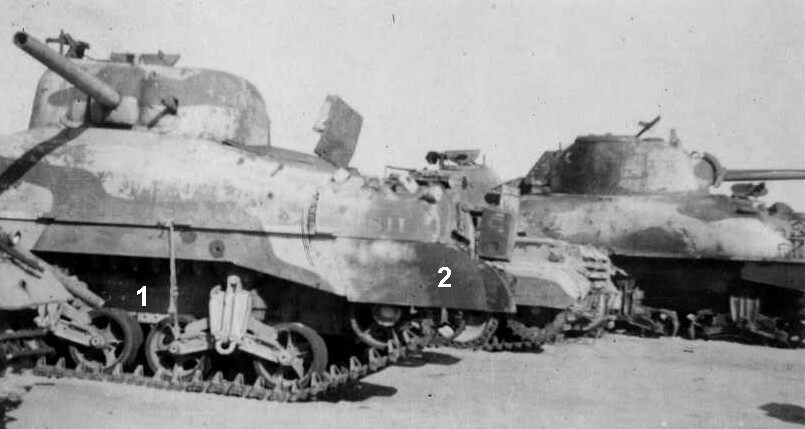

The Shermans began to arrive in Egypt in September, 1942. At least some came equipped with sand shields, as seen above. Others were outfitted with them in British workshops as they were processed for issue. Most of the M4A1s can be seen fitted with welded air scoops. M4A2s did not require them and the grouser holes were simply blanked off. M4A2s were built with tail light guards from the start. Lima began to install them around July, while Pressed Steel Car M4A1s appear to have been the last Shermans to have them introduced in October, 1942. The M4A1 in the photo was produced by PSC, and appears to be USA 3014837, indicating May, 1942 acceptance. Other photos in this series show it was T-74418, which is listed in the 24th Armoured Brigade's War Diary in late October, 1942 as with the 45th Royal Tank Regiment. The "UFS" seen painted on the side of the M4A2 is shipping code for "US-Freetown-Slow." It was a slow speed, zig-zagging convoy from the US to Freetown in West Africa. From there, the British Navy took over escort duty for the journey around Africa, through the Suez Canal and on to Egypt. This tank can be seen to be T-74291. Units records list T-74291 as with the 47th Royal Tank Regiment. It was battle damaged during the Alamein campaign, but recovered and repaired. In a General Motors Technician's Report from Tripoli dated August, 1943, T-74291 is listed as Pullman Serial Number 955, which would have made it July 1942 production. IWM E16607.

Few if any Pacific Car M4A1s would have been available by mid July, 1942 when the convoy sailed, so the 200 odd M4A1s the British received would have been a mix of Lima and Pressed Steel Cars. The British repainted their Shermans for desert conditions, which would have covered the USA Registration Numbers. Some of the paint appears to have burned off the example above, revealing USA 3014811. This would have been Serial Number 55, built by Pressed Steel in May, 1942. Note the riveted lower hull (1), and the odd shape of the sand shields (2), which suggests that they were locally fashioned. The Shermans in the photo were filmed at a Collecting Point after the El Alamein Campaign, and appear to have only one flap on the commander's hatches. British and US tankers were essentially "crash test dummies" for the early Sherman, and it is noted that severe injuries resulted due to the lack of effective locking mechanisms on all of the hatches. The British attempted to remedy the problem through several expedient fixes, including one which involved the removal of one flap on the commander's hatch.

It is thought that most of the Alamein M4A1s would have had plates covering the holes of the original "pepper pot" exhaust. The example shown above was featured in a Military Intelligence Report sent to the US in December, 1942 showing "battle damage encurred (sic) by American tanks during the recent Alamein Offensive." Photographed at the "Rahman Collecting Point" this M4A1 can be seen to have an octagonal blank off plate bolted on (1). The tank has several features typical of Lima Locomotive. Note the rounded transition piece (2), the Lima tail light guards (3) and the extra cable clamp (4). Lima appears to have been the only builder to mount the engine access door bumpers on the doors themselves (5). While some later LLW M4A1s were equipped with round air cleaners, only the square type Vortox air cleaners are seen in photos of the Alamein Shermans. The turret shows a number of scoops and a penetration, reportedly by a 75mm or 76.2 mm [captured Soviet] shell. It appears to be Union Steel #90, and has the "high" lifting rings.

It is obvious in period photos that most of the British M4A1s had "high" lifting rings on their turrets. This particular example does not. It was photographed "About 2 1/2 miles north of El Wishka." It has been identified by the tactical markings as a Sherman of the 10th Hussars, 2nd Armoured Brigade, 1st Armoured Division. Note the early use of "sandbag armor." The turret serial number of this tank can be seen as 502, which seems a bit high for what would have been available up to mid-July, 1942. Aside from "Last In, First Out" production, one possible explanation may be that this M4A1 originally had a rotor sight turret that would have been considered not "combat worthy." The "5185 Shipment" documents mention that "19 were sent back to Chester Tank Depot." Perhaps these 19 had rotor sight turrets that were replaced, and they were shipped later on July 29 with the Sea Train Texas, to make up for the Shermans lost when the Fairport went down?

The British preferred the GM twin diesel engine M4A2, and later, the M4A4 with Chrysler Multibank engine, over the radial engine M4A1 and M4. Indeed, they were not originally intended to receive any radial Shermans except for a few samples from early Lima production. It had been agreed that they would be allocated the entire output of Pullman M4A2s, but of course, the emergency shipment essentially rounded up all of the available Shermans at the time, the majority of which happened to be M4A1s. In the event, the Brits were not allocated any further radial Shermans until the Summer of 1943, when shortages of their preferred types made it necessary. Following the Axis defeat in North Africa in the Spring of 1943, Sherman based Commonwealth formations in the Mediterranean were organized around M4A2s and M4A4s. Many of the Alamein M4A1s that survived appear to have been redeployed as training tanks within the Middle East Command. The photo above is dated May 18, 1943, and was taken at a former Lancia auto facility in Tripoli. It shows GIs of the First Provisional Ordnance Maintenance Battalion replacing the radial engine of a well-worn Eighth Army M4A1. The US provided technical and mechanical support for Lend Lease tanks shipped to the British throughout the Campaign in North Africa. The tail lamp guard and welded lower hull identify this M4A1 as a Lima. Its original rotor shield or more likely the entire gun and mount was probably replaced by a later gun mount that included a rotor shield casting with the integral side pieces (circled). We don't find any evidence that Lima ever factory installed this later type of rotor shield. The inset shows a front view of the tank with plugged fixed MG holes (asterisked). Based on the WD Numbers seen on other Shermans in this photo series, we suspect this M4A1 was T-145112. If so, it was listed in November 1942 as "Fit" with the 3rd Royal Tank Regiment.

British workshops made various modifications to the Shermans before issue. It is noted that the number of rounds carried by the M4A1s was increased from 90 to 96. The "Tank State" for 23 October 1942 lists 318 Shermans in the Middle East, with 235 reported as "serviceable with formations" of the Eighth Army. The tank had its combat debut at dawn the next day with the start of the decisive Second Battle of El Alamein. The M4A1s shown above were filmed shortly before the outset of the offensive. They have been identified as with C Squadron, 9th Queen’s Royal Lancers, 2nd Armoured Brigade, 1st Armoured Division. Three of C Squadron's Shermans were reported knocked out on the first day. The lead tank can be seen as T-145063 and can be identified as a Lima M4A1 by the taillight guard and the additional cable clamp. By the end of the year, it was reported that 119 Shermans remained serviceable with the Eighth Army, and that 66 had been lost in action up to that point. An October 30th MILSTAF telegram on the progress of the battle, provides some insight regarding the performance of the tank, "First reports from Western Desert indicate great satisfaction with Sherman...Troops are saying send us more Shermans earliest." Courtesy of the Imperial War Museum, Photo E18377.

Elements of both the 1st and 2nd Armored Divisions took part in Operation Torch, the joint US/British Invasion of Northwest Africa, launched on November 8, 1942. The 1st AD deployed from the UK with Combat Command B that included 2 Battalions of M3 Light Tanks and one Battalion, the 2nd of the 13th Armored Regiment, made up of M3 Lees. CCB of the 2nd AD deployed from the US with 2 Battalions of Light Tanks and one Battalion, the 3rd of the 67th Armored Regiment, consisting of 54 Shermans, all M4A1s according to some sources. CCB/2AD was part of the Western Task Force that landed on the Atlantic coast of French Morocco with the goal of capturing the major port of Casablanca. Until the rest of the 1st and 2nd ADs arrived in late December, CCB had the only Shermans in the theater. They were not reported to have engaged in combat with the French during the landing phase, although there is mention that the CCB column was "bombed and strafed" on 9 November. Perhaps reflecting the confused political situation and divided loyalties, French forces in Tunisia, who could have easily crushed the first German air landings there, failed to act, permitting the Axis to build up enough strength to thwart the Allied attempt to rush east and seize the ports of Bizerte and Tunis before the end of the year. In any case, CCB/1st AD provided tank support in Tunisia, while CCB/2nd AD remained behind with Patton's Western Task Force to guard against any possible Axis threats on the Spanish/French Moroccan border. A platoon of Shermans from the 67th AR/2nd AD was sent to the front in order for their crews to gain experience. They were attached to Company E of the 2/13 AR which was down to 9 Lees as a result of earlier battles. On 6 December 1942, Company E was ordered to "charge up the valley" in order to relieve the 1st Battalion of the 6th Armored Infantry Regiment exposed at Djebel el Guessa. The Axis forces were well prepared for such a counterattack, and within 15 minutes, all of the Shermans and most of the Lees had been knocked out. The records are somewhat unclear, but not including the "bombed and strafed" incident on 9 November, it would appear that this sad episode was the Sherman's US combat debut. We are not aware of any photos of the ill-fated Sherman platoon, so instead show the 6-man crew of one of the Lees of Company E as photographed at Souk el Arba on 23 November 1942.

The US Army paid a heavy price for its inexperience when it encountered the Germans for the first time in Tunisia. The newly arrived 1st Armored Regiment of the 1st Armored Division suffered the humiliation of having its two Medium Tank Battalions virtually wiped out on February 14th and 15th, 1943 during the Axis Offensive which came to be known as the Battle of Kasserine Pass. In the early stages of the stunning but ultimately failed offensive, the Germans captured at least one Sherman intact. USA 3067641 was a July, 1942 production Lima built M4A1 named "War Daddy II." The tank carried the tactical markings of Company G, 3rd Battalion, 1st Armored Regiment. War Daddy II was shipped to Germany for evaluation. In June 1943, the German weekly, "Das Reich," published an analysis of the various Allied tank designs. Surprisingly, there was praise for certain qualities of the Sherman, which was described as a "running" tank, "embodying a type of strategy that is conceived in terms of movement." (This represents a clear understanding of the intent of the tank's designers.) The article concludes, "In Tunis, German soldiers have demonstrated their ability to deal with this tank, but they know the danger represented by these tanks when they appear in large herds."

Allied shipping capacity was always limited, but in early 1943 the situation improved somewhat, and large numbers of Shermans and other AFVs arrived at the ports in Northwest Africa in the Spring. These were meant to fit or refit US, Commonwealth and Free French forces. The combat career of the Grant and Lee in the West ended with the Tunisian Campaign, as they were replaced with new Shermans. Above shows the scene on April 1, 1943 at Ordnance Dump # 63, Casablanca, French Morocco. A number of the M4A1s can be seen with the Lima tail light guards. Unlike our previous examples, these Shermans are outfitted with M4 type bogie units. LLW was rather late in completing the transition to these in October, 1942. A couple types of steel tracks are also evident. Supplies of natural rubber became scarce due to Japanese conquests in Asia, and the Ordnance Department found it necessary to employ some steel track alternatives. Only a few of these M4A1s can be seen outfitted with sand shields. An attempt was made to supply them on Shermans destined for desert use, but they were not mandated to be installed on all M4 series tanks until a universal type became available around mid 1943.

As mentioned earlier, power trains protected by 3-piece differential housings had been designed originally for the M3 Medium, but were carried over to the M4 series. It was intended that they be replaced by a simpler and stronger 1-piece housing which entered production in mid 1942. However, some power train manufacturers, including Lima's primary supplier at the time, the Iowa Transmission Co., stated that they could not retool for the new configuration without it creating a serious slowdown in Sherman production. Consequently, the majority of the differentials of Lima Shermans were equipped with 3-piece housings until about Spring 1943. In late 1942, Iowa began the transition to a new configuration in which a "lip" was added to each of the 3 cast sections in order to protect the top bolts from bullet splash. Above left shows the original "no lip" differential as seen on Michael, while the later "lipped" configuration is shown on the right. At the transition point, some differential housings were assembled with a combination of lip/no lip sections. An example of this can be seen on the M4A1 facing the camera in the previous caption. Left side photo courtesy of Massimo Foti and right side picture courtesy of Trevor Larkum.

Period documents indicate that Lima received some E4186 1-piece differential power trains from both the Caterpillar Tractor Co. and Buick. The photo above shows an example on USA 3058661, a December, 1942 Lima. These seem to have completely replaced the 3-piece differentials on LLW Shermans around the Spring of 1943. While all of the photos we have examined show the Alamein M4A1s with 3-piece differentials, we don't discount the possibility that some might have had 1-piece housings, as seen on a few of the M4A2s and M7 Priests that were part of the emergency shipment. A number of items were introduced at Lima in late 1942. These include the bow machine gun dust cover (1), the step bracket (2) and the "spot and signal lamp." (The lamp's bracket can be seen as item 3.) The head lamp plug holders were reoriented from their original mounting parallel to the glacis to the standard vertical position (4). Photos such as the above suggest that Lima was supplied with a different siren around this time, made by the the Mars Signal Light Company (5).

Sherman production began with the same type of drive sprocket as used on the M3 Medium series. Reports from the field noted that a number of these were suffering a "breaking teeth" problem. In late 1942, many of the Sherman manufacturers, including LLW, replaced the original M3 type sprocket with a new design as seen on the right. For want of a better term, we refer to this as the "plain sprocket." It is thought that Lima began the transition to the "plain" type in November 1942, and used them to the end of production in September, 1943.

At at their introduction around October, 1942, the M4 bogies on Lima Shermans are seen in the "early" configuration, but with the second type of track skid (1). An example of such a bogie unit is shown above on the left. In late 1942/early 1943, some improvements entered the production pipeline, and these are reflected in the bogie unit shown on the right. The use of heavy steel tracks created a friction problem with the track skid. This was remedied by the addition of a spacer (2) that elevated the return roller by about an inch. A modification kit was also provided in the Summer of 1943, so that the spacer could be retrofitted to any Sherman built without it. The "final" type of bogie arms (3) were also introduced in late 1942. In order to prevent the bogie arm rubbing plate bolts from working loose, they were secured at the bottom with a nut. "Wrench holes" provided access to the nuts. Lima appears to have been the first builder to introduce the "final" type of track skid (4) in January, 1943. "Upturned" return roller arms, which obviated the need for the spacer, were introduced right about the time that Sherman production ended at LLW in September, 1943. We have found no evidence that they ever were factory installed on any Lima built M4A1s.

The photo above is dated 22 March 1943, and documents a "shifted cargo" incident that occurred aboard the Liberty Ship William Johnson during its voyage from the US to Casablanca. The Registration Number, USA 3058815, may be painted on in black as opposed to blue drab in this case. It indicates that this M4A1 was accepted at Lima in January 1943. The bogie units can be seen in the later configuration with the bogie arms with wrench holes and the spacers installed. We would note that January production is the earliest we have seen the "final" type of track skid on any Sherman. As supplies increased in 1943, it became standard on all models to the end of VVSS production. Note the Mars Signal Light Co. siren, and the T54E1 steel tracks. Based on this and a few other photos, we would guess that "BLOT" was the shipping destination code for the port of Casablanca.

The Allied victory in Tunisia in May 1943 came months later than the planners had hoped, but was quite impressive, nonetheless. Hitler's "no retreat" obsession, coupled with the growing strength of Allied Naval and Air power in the Mediterranean set the stage for one of those rare occasions in warfare where the entire enemy force was destroyed. A quarter of a million Axis troops were captured, which rivaled in scope the Soviet victory at Stalingrad a few months earlier. The green US Army did not perform very well in its first major campaign. Allied planners had decided that the next objective would be Sicily, and that the new US 7th Army under Patton would be relegated to the secondary role of flank protection for Montgomery's vaunted British 8th Army. The 2nd Armored Division provided the bulk of 7th Army's tank support, while the depleted and demoralized 1st AD refitted and retrained in Northwest Africa. The photo above shows "Eternity" "after landing on beach in Sicily. July 10, 1943" according to the Signal Corps caption. The tactical symbols below the name have been identified as denoting Company E, 2nd Battalion, 67th Armored Regiment. The planners had provided for 2 platoons of Co. E to be attached to the 1st Infantry Division to provide tank support during the initial assault on D-Day. However, there is no evidence in the various reports that any Shermans landed in the Gela area on D-Day, so it is thought that the photo must have been taken on D+1, July 11th. Note that "Eternity" does not have a rear wading trunk installed. On the 11th, it was reported that a single platoon of Co. I, 3rd Battalion, 67th Armored Regiment whose Shermans had not yet been "de-waterproofed" were the only tanks in position to meet an attack against the beachhead by the Herman Goering Panzer Division. The Shermans, along with a few pieces of 1st Infantry Division artillery plus prodigious Navy gunfire support, all played a significant role in repelling this, the most threatening attack against the 1st ID's beachhead. Above, what can be read of the USA Number, 306785X, indicates September 1942 production. Note that the installation of M3 bogies at Lima continued into September. While "Eternity" can be seen with the standard cast air scoop, the bow machine gun dust cover, step bracket and spot lamp had yet to be introduced when this tank was accepted.

A handful of the 2nd AD's Shermans had a part in repelling the Axis armored attacks on the second and third days of the invasion, but for the most part, tanks played an infantry support role in the mountainous terrain of Sicily, and later in Italy. General Patton was anxious to redeem the reputation of the US Army, as well as grab a bit of personal glory. Once the bridgehead was secure, he formed a Provisional Corps which utilized the entire 2nd AD in a classic "breakthrough" role. The Corps conducted a "power drive" across the island and captured the Sicilian capital of Palermo on July 22, 1943. Above shows some of the 2nd AD's M4A1s in Palermo on that day. We identify the lead tank as Lima built solely based on the Mars siren (1). All three of the manufacturers of the M4A1 started out with the smaller Federal type siren with the "V for Victory" grill. Pacific Car and Pressed Steel continued to use it throughout production, while Lima switched over to the Mars in late 1942. A new feature seen on the lead tank is the cast shield (2) for the .30 caliber coaxial machine gun. It was introduced in late 1942, and included as On Vehicle Materiel on tanks that were scheduled for shipment to combat zones. Most of the Shermans that arrived in Northwest Africa in the Spring of 1943 were "still" equipped with the M34 gun mount, and many of these appear to have been provided with the MG shield.

The victory in Sicily led to the overthrow of Benito Mussolini, followed by the surrender of Italy in September 1943. Nonetheless, the campaign was somewhat unsatisfying. The Allies failed to blockade the island, so that there was no repeat of "Tunisgrad." German units in particular were able to withdraw into Italy with most of their equipment, and "live to fight another day." The Allied decision to engage in a major campaign in Italy, whose terrain features are ideally suited to defense, remains controversial to this day. It was expected (or hoped) that the Germans would withdraw to the northern mountains, but they chose to occupy the country and contest the Allied advance. The photo above shows M4A1s of Company C, 191st Tank Battalion coming ashore from a special purpose pontoon ramp put down by LST 379 at Salerno Bay on D-Day, September 9, 1943. The lead tank appears to be a Pressed Steel Car. Note that the siren has been relocated from the left front fender to the glacis, and is protected by a brush guard. LLW M4A1s would have the siren repositioned in this fashion at about the same time as the introduction of the M34A1 Gun Mount, end of March, 1943.

US planners were intent on an attack across the English Channel (Operation Overlord) as the most direct route to Germany, while the British hoped that a campaign in Italy would make such an invasion unnecessary. Churchill rather reluctantly agreed to set a firm date for D-Day in May, 1944. At that point, the Italian Campaign was relegated to secondary status. After Sicily, two seasoned US divisions, the 1st Infantry and 2nd Armored were redeployed to the UK. The 2nd AD left its tanks behind for use by the US armored units that remained in theater, including the 1st AD, and a number of independent tank battalions, such as the 191st and 751st TBs, both of which took part in the landings in the Gulf of Salerno. The map above shows the situation in Italy up to early May 1944. Allied planners projected a phase line 30 miles north of Rome before the end of 1943, but any hopes for such progress were dashed as further advance was halted in the Fall at the nearly impregnable position known as the Gustav Line. To break the stalemate, the Allies attempted an end run with a landing at Anzio in January. However, the Germans managed to hold both the Gustav Line and the Anzio perimeter until the Spring of 1944.

The photo above is dated April 18, 1944 and was taken inside the perimeter of the Anzio beachhead. The 1st Armored Division Sherman slipped into a bomb crater, and so provides a nice overhead view of a late 1942 production Lima M4A1. Periscope covers were produced in various shapes. The covers used for the auxiliary periscopes of the drivers' hatches (1) were consistently "flat." As a matter of "Sherman minutia" we would observe that starting in the third quarter of 1942, Lima appears to have received steady supplies of the peaked periscope covers (inset) for use in the 5 other periscopes positions. Allied forces were contained within the Anzio beachhead for 4 long and bitter months. The Germans held the high ground and could zero in on any sector within the perimeter. They bragged that Anzio was "the largest self sustaining prison camp in Europe." In a sense, the Italian Campaign imprisoned both sides as the strategy devolved into a goal of tying down as many enemy forces as possible so that they could not be used elsewhere. For most of the campaign, the opposing forces were evenly matched at about 400,000 troops.

A number of improvements were introduced into Sherman production starting in February, 1943. Some are shown in the LLW factory photo above, dated April 28, 1943. The Positive Hatch Lock Mechanisms (1) for the drivers' and commander's hatches are reported to have been introduced at Lima on February 28, 1943 at Serial Number 29606. In the same document, "Effective Points of Modifications," the M34A1 Gun Mount (2) is listed as having been introduced exactly one month later at Serial Number 29710. The dates and serial numbers don't quite match, and we haven't been able to collect enough information to confirm the dates through "counting heads," but they seem to be reasonably accurate. The siren (3) appears to have been moved to the glacis at about the same time as the introduction of the M34A1. Oddly, the new siren position is only seen on M4s and M4A1s. The tank in the background of the photo is equipped with sand shields. A "Universal" type sand shield, where the front and middle sections were common to all Shermans, was delayed somewhat in its introduction, but a number of companies, including Lima, had designed and installed custom versions before that. The Universal type, which featured a vertical slit in the middle section, is said to have been introduced at Lima on July 23, 1943 at Serial Number 29993.

The "Original Design" exhaust deflector (1) is stated to have been introduced at Lima at the same time as the Hatch Lock Mechanisms, February 28, 1943. The deflector was notched to accommodate the exhaust pipe (2) for the auxiliary generator. The later Barber-Colman type deflector was not incorporated before production ended in September. It was noted that some users felt that the original design was more effective than the Barber-Colman. Lima is reported to have introduced the "long" trailer towing pintle (3 and inset) on April 28, 1943 at Serial Number 29814. In some instances, the long pintle got bent up in service, which created an interference issue with the engine access doors. A shorter pintle was designed, and became available by the end of 1943. It was used on "second generation" and remanufactured Shermans. In the absence of a good photo of these items on an LLW M4A1, we show a March, 1943 production Pressed Steel Car (note the rivets, circled) that was used as a test bed for the installation of the 76 mm gun in a modified D50878 (small) turret.

Two areas on the inside right front of the original D50878 turret casting had been thinned to allow for the proper operation of the traversing mechanism. As the first Shermans entered combat, troops began to report that the enemy aimed for these "thin spots." In mid 1943, armor applique kits were produced to protect the "thin spots." Approximately 900 of the first of these were shipped to the Mediterranean Theater of Operations, and arrived in September. Many of the US Shermans that had served in Northwest Africa and Sicily continued in use in Italy to the end of the war. The turret applique is often the only modification seen in Italy on these 1942/early 1943 production tanks. The photo above is dated May 12, 1944 and shows a column of Shermans of the 760th Tank Battalion advancing from Tufo at the start of the Allied Spring Offensive. The "thin spot patch" (1) and the "Towing Shackle with Handle" (2) are the only modifications evident on the lead M4A1. The so called "Quick Release" towing shackles were reported installed on the front only at LLW starting in mid August, 1943. A Modification Kit was also provided in August, which enabled quick release handles to be retrofitted to existing towing shackles.

A few more of the 760th TB Shermans in column are shown above. The notched item (circled) on the center of the glacis is something of a mystery. This is seen in a few photos of M4A1s in Italy. The inset is the clearest photo we have come across that shows the piece. It is obvious that it is a plate welded to the glacis rather than an alteration to the hull casting or a cast fitting welded on. The simplicity of the part suggests that it could’ve been added at a very low organization level. We have not come across a surviving M4A1 with this feature, nor have we seen any production line type photos where it is present. The US 5th Army in Italy does not appear to have received many later production M4A1s outfitted with the M34A1 Gun Mount. Registration Numbers listed in unit reports indicate a few were present, but despite extensive searching of the Signal Corps Collection, we could not find a photo of one. On the other hand, there are a number of shots of US Army M4s with M34A1 Gun Mounts. An example can be seen in the background of the previous photo.

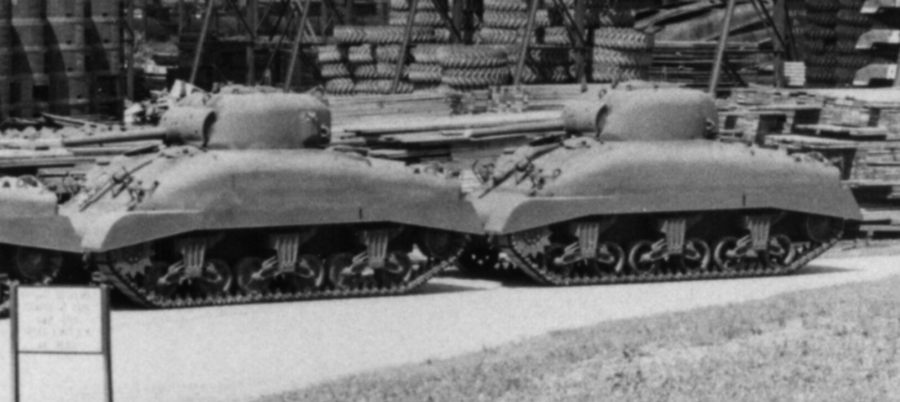

In April 1943, the D50878 turret was revised to eliminate the pistol port, as well as "increase thickness of turret in area of the traversing mechanism." The reconfigured turret castings began to enter the production pipeline at Lima around July, 1943. We estimate that about the last 200 Lima M4A1s were produced with "no pistol port" turrets. These turrets included "cast in thickened cheeks" which obviated the need for the "thin spot patch." In the summer of 1943, before the new turret castings became available, manufacturers were instructed to weld up the pistol ports and apply the patch to older D50878 turrets. At present, we cannot confirm if Lima ever welded up any pistol ports, or added the turret patches during production. Of course, some LLW M4A1s may have had these items added as they were processed through Tank Depots. Above is a blow up of a photo taken outside the assembly hall at Lima. The tank on the left appears to have a working pistol port, while the one behind has a later casting without it. These tanks can be seen with different types of road wheels. Lima transitioned from the original welded spoke wheels and idlers to the pressed metal in Summer, 1943. The sand shields can be identified as the "Universal type" by the vertical slit in the center section. Earlier we mentioned that these were said to have been introduced at Lima on July 23rd, and this photo is dated July 23, 1943. Note that the turret baskets seen in the upper left "still" have the perforated sheet metal.

Starting in the Spring of 1942, British Workshops in North Africa proposed armoring the ammunition racks of Grants as a way to reduce tank fires. They passed their suggestions on to the US, and about a year later, the Ordnance Department tested the idea in the third production Lima, which had remained in the US, but retained its British WD Number, T-25191. Based on other British proposals regarding the Sherman, the 12 unprotected ready rounds affixed to the turret basket wall were removed, and the 8 round ammunition box on the basket's floor was encased in armor. At the same time, the turret basket was "skeletonized," meaning that the perforated sheet metal that encompassed the basket was removed. This provided for more escape options, since the original configuration tended to isolate the turret crew from the drivers. This turret reconfiguration was one step of the "Quick Fix" modification. T-25191 was also used in trials which relocated most of the ammunition stowage to the floor of the hull, in so called "watered ammunition racks." This concept became the "wet stowage" configuration used on the second generation series of Shermans. It is thought that T-25191 was destroyed during these tests.

20,000 "Quick Fix" kits were produced from July through September, 1943. Manufacturers began installing them on new production Shermans in August. As supplies became available in the Fall of 1943, Tank Depots were directed to retrofit the mod. Another step of the modification involved the welding of 1 inch "sponson side protector" plates to the exterior of the tank in the areas of the sponson ammunition racks. Above shows one of the plates being welded on at the Lima Tank Depot. Lima Locomotive is reported to have begun installing the "Quick Fix" modification on August 13, 1943 at Serial Number 30074. The applique plates installed on cast hull Shermans are often seen made up of a number of sections to match the contours of the hull. However, photos suggest that the plates installed by Lima Locomotive and the nearby Lima Tank Depot were in one piece as seen above.

Production Order T-4154, Block 1: 28 units: T-25189 through T-25194 for the first 6 units, the rest unknown (interpolation that no US Serial and Registration Numbers were assigned)

Production Order T-4154, Block 2: 100 units: Serial Number 25705 / USA 3058972 through S/N 25804 / USA 3059071

Production Order T-4154, Block 3: 272 units: Serial Number 25805 / USA 3067630 through S/N 26076 / USA 3067901

Production Order T-3208: 655 units: Serial Number 6805 / USA 3058317 through S/N 7459 / USA 3058971

Production Order T-3606: 600 units: Serial Number 29605 / USA 3038135 through S/N 30204 / USA 3038734

Introduction

Despite US neutrality before December 7, 1941, the British Government, which had been at war since September 1939, was permitted to contract with US firms for war materiel produced on a strictly "Cash and Carry" basis. One of the last contracts let before British dollar and gold reserves were depleted came in February, 1941. The Lima Locomotive Works of Lima, Ohio was engaged to produce 400 Grant Medium Tanks. The contract included funds for the construction of a 125,000 square foot assembly hall, along with the purchase of machine tools and other equipment necessary for the production of 50 tanks per month. The plant was not scheduled to come on line until late 1941. In the meantime, the Lend Lease Act was signed into law on March 11, 1941. The survival of Great Britain was considered a matter of vital national defense to the United States, and Lend Lease was a contrivance which permitted supplies to continue to flow to the beleaguered country despite its inability to pay for them. The Ordnance Department took over all of the existing British contracts in the US, so that the materiel could be provided and shipped "free" as Lend Lease. In partial exchange, British purchased plant and equipment was transferred to the US as Reverse Lend Lease. In the midst of this was Lima Locomotive, under contract with the British, but not yet producing tanks. Because the new facility, shown above under construction in April 1941, would not be ready to come on line until the end of the year, it was decided to terminate the Grant Contract, and tool up the plant for production of the newly designed cast hull M4A1 Sherman instead.

Lima

Locomotive has the distinction of having made the first production

Sherman. It was accepted on the last day of February 1942 and

immediately shipped to Aberdeen Proving Ground in Maryland. The 11 March

1942 photos above show that British War Department Number T-25189 was

painted on the sides. The British had assigned WD Numbers T-25189

through T-25588 to the 400 Grants they had ordered, and these numbers

were still used on some of the earliest LLW M4A1s. From "counting

heads," we interpolate that

no US Serial and Registration Numbers were assigned to the first 28

units. The first 6 Lima M4A1s appear to have retained their British

Numbers, T-25189 through T-25194 at

least at first. Unfortunately, we can't document the remaining 22

units. From counting heads, it would seem that most of the original

range T-25189 through T-25588 was reassigned to M3 Lees, perhaps

starting with T-25199 which was reported as in "3 Australian Ordnance

Tk Depot Wskp, 16 September 1943". We will continue to try to unravel

that mystery. In the meantime, the

letters and numbers cast on the left side of the tank in the rear

(inset) show that the hull was produced by the Continental Roll &

Steel Company (later renamed Continental Foundry & Machine). As with

most M4A1 small hatch upper hull castings, the part number can be seen

as E4153. This particular casting was serial number 3. Lima documents

state that this hull was received in November 1941, and was made to the

specifications for E4153, revision 7. It incorporated many changes from

the T6 (Sherman pilot) but retained

the side doors. Lima officials noted that future hulls would be made to

revision 11 or later, without the doors. Consequently, they requested

authority to blank off the doors on hull #3 using "specially fabricated

castings" as seen in the photos.

The T6 Pilot along with Lima's first Sherman do not appear to have been preserved by the US Army. The British, with perhaps a greater sense of history, saved the second production Sherman for posterity. It is now on display at the Tank Museum at Bovington. It was named in honor of Michael Dewar, chief of the British Tank Mission in the US. "Michael" plates were affixed to each side for photo opportunities in both the US and UK. The tank is shown above on the Lima factory floor at the outset of production. It was rather crudely sealed, and we would be curious to know if it was actually shipped with the hull machine guns installed as shown here. The "5190" that can be seen painted on directly behind the "MICHAEL" plate is the British War Department Number T-25190. Just above that is "LINK" and just below is "1 of 2", which we take to be part of the shipping codes. It was intended to equip the new Shermans with the longer M3 75mm guns, but they were not yet available, so that Michael was originally outfitted with the earlier M2 gun counterweighted for balance.

The first mention of the Sherman in British Purchasing Commission Export documents comes on 31 March 1942. The model is listed generically as "M4" with a total of 400 "On Contract or Requisition." One unit is stated to be "On Ship Awaiting Sailing." The destination is not revealed until 3 April when it is shown to be "United Kingdom." For a little context, 10 Grants and 94 Lees had been exported to the UK by that date. On 1st May, the export docs have it that one "M4" was in the UK, with 3 others "In Transit." The photo on the left is of "Michael" and is captioned "The first Sherman tank delivered to Britain, on display at Horse Guards Parade in London, 8 May 1942." On 15 May, two "M4s" are listed in the UK. The photo on the right shows the next arrival, the sixth Lima M4A1, T-25194. Again, we see "LINK 1 of 2." The other two "In Transit" were heading for the "Middle East" and had arrived by 26 June 1942. At that point, the nomenclature for these four Shermans had been changed from "M4" to "M4A1 (BR.) Gas." In any case, both "Michael" T-25190 and T-25194 remained in the UK and performed service as test vehicles during the war years. The "MSU inside a triangle" seen in the inset is shipping code for Lend Lease AFVs destined for Great Britain. "Michael" does not have it, but some early production Lima M4A1s, such as T-25194, have been noted with an extra cable clamp in the center (1). This is one of those oddities of Sherman minutia that appears in a few period photos, and then vanishes. We know of two surviving Lima built examples that have the additional cable clamp and have not seen it on any of the other builders' Shermans. Note that on T-25194, but not on "Michael", metal "eyelets" (2), likely used to secure the open hatches with wire or a screen door type hook, were retrofitted next to the drivers' hatches. Hunnicutt Collection, Patton Museum.

"Michael" does not have the E4153 casting information on the left rear side of the hull as on T-25189. It is cast in on the hull's underside in the area of the right pepperpot exhaust as shown above on the left. This casting is serial number 6. All of the few other Continental hull castings we have examined have the E4153 info cast in on the firewall facing the fighting compartment, as shown on hull serial number 20 on the right. Until late 1942, Continental cast all of the E4153 hulls. The cost to produce and machine an upper hull was listed as $4500. An Ordnance Department Memo mentions that some of the early castings had "drooped" slightly in the rear. Anxious to get the Sherman into production, rather than reject these massive castings, it was decided to grind down the turret splash to enable the turret to rotate, and cut the underside sponson plates so that they would fit. Over time US companies improved their techniques, and produced high quality cast and plate armor.

The first range of British War Department Numbers set aside specifically for the new Sherman models was for 400 units - T-74194 through T-74593. By June 1942, "Michael" had been assigned the second number within this range - T-74195. Above, shows that the tank was retrofitted with the new M3 75mm gun. However, a "Preliminary Report" noted that "lack of information," and defects in the gun mount and turret had delayed firing trials. The Americans and British were anxious to examine the new design, and rushed to get some tanks finished before all the bugs had been ironed out. Indeed, many of the Shermans produced in April 1942 and earlier were shipped back to the factories to incorporate improvements and fixes that had been made in the interim. The photo above was doctored in anticipation of the elimination of the rotor sight (1). The twin fixed machine guns were removed as well (2). There is no mention in the Lima records of the use of anything but armor hulls. However, "Michael" is listed in the Lulworth Camp Report as "Mild Steel," and a triangular warning plate with "UNARMOURED" (inset) was (and still is) affixed to the right side of the hull. Perhaps a Brinell Hardness test could determine the composition of the metal, but we suspect that the tank was labeled "Mild Steel" simply because it was not "combat ready." In any case, the Report concludes, "This tank, in spite of its defects, shows promise of being a much better fighting machine than the M3 [Medium]. The general layout is good, and the arrangement of the mounting is excellent." Significantly, it was around this time that the British first made the suggestion to US Ordnance that most of the main gun rounds be relocated from "up high" on the sponsons to the floor of the hull.

Based on the retrofitted "eyelets" (1) by the drivers' hatches, we believe that the early M4A1 with rotor sight turret shown above was T-25194, renumbered to T-74199. The photos appear in a "Protection Against Magnetic Grenades" Report dated 25 July 1944. These trials were carried out in the UK on Chobham Common. The letters represent various anti-magnetic patches that were applied to the armor with adhesive: A = Asbestos fabric, F = Felt quilted on hessian, P = Plastic, and H = 4 ply hessian packed with plastic. The tank ran for 29 miles through a "lightly wooded country" which did considerable damage to the patches, in some cases causing them to fall off. At about 20 miles, "it was observed that smoke was coming from the rear upper hull plate which is situated to the rear of the exhaust outlets. As far as could be ascertained it was caused by the adhesive which appeared to be smoldering." We would note that this tank was still running with its original R975-EC2 engine with the problematic pepper pot exhausts. In any case, it was concluded that while all of the materials prevented the adherence of magnetic grenades, none held up under "rough usage." Only the "Bituminous Plastic" was recommended for further testing. T-74199 probably met its end when it was later used in more lethal trials involving Teller Mines and "Flame Thrower attack." With thanks to Peter Brown.

We can document that one of the two "M4A1 (BR.) Gas" that were reported to have arrived in the Middle East by 26 June 1942 was T-25193 as seen above in a snapshot believed to have been taken at the US Middle East Training Center by its Director [then] Maj. George Burling Jarrett from Aberdeen Proving Ground. The school had been established in May 1942 to instruct members of the British armoured corps in the maintenance of US tanks and self-propelled guns. The "UFS" seen painted on T-25193 is shipping code used on Lend Lease materiel intended for the Middle East. The destination is often listed as "Suez", as in "New York (or Baltimore) to Suez." There was no caption or date with the photo, but it would have to have been sometime after the two tanks reportedly arrived in late June. The British repainted their Shermans for the desert, but T-25193 still appears to have been in its original olive drab paint at the time this photo was taken. It can be seen to have been retrofitted with locally produced sand shields and a Crusader tank type stowage box on the turret bustle. The Mechanization Experimental Establishment (Middle East) devised a suite of additional modifications that were applied to the Shermans as they were processed for issue before they had their combat debut at the Second Battle of El Alamein in late October. T-25193 is another example that can be seen with the extra cable clamp in the center. Unfortunately, at present we can't document the other early "M4A1 (BR.) Gas" that was shipped to Egypt, but, by process of elimination, would guess that it was T-25192. Jarrett Collection, Military History Institute, Carlisle, Pa. via Steve Zaloga.

The process had begun much earlier, but in April, 1942 the Ordnance Department formally took over the British Tank Contract at LLW. Lima's M4A1s were now to be procured on a retroactive basis under US Production Order T-4154 for 400 units. While the first few M4A1s can be seen with British T-Numbers, US Ordnance Serial and Registration Numbers were assigned after the fact. One might expect that the Serial Numbers assigned to the first Shermans would be very low, but because they were initially ordered on a British contract, no US Serial Numbers had been set aside. Based on historic documents and period photos that list or show Serial and/or USA Registration Numbers, we have "interpolated" that these M4A1s were assigned the numbers shown at the top of the page. One interesting Serial Number source comes from a "Thank You" letter, shown above, written to the employees of Lima by Sgt. L. Callet of B Squadron, 5th Royal Tank Regiment. He mentions that "25734 (Serial No.)...was "in it" and gave much more than it took right from Alamein to Tripoli." By our reckoning, Serial Number 25734 would have been Lima's 58th M4A1, and would have been accepted in July, 1942. A footnote to PO T-4154 states " 1 tank purchased by the British." No doubt, this was "Michael," the only Sherman the British Government actually paid for. The US ordered additional M4A1s from Lima, and provided funds to expand the facility for the production of 200 tanks per month.