Part 1

: Pullman M4A2(75)s

To

date we have only come across a textual listing for the first Pullman

built

M4A2, but no photos. Serial Number 905 is listed in a

“Defects & Missing

Items” report dated May 28, 1942. The second one, Serial

Number 906, was sent

to the General Motors Proving Ground where it was described as

“the first pilot

model of Medium Tank M4A2,” and photographed in early May. Of

interest is that

this unit was shipped with the tank’s Ordnance Serial Number,

as opposed to the

USA Registration Number, painted on the sides as shown in the inset.

Pullman

had made Grants on which the British War Department Number (T-Number)

was

painted. This was also the tank’s Serial Number, which was

stamped, minus the T

prefix, on the dataplate, so perhaps the firm was confused about which

number

to paint on? In any case, in April, 1942, Pullman and Fisher Body began

production of the first welded hull Shermans. Their M4A2s were very

similar,

but not identical. We invite readers to have a look at the first few

captions

on our Fisher

M4A2 page for an idea of the rather elaborate glacis

configuration used on a number of early Shermans. Unlike a few of the

first

Fisher M4A2s, SN 906 is not seen with the fixed MGs installed, nor are

the MG

holes visible.

To

date we have only come across a textual listing for the first Pullman

built

M4A2, but no photos. Serial Number 905 is listed in a

“Defects & Missing

Items” report dated May 28, 1942. The second one, Serial

Number 906, was sent

to the General Motors Proving Ground where it was described as

“the first pilot

model of Medium Tank M4A2,” and photographed in early May. Of

interest is that

this unit was shipped with the tank’s Ordnance Serial Number,

as opposed to the

USA Registration Number, painted on the sides as shown in the inset.

Pullman

had made Grants on which the British War Department Number (T-Number)

was

painted. This was also the tank’s Serial Number, which was

stamped, minus the T

prefix, on the dataplate, so perhaps the firm was confused about which

number

to paint on? In any case, in April, 1942, Pullman and Fisher Body began

production of the first welded hull Shermans. Their M4A2s were very

similar,

but not identical. We invite readers to have a look at the first few

captions

on our Fisher

M4A2 page for an idea of the rather elaborate glacis

configuration used on a number of early Shermans. Unlike a few of the

first

Fisher M4A2s, SN 906 is not seen with the fixed MGs installed, nor are

the MG

holes visible.

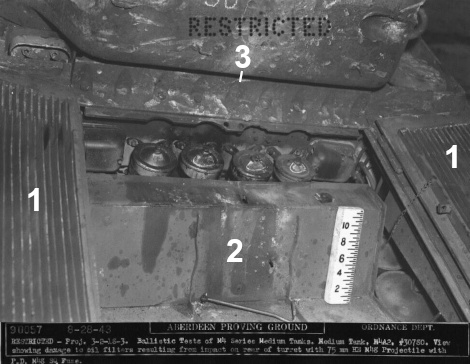

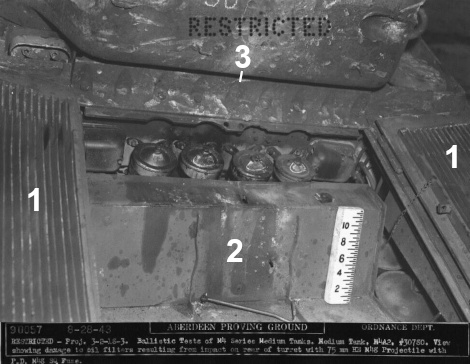

Serial

Number 906 was photographed again in June, 1943 at Aberdeen Proving

Ground

where it was used in tests of the turret reinforcement patch. It can be

seen

that the proper USA Registration Number, 3053116, (1) had since been

painted

on. This is the only example we have encountered of the “high

weep holes” (2)

on a Sherman other than a Pressed Steel Car M4. Perhaps they were part

of the

original welded hull design, which only PSC retained? Period photos and

surviving examples leave little doubt that the “weep holes at

the base of the

turret splash” was the standard configuration used by all of

the other welded

hull manufacturers, including Pullman. SN 906 can also be seen with a

rounded

transition piece (3) where the lower rear hull plate joins to the belly

plate. It

is thought that was limited to just a few units, and that the standard

method

of lower hull construction at Pullman used an angled plate. Early M4A2s

utilized 11 bolts (4) to secure the rearmost engine deck plate.

Eventually, the

number of bolts was reduced to 6. At Pullman this change appears to

have

occurred in early 1943. The original design of the M3 Medium included

the use

of rubber mud flaps. These were changed to sheet metal (5) on the

Sherman.

Serial Number 906 was probably destroyed at APG in July, 1944 when it

was used

in firing tests of “watered ammunition racks” [wet

stowage].

Serial

Number 906 was photographed again in June, 1943 at Aberdeen Proving

Ground

where it was used in tests of the turret reinforcement patch. It can be

seen

that the proper USA Registration Number, 3053116, (1) had since been

painted

on. This is the only example we have encountered of the “high

weep holes” (2)

on a Sherman other than a Pressed Steel Car M4. Perhaps they were part

of the

original welded hull design, which only PSC retained? Period photos and

surviving examples leave little doubt that the “weep holes at

the base of the

turret splash” was the standard configuration used by all of

the other welded

hull manufacturers, including Pullman. SN 906 can also be seen with a

rounded

transition piece (3) where the lower rear hull plate joins to the belly

plate. It

is thought that was limited to just a few units, and that the standard

method

of lower hull construction at Pullman used an angled plate. Early M4A2s

utilized 11 bolts (4) to secure the rearmost engine deck plate.

Eventually, the

number of bolts was reduced to 6. At Pullman this change appears to

have

occurred in early 1943. The original design of the M3 Medium included

the use

of rubber mud flaps. These were changed to sheet metal (5) on the

Sherman.

Serial Number 906 was probably destroyed at APG in July, 1944 when it

was used

in firing tests of “watered ammunition racks” [wet

stowage].

The

next Pullman M4A2 we can document is Serial Number 908, USA 3053118,

which is

shown above during trials of a gunner’s telescope at APG in

the Summer of 1942.

Originally, this tank had been shipped to APG for an Inspection Test,

where it

was noted that “This vehicle was formerly reported as Tank

#4. This tank

arrived without the name plate. The packing list accompanying this

vehicle

showed the serial number to be 3053118 and tank number as

“4”. Inasmuch as

3053118 was not the serial number but the registration number, it was

assumed

that the tank number was likewise reversed and was No.

“4”. Upon receipt of the

name plate and a corrected packing list, it was found that the serial

number of

this tank is 908.” This illustrates the confusion which

persists to this day

over the Serial Number vs. Registration Number. Like SN 906, 908 was

built with

M3 type bogies (1). However, note the newly designed 1-piece

differential

housing (2) on 908 as opposed to the 3-piece on 906. Pullman is

reported to

have received supplies of transmissions from Caterpillar and Iowa. The

evidence

suggests that the Caterpillar Transmission Company, like Buick and

Ford, never

made any transmissions with 3-piece differential housings, but began

production with

the 1-piece housings, Part Number E4186. Citing that a changeover would

disrupt

production, Iowa and Chrysler continued to make the 3-piece jobs well

into

1943. Note that 908 can be seen with the standard “weep holes

at the base of

the turret splash” (circled). Unlike SN 906, the turret

lifting rings can be

seen in the standard “low” position. The evidence

suggests that all succeeding

Pullmans had the “lows.” Barely visible here is

what we informally call “the

bump” on the glacis casting (3).

Serial

number 908 was employed as a test vehicle at APG, and one project

involved the

use of “Vacuum Power Controls for Medium Tanks,

M4.” From the start, the

designers of the M3 and M4 had sought ways to make it easier for the

driver to

manipulate the steering levers (1) using various methods of power

assist. None

of these trials proved satisfactory, and steering the Sherman required

a good

deal of muscle. Unlike the M4A1, the M4A2 instrument panel (2) was

“tombstone”

shaped from the start. Note that there are pairs of some of the gauges,

reflecting the twin engine configuration of the Model 6046 power pack.

The

tank’s dataplate (3) appears to be made of cast brass, as was

the case with

Pullman’s Grants. Shortly thereafter, the dataplates were

ordered to be made of

a cheaper metal in order to conserve brass. This photo permits us to

see a bit

of the interior appearance of the “bump” glacis

casting. Note the inside

groove (4) of the bump, and one of the two fittings for the fixed

machine guns

(5) which was part of the glacis casting.

Serial

number 908 was employed as a test vehicle at APG, and one project

involved the

use of “Vacuum Power Controls for Medium Tanks,

M4.” From the start, the

designers of the M3 and M4 had sought ways to make it easier for the

driver to

manipulate the steering levers (1) using various methods of power

assist. None

of these trials proved satisfactory, and steering the Sherman required

a good

deal of muscle. Unlike the M4A1, the M4A2 instrument panel (2) was

“tombstone”

shaped from the start. Note that there are pairs of some of the gauges,

reflecting the twin engine configuration of the Model 6046 power pack.

The

tank’s dataplate (3) appears to be made of cast brass, as was

the case with

Pullman’s Grants. Shortly thereafter, the dataplates were

ordered to be made of

a cheaper metal in order to conserve brass. This photo permits us to

see a bit

of the interior appearance of the “bump” glacis

casting. Note the inside

groove (4) of the bump, and one of the two fittings for the fixed

machine guns

(5) which was part of the glacis casting.

The previous photo

provides an interior view of a direct vision driver's hood welded to

other castings and plates to form the tank's glacis. We thought readers

might like this stand alone, exterior shot of the piece. It is

representative of the so called "narrow" driver's hood castings used on

small hatch welded hull M4s and many M4A2s, including Pullmans. The

authors have measured a few of these castings, both direct vision and

the later elongated hoods, and found them to be about 18 1/2 inches

wide. The photo is dated September 1942 and captioned, "Machining hoods

for America's medium tanks is much more than just a job to Peter

Dykzeul. Born in Holland, this employee of a Midwest tank plant knows

the brutality and horror Nazi aggression can bring to a

freedom-loving people. And he's just one among America's many loyal,

foreign-born workers who are pitching in with every ounce of strength

to keep the nation free, and to lift the yoke from their native lands.

Pressed Steel Can [sic] Company, Chicago, Illinois." The image was

taken by Ann Rosener, a noted photojournalist who documented various

aspects of life on the home front for the Office of War Information

during WW II.

The previous photo

provides an interior view of a direct vision driver's hood welded to

other castings and plates to form the tank's glacis. We thought readers

might like this stand alone, exterior shot of the piece. It is

representative of the so called "narrow" driver's hood castings used on

small hatch welded hull M4s and many M4A2s, including Pullmans. The

authors have measured a few of these castings, both direct vision and

the later elongated hoods, and found them to be about 18 1/2 inches

wide. The photo is dated September 1942 and captioned, "Machining hoods

for America's medium tanks is much more than just a job to Peter

Dykzeul. Born in Holland, this employee of a Midwest tank plant knows

the brutality and horror Nazi aggression can bring to a

freedom-loving people. And he's just one among America's many loyal,

foreign-born workers who are pitching in with every ounce of strength

to keep the nation free, and to lift the yoke from their native lands.

Pressed Steel Can [sic] Company, Chicago, Illinois." The image was

taken by Ann Rosener, a noted photojournalist who documented various

aspects of life on the home front for the Office of War Information

during WW II.

The

next Pullman M4A2 we can document is the 15th vehicle, USA 3053129,

which would

have been accepted in June, 1942. It was used as a test bed for the

anti-aircraft, Multiple Gun Motor Carriage, T52. Ultimately, the design

was

deemed unsatisfactory, and the project was cancelled in November, 1944.

Our

photo shows the T52 at the Ordnance Museum at Aberdeen in February,

1947. It is

assumed that it was scrapped some time after this photo was taken,

since we

never encountered it during any of our frequent visits to the Museum

over the

years. In any case, the hull features the most elaborate glacis pattern

we have

encountered on a welded hull Sherman. It consists of a record 8

sections – the

drivers’ hoods (1-2) and the bow machine gun piece (3) were

castings that were

welded to 5 different armor plates (4-8) to form the glacis. The cast

antenna

bracket (9) was welded flush with the glacis. This particular type of

bracket

is seen on early Fisher and Pullman M4A2s, and something similar was

used

throughout production by ALCO and Pressed Steel Car. The designers were

aware

of the inherent weakness of the numerous joints and protrusions of the

welded

hull design, and undertook to reduce the number of plates used to form

the

glacis as production proceeded. We believe that Pullman used castings

for the

turret splash throughout production. However, the T52 can be seen with

fabricated rear sections as outlined in red in the inset. This may have

been

done in this case to provide clearance for T52 turret turntable. The

evidence

suggests that only Fisher Body adopted the use of such fabrications on

its

small hatch M4A2s.

Click on

the photo for larger size

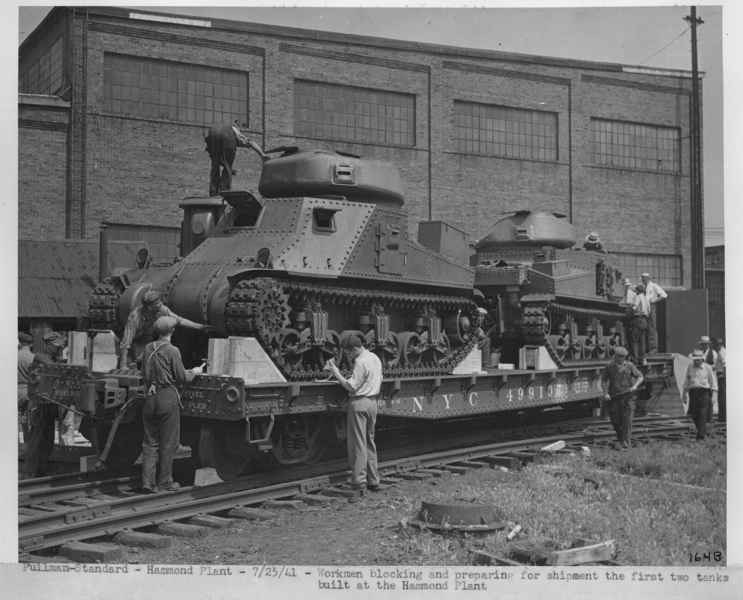

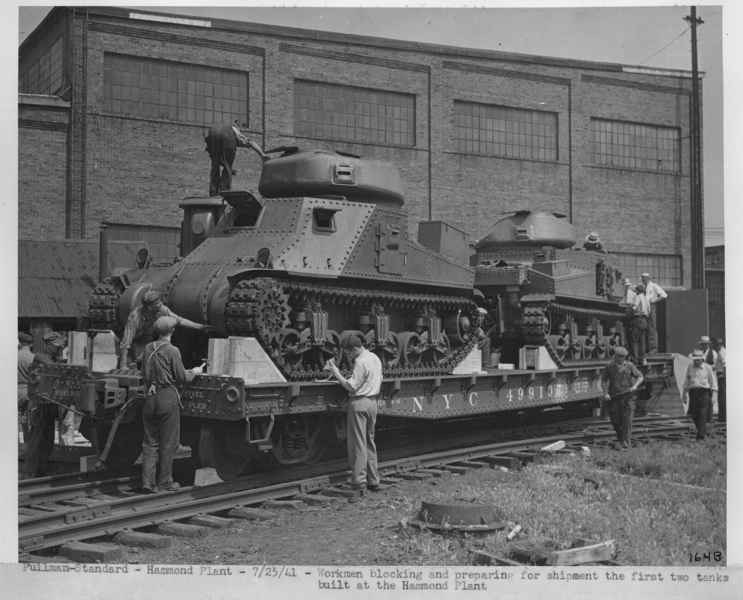

Pullman completed the

last 15 of its 500 M3 [Radial] Grants in July 1942. From April through

July, the company produced both Grants and diesel Shermans, with its

first M4A2 accepted in April, and a further 7 in May, 35 in June and

130 in July. The photo above is part of a series showing “the

Army’s new M4 tanks” ready for shipment from

Pullman in late July 1942. The US Tank Depot system was in the early

stage of organization by mid 1942, and in the meantime the builders

were responsible for sealing the tanks for shipment. Pullman Grants and

early M4A2s can be seen covered with what is called in a British report

"Scotch tape." This is not a reference to the small, clear

home and office tape, but instead refers to one of the masking tapes

invented by the 3M Company in the 1920s, and used in the painting of

cars, etc. at factory and body shops. We were able to read the

Registration Number of the lead tank from the glossy print at the US

Archives. It is USA 3053206, indicating that it was accepted in July,

and would have been the 92nd M4A2 produced by Pullman. As supplies

became available, M4 bogies were ordered to replace M3 bogies in

Sherman production and in this photo, we see the transition as only the

fourth tank has the earlier suspension. USA 3053206 is the only example

seen here with a 1-piece differential housing. These were considered

greatly superior to the 3-piece units, but, as noted earlier,

Pullman’s primary transmission suppliers were Caterpillar

(1-piece) and Iowa (3-piece). The Iowa Transmission Co. is reported to

have changed over to production using 1-piece differentials in April

1943, and it would appear that, shortly thereafter, all of

Pullman’s Shermans were built with them. USA 3053206 also

shows the recent introduction of hull lifting rings that were castings

with rectangular pads at the base. The two tanks directly behind are

seen with the original fabricated [not cast] type of lifting rings. As

an informal means of identification, we refer to the former as "padded"

hull lifting rings and the latter as “bent rods.”

Click on

the photo for larger size

Pullman completed the

last 15 of its 500 M3 [Radial] Grants in July 1942. From April through

July, the company produced both Grants and diesel Shermans, with its

first M4A2 accepted in April, and a further 7 in May, 35 in June and

130 in July. The photo above is part of a series showing “the

Army’s new M4 tanks” ready for shipment from

Pullman in late July 1942. The US Tank Depot system was in the early

stage of organization by mid 1942, and in the meantime the builders

were responsible for sealing the tanks for shipment. Pullman Grants and

early M4A2s can be seen covered with what is called in a British report

"Scotch tape." This is not a reference to the small, clear

home and office tape, but instead refers to one of the masking tapes

invented by the 3M Company in the 1920s, and used in the painting of

cars, etc. at factory and body shops. We were able to read the

Registration Number of the lead tank from the glossy print at the US

Archives. It is USA 3053206, indicating that it was accepted in July,

and would have been the 92nd M4A2 produced by Pullman. As supplies

became available, M4 bogies were ordered to replace M3 bogies in

Sherman production and in this photo, we see the transition as only the

fourth tank has the earlier suspension. USA 3053206 is the only example

seen here with a 1-piece differential housing. These were considered

greatly superior to the 3-piece units, but, as noted earlier,

Pullman’s primary transmission suppliers were Caterpillar

(1-piece) and Iowa (3-piece). The Iowa Transmission Co. is reported to

have changed over to production using 1-piece differentials in April

1943, and it would appear that, shortly thereafter, all of

Pullman’s Shermans were built with them. USA 3053206 also

shows the recent introduction of hull lifting rings that were castings

with rectangular pads at the base. The two tanks directly behind are

seen with the original fabricated [not cast] type of lifting rings. As

an informal means of identification, we refer to the former as "padded"

hull lifting rings and the latter as “bent rods.”

The manufacturers, of

course, were responsible for seeing to it that the tanks

“worked” before acceptance. In the early days, the

government continually exhorted the plants to produce more tanks. The

manufacturers stated that they couldn’t up production without

receiving steadier supplies of engines and transmissions. They reported

that they had numbers of vehicles clogging up their lots that were

complete, but without transmissions. (Engines could be tested on

stands, but transmissions had to be installed.) Pullman had created a

dirt test track during their Grant program, which included a 30 degree

ramp (inset). By the time M4A2 production commenced, this had been

paved as shown above in late July, 1942. The tank seen here, which by

the number stenciled on the front and side, we take to be the 134th

unit produced, has an elaborate 7 section glacis pattern. However, the

middle plate is unusual, as it is one piece that spans the glacis from

the top to the bottom. The E4186 differential housing shown here is in

the “early” configuration. Not long thereafter, the

molds were revised on both the one and three piece diffs to include a

“lip” in front of the bolt strip at the top,

presumably to protect the bolts from bullet splash.

Here

we have another of the M4A2s photographed on railroad cars at Pullman.

This unit can be seen as US 3053261, indicating July 1942 acceptance,

overall, their 147th M4A2. The glacis pattern seen here is the one we

most closely associate with Pullman built Shermans. It consists of a

rather large armor plate on the left side (1), notched out to accept the

driver's hood (2). A smaller plate (3) on the right holds the antenna

bracket (4) and is welded to the bow gunner's hood (5) and the bow

machine gun casting (6). Most manufacturers of welded hull Shermans

settled into consistent glacis patterns after the first few months.

Thus, one might think that this "5 part" pattern would have been what

Pullman adopted starting around July for its entire subsequent run of

Shermans, but as we shall see, in late 1942, they took an interesting

little detour with the use of fabricated parts.

The

M4A2 shown here is on display at Camp Borden in Canada. This tank was

retrofitted with the "Canadian Indestructible Roller Device" [CIRD] at

some point during the course of its service. The plates on the hull

sides (arrow) are not standard appliqué plates, but mounting plates for

the CIRD. We are "pretty sure" that this one-of-a-kind surviving M4A2

was built by Pullman Standard, but the Museum staff doesn't appear to

have any accession information with the serial number. In any case, the

photo, which was taken by Jim Goetz on a sunny day, provides a slightly

better view of the "5 part" glacis pattern. Note the "buttons" on the

corners of the trapezoidal shaped bow machine gun casting. These appear

to have been eliminated from later molds. Jim found "185" stamped into

the glacis in the area indicated. Could that be the build number? If so,

it would have been accepted in August 1942. In

September 2024, Jim and Pierre-Olivier were able to get a look inside

and found to their disappointment that the dataplate is missing.

The

Sherman’s combat

debut came with the British at the Second Battle of El Alamein, which

commenced on October 24, 1942. The story is well known, but to

recap...On June 21, Prime Minister Winston Churchill was at the White

House when he got the news of the surrender of Tobruk. President

Franklin Roosevelt asked if there was anything he could do to help, and

without hesitation, Churchill replied, "Give us as many Sherman tanks

as you can spare and ship them to the Middle East as quickly

as

possible." Soon after, Roosevelt ordered the dispatch of 300 Shermans

and 100 M7 Priests. This would have been pretty much the entire

production of Shermans up to that point. The tanks were collected up

from the factories, as well as from US units that had just begun

training with them. The "5185 Opportunity" convoy sailed on July 15,

1942, with 302 Shermans and 100 Priests. The Shermans break

down

to 212 M4A1s and 90 M4A2s. The S.S. Fairport with 51 M4A1s and 32

Priests on board was sunk by a U-Boat the next day. The Seatrain Texas

sailed unescorted two weeks later with replacements of 52 M4A1s and 25

Priests. The voyage took two months, and the Shermans began to arrive

in Egypt in September 1942. Apart from these, an earlier

“regular” Lend Lease shipment of 15 M4A2s

“which had

been intended to come well ahead...actually only preceded [the

emergency shipment] by a few days." The IWM photos above are dated

September 9th. On July 15, when the convoy sailed, the only

M4A2s

that were in production were made by either Fisher or

Pullman. This tank can be seen as T-74271. In another photo

from

this series, the USA Number is partially visible as

“305313X,” indicating that it was made by Pullman.

Note the

“low” position of the turret lifting rings.

Counting heads

suggests that Fisher continued with the “high”

lifting

rings until the end of 1942. From that we

“interpolate”

that any of the 105 M4A2s in theater at the time and seen with

“high” lifting rings would have been Fishers, and

any with

the “lows” would have been

Pullmans. Counting heads

also suggests that the British War Department Numbers of these first

105 were all in the range running from about T-74213 through

T-74317. The M3 Medium was built without hull lifting rings, and this

deficiency was corrected with the M4 series. However, stevedores were

reluctant to “trust” the lifting rings

and continued

the damaging practice of hoisting the tanks as shown above, using

slings running under or across the belly plate. IWM E16599

and E16603.

In

a photo from the same IWM series, the USA Number, 3053165 (inset), is

just visible on the rear side of the M4A2 in the foreground.

This tank

can also be seen to be T-74291. Units records list T-74291 as with the

47th Royal Tank Regiment. It was battle damaged during the Alamein

campaign, but recovered and repaired. In a General Motors Technician's

Report from Tripoli dated August, 1943, T-74291 is listed as Pullman

Serial Number 955, which is an exact mathematical match to USA 3053165.

Serial Number 955 would have been accepted in early July 1942, overall

Pullman’s 51st M4A2. Since the convoy sailed on July, 15th,

it is pretty certain that this was a new tank shipped directly from the

production lines, not one that had been issued to US troops. There

wouldn’t have been any time for that. The "UFS"

seen painted on these Shermans is shipping code for "US-Freetown-Slow."

It was a slow speed, zig-zagging convoy from the US to Freetown in West

Africa. From there, the Royal Navy took over escort duty for the long

journey around Africa, through the Suez Canal and on to Egypt. Most of

the “Alamein Shermans” are noted with 3-piece

differential housings, but a close examination of the front reveals

that SN 955 was built with a 1-piece. The engine deck of the M4A1 in

the background is “clean,” while the

M4A2’s is “busy” with a number of

additional cable clamps on the rear most plate. This reflects the

original plan to stow the towing cable on the engine deck in the manner

of the M3 Medium and T6 (Sherman) pilot. Ultimately, the tow cable was

stored along the left side of the Sherman, but the rear deck clamps are

seen in a few photos of early Fisher and Pullman M4A2s. Based on what

we know of this M4A2, we could observe that "the rear deck clamps are

seen on some Pullmans produced up to July, 1942." Note the "engine cover plate"

above the soldier inspecting the twin diesel power pack. This was made

of 1/4-inch steel and was hinged at the front. In the down position, it

covered the engines and served to protect them from any shrapnel that

might penetrate the tightly louvered engine access doors.

IWM E16607.

In

this view from the same IWM series of September 9th, the M4A2 can be

seen as

USA 3053166, the next tank built by Pullman after SN 955 of the

previous

caption. This tank carries the British Number T-74299, and like its

sister tank

above, is listed in unit records as in service with the 47th Royal Tank

Regiment during the Alamein Campaign. Since we’ve been asked

many times, we

would like to point out that there is no mathematical correlation

between the

British assigned WD Numbers and the US Ordnance Serial and/or

Registration

Numbers. For instance, in this case, we see that 3053165 of the

previous

caption was T-74291, while 3053166 was T-74299. The WD Numbers were not

assigned in strict sequence, which makes it impossible to determine the

builder

or month of production of a Sherman if all one knows is the WD Number.

It is

evident that the Shermans seen in this series were outfitted with sand

shields

before they left the US. Pullman provided and installed sand shields

for most of

their Grants, but in the case of the "5185 Opportunity" shipment, the

evidence suggests that these were installed at the Tank Depots which

were just

coming on line in the US. Note

that the front section of the sand shield is rounded on the

Shermans, as opposed to the angled fronts on the Grants and Priests.

The

rounded configuration was adopted when the Ordnance Department mandated

the

installation of sand shields in mid 1943. T-74299 still has some of its

“On

Vehicle Materiel” [OVM] boxes mounted on the rear deck. Most

of the items would

have been unpacked and placed in or on the vehicle when it was

processed for

issue at a Base Workshop. Note

that T-74299 can also be seen with additional cable clamps on the rear

engine deck.

IWM

E 16608.

In

this view from the same IWM series of September 9th, the M4A2 can be

seen as

USA 3053166, the next tank built by Pullman after SN 955 of the

previous

caption. This tank carries the British Number T-74299, and like its

sister tank

above, is listed in unit records as in service with the 47th Royal Tank

Regiment during the Alamein Campaign. Since we’ve been asked

many times, we

would like to point out that there is no mathematical correlation

between the

British assigned WD Numbers and the US Ordnance Serial and/or

Registration

Numbers. For instance, in this case, we see that 3053165 of the

previous

caption was T-74291, while 3053166 was T-74299. The WD Numbers were not

assigned in strict sequence, which makes it impossible to determine the

builder

or month of production of a Sherman if all one knows is the WD Number.

It is

evident that the Shermans seen in this series were outfitted with sand

shields

before they left the US. Pullman provided and installed sand shields

for most of

their Grants, but in the case of the "5185 Opportunity" shipment, the

evidence suggests that these were installed at the Tank Depots which

were just

coming on line in the US. Note

that the front section of the sand shield is rounded on the

Shermans, as opposed to the angled fronts on the Grants and Priests.

The

rounded configuration was adopted when the Ordnance Department mandated

the

installation of sand shields in mid 1943. T-74299 still has some of its

“On

Vehicle Materiel” [OVM] boxes mounted on the rear deck. Most

of the items would

have been unpacked and placed in or on the vehicle when it was

processed for

issue at a Base Workshop. Note

that T-74299 can also be seen with additional cable clamps on the rear

engine deck.

IWM

E 16608.

Earlier

we showed SN 908 with “the bump” on the glacis

casting. The IWM photos above

are part of a series dated October 10, 1942, about two weeks before the

start

of the Second Battle of El Alamein. They document the visit of a child

entertainer named Tita Rickard to a repair crew working on a Sherman

“in the

Western Desert.” Note the presence of the bump in the photo

on the left. Due to

the date and the low position of the turret lifting ring, we take this

example

to be another Pullman M4A2 from the emergency, or what the British

frequently

termed, "the special shipment." At first we thought that the use of

the glacis casting with the bump was short lived, and limited to a few

early

M4A2s, along with the two Ford M4A3 pilots. These castings, with the

machine

gun fittings on the inside, would have been rendered obsolete with the

elimination of the twin fixed machine guns in March, 1942. We would

note that

in the few period photos showing the "bump" on M4A2s, as well as on

the two known surviving examples, the tanks have direct vision.

However, the

bump has also been observed in a pair of photos of early 1943

production M4s

thought to have been made by ALCO, and with the later type of drivers'

hoods. We

can only guess that the use of these castings in 1943 was a case of

recycling,

or “waste not, want not.” At any rate,

“the bump” provides us with an

interesting and ongoing little Sherman mystery. Note that this unit has

a

1-piece differential housing, which is seen in period photos on a small

number

of the special shipment M4A2s and M7 Priests, but so far not the M4A1s.

The

British added a number of internal and external items when they

processed these

tanks for issue. An obvious one here is the sunshield framework running

along

the side of the vehicle. Another

is the Crusader tank style stowage box affixed to the rear of the

turret. Based on the locations given in the War Diaries of the 41st and

47th

RTRs, we believe this scene was shot in the area of Wadi El Farigh, about 50

miles (80 km) northwest of Cairo. IWM E

17857 and E

17854.

It has been difficult to

determine the exact appearance of the Alamein M4A2s, since there is

usually only one period photo of any particular example, and details

such as the glacis pattern are often indistinct or obscured. We believe

that there is a surviving M4A2 that may have been one of the 90 M4A2s

received by the Brits as part of the "Special Shipment," or one of the

15 that was sent to the Middle East just before that as the first

regular Lend Lease shipment. All 105 of these arrived in Egypt at about

the same time in September, 1942. All would have to have been made

before mid July, 1942, when the convoys sailed. This M4A2 is on display

at the World War II Military Museum in El Alamein, and still has its

original Pullman "1942" dataplate, but, alas, the serial number is

obscured, so we can't determine exactly when it was produced.

Nonetheless, it has some early features, the most obvious being direct

vision. It is thought that Pullman transitioned to the later driver's

hoods in November 1942. The rear hull liftings rings are the earliest

"bent rod" type, while the ones on the glacis are the "padded" castings

which quickly replaced them. The rearmost engine deck panel is

indented, and there are 11 bolts running across the upper rear hull

plate. Pierre-Olivier has personally examined this Sherman, and despite

some obscuration by the track holders, determined that it has an

unusual 7 section glacis pattern, such as seen in a factory photo

(inset) of a Pullman M4A2 with "134" stenciled on the side. (We suspect

that was the build number, and if so, it would have been accepted in

July, 1942.) The tank was extensively rebuilt by cobbling at some point

in 1943 or later. However, we don't think this was one of the 535 M4A2s

remanufactured in the US in 1944, since they would have been installed

with the drivers' hood appliqué, a bow MG dust cover fitting, and the

"official" cast gun travel lock, not the fabricated one it currently

has. This leads us to theorize that this tank was rebuilt, perhaps more

than once, at British Workshops in the Middle East. A peek inside by a

visitor 25 years ago revealed armored ammunition racks and a

skeletonized turret basket, which, along with the appliqué armor on the

hull sides indicates that it received the full Quick Fix Modification.

It currently has a “no pistol port” turret, which

didn't enter the production pipeline until the Summer of 1943. The

3-piece differential housing would appear to be appropriate, but it has

a "lip" which was not introduced until late 1942. We suspect that this

particular diff was taken from a Chrysler M4A4, and the comb device it

still has is typical of the type used by Chester Tank Depot starting in

late 1942. If this tank was built with M4 bogies, they would have been

earlier than the ones currently on there with the 1943 casting dates.

In any case, despite all of the changes, an M4A2 of this vintage

certainly has a place at the El Alamein Museum.

It has been difficult to

determine the exact appearance of the Alamein M4A2s, since there is

usually only one period photo of any particular example, and details

such as the glacis pattern are often indistinct or obscured. We believe

that there is a surviving M4A2 that may have been one of the 90 M4A2s

received by the Brits as part of the "Special Shipment," or one of the

15 that was sent to the Middle East just before that as the first

regular Lend Lease shipment. All 105 of these arrived in Egypt at about

the same time in September, 1942. All would have to have been made

before mid July, 1942, when the convoys sailed. This M4A2 is on display

at the World War II Military Museum in El Alamein, and still has its

original Pullman "1942" dataplate, but, alas, the serial number is

obscured, so we can't determine exactly when it was produced.

Nonetheless, it has some early features, the most obvious being direct

vision. It is thought that Pullman transitioned to the later driver's

hoods in November 1942. The rear hull liftings rings are the earliest

"bent rod" type, while the ones on the glacis are the "padded" castings

which quickly replaced them. The rearmost engine deck panel is

indented, and there are 11 bolts running across the upper rear hull

plate. Pierre-Olivier has personally examined this Sherman, and despite

some obscuration by the track holders, determined that it has an

unusual 7 section glacis pattern, such as seen in a factory photo

(inset) of a Pullman M4A2 with "134" stenciled on the side. (We suspect

that was the build number, and if so, it would have been accepted in

July, 1942.) The tank was extensively rebuilt by cobbling at some point

in 1943 or later. However, we don't think this was one of the 535 M4A2s

remanufactured in the US in 1944, since they would have been installed

with the drivers' hood appliqué, a bow MG dust cover fitting, and the

"official" cast gun travel lock, not the fabricated one it currently

has. This leads us to theorize that this tank was rebuilt, perhaps more

than once, at British Workshops in the Middle East. A peek inside by a

visitor 25 years ago revealed armored ammunition racks and a

skeletonized turret basket, which, along with the appliqué armor on the

hull sides indicates that it received the full Quick Fix Modification.

It currently has a “no pistol port” turret, which

didn't enter the production pipeline until the Summer of 1943. The

3-piece differential housing would appear to be appropriate, but it has

a "lip" which was not introduced until late 1942. We suspect that this

particular diff was taken from a Chrysler M4A4, and the comb device it

still has is typical of the type used by Chester Tank Depot starting in

late 1942. If this tank was built with M4 bogies, they would have been

earlier than the ones currently on there with the 1943 casting dates.

In any case, despite all of the changes, an M4A2 of this vintage

certainly has a place at the El Alamein Museum.

As

mentioned previously, early M4A2s are seen with 11 bolts running across

the top of the upper rear hull plate (top left photo). Eventually, the

number of bolts was reduced to 6, no doubt in order to provide crews

with faster access when servicing the engine (top right). At Pullman

this change appears to have occurred in early 1943. So far, the

examination of surviving M4A2s reveals that those with 11 bolts have

rearmost engine deck plates that are “indented,” as

seen in photo 3. For whatever reason, a spacer (arrow) was welded on to

each side of the hull, forcing the indentation of the rear engine deck

plate. It may or may not be significant that the indent measures 12

inches from front to rear, which corresponds to the size of

the small rearmost engine deck panel that was welded in to M4

Shermans. On all but two of the “indented”

M4A2s examined to date, there are 3 bolts on each side. It would appear

that Pullman reduced the number of side bolts to 2 in late 1942, before

changing over to the rectangular rear deck plates with the 6 bolt upper

rear hull configuration.

M4A2s

have been difficult to study because most of them "disappeared" to Lend

Lease. Not many were used in tests in the US, where evaluation reports,

etc. often provide the Serial and/or USA Number and some photos, which

in many cases, enables us to gain insight into their appearance at a

particular time. Here we would like to show a surviving example of a

Pullman M4A2 that features cast drivers' hoods, coupled with fabricated

bow machine gun and antenna sockets. This tank was listed as Serial

Number 9882 when it was turned over to the Armoured School Museum in

the mid 1950s. Additionally, according to author Paul Handel's "Australian

Shermans" webpage, "The

tank arrived in Australia during mid 1943, and on arrival carried both

a US registration number (USA W 3096073) and a British registration

number (T 146142)." The "XXI in a diamond" shipping code, and the "as

built" appearance of the tank upon arrival, would lead us to conclude

that SN 9882 was shipped directly to Australia from the US. The tank

was one of 3 Shermans used in trials in Australia, and, thankfully,

this one and an M4 Composite were preserved by the Australian Army Tank

Museum in Puckapunyal. SN 9882/USA USA 3096073 would have been accepted

at Pullman Standard in December 1942. Note the distinct shape of the

"narrow" drivers' hood castings (1), and the sharp angles of the

fabricated MG (2) and antenna (3) sockets. The glacis armor is a single

plate into which these components have been welded. We would assume

that Pullman sourced the fabrications from Fisher Body. Fisher M4A2s of

this period used a number of other fabricated components, such as the

drivers' hoods, turret splash guards, and head lamp sockets, while

these parts are castings on SN 9882.

Since SN 9882 has been preserved nearly "as built," we can gain a

little insight about some of the components being used in December

1942. There is an AWM photo showing

that 9882 arrived in Australia equipped with sand shields. The

sand shields were removed at some point, revealing

the "aircraft type cowl fasteners" underneath the sponson (top

left). The Ordnance Department accommodated the British when

they requested sand shields on their Grants. The Brits made the same

request for their Lend Lease Shermans, and the US began to consider

equipping their tanks with sand shields as well, particularly those to

be deployed to the desert. On the "Original Design" with the "aircraft

cowl fasteners," "The forward members of these sand shields

are common to all vehicles," while the rear section was the same on the

M4 and M4A1, but differed on the M4A2, A3 and A4. In any

case, the "Original Design" was used early on. For

instance, it can be seen on some of the "Emergency Shipment" M4A1s and

M4A2s. While a number of surviving Shermans have the cowl type

fasteners, the authors are not aware of any surviving

examples with the earlier style of sand shields still fitted.

In the photo at the top right, an L-shaped bar can be

seen attached to the bottom of the fasteners. The sand shields

were hung on to this bar, presumably attached with bolts or

screws. At bottom left we see the early style sand shields

attached to 3053416, a Pullman M4A2 accepted in August, 1942. Note the

small gap often seen between the sand shields and the

hull. The use of the "Original Design" sand

shields appears to have been limited by availability. They

were cancelled on 26 March 1943 and replaced with

the "Universal" or "Interchangeable" sand shield design, which

was mass produced and mandated to be installed on all Shermans

beginning in mid 1943. On the universal design, the sand shields were

screwed to attachment strips welded on to the lower edge of the hull

sides (bottom right).

We were somewhat surprised to

note that 5 of the 6 bogies on SN 9882 have the original half round

track skids (left). Indeed, period photos show that the left front

bogie also had a half round. We suspect that the entire bogie, shown on

the right, must have been changed out at some point in the course of

service, since it is the only bogie bracket not cast by "GAD" (Ford).

We would have thought that the supply of half rounds would have been

exhausted by the time this tank was built in December 1942. For a

little background, Chrysler quickly designed an improved track

skid with a larger contact area. We refer to this type by the informal

name "asymmetrical." The left front bogie of 9882 is installed with an

example. These entered the production pipeline at Chrysler in August

1942 and were themselves replaced with what we term

the

"standard" type in early 1943. We can only assume that the vagaries of

production and supply may have delayed the transitions at Pullman. Not

unexpected, but we would note as well the absence of return roller

spacers (circled in red) on any of the bogies of 9882. The use of steel

tracks created a

friction problem with the track skids. This was remedied by the

addition of a spacer that elevated the return roller by about an inch.

Spacers were incorporated in new production starting in early

1943. Modification kits were also provided shortly thereafter

so that spacers could be retrofitted to any M3 or M4 Medium type AFV

built without them. However, as

evidenced by SN 9882, and any number of 1943 period photos, many

Shermans soldiered on without the spacers.

293 of the British

Duplex Drive conversions were based on the M4A2 or Sherman III. The

unit preserved at the Tank Museum at Bovington is the only surviving DD

with its original floatation screen intact. This example has several

improvements introduced in late 1944/early 1945 as a result of user

experience with the original DD design. In order to prevent the raised

screen from collapsing in rough seas, the struts were strengthened and

made self locking, turret struts were added, and the rear screen was

raised. In 2021, a correspondent reported that a member of the staff

looked inside at the dataplate, and found that the tank was produced by

the Pullman Standard Car Co, and that the Serial Number is 9992. Like

Serial Number 9882 preserved in Australia, it was accepted in December

1942, and has cast drivers' hoods (1), along with fabricated antenna

(2) and bow machine gun sockets (3). From this we would posit that some

Pullman M4A2s produced in late 1942/early 1943 had these features. As

it sits, this tank has bogies with half round track skids and no

spacers, and based on the same items on SN 9882, we would judge that it

was built with those features. It differs from 9882 in that it has a

3-piece differential housing (4). The 1-piece diffs are most prevalent

in photos, but it is thought that Pullman M4A2s were built with both

types before the company transitioned to the use of the 1-piece

exclusively about mid 1943.

The

photo at the top left shows what we consider to be the "typical" cast

antenna bracket seen on Pullman and FMW Shermans produced in 1943. Note

how the bracket is mounted on top of the glacis plate, as opposed to the

flush mounting seen on some other makers' Shermans. Many early

production Pullman M4A2s have been observed with the trapezoidal shaped bow

machine gun socket casting shown at the top right. This configuration

appears to be identical to that used by FMW throughout

production. However, as mentioned earlier, fabricated antenna brackets

(bottom left) and bow MG sockets (bottom right) have been noted on some

Pullman M4A2s produced in late 1942/early 1943. The available evidence

suggests that after early 1943, Pullman no longer used these fabricated

antenna and MG sockets and returned to using the cast components for the

remainder of its production of M4A2 and M4 Shermans.

Serial

Numbers 9882 and 9992 are the only surviving examples with "cast

hoods/fabricated sockets" that we have been able to identify positively

as Pullmans. However, Pierre-Olivier has seen a "probable" - an M4A2

dozer on display at the Citadel in Cairo, Egypt. This unit shares many

of the same features as 9882 and 9992, including the glacis pattern,

padded hull lifting rings, and "indented" rearmost engine deck panel

with 11 bolts across the upper rear hull. From what little data we have

to work with, we would theorize that Pullman started production using

all cast components, and introduced the fabricated components, perhaps

mixed in, in the Fall of 1942, and then went back to using all cast

components in early 1943.

Serial

Numbers 9882 and 9992 are the only surviving examples with "cast

hoods/fabricated sockets" that we have been able to identify positively

as Pullmans. However, Pierre-Olivier has seen a "probable" - an M4A2

dozer on display at the Citadel in Cairo, Egypt. This unit shares many

of the same features as 9882 and 9992, including the glacis pattern,

padded hull lifting rings, and "indented" rearmost engine deck panel

with 11 bolts across the upper rear hull. From what little data we have

to work with, we would theorize that Pullman started production using

all cast components, and introduced the fabricated components, perhaps

mixed in, in the Fall of 1942, and then went back to using all cast

components in early 1943.

A

small number of WW2 period photos show what we believe are Pullman

M4A2s produced in late 1942 or early 1943 with cast driver's

hoods, and fabricated antenna and machine gun sockets. By the

chronology of Lend Lease allocations, we believe that the British would

have received most of this type. They were assigned over 2100 M4A2s

from May 1942 through April 1943. Most Soviet and French M4A2

allocations were from mid 1943 on, so would have been later

models. The US Army photo above is dated 16 April 1943 "On the

Tunisian Front." It shows Sergeant Manuel Sylvia of Mattapoisett,

Massachusetts adjusting a bogie wheel on a Sherman undergoing "repair."

This tank can be identified as an M4A2 by the open engine deck door

(1). Its appearance is nearly identical to SN 9882 in Australia with

one interesting addition - the sun compass fitting (2)

requested by the British. It is mentioned that US Army personnel

assisted with the processing of British Shermans received in Northwest

Africa in the Spring of 1943, and we suspect this photo was taken

before the tank had been issued to a combat unit.

The US Coast Guard photo above

depicts a Sherman III unloading "onto a "Rhino" barge during the early

hours of the invasion on Gold Beach, 6 June 1944." "Virgin" can be seen

as T-147013. The combined fox face and "993" formation and Arm of

Service marking identify this as a Sherman of the 8th Armoured Brigade

Headquarters. Note that the outline of the M34 Gun Mount is visible

through the waterproofing cover. It is thought that Pullman completed

the transition to the M34A1 Gun Mount in April 1943, so we would guess

that all of their "cast hoods/fabricated sockets" M4A2s would have been

produced with M34s. The tank appears to be unmodified or "as built,"

except that the sand shield strip observed on the left seems out of

place on a unit of this vintage. We can only assume that the strips

along with sand shields were retrofitted, most likely in the UK, but as

was so often the case, the sand shields were removed by the crew. Note

that this example has a 3-piece differential housing. The small fitting

seen atop the fabricated antenna bracket suggests that this was a

command tank in which the ammunition stowage on the right sponson was

removed and replaced with an additional radio.

One of the

most interesting M4A2s that P-O has examined is the range recovery

shown above. The glacis pattern is easy to trace from the exposed weld

seams and is similar to that of direct vision Fisher M4A2s produced

from July 1942 until the introduction of the elongated, fabricated

drivers' hoods in November or perhaps December 1942. However, unlike

the Fishers, the turret splash sections and the head light sockets are

castings on this example. The grouser covers are missing, but the holes

are "lipped" so that the grousers covers could be mounted flush. Like

SNs 9882 and 9992, this tank has an "indented" rearmost engine deck

panel with 11 bolts across the upper rear hull. Unlike 9882 and 9992,

the rear turret splash casting utilizes all 9 bolt slots, whereas the

others were drilled for only 6. This might indicate a transition point,

but it would be hard to say for certain, since this tank was

extensively modified. The dataplate is long gone, with nothing stamped

inside the frame that held it. Also, the paint has mostly burned away,

so there is little chance of finding period tactical markings or other

clues by "paint archeology." In any case, this is the only

surviving M4A2 with these features we have encountered. We suspect it

was produced by Pullman in October or November

1942. Furthermore, this tank can be seen with a pair

of "welding resumptions" pointed out with thumb and

forefinger by Johann Steinebach (a mechanic and Sherman tank

restorer) in the photo in the upper right. These can be seen in the

same shapes and in the same locations in the period photo at the lower

right. Along with a number of other similarities, we are "pretty sure,"

and Johann concurs, that this M4A2 is

the historic "Chinon" of the 3ème Escadron, 12ème

Régiment de Cuirassiers, 2ème Division

Blindée.

A period photo dated 9 August 1944 and taken in Château-Gontier shows citizens celebrating liberation around

a direct vision M4A2 with turret number 46, identified as "Chinon" of the 3ème Escadron, 12ème Régiment de Cuirassiers. The

tank is seen with the interesting combination of M34 gun mount, "thin

spot" turret patch, and hedge row cutter. The 12ème Cuir's After Action

Report states that "Chinon" suffered a major mechanical failure on 23

August and was listed as a loss. On 25 August, "Mort-Homme" of the

501ème Régiment de Chars de Combat was involved in the assault on

the German Headquarters at the Hôtel Meurice in Paris, and its turret

was damaged by fire (see more of its story

on this page).

"Chinon's" turret was reported to have been cannibalized in order to

repair "Mort-Homme", and "Chinon" later received a turret from another

tank, before being returned to service. The photos above were taken

at Camp des Loges in Maisons-Laffitte, a training area for the 2ème

DB's Bataillon de Remplacement. "Chinon" can be seen with the same

features as our surviving M4A2 shown in the previous caption. The

multi-part glacis has Direct Vision (1), padded hull lifting rings (2), a

fabricated antenna mount (3) and cast head light sockets (4). The

replacement turret (now with speed number 32) has a welded up pistol

port (5) and M34A1 gun mount. A close-up view of the tank in a video

shows the number "40Y289" on the left side turret splash guard (inset),

confirming that it is a casting. Note that the appliqué plate has a

continuous weld on the side, which is rather unusual for an M4A2 of the

2ème DB, as most of the plates are seen to have been merely "tack

welded."

A

number of period photos and videos show "Chinon" at Maisons-Laffitte,

enabling us to get a detailed look at the tank's appearance on 16 April

1945. It can be seen to have the early bogies with half-round track

skids (1) and suspension arms without the "wrench holes" (2). The rear

view shows that the upper rear hull plate has 11 bolts, and the

replacement turret's casting mark (3) indicates that it was produced by

American Steel Foundries in East Chicago, Indiana. The French "Matricule

Number" can be read as 420 843.

A

number of period photos and videos show "Chinon" at Maisons-Laffitte,

enabling us to get a detailed look at the tank's appearance on 16 April

1945. It can be seen to have the early bogies with half-round track

skids (1) and suspension arms without the "wrench holes" (2). The rear

view shows that the upper rear hull plate has 11 bolts, and the

replacement turret's casting mark (3) indicates that it was produced by

American Steel Foundries in East Chicago, Indiana. The French "Matricule

Number" can be read as 420 843.

What convinced us that "Chinon" and our M4A2 survivor are one and same

tank are the anomalies seen on the hull and appliqué plate

welds. In our eyes, the "welding resumptions" where the glacis is

joined to the side plate (circled blue, red, orange and yellow) create

a series of "blobs" that can only have been unique to one tank.

Furthermore, most period photos and the few known 2ème

Division Blindée M4A2 survivors show that the hull

appliqué plates that were part of the "Quick Fix" modification

were merely tack welded on. However, "Chinon" is seen with a more

elaborate pattern featuring continuous welds on the sides of the plates

and just tacks on the edges at the top (circled in purple). The period

photos of Chinon are the only ones we know of that show this welding

configuration on the appliqué plates, and the range

recovery M4A2 is the only known surviving example with it. If this

method was not unique, it was certainly unusual, and coupled with the

"blobs" makes a pretty good case that "Chinon" has

survived. Perhaps "Chinon" was one of the first 2ème DB M4A2s to

receive the "Quick Fix" mod, and it was realized that the

method of attaching the plates was too time consuming and/or wasteful

of welding rod, so subsequent units just had the plates tack welded on?

"Chinon" apparently

continued to serve as a training tank in the immediate post-war years.

Its French Matricule Number, 420 843, was retained, but the tank itself

was renamed "Tornade." French

Matricule Numbers were reported to have been changed to an "8xx xxx"

format in 1947, so it is thought that the photos were taken between 1945

and 1947, probably in North Africa. The image

on the left shows that its distinctive glacis with Direct Vision and

fabricated antenna and MG sockets remained untouched but note that

parts of the running gear were replaced. In particular, the original

suspension arms were changed out for the later type arms with "wrench

holes." Some of the pressed spoke road wheels can be seen to have been

replaced with the "dished" type that entered the production

pipeline in the second half of 1944. The right side photo confirms

that the tank "still" has the ASF welded up pistol port turret.

These

photos were taken a few years ago near Bordeaux, France. The one at the

top left shows the turret splash guard casting marks, which are

identical to those seen in one of the period photos of "Chinon." We

wouldn't go say far as to state that these casting marks were exclusive

to Pullman Shermans, but can observe that they are "typical." The top

right shows an American Steel Foundries turret with welded up pistol

port, such as is seen in the 1945 photos of Chinon. The bottom left

photo shows the engine deck. Note that the rearmost engine deck plate

has an armored filler cap which would not have been original to an M4A2

of this vintage. The panels on either side of the engine deck

doors are different. It is thought that production started with 6

bolts along the outside edge (1), but at some point early on, the

number of bolts was decreased to 4 (2). The differential housing

seen here (bottom right) has the sort of fittings which suggest it was

recycled from an M10. The bogies have the final type of track skid

and suspension arms with "wrench holes," whereas the 1945 photos of

"Chinon" show half round skids and suspension arms without wrench

holes. The tank carries a French plate which records its

reconstruction at the French ERGMEB shop in Gien on 3

December 1952. We believe that the engine deck, differential

housing and bogie parts were changed during one of the repairs or the

1952 remanufacture of this tank.

We

haven't been able to find a period photo that clearly shows the

multi-part glacis pattern observed on the range recovery M4A2 thought to

be "Chinon," but here we see an example with a single piece glacis

plate and direct vision drivers' hoods. This photo is part of a series taken at the port of Oran in the

Spring of 1943 showing a load of British Lend Lease M4A2s being

prepared for issue by US personnel. One might take this for a Fisher

M4A2, but the 3-piece differential would tend to rule that out, since

Fisher transitioned to the use of 1-piece diffs exclusively by the end

of June 1942. The differential on our example is the early version

without the protective lip in front of the bolt strip. The "comb

device" (1) is typical of those used by the Chester Tank Depot starting

in late 1942. A "zinc tag" (2) with instructions on how to use the comb

can be seen attached just above it. The tag is reported to have read,

"NOTICE - Do Not Open Door - Unlock Cable to Release Brakes - Reset

cable when tank is in position." The head light sockets (4)

are

castings, and the plug holders (3) are mounted in the first or

early position parallel to the glacis. We would observe that

these

are mounted in the upright position on SN 9882 in Australia, which was

accepted in December 1942. We regret that we lack any solid proof, but

the circumstantial evidence suggests that this tank and the range

recovery M4A2 would have been built by Pullman in October or November

1942. The Allies had failed to capture the ports of Bizerta and Tunis

before the end of 1942, which seriously disrupted the timeline of

Operation Torch. Consequently, the supply line to the front in Tunisia

was extremely long and tenuous. For instance, the

Mediterranean Base Section at Oran was over 600 miles away.

We

haven't been able to find a period photo that clearly shows the

multi-part glacis pattern observed on the range recovery M4A2 thought to

be "Chinon," but here we see an example with a single piece glacis

plate and direct vision drivers' hoods. This photo is part of a series taken at the port of Oran in the

Spring of 1943 showing a load of British Lend Lease M4A2s being

prepared for issue by US personnel. One might take this for a Fisher

M4A2, but the 3-piece differential would tend to rule that out, since

Fisher transitioned to the use of 1-piece diffs exclusively by the end

of June 1942. The differential on our example is the early version

without the protective lip in front of the bolt strip. The "comb

device" (1) is typical of those used by the Chester Tank Depot starting

in late 1942. A "zinc tag" (2) with instructions on how to use the comb

can be seen attached just above it. The tag is reported to have read,

"NOTICE - Do Not Open Door - Unlock Cable to Release Brakes - Reset

cable when tank is in position." The head light sockets (4)

are

castings, and the plug holders (3) are mounted in the first or

early position parallel to the glacis. We would observe that

these

are mounted in the upright position on SN 9882 in Australia, which was

accepted in December 1942. We regret that we lack any solid proof, but

the circumstantial evidence suggests that this tank and the range

recovery M4A2 would have been built by Pullman in October or November

1942. The Allies had failed to capture the ports of Bizerta and Tunis

before the end of 1942, which seriously disrupted the timeline of

Operation Torch. Consequently, the supply line to the front in Tunisia

was extremely long and tenuous. For instance, the

Mediterranean Base Section at Oran was over 600 miles away.

In this view of our

subject, one can see that the tank was nicknamed "Bill Crowe Special"

perhaps after the boss of the crew that processed it. T-145309 can be

seen stenciled on, along with "C.T.D." (Chester Tank Depot). It is our

theory that these tanks represented the third allocation of Lend Lease

M4A2s to Great Britain, and that their WD Numbers ran roughly

from T-145219 through T-146189 and encompassed about 1000 units. The

turret splash sections can be seen as cast, not fabricated as on Fisher

M4A2s of this vintage. Note the casting numbers (circled) on one of the

sections of the splash. A bit of the armored fuel covers in the M4A2

location (arrow) are just visible. The lifting ring on the turret is in

the "low" position, whereas "counting heads" suggests that all direct

vision Fisher M4A2s would have had these in the high position.

In this view of our

subject, one can see that the tank was nicknamed "Bill Crowe Special"

perhaps after the boss of the crew that processed it. T-145309 can be

seen stenciled on, along with "C.T.D." (Chester Tank Depot). It is our

theory that these tanks represented the third allocation of Lend Lease

M4A2s to Great Britain, and that their WD Numbers ran roughly

from T-145219 through T-146189 and encompassed about 1000 units. The

turret splash sections can be seen as cast, not fabricated as on Fisher

M4A2s of this vintage. Note the casting numbers (circled) on one of the

sections of the splash. A bit of the armored fuel covers in the M4A2

location (arrow) are just visible. The lifting ring on the turret is in

the "low" position, whereas "counting heads" suggests that all direct

vision Fisher M4A2s would have had these in the high position.

Our final view of "Bill

Crowe Special" shows the "aircraft cowl fasteners," and provides an

idea of the appearance of the bogie units. As mentioned, we believe

that this tank was produced by Pullman a month or two before SN 9882 in

Australia or the Bovington DD, but it can be seen with the

"asymmetrical" track skids not the earlier half rounds.

Also, unlike 9882 and 9992, this tank was equipped with return

roller spacers. We suspect these were installed at the Chester Tank

Depot in early 1943 during processing for overseas shipment.

Our final view of "Bill

Crowe Special" shows the "aircraft cowl fasteners," and provides an

idea of the appearance of the bogie units. As mentioned, we believe

that this tank was produced by Pullman a month or two before SN 9882 in

Australia or the Bovington DD, but it can be seen with the

"asymmetrical" track skids not the earlier half rounds.

Also, unlike 9882 and 9992, this tank was equipped with return

roller spacers. We suspect these were installed at the Chester Tank

Depot in early 1943 during processing for overseas shipment.

Federal Machine

& Welder and Pullman M4A2s produced from early 1943 to the end

of production are so similar in appearance that we have had difficulty

identifying the maker of the few surviving examples. From counting

heads on an admittedly small sampling, it seems likely that FMW mounted

the grouser compartment blank off plates on top of or "proud" of

the sponson armor. We would note that the evidence is

overwhelming that Fisher mounted them "proud" as well. On the

other hand, the evidence suggests that Pullman mounted the plates

"flush." Flush mount required the additional step of providing

a "ledge" (arrow) under the sponson armor to hold the blank off.

Federal Machine

& Welder and Pullman M4A2s produced from early 1943 to the end

of production are so similar in appearance that we have had difficulty

identifying the maker of the few surviving examples. From counting

heads on an admittedly small sampling, it seems likely that FMW mounted

the grouser compartment blank off plates on top of or "proud" of

the sponson armor. We would note that the evidence is

overwhelming that Fisher mounted them "proud" as well. On the

other hand, the evidence suggests that Pullman mounted the plates

"flush." Flush mount required the additional step of providing

a "ledge" (arrow) under the sponson armor to hold the blank off.

We can

document that Pullman Production Order T-3322 was for 400 M4A2s. These

were all produced in 1943: 1 in January, 0 in February, 69 in March, 267

in April and 63 in May. Unfortunately, we have no reliable information

about the Serial and Registration Numbers assigned. Our working theory

is that their serial numbers ran from 13860 through 14259, and that

their Registration Numbers might have been in the 3097XXX range. The

M4A2 shown above is located in Montfaucon d'Argonne, near Verdun. We

take it that the "13859" (inset) stamped on the glacis was done by the

post war French Army, and in most, but not all instances, it is the

serial number of the tank. However, this immediately presents us with an

interesting dilemma since we have "interpolated" with pretty good

documentation that 13859 was the last serial number in a range of 400

allocated to Pressed Steel Car M4s and M4A1s, and that 13860 would have

been the first serial number allocated to the 400 Pullman M4A2s. In any

case, as an M4A2 with features like the "final" or "standard" type of

hull lifting ring castings, cast drivers' hoods, small bow machine gun

casting, and cast antenna bracket mounted on top of the glacis plate,

this tank has the appearance of a Sherman built in 1943 (but probably

not January 1943) by either Pullman Standard or Federal Machine and

Welder. We narrow it down to Pullman because the grouser compartment

blank off plates are mounted flush on this example. The neatness of the

appliqué welds and the presence of the gun travel lock suggest that this

tank was remanufactured in the US, probably in 1944. We doubt if the no

pistol port turret with a May 1943 casting date is the original, and

the differential housing has "7855" stamped on the towing lugs, which we

take to mean that it came from Fisher M4A2 Serial Number 7855.

The photo above shows the Beach Armoured Recovery Vehicle or BARV

on display at the REME (Royal Electrical and Mechanical Engineers)

Museum in Lyneham, UK. It is thought that all of the BARV conversions

were painted gray as seen here. This M4A2 was built with the later,

elongated drivers' hood castings. The drivers' hatches and periscopes

were removed, and the holes blanked off, since the hoods were partly

covered over by the addition of the bow superstructure. Ironically,

direct vision was retrofitted to the front of the hood castings in the

form of rectangular, glassed in "port holes." Thus, the driver's vision

was extremely limited, and the commander, positioned in a hatch on top

of the superstructure, navigated the vehicle by transmitting

instructions to the driver. Again, we have the glacis configuration with

the "narrow" drivers' hoods, the particular type of cast antenna

bracket mounted "proud" of the glacis, and the rectangular-ish cast

"plate" of the bow machine gun socket, all typical of M4A2s built by

Federal Machine and Pullman Standard starting in early 1943. As best we

have been able to determine, Pullman did not stamp the Serial Number on

the towing lugs or anywhere else on the exterior of its Shermans.

However, in 2023, the Museum staff sent us a photo of the tank's

dataplate confirming that it was produced by Pullman and is Serial

Number 13895. As such, it falls within our working theory range of

Pullman M4A2 SNs, 13860 through 14259. Of interest, is that the year

"1942" is stamped into the box at the lower left on the dataplate, but

the "2" is crossed out and a "3" is stamped alongside. All of the M4A2s

built on Pullman Production Order T-3322 were made in 1943, starting

with the first one in January. As noted in the previous caption, none

were produced in February, and we might theorize that this was the point

where Pullman introduced the "final" type of hull lifting ring casting

(circled), and dispensed with the use of fabricated components, and

"returned" to using a cast antenna bracket, along with a cast bow

machine gun "plate." By our working theory, SN 13895 would have been

accepted in April 1943.

The photo above shows the Beach Armoured Recovery Vehicle or BARV

on display at the REME (Royal Electrical and Mechanical Engineers)

Museum in Lyneham, UK. It is thought that all of the BARV conversions

were painted gray as seen here. This M4A2 was built with the later,

elongated drivers' hood castings. The drivers' hatches and periscopes

were removed, and the holes blanked off, since the hoods were partly

covered over by the addition of the bow superstructure. Ironically,

direct vision was retrofitted to the front of the hood castings in the

form of rectangular, glassed in "port holes." Thus, the driver's vision

was extremely limited, and the commander, positioned in a hatch on top

of the superstructure, navigated the vehicle by transmitting

instructions to the driver. Again, we have the glacis configuration with

the "narrow" drivers' hoods, the particular type of cast antenna

bracket mounted "proud" of the glacis, and the rectangular-ish cast

"plate" of the bow machine gun socket, all typical of M4A2s built by

Federal Machine and Pullman Standard starting in early 1943. As best we

have been able to determine, Pullman did not stamp the Serial Number on

the towing lugs or anywhere else on the exterior of its Shermans.

However, in 2023, the Museum staff sent us a photo of the tank's

dataplate confirming that it was produced by Pullman and is Serial

Number 13895. As such, it falls within our working theory range of

Pullman M4A2 SNs, 13860 through 14259. Of interest, is that the year

"1942" is stamped into the box at the lower left on the dataplate, but

the "2" is crossed out and a "3" is stamped alongside. All of the M4A2s

built on Pullman Production Order T-3322 were made in 1943, starting

with the first one in January. As noted in the previous caption, none

were produced in February, and we might theorize that this was the point

where Pullman introduced the "final" type of hull lifting ring casting

(circled), and dispensed with the use of fabricated components, and

"returned" to using a cast antenna bracket, along with a cast bow

machine gun "plate." By our working theory, SN 13895 would have been

accepted in April 1943.

At last we have an example of a Pullman M4A2 that was photographed by

the Ordnance Department. Serial Number 30444/USA 3038974 would have

been accepted in June 1943 and was photographed at APG in July. It was

one of 637 M4A2s made on Production Order T-3610 which ran from May

until September 1943 when Sherman production at Pullman was

terminated. Note the now familiar glacis pattern. The M34A1

gun mount (1) was introduced in production as early as January 1943 at

Pacific Car. However, demand outpaced supply and the complete

transition did not occur until April, with Pullman being one of the

last manufacturers to make the change. The example seen on SN 30444 is

the later type of M34A1 without the lifting rings and the bolt flange