The photo above shows an 11th

Armored Division M4 named "Bambino" at Camp Banning, California in

January, 1944. A close examination of the original print revealed

the Registration Number to be 3015981 indicating January, 1943

acceptance. From this, we might assume that PSC introduced the elongated

drivers' hoods in late 1942/early 1943. Bambino can be seen with a couple of new items - the

fittings for the spot and signal lamp and the bow machine gun dust cover (both

circled). The siren has been moved from its original position on the left front

fender to the glacis, where it sits on a brush guard. This unit

"still" has the early "bent rod" hull lifting rings,

although some December, 1942 PSC Shermans have been noted with the standard

lifting ring castings. Quite a few modifications were available for first

generation Shermans by the time this photo was taken in January, 1944. However,

modification kits were produced in limited numbers, and they were generally

reserved for tanks overseas or headed there. Training tanks in the US are

mostly seen unmodified, or in "as built" condition. The 11th Armored

Division left the Desert Training Center in early February, 1944, and Bambino

would have been inherited by the next unit assigned there. Most likely, this

tank would have become one of the 795 M4s remanufactured from August 1944

through April, 1945.

We don't know the tank's serial number, but the remanufactured M4 on

display at the Commemorative Air Force Museum in Dallas has features

that we associate exclusively with PSC. It is one of 3 surviving M4s

thought to be PSCs with the elongated drivers' hoods. From personal

examination, we can confirm that the lower section of the glacis is a

long casting that includes the bow machine gun socket. However, note

that it does not have the D51011 info cast in on the front, nor does it

have the little "buttons" on the corners of the casting. Like "Bambino"

in the previous caption, it "still" has the "bent rod" hull lifting

rings. This would likely be a clue that the production date was around

late 1942/early 1943. As with the Saumur M4 we suspect the turret is not

the original. It is another Buckeye Steel, in this case with a casting

date of 1-43 (January 1943) and a serial number of 1074 compared to 1475

of the Saumur's 3-43 turret. We were somewhat surprised to note that

the pistol port on a January 1943 turret is welded up (inset), since the

"eliminate the pistol port" edict did not really go into force until

mid 1943.

In 2025, Pierre-Olivier visited another PSC M4 with

elongated drivers' hoods. This example is on display at Camp de Bitche, a

military installation in eastern France. It was likely remanufactured

in the US during WW II and perhaps rebuilt or reconditioned in France in

the postwar years. A number of surviving Shermans used by the French

are noted to have the tank's Serial Number stamped into the glacis

plate. Despite a heavy paint build up, P-O is "pretty sure" that this

one is stamped with 11158. If accurate, it would indicate January 1943

production like "Bambino", but this one was built with the standard

lifting ring castings as opposed to the "bent rods". Like the M4 at the

Commemorative Air Force Museum, the lower section of the glacis is a

long casting that includes the bow machine gun socket but lacks the

D51011 info cast on the front or the little "buttons" on the corners.

The differential housing seen here looks like it might have come from an

M10 Tank Destroyer. We would guess that the original diff, whatever it

was, was replaced by the French.

The

Camp de Bitche M4 was extensively modified during perhaps more than one

rebuild and appears to have been a range target that was patched up

before being put on display. The Union Steel turret serial number is

1460, which seems like it would be appropriate to a late 1942/early 1943

Sherman. As a matter of minutia, we wanted to point out what we call

the "angled" orientation (arrow) of

the casting mold's join line at the bottom of the turret in the rear.

Most 75mm Sherman turrets are seen with straight mold join lines, but this little quirk is observed on some surviving Union Steel turrets and in some period photos. The line

in whatever orientation, reflects the join of the components of the

multi-piece molds for the sand-casting process. The turret casting

itself comes out as a single piece. We

have recorded the "angle" on nine Union Steel turrets at present with

the lowest SN being 1247 on a PSC M4A1 in Chino, California and the

highest 2100 on another PSC M4A1 at Ft. Stewart, Georgia. The inset

shows the "angle" on turret SN 1990 on a December 1942 Lima built M4A1

(USA 3058580) named "Arlene III". This Sherman was A-10 of the 760th

Tank Battalion and was used to demonstrate a 54-tube, turret mounted

rocket launcher for 5th Army officers in Viareggio, Italy, 19 December

1944. It can be seen that the turret's cast in antenna "pot" was burned

off, presumably to avoid an interference issue with the rocket launcher.

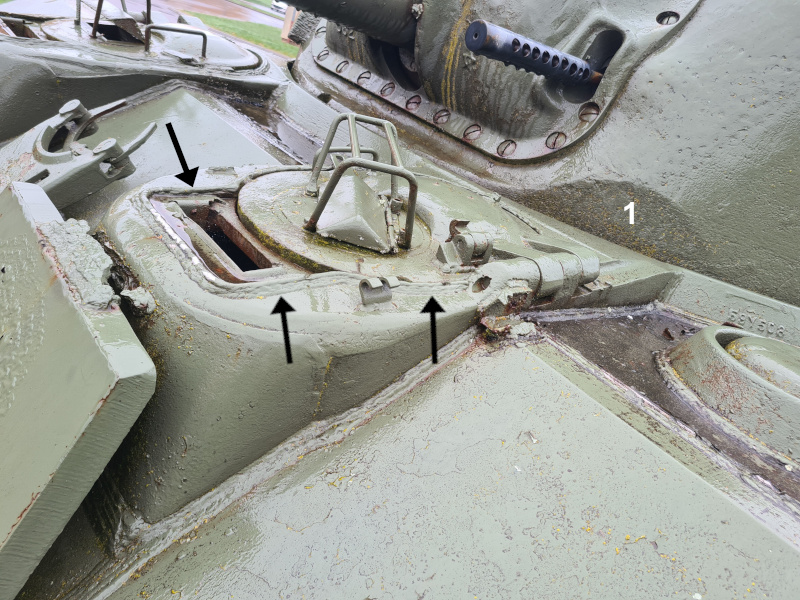

For future reference, note that the hull ventilator (1) seen here

drains to the rear.

Note the weld beads (arrows) that have been added around the drivers

hatches and auxiliary periscopes. Indeed, they surround both of the

hatches and periscopes completely. This would have taken a bit of time

to add, and we must assume it was done to correct some sort of

deficiency in the driver's hood castings. The same thing is seen on the

Commemorative Air Force Museum M4. On the direct vision PSC M4s at

Mobile and Saumur, just the front half of the hatch openings have been

treated in this manner. There simply aren't enough surviving examples of

PSC M4s to do more than observe what we have seen. In a similar vein,

we can note that the hull ventilators on all of the few surviving PSC

M4s drain directly to the rear (6 o'clock). Most other small hatch,

welded hull Shermans have them draining to the outside edge (3 o'clock,

right; 9 o'clock, left). Surviving Ford built M4A3s are consistently

observed with the hull ventilators draining at 5 o'clock on the left and

7 o'clock on the right. There are enough surviving Fords, about 100, to

make us posit that this was a Ford "thing". On another note, 75mm

Sherman turrets are seen with a "flat spot" (1) as indicated here. On

some castings, the flat is not as obvious as it is on this example.

There

may be a couple more PSC M4s with the elongated drivers' hoods on this

earth, but perhaps buried deep underground at the Trinity Site at the

White Sands Missile Range in New Mexico. These tanks were

lead lined and outfitted with oxygen tanks for use by their two-man

crews. Various sensors were installed along with tethered rockets used

for gathering and retrieving soil samples inside the A-Bomb crater. The

photo above is thought to have been taken in April 1945 not long after

the tanks arrived at the test site. The turreted M4, which can be seen

as USA 3015952 (Jan. 1943) had not yet been painted silver, while the

turretless tank had already been painted white. In the series of photos,

USA 3015952 or the "silver tank" as it was called, is noted to have a

riveted lower hull, "bent rod" lifting rings and somewhat unexpected,

the fabricated type of air scoops. The "white tank" has later features

such as standard hull lifting rings and a welded lower hull. The

location of the additional steel slabs on the side of the "white tank"

indicate that it was a former T3 Mine Flail. As we shall discuss further

along, PSC converted 41 of its M4s to T3 Mine Flails. The sharp nosed

E8543 differential was likely a replacement, but there's a small chance

that it is the original since the last 11 T3s were converted by PSC in

July 1943. The tanks were used on 16 July 1945, the day that the bomb

was detonated as well as the day after. With that their mission was

complete. A caption on a photo of 3015952 (inset) states, "Enrico Fermi

was inside this modified lead-lined M-4 Sherman Tank. He entered the

blast area around 7:00 a.m. on July 16, 1945, to take soil samples." In

his book, "Birthplace of the Atomic Bomb," William S. Loring has it that

in February 1947, it was reported that "two tanks [were] in a dump to

the northeast of the base camp in amongst tractors, tracks, wire and

other debris." He believes that the most likely end for these

contaminated Shermans was that they were buried somewhere on the site.

The other manufacturers didn't

begin M4 production until early 1943, so PSC M4s would have been the only such models

available during the battles in Tunisia at that time. Most of the photos of US

Army Shermans seen in Sicily are M4A1s, but above shows an M4 advancing towards

Messina on August 15, 1943 two days before the end of the campaign. This tank

is named "Bad Boy," and is thought to have been with the 753rd Tank

Battalion. We identify it as a PSC built M4 based on the "high" weep

holes. This tank can be seen with what we label "the plain sprocket,"

which was introduced on PSC M4s and M4A1s in early 1943, and used by them until

the end of production in 1945. Quite a few PSC M4s and M4A1s are noted with the

aircraft cowl type fasteners used to secure sand shields before the

introduction of the "Universal" or "Interchangeable" type

sand shields in mid 1943. PSC already had some experience producing sand

shields from their time making Grants for the British. In the photo, one can

see how the section hangs off the fasteners. Later versions, including the

universal type sand shields, were screwed or bolted on to attachment strips.

Most "combat shots"

of PSC M4s are from the Italian Campaign. This well known photo of the

"Belle of Little Rock" of the 755th Tank Battalion was taken in the

Castelforte area on May 12, 1944 at the start of the Allied Offensive which

culminated in the capture of Rome on June 4th. PSC is reported to have

introduced the M34A1 Gun Mount into production at the end of March, and the

“universal type” sand shields at the end of April, 1943. Sand shields were not

popular with the troops and, as seen here, were mostly removed. Note the

attachment strips used to hold the later types of sand shield. "Belle"

can be seen with a welded lower hull. Pressed Steel "joined the pack"

and, by our head count, completed the transition to this around May, 1943. Casting

flaws were repaired by filling in with weld material. Belle's turret has about

the most extensive repairs we have ever seen. The M4 behind Belle appears to be

an earlier PSC with direct vision, and the Signal Corps photographer captured

the moment that the projectile left its 75mm gun.

The photo above shows tanks

B-14 (left) and B-13 of the 1st Tank Battalion, 1st Armored Division preparing

to advance to the Arno River on August 31, 1944. The tank riders are GIs of the

370th Infantry Regiment, the first element of the 92nd Infantry Division

(composed of "Negro troops" (sic)) to arrive in Italy. As best we

have been able to determine, only Pressed Steel Car and Baldwin Locomotive

produced M4s with direct vision. B-13 has the PSC glacis pattern, while B-14

can be seen with the sharp edged fabricated bow machine gun and antenna sockets

typical of Baldwin M4s. One might not expect to see the later M34A1 Gun

Mount on a direct vision M4, but "counting heads" years ago, we were

surprised to find no examples of Baldwin M4s that did not have direct vision. As

mentioned earlier, the Ordnance Department ordered the elimination of direct

vision from the M4 design on August 13, 1942. Baldwin produced 1233 M4s from

January 1943 through January 1944, and although we have yet to find any

documentation, the available evidence leads us to conclude that ALL of them

were made with direct vision. We suspect that the PSC M4 in this photo is at

least 7 months older than the Baldwin.

Above shows the scene in a

tank dump in the United Kingdom a few months before D-Day, June 6, 1944. The M4

in the foreground can be identified as a Pressed Steel by the Registration

Number 3036751, indicating April, 1943 production. This tank appears to have a

welded lower hull, and if so, it would have been one of the first to make the

transition. The Ordnance Department wanted a great number of modifications to

be applied to the US Army pool of approximately 1000 M4s and 400 M4A1s that

were in the U.K. in the months preceding the Invasion. Indeed, the number of

such modifications was so large that ETOUSA estimated that it would take 2

years for their personnel to complete the job. Consequently, many of the

Shermans had the mods installed assembly line fashion by British contractors. It

was noted that half of the US Shermans in the UK had the M34A1 Gun Mount (a

"Must" modification), but all of those were equipped with the earlier

M50 telescopic sight, when the M70F telescope was a "Must." Note that

one unit (arrow) still has the M34 Gun Mount. None of the US Shermans in the UK

had the "Quick Fix" modification (1) which was another

"Must." The "thin spot turret patch" (2) was merely

"Urgent," and was reported missing on 70 percent of the pool. In the

photo, the "overwritten" stars would not have been acceptable at a US

Tank Depot, which suggests that the applique armor was done in the U.K. The new

"Commander's Vane Sight" (inset) was a "Must," but is not

seen on these tanks, possibly because supplies had not yet arrived in theater. Certainly

some of the modifications were unreasonable. Sand shields were

"Urgent"? Many were removed even before the tanks landed in France. The

sand shields on 3036751 can be identified as the universal type by the vertical

slit (3) in the center section.

Only 525 units were produced

by PSC in 1943 before M4 production ended in August. Consequently, they are

relatively rare in photos in Northwest Europe. Above shows a well known image

of a PSC M4 in Belgium, September 9, 1944. The caption identifies the GIs as

60th Regiment, 9th Infantry Division. The 746th Tank Battalion was attached to

the 9th ID at the time. The 746th landed on Utah Beach as part of the second

wave on D-Day. This Sherman typifies the appearance of US Army M4s and M4A1s at

the outset of the Campaign in Normandy. Just about every modification made

available by the end of 1943 is seen installed. Note how the Commander's Vane

Sight has been retrofitted next to the original blade sight. The hedgerow

cutter would have been added in the field in July 1944 before the start of

Operation Cobra. Pressed Steel Car M4s and M4A1s were outfitted with either the

original welded spoke road wheels seen in the previous photo, or the pressed

metal type shown here.

This Signal Corps photo is dated 4 January 1945, and captioned, "Combat

photographer, Sgt. Robert W. Curry, Los Angeles, Cal., with 166th Signal

Photo Company, inspects an American Sherman tank that had been captured

by the Germans and used against the Americans. Men of the 26th Infantry

Division weren't fooled, and it was knocked out in the town of

Esch-Sur-La-Sure, Lux." The British (Winston Churchill, perhaps) named

it, so "General Sherman" or "Sherman" tank are commonly used terms in

Brit documents. Contemporary US docs mostly use the generic "M4 tank" or

even just "medium tank". In any case, the use of "Sherman tank" by the

caption writer, possibly the photographer, PFC James A. Ryan, is a bit

of minutia worthy of note. This photo provides a very limited view of

the Sherman, but even so, a lot can be read from it. The rivets (1) on

the lower hull identify it as a PSC M4. The tank had obviously received

the "Quick Fix" modification (2), but it does not have the strips

associated with the universal sand shield mod. Rather, it can be seen

with the aircraft cowl type fasteners (3) used to secure the earlier

type of sand shields. The serial

number of the Union Steel turret can be seen clearly as "1546" and it is

to be noted as an example with the "angled" mold join line (4). The folding luggage rack (5) on the turret

bustle has the same distinctive design as those seen in period photos of

Shermans of the 707th Tank Battalion which was surrounded and destroyed

in the area around Wiltz, Luxembourg, 6 miles (10 km) to the north.

During the opening stages of the Battle of the Bulge, 16 to 19 December

1944, the 707th TB reported losses of 423 missing in action, along with

28 Medium Tanks (75mm), 6 Medium Tanks (105mm), 17 Light Tanks and a T2

Recovery Vehicle. It is thought that the Germans captured our subject

from the 707th and pressed it into service. Another Signal Corps

photographer filmed the M4 again on 24 January showing where it had come

to rest next to the Hotel des Ardennes (inset). This and a few GI

snapshots show that the M4 had the earlier M34 gun mount, which is a

pretty rare sight on US Army M4s and M4A1s in northwest Europe. A

Luxembourgish photojournalist named Tony Krier filmed the tank in the

same location on 28 April 1945, at which point the differential housing

had been salvaged from the tank. Eventually the tank "disappeared", but

one of the M4s lost by the 707th TB is on display as a monument in Wiltz.

This Signal Corps photo is dated 4 January 1945, and captioned, "Combat

photographer, Sgt. Robert W. Curry, Los Angeles, Cal., with 166th Signal

Photo Company, inspects an American Sherman tank that had been captured

by the Germans and used against the Americans. Men of the 26th Infantry

Division weren't fooled, and it was knocked out in the town of

Esch-Sur-La-Sure, Lux." The British (Winston Churchill, perhaps) named

it, so "General Sherman" or "Sherman" tank are commonly used terms in

Brit documents. Contemporary US docs mostly use the generic "M4 tank" or

even just "medium tank". In any case, the use of "Sherman tank" by the

caption writer, possibly the photographer, PFC James A. Ryan, is a bit

of minutia worthy of note. This photo provides a very limited view of

the Sherman, but even so, a lot can be read from it. The rivets (1) on

the lower hull identify it as a PSC M4. The tank had obviously received

the "Quick Fix" modification (2), but it does not have the strips

associated with the universal sand shield mod. Rather, it can be seen

with the aircraft cowl type fasteners (3) used to secure the earlier

type of sand shields. The serial

number of the Union Steel turret can be seen clearly as "1546" and it is

to be noted as an example with the "angled" mold join line (4). The folding luggage rack (5) on the turret

bustle has the same distinctive design as those seen in period photos of

Shermans of the 707th Tank Battalion which was surrounded and destroyed

in the area around Wiltz, Luxembourg, 6 miles (10 km) to the north.

During the opening stages of the Battle of the Bulge, 16 to 19 December

1944, the 707th TB reported losses of 423 missing in action, along with

28 Medium Tanks (75mm), 6 Medium Tanks (105mm), 17 Light Tanks and a T2

Recovery Vehicle. It is thought that the Germans captured our subject

from the 707th and pressed it into service. Another Signal Corps

photographer filmed the M4 again on 24 January showing where it had come

to rest next to the Hotel des Ardennes (inset). This and a few GI

snapshots show that the M4 had the earlier M34 gun mount, which is a

pretty rare sight on US Army M4s and M4A1s in northwest Europe. A

Luxembourgish photojournalist named Tony Krier filmed the tank in the

same location on 28 April 1945, at which point the differential housing

had been salvaged from the tank. Eventually the tank "disappeared", but

one of the M4s lost by the 707th TB is on display as a monument in Wiltz.

Ordnance documents note that

41 new production PSC M4s were converted to T3 Mine Flails. These were

essentially copies of the British "Scorpion" design. The first batch

of 30 were converted in April 1943 from M4s built on Production Order T-3321. The

101 M4s and 299 M4A1s from this P.O. were produced in March and April, 1943. Thus,

the photo above provides an idea of the front appearance of a Spring 1943 PSC

M4. The positive hatch lock mechanisms (1) were reported to have been added to

the commander's and drivers' hatches in early March. Note the standard hull

lifting ring castings (2), the step bracket (3) and the "second"

position of the siren (4). The few photos of the first 30 T3s show them with

M34 Gun Mounts, and oddly, the rotor shields noted are seen "back" in

the earlier configuration, without the cast in side pieces (5).

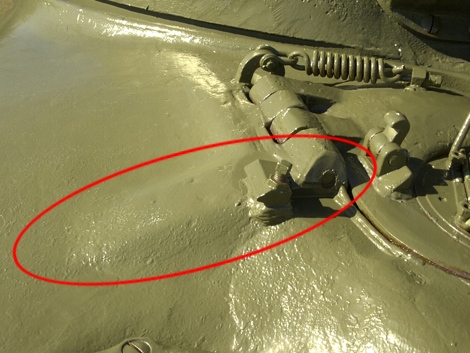

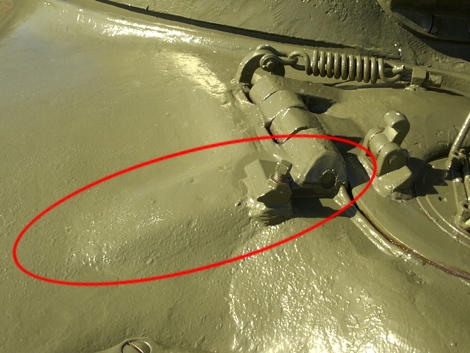

In this rear view, one can see

the addition of the exhaust deflector (1), which is in the "closed"

position. This was said to have been introduced at PSC on March 11, 1943 at

Serial Number 13610. This tank "still" has a riveted lower hull

(circled). We believe that PSC began the transition to the welded lower hull in

April and completed it by May, 1943. Starting around the 2000

range, some Union Steel turrets are seen with the turret Part Number, D50878,

cast in on one or the other side. We would guess that the "12" above the Part Number may be

a reference to the turret mold that was used. The numbers noted run from 1 to

14. This turret appears to be serial number 2990. A very unscientific

"head count" suggests that the M34A1 gun mount was factory installed

on US turrets with Serial Numbers 3100 and higher. US turrets from about 3500

through 4400 are noted in the revised configuration that eliminated the pistol

port. The high or low position of the rear turret lifting rings may have

depended on the mold that was used. The earliest Union Steel turret we've noted

with the "lows" is 239, seen on a May 1942 production M4A1. However,

from about turret SN 300 through 470 the “highs” are seen again, with most of

those having the unusually large lifting rings, such as on turrets 345 and 415

discussed earlier. Finally, every US turret recorded from SN 494 and above has

the “lows.”

A number of the first 30 T3s

were shipped to Northwest Africa soon after they were converted. The 5th Army

Engineer Training Center in Algeria published a report on August 12, 1943

detailing a demonstration in which 2 standard "T-3 Exploders

(Scorpions)" and 1 "T-3 Exploder, Modified" negotiated their way

through minefields and wire obstacles. The two standard T3s completed most of

the course, although it is noted that they were fortunate to escape intact,

because their flails had failed to detonate some mines. The modified unit was

widely photographed, and may be the subject of some confusion. During the

demonstration, it "blew up" on a pair of mines that its flails had

missed. Both tracks were broken, and some bogies damaged, but the crew was

unharmed. Above shows the modified unit and the suspension damage sustained on

the right side. The boom of the modified T3 was 2 1/2 feet shorter than

standard, skids were added under the gearbox, and shielding plates were

installed to further protect the front of the tank. Note that even the siren's

brush guard was given some extra protection.

The tank Serial and T3

conversion numbers were stenciled on to the various mine flail components. The

outboard flail engine, and most likely the M4 itself, was Serial Number 13771,

T3 conversion number 12 (left). The boom sections (right) of the modified unit

appear to have been cobbled together from other T3s, including SN 13796,

conversion 20 and SN 13797 conversion 22. By the Serial Numbers, all of these

M4s would have been accepted in April, 1943. The report concludes that the T3

cannot "be expected to negotiate anything but fairly level ground." Additionally,

"concertina wire...entangled around the rotor...may be counted on to stop

current models," and "overheating of the Scorpion engine is a serious

problem which will necessitate modifications." Despite the negative

report, the 6617th Mine Clearing Company (Provisional) employed 12 T3s in

support of the 1st Armored Division during the breakout from Anzio in May,

1944. The T3s could not do an effective job, and were removed from service.

Here we see one of the final 11 T3s converted in

July, 1943 from new M4s built on Production Order T-3605, the last

Pressed Steel P.O. that included M4s. In August, 1944, this unit served

as the test bed for the installation of a large diameter drum known as the

"Rotoflail." Some Ordnance personnel suggested that flailing operations

were best performed with the turret reversed as seen here. USA 3037333

would have been accepted in June, 1943, and unlike the earlier T3s, can

be seen with the M34A1 Gun Mount. We suspect that June saw PSC's

transition to the "no pistol port" D50878 turret (1). Other items of

interest include the round air cleaners (2), the exhaust deflector (3)

in the open position and the "long" trailer towing pintel (4), reported

to have been introduced at PSC at the end of April. The original welded

spoke idler wheel gave some problems, and, in mid 1943, the Ordnance

Department mandated that they be replaced with the disc type (5) on all

new production Shermans. The last 50 PSC M4s were completed in July and

August. The drivers' hood applique and Quick Fix mods were reported to

have been introduced at PSC at that time, but we have not come across

any period photos of PSC M4s that would confirm if any had those

modifications factory installed.

This undated photo was taken

at the Lima Tank Depot in Ohio, most likely in the Fall of 1943. The lack of

bullet splash protection around the fire extinguisher pull housing (1) suggests

that the Sherman is a Pressed Steel Car M4. The installation of the Quick Fix

Modification is said to have taken over 140 man hours. It was necessary to

remove the turret in order to retrofit 1/4 inch armor plates and doors to the

ammunition bins. The weld scorch marks indicate recent completion of the job. After

all modification work was done, the depot was directed to clean and repaint the

interior in white where necessary. We've seen a few surviving Shermans that

have "decalcomanias" or stencils with "75 MM RDS"

affixed to the ammo bins (inset). The bins are marked with the number of rounds

as listed in the November, 1942 Technical Manual. The capacity of the original

M4 and M4A1 is stated as 90 rounds (or 94 if the tank was equipped with a .30

caliber AA machine gun, instead of a .50 caliber). The 12 unprotected ready rounds

around the turret basket wall were eliminated with the Quick Fix modification,

which reduced the number of rounds carried to 78. There were complaints about

this from users in the field, and it is mentioned that some crews removed the

armored lid from the 8 round rack on the turret basket floor, and piled

additional rounds on top.

Here we have an overhead view of Serial Number 28203 which would have

been accepted in April 1943. We approach the dates and Serial Numbers

listed in the Ordnance documents with some skepticism, but it was

reported that the company introduced the M34A1 Gun Mount on 29 March

1943, at SN 28203, so this might have been one of the first units built

with the M34A1. Most of the modifications seen on this tank were

introduced after April 1943, and the remanufacturing programs didn't

begin until August 1944, a few months after this photo was taken. Thus,

most of the mods were likely retrofitted as this unit was processed at a

Tank Depot. We've pointed out the weld seams at the point where the

hull top armor angles down. As a matter of Sherman minutia, we would

observe that there are no further seams from that point to the rear of

the hull on the few PSC M4s we have examined. Chrysler M4A4s are also

noted to have used this "seamless" configuration. Other welded hull

Shermans, including Second Generation models, are seen with seams at the

point where the turret splash meets the fuel cap splash guard (black

arrows). This tank was retrofitted with doubled up tow cables ("bridle

assemblies") on the front and rear. SN 28203 was used in trials of the

automatic tow hook. This would have permitted crews to recover a tank

without getting out to hook up when under fire (inset). The tow hook was

wanted on all retrievers intended for the Invasion of Japan, and a

Modification Work Order was released in late April stating that Tank

Recovery Vehicles "will not be shipped overseas after 30 April 1945,

unless this work order has been applied." Had the Invasion gone forward,

it is thought that bridle assemblies would have been retrofitted to all

AFVs taking part, as per the MWO, "The field will be instructed to

improvise bridles on combat vehicles to allow the hook to be connected

to the vehicle and tow it to a protected area for repairs." As another

matter of Sherman minutia, we would point out that this M4 can be seen

with the prominent D51011 casting marks with the highest serial number

we have recorded - 332, suggesting that at least 332 of these were cast.

The hull ventilators can be seen draining to the rear as we discussed

earlier. Photo courtesy of George Fancsovits.

Pressed Steel Car built nearly

4 times as many M4A1(75)s as M4(75)s, and they served in all theaters from the

Sherman's debut with the British at El Alamein to the "last battle"

on Okinawa. On August 23, 1942 the company was given verbal instructions that it

was to produce 1000 standard made M4A1 Medium Tanks with an engineering change

that incorporated the 76mm Gun M1 mounted in the newly designed M34A1

Combination Gun Mount. It was intended that this order would be completed

before the end of 1942. This was entirely unrealistic, and as it turned out,

exactly one such unit was produced in 1942. SN 549, USA 3015305 was the pilot

model M4A1(76M1) and tests at APG led to recommendations for a number of

improvements to be made to subsequent units. One can see that this September 1942

production M4A1 "still" has M4 bogies with the original half round

track skids. Note that the standard cast air scoops and tail light guards have

not yet been installed. The Union Steel turret serial number appears to be

1034.

USA 3015334 was also accepted

in September, 1942, only a few units after the M4A1(76M1) pilot. This Sherman

was photographed in January, 1943 when it was used by the Barber-Colman Company

to demonstrate its "Air Flow Corrective Devices." The Barber-Colman

system was adopted for use on PSC M4A1s starting on December 1, 1943, and

Chrysler M4s starting on January 1, 1944. It featured "Pyramid Turning

Vanes" on the engine air intake and a "Hinged Air Exit Vane" in

place of the original exhaust deflector (insets). This unit is installed with

the standard cast air scoops (1), as is every PSC Sherman we have been able to

record with higher Serial or Registration Numbers. We might infer that the

later asymmetrical track skids (2) seen here were introduced at PSC in

September. This tank "still" lacks tail light guards, which our head

count suggests were introduced in October. Because they are often readable in

period photos, we like to record the Union Steel turret serial numbers and the

features visible. This one is # 1137.

The second model of the

M4A1(76M1), Serial Number 10953, USA 3015954, was not accepted until January,

1943, and was immediately shipped to the Armored Force Board at Ft. Knox,

Kentucky. Based on feedback from trials with the original pilot, a new turret

casting was made that featured an enlarged bustle which served to

counterbalance the gun, and provide the turret crew with a little more room. These

turrets were produced by Union Steel, and this particular casting can be seen

to be Serial Number 2. Note the access hatch at the top of the bustle. The gun

mount setup featured a new heavy duty recoil guard that weighed 800 pounds. Firing

tests were suspended in early February when it was found that recoil piston

rods were too weak. Improved piston rods were installed on the next M4A1(76M1)

(USA 3016065) received at Ft. Knox, and firing tests commenced on March 1,

1943. Gun travel locks were installed on both the front and rear of the

M4A1(76M1)s, and we would note that the securing arm of the front travel lock

was a single, wrap around piece, as opposed to the standard, but less stable

two piece units that entered Sherman production in the Fall of 1943. Pressed

Steel Car began the transition to the standard cast hull lifting rings in

December, 1942, but note that 3015954 can be seen with padded hull lifting

rings (asterisked) on both the front and rear. A Ft. Knox Receiving Report

lists not only the Serial and Registration Number, but "C723" as

well. We take this to mean that Serial Number 10953, USA 3015954 was the 723rd

cast hull (M4A1) produced by PSC. We believe this number is what is seen stamped

on the hull side in the rear of surviving PSC M4A1s.

The third M4A1(76M1) was

photographed at APG on April 1, 1943. This tank was Serial Number 13669, USA

3016670, US turret # 3 accepted in March, 1943. A few items of interest from a

production standpoint can be noted. The track skids (1) are in the

"final" or standard configuration. The use of heavy steel tracks

created a friction problem with the track skids. This was remedied by the

addition of a spacer (2 and inset) that elevated the return roller by about an

inch. A

modification kit was provided in mid 1943, so that the spacer could be

retrofitted to any Sherman built without it. Five of the six bogie arms seen

here are the "final" type (3), introduced at PSC starting around

January, 1943. In order to prevent the bogie arm rubbing plate bolts from

working loose, they were secured at the bottom with a nut. "Wrench

holes" (circled) provided access to the nuts. These bogies represent the

configuration used by PSC until early 1944, when the straight return roller

arms were replaced with upturned arms that eliminated the need for the spacer. The

positive hatch locks (4) are present on the commander's hatch, but not the

driver's hatches. However, the fitting for the equilibrator spring (5) can be

seen by the bow gunner's hatch. A couple of items we would not expect to see on

a March, 1943 PSC Sherman include the M3 type drive sprocket (6), and the

"padded" hull lifting ring (7) in the rear. The "padded"

lifting ring castings are oddities noted in only a few period photos of PSC

M4A1s made in late 1942, early 1943. Most of their Shermans appear to have

started out with the "bent rod" lifting rings, with a transition made

to the standard castings around December, 1942. We are not aware of any

surviving PSC M4s or M4A1s with the "padded" hull lifting rings.

This M4A1(76M1) was Serial

Number 13679, USA 3016680, US turret # 4 produced in March, 1943, a few units

after SN 13669 of the previous caption. This tank was the subject of a test in

the Spring of 1943 by the 40th Armored Regiment, 7th Armored Division stationed

at the Desert Training Center in California. There was some indecision, or

perhaps dissension, about the caliber of the Antiaircraft Machine Gun to be

carried by the Sherman. The 3rd Armored Division arrived in the UK in the Fall

of 1943. When they drew their Shermans, it was reported that half were equipped

with .30 caliber and half with .50 caliber AA MGs. "In many instances,

tanks that are equipped with the .30 caliber...had spare parts and accessories

for the .50 caliber." On April 1, 1943 the Ordnance Department settled the

issue by directing that only the .50 caliber was authorized for the Medium

Tank. The M4A1(76M1) program perhaps reflected the indecision, as they were to

be equipped with .30 caliber AA MGs. A purpose made travelling clamp was

provided, as shown above. The Reports from APG and the DTC concerning the

M4A1(76M1) were not negative, although suggestions were made for improvements. However,

on April 5, 1943, an Armored Force Board Report concluded that the turret was

unsatisfactory, too small "to develop the full potential capabilities of

the 76-mm gun." A month later, the Ordnance Committee terminated the

program. Only 12 units had been produced, and 9 were converted back to

M4A1(75)s. It should be noted that a few Shermans with "small"

turrets were upgunned with 76mms in the ETO during WW II. In the early 1950s,

over 700 such tanks were upgunned, and provided to Allies as Military

Assistance.

This rear view of SN 13679

shows the "Original Design" exhaust deflector (1) reported to have

been introduced at PSC on March 10, 1943 at Serial Number 13610. The deflector

was notched to accommodate the exhaust pipe (2) for the auxiliary generator.

The later Barber-Colman type deflector is said to have replaced this on

December 1, 1943, PSC's last month of M4A1(75) production. The "long"

trailer towing pintle (3 and inset) was reported introduced on April 29, 1943

at Serial Number 28205, so its appearance on SN 13679 seems a little early. We

suspect that, like the .30 caliber AA MG, the pintle was intended to be

standard equipment on the M4A1(76M1) series. In some instances, the long pintle

got bent up in service, which created an interference issue with the engine

access doors. A shorter pintle was designed, and became available by the end of

1943. It was used on "Second Generation" and remanufactured Shermans.

Note the rivets on the lower rear hull plate, including those used to secure

the idler wheel assemblies. The rear gun travel lock (4) of the M4A1(76M1) was

a 2 piece affair. When PSC finally got around to installing tail light guards

(5) on its M4A1s, circa October 1942, they were in the configuration shown

above. We've used an arrow to point out the groove in the center of the hull

casting. This is typical of upper hulls cast by General Steel.

The tail light guards used by

Pressed Steel, Lima Locomotive, and PCF are shown above. Each shape is unique,

and can help identify the maker of an M4A1 when seen in period photos.

Surviving M4A1s must be viewed with some skepticism, since the original guards

might have been damaged, and replaced with something non standard during

remanufacture or restoration.

In late 1942, the General

Steel Casting Company's Commonwealth Plant in Granite City, Illinois began

production of M4A1 upper hulls. Except for the T6 (Sherman) pilot, we don't

find any evidence that GS produced any hull castings with direct vision. By early

1943, GS provided approximately half of the upper hulls used by Pressed Steel

Car. Continental Foundry & Machine provided the balance of PSC's castings,

as well as nearly all of those required by the other M4A1 manufacturers - Lima

Locomotive and Pacific Car & Foundry. Starting in early 1943, General Steel

began to cast their logo (1) on the front of the hulls they produced. If it can

be seen in a period photo, the "G in a shield" logo can be considered

a recognition feature of an M4A1 made by Pressed Steel, or one of the 188

Grizzlies made by Montreal Locomotive. Above shows machining operations on a

General Steel hull. The groove at the rear (2) was not a feature of Continental

castings.

In the Spring of 1943, the

Armored Board at Ft. Knox directed Pressed Steel Car to provide 4 M4A1(75)s

(later reduced to 3) for inspection and test. Each would be installed with

progressively more modifications from the so called "Blitz List." PSC

shipped "1st Blitz" on May 17. With the exception of Blitz Item 35a,

"Eliminate Pistol Ports," most of the modifications on this unit had

already been incorporated into Sherman production. "2nd Blitz" was

accepted in May, 1943, and was shipped out on June 19, 1943. It is somewhat

more interesting as it included several new mods. Blitz Item 16a,

"Improved Suspension, Horizontal Volute Springs" was installed on

"3rd Blitz" as well. This version of HVSS had been in development for

about a year. The ride was a little smoother over rough terrain, but the track

width remained the same as VVSS at 16 and 9/16 inches, so this HVSS did nothing

to reduce the Sherman's ground pressure. This project was terminated in favor

of the improved HVSS with 23 inch tracks being developed by Chrysler. The

"no pistol port" Union Steel turret can be seen to be Serial Number

3432, mold(?) 7. On April 14, 1943, the turret drawing was revised to eliminate

the pistol port, as well as "increase thickness of armor in region of

traversing mechanism." We don't have a right side photo to confirm, but

suspect that turret 3432 was one of the first of the new castings that included

the so called "thickened cheek" on the right front.

This overhead view of "2nd Blitz" shows a few more new items. The

commander's hatch (1) is a revised design which featured integral springs on

the hinges. The final version of this hatch was released as a "Critical

Modification" on July 24, 1943, with "No tanks without this item to

be accepted after 11/8/43." Perhaps the most important safety item was

Blitz #46, "Hatch Over Loader.” "2nd Blitz" shows a prototype

version of the loader's hatch (2) with a different "hold open"

configuration. The final revision with head padding was released as a Critical

Modification on September 29, 1943, and PSC is reported to have introduced it

in October at SN 37300. Chrysler and Fisher Body, the other builders that

remained in the Sherman program after January, 1944, are said to have

introduced the loader's hatch in December, 1943. Plans for a field modification

kit were abandoned, as it was thought that a retrofit was too complicated. "2nd

Blitz" can also be seen with a preproduction version of the

"Commander's Vane Sight," Blitz Item 43. This was said to have been

introduced at PSC at about the same time as the loader's hatch. The machine gun

pintles on the turret roof may have been added by the Armored Board. In the

Fall of 1943, "2nd Blitz" was used as a test bed for a wooden mock up

of the commander's vision cupola (inset).

Pressed Steel Car shipped

"3rd Blitz" on August 23, 1943. This tank was listed as SN 29203/USA

3037734, PSC #3300, and would have been accepted in August. The "PSC

Number" may have been the Manufacturer's Serial Number. The MFR's SN is

stamped on the dataplates of some US built WW II AFVs, but we have never seen

it on a Sherman plate. In any case, if we've done the math correctly, this tank

would have been the 3300th overall Sherman, both M4 and M4A1, accepted at PSC. "3rd

Blitz" is dramatically different from "2nd Blitz." The hull

casting was revised to incorporate larger drivers' hatches as recommended by

the Army Medical Research Lab. "3rd Blitz" was installed with the

"Quick Fix" modification, as evidenced by the 1 inch applique plates

in the areas of the sponson ammunition bins. "Counting heads"

suggests that the last 100 M4A1(75)s made by PSC in December, 1943 featured the

large hatch hull casting, Part Number E8550. The examples noted differ from

"3rd Blitz" in that the hull castings were thickened in the area of

the sponson ammunition bins, eliminating the need for the welded on applique

plates.

This overhead view highlights

another dramatic change. Some Ordnance Department engineers found the original

D50878 turret to be too small, and recommended a larger turret. The casting

seen here was "borrowed" from the T20 series Medium Tank program, and

is listed as Part Number E6275. Ironically, the Armored Board concluded,

"The T23 type turret is not satisfactory for use as a 75-mm gun

turret...because the additional turret space is not essential and the increased

weight is not desirable." The Ordnance Committee action that terminated

the M4A1(76M1) program, authorized development of a larger turret for the 76mm

gun. Another E6275 turret was used for the pilot installation, and, with some

changes, this basic shape was adopted for use on Second Generation Shermans

armed with the 76mm gun. 1944 and later production 75 and 105mm Shermans used a

modified version of the original small turret that reinstated the pistol port

and added a loader's hatch. The only Sherman that mounted the 75mm in a larger

turret was the M4A3E2 (Jumbo). "3rd Blitz" can be seen with periscope

guards, which entered the Sherman production pipeline starting in September,

1943. The armored housing (1) around the gunner's periscope became a standard

fixture on Second Generation Shermans, as did the Blanket Roll Rack (2). The

rather large gun travel lock seen on "3rd Blitz" appears to be the

same as used on the M4A1(76M1)s. A "2 fingers" travel lock (Assembly

Number B301301) became standard on 75mm Shermans starting in the Fall of 1943.

It was about 4 inches shorter than the fixture used on Second Generation 76 and

105mm Shermans.

The factory installation of

the Quick Fix modification at PSC is reported to have occurred in August, 1943

at SN 29317. This seems to be pretty close to what we have found counting

heads. Many M4A1(75)s can be seen with the flat, rolled armor applique plates

made for welded hull Shermans. These were cut into sections or otherwise

adapted to fit the contours of the cast hull. Although undocumented so far, it

is obvious from period photos and surviving examples that PSC procured castings

made to fit the contours of its M4A1s. Our observations suggest that, until mid

October, most of the M4A1s that PSC produced with the Quick Fix modification

factory installed, used these castings. Above shows the castings on an M4A1 on

display in Springville, Alabama. Note the multiple contours of the front

"plate." We do not know the Serial Number of this tank, but recorded

the number "2687" stamped on the right rear side. We take this to be

a loose build sequence number (plus or minus 30). The 2687th PSC M4A1 would

have been accepted in September, 1943. Like Serial Number 415 in Nattick shown

previously, this tank was remanufactured in 1945, and converted to M42B1

Flamethrower shortly thereafter. The fenders have been extended out to

accommodate the E9 modification. The rather complex fender braces were

adjustable to fit the contours of the tank as demonstrated here. These braces

are seen on both M4s and M4A1s remanufactured by Chrysler-Evansville and

International Harvester. When Pressed Steel Car began producing the

M4A1(76)HVSS in January, 1945, the same type of adjustable fender braces were

used.

Quite a few of the PSC M4A1s

with cast applique appear in photos in the Pacific Theater of Operations. Above

shows "Margaret Anne" of D Company, 754th Tank Battalion. This tank

is listed as USA 3069681, indicating September, 1943 acceptance. In April, 1945

"Margaret Anne" was pulled out of the line near Manila, and used to

test the merits of an in tank air purification system that had been shipped

from the US. Trials of the system in a number of Shermans from 3 Tank

Battalions, and including combat use, found that the Protector, Facepiece,

E21R2 (inset) was much superior to the use of individual gas masks. On June 20,

1945, the Pacific Warfare Board recommended that the E21R2 system "be

standardized as the method for protecting tank crews against chemical warfare

agents." The standardization and installation of this system in medium

tanks appears to have been abandoned with the Japanese surrender. PSC began

installation of the gun travel lock in August at about the same time as the

Quick Fix modification. On "Margaret Anne" it can be seen that the

siren and brush guard were moved over to the left to avoid any interference

issues with the travel lock. This tank features the "turret patch"

and it is assumed that the pistol port would have been welded up. These appear

to have been used alongside the no pistol port turrets that PSC introduced in

June, 1943 until an improved turret entered the production pipeline in October.

Here we see a PSC M4A1 with

the cast applique and a no pistol port turret in the European Theater. USA

3038028 would have been one of the last tanks accepted at Pressed Steel in

August, 1943. This tank carries tactical markings of the 771st Tank Battalion,

and was photographed in Baal, Germany on February 24, 1945. Note the M4A3(76)

just in front. Had they been available in sufficient quantities, the US Army

would have replaced 75mm Shermans with this model powered by the superior 500

HP Ford V8 engine. The shipping destination code on 3038028 begins with

"HAIL," indicating Antwerp. The port, which has an immense shipping

capacity, was vital to the Allied drive into Germany. It was captured intact on

September 4, 1944, but due to an overly casual attitude on the part of the

Allied High Command, its approaches were not immediately cleared of the enemy. As

a consequence, it was not opened to shipping until the end of November. The

771st probably received this tank as a replacement in early 1945. When built,

USA 3038028 would not have been installed with the machine gun stowage on the

turret bustle or the blanket roll rack. These items were part of a combined

Modification Work Order released in July, 1944. The presence of these mods,

along with the concave replacement road wheels, suggests that this tank may

have been remanufactured at the outset of the program in August, 1944.

Above shows an M4A1 of the

767th Tank Battalion, photographed on October 24, 1944 during the Leyte

Campaign. The Technical Manuals have it that a total of 26 grousers were stored

in the sponson compartments beneath the air scoops. "Man O' War"

appears to have nearly 40 installed on the left side alone. An improved

transmission with double anchor brakes, and featuring the sharp nosed, E8543

differential housing was mandated to be installed on all US built Shermans

starting in September, 1943. With this change, PSC reintroduced the front cable

clamp (circled) originally seen on a few of its earliest M4A1s. There is no

Registration Number visible to "date" this tank, but if we assume

that the 2 inch smoke mortar was factory installed, we would guess early

October, 1943 acceptance. The turret serial number can be seen as 4318, mold(?)

13, the highest SN we have recorded from a no pistol port Union Steel turret. Counting

heads suggests that at around turret 4400 the castings were revised to include

a loader's hatch and pistol port.

This

"after the battle" photo is part of a series showing US tank losses on

Okinawa. Note how a section of armor has been cut out and salvaged from

the differential housing on the M4 Composite in the background. We

believe that the M4A1 in the foreground may have been the last Pressed

Steel Car Sherman battle casualty of WW II. In mid-May 1945, the records

of the 706th Tank Battalion report the loss of 3 Medium Tanks which are

specifically listed as M4A1s: 3069617 (PSC Sept. 1943 production),

3069808 and 3069829 (both PSC Oct. 1943 production). We suspect that all

of these would have had the welded on, cast applique, as seen on the no

pistol port turret M4A1 in the foreground. The inset shows that the

M4A1 was named "Dude Sr." and the last 3 digits of the Registration

Number can be seen as "617" which we take to mean that this example was

USA 3069617. According to an official report, 3069617 was KO'd on 14 May

1945, which was D Company's worst day for "Vehicular Casualties" as

they reported the loss of 4 Medium Tanks "destroyed by fire." The

706th's After Action Report states that D Company was in support of the

306th Infantry Regiment of the 77th Infantry Division during its

unsuccessful assault on Flattop Hill. The AAR reports that "four tanks

were disabled during the operation" on the 14th, while the "Vehicular

Casualties" report states that they were destroyed. We would mention

that D Company was ordinarily the light tank company of a US tank

battalion, but the "Vehicular Loading" table" for the 706th TB has it

that the unit came ashore with 60 "Med Tks" and 6 "105mm AG" [Assault

Guns] and no Light Tanks. Note that "Dude Sr." has features nearly

identical to "Man O' War" of the previous caption, even including the

2-inch smoke mortar fittings. However, just the stub of the original

blade sight remains on "Dude Sr." The M4

Composite, possibly named "Butt Buster", is thought to have been lost

by B/706th a few days before. These Shermans were likely KO'd on the

trail and pushed out of the away not long after.

Around mid-October 1943, Pressed Steel Car introduced a revised small

hatch upper hull that featured thickened sides in the areas of the

sponson mounted ammunition bins. The new casting eliminated the need for

welding on the external applique. The M4A1 on display at Ft Jackson, in

South Carolina was converted to E13-13 Mechanized Flamethrower in early

1944. We suspect that this was one of the first PSC M4A1s to

incorporate the revised hull. We've asterisked the cast in "bumps" on

the right side. Unfortunately, the Test Report on the E13-13 does not

list the Serial and/or Registration Number of this unit. The build

sequence number 3175 is stamped on the left rear of the hull, which we

take to mean that it was the 3175th (give or take) M4A1 produced by PSC.

We would note that a surviving October 1943 production PSC M4A1, build

sequence number 3153, "still" has the cast applique welded on. Another

change which appears to have been introduced at PSC in October is the

relocation and new configuration of the siren brush guard (circled).

Photo courtesy of Paul and Lorén Hannah.

Another change that was

introduced in late October, 1943 is the revised D50878 turret casting that

"brought back" the pistol port, and incorporated the loader's hatch. The

manufacturers that continued to produce Shermans in 1944 and 1945 were Pressed

Steel, Chrysler and Fisher Body. Each was given a "Freeze Date" for

the loader's hatch. PSC's was November 1, 1943, but "counting heads"

suggests that they began the transition in October. Since the E13-13 was a

conversion, we can't say with certainty that the General Steel (not Union

Steel) D50878 turret, serial number 5573, is original to this tank. The turret

can be seen with a few flamethrower fittings, and we would guess the

commander's vision cupola and machine gun stowage modifications were added

during the E13-13 conversion. We don't find any evidence that PSC factory

installed these mods to any of its M4A1(75)s. The E13-13 does not appear to

have been remanufactured before conversion. Note that it still has the original

type exhaust deflector (1) as well as the problematic "long" trailer

towing pintel (2). The double rear tow lugs (3) are first seen on Third Blitz. These

served to accommodate the quick release towing shackle with handle, and appear

to have been introduced at PSC in late September.

While examining the M4A1 at

Ft. Jackson, we noticed that the hull casting features ramp-like raised areas

by each of the drivers' hatches. This bit of Sherman minutia has since been

seen on a few other surviving M4A1s, such as SN 37260, a PSC October, 1943

production M4A1 on display in Sinsheim, Germany (right). Counting heads suggest

that the "ramps" first appear around August, 1943, and are limited to

hulls cast by Continental Foundry & Machine. Perhaps they were added to the

castings to provide a better platform for the catch of the positive hatch lock

mechanism?

The Ordnance Department

continued to cast about, without much success, for anti-mine solutions. Above

shows the T9E1 Mine Exploder at APG in April, 1944. Like most of the

"Pressure Type" Mine Exploder experiments, the T9E1 was found

"impractical for use under combat conditions." The device was tested

with Serial Number 37421, USA 3070018, which would have been one of the last

M4A1s accepted at PSC in October, 1943. This tank can be seen with the revised

hull with cast in "bumps," and the new low bustle turret casting with

pistol port and loader's hatch (arrow). Counting heads suggests that from this

point to the end of 75mm production at PSC (Serial Number 37899, USA 3070496),

all of the M4A1 had turrets that incorporated the loader's hatch.

It was the practice of the

Ordnance Department to conserve certain pilots at APG for future reference. USA

3070018 was photographed in February, 1947. We assume the T9E1 roller would

have been been retained as well, although it does not appear in the photo. The massive roller weighed as much as the tank, and the bumper (arrow) at the rear was installed so that a second tank could help push it. 3070018 can be seen with

the new siren brush guard. The "2 fingers" or "scissors

jaw" configuration of the gun travel lock shows to good effect. It is

thought that this type may have been designed since, in theory at least, the

gun could be released from its travelling position from inside the tank by

means of a wire. Tests at APG in September, 1944 found it to be unstable and

inadequate for either the 75mm or 76mm gun, and suggested a new design with a

wrap around clamp, similar to what had been used on the M4A1(76M1). Many

surviving Shermans are seen with the improved locking clamp (inset), but we

don't find any evidence that this was factory installed on any Shermans before

production ended in the Summer of 1945. Unlike Chrysler and Fisher Body, PSC

continued to install the step bracket after the gun travel lock was introduced.

This small item was eliminated on the M4A1(76) and other Second Generation

Shemans. On the subject of steps, the E8543 differential housing seen here is

the early type with the cast in steps. These interfered with the operation of

the quick release towing shackles. Consequently, the differential castings were

altered to eliminate the cast steps, and the standard E8543 differential was

installed with welded on metal strip steps instead.

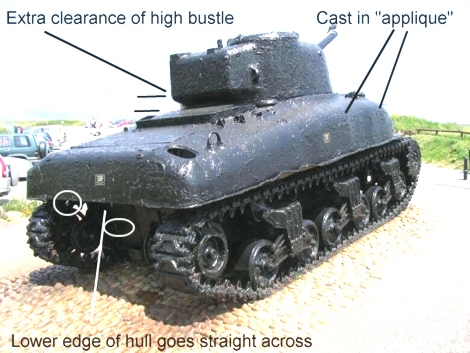

The Ordnance Department's

constant demand for modifications was a sore point for some of the

manufacturers. Henry Ford, the "father" of mass production, was

somewhat vocal about this, since the Government was asking for greater and

faster production, while introducing numerous changes that required the design

and procurement of new parts, and only slowed down the process. Pressed Steel

Car's management appears to have been more willing to go the extra mile, and

provide the Government with whatever it wanted as quickly as possible. Consequently,

the many changes introduced in quick succession by PSC, make them the most

interesting of the manufacturers of the Sherman. Above shows the first two T1E3

Mine Exploders during a demonstration in the UK in May, 1944. "Aunt Jemima

2" can be seen as USA 3070232 indicating November, 1943 acceptance. When

the cast and welded hulls were redesigned to incorporate larger hatches, it was

noted that the bustle of the original 75mm turret could be fouled on the

protrusions of the large hatch hull. Consequently, the turret casting was

revised yet again. The turret bustle was raised a few inches in order to permit

the turret to rotate freely. "High bustle" and "low bustle"

are informal terms used to distinguish the difference in the castings. In the

photo, it can be seen that both "Aunt Jemimas" have small hatch upper

hulls with the cast in "bumps." However, both have high bustle

turrets, introduced by PSC in November, 1943 in anticipation of the large hatch

E8550 hulls that would come on line the following month.

This overhead view of USA 3070232 was taken at APG in March 1944 before

the tank was shipped to Great Britain. It can be seen that the part

number of the turret (circled) is "still" D50878. The turret serial

number appears to be 4595, the next to the highest Union Steel 75mm

turret SN we have recorded. It is thought that about the last 200 Union

Steel 75mm turret castings were in this high bustle format, and that

they were the only such turrets that retained the D50878 part number. At

present, all other high bustle, loader's hatch turrets we have

encountered are seen with a new part number - D78461. In fact, an item

in the Ordnance files lists "Turret D78461, to provide clearance for

doors, released 9/28/43." Note that the gunner's periscope was not

provided with a wire guard. An armored housing, similar to what can be

seen on Third Blitz, was introduced on Second Generation series

Shermans. The Whiting Corporation produced 200 T1E3 assemblies from

March through December 1944. About 72 were shipped to Europe.

Ultimately, it was concluded that the T1E3 "failed to meet the

requirements" for "locating and breaching minefields, and expeditiously

clearing and/or detecting scattered mines on roads and trails."

The final major change before

the end of M4A1(75) production at PSC was the introduction of the large hatch

hull casting. Since PSC was the only remaining manufacturer producing the M4A1,

the change only applied to them. The "Freeze Date" was given as November

30, 1943, which would indicate that the 175 units accepted in December would

have used the large hatch E8550 hull castings. However, "counting

heads" suggests that PSC was not able to meet the freeze date, and that

only about 100 such units were produced. At present, the large hatch hulls

recorded fall within the range from Serial Number 37800, USA 3070397 through to

the last PSC M4A1(75) Serial Number 37899, USA 3070496. Above shows an example

that was recovered in 1984 from the sea bed in what had been the US Amphibious

Assault Training Area in Devon in the UK. This tank had been converted to a

Duplex Drive "swimming tank", and was engaged in a training

exercise with Company A, 70th Tank Battalion when it sank 3/4 of a mile

offshore. An article in "After the Battle #45," describes the

efforts of a group of local citizens headed by hotelier Ken Small to recover

the tank, which Mr. Small had purchased 10 years earlier from the US Government

for $50. A couple of sentences in the article are of particular

interest..."A special search was made beneath the silt for the works

number plate...and fortunately although badly corroded the plate was still in

place. After cleaning the plate was still legible: 87830." We have not be

able to contact the late Mr. Small's son, but it seems highly likely that the

Serial Number from the dataplate would be 37830.

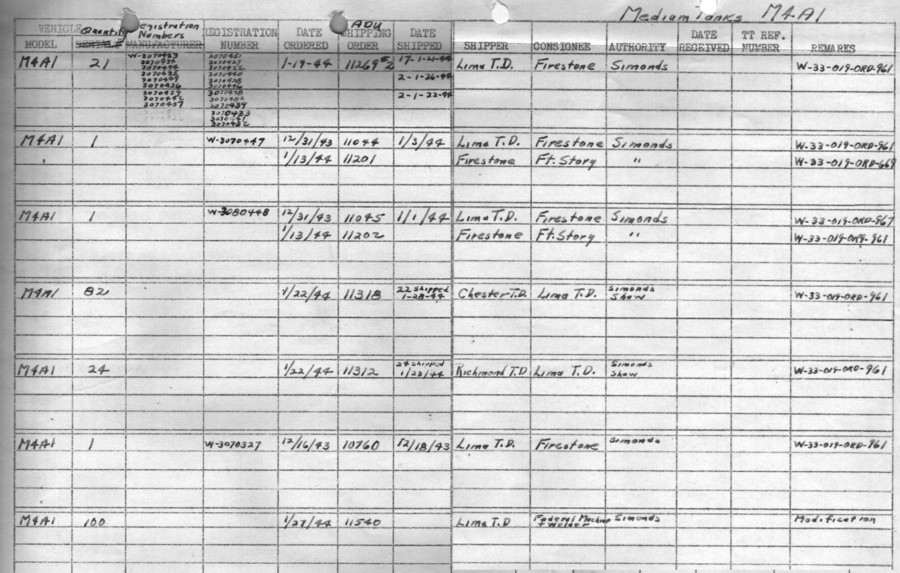

In December 1943, the Army

contracted with the Firestone Tire & Rubber Company for the production of

350 Duplex Drive assemblies to be applied to new M4A1(75)s. Because they were

recently built, unallocated and available, the majority of the DD swimming tank

conversions used Pressed Steel Car M4A1(75)s that had been produced in the last

few months of 1943. We suspect that about 90 of the large hatch M4A1(75)s were

converted to DDs, while another 10 were used in Engine Endurance and other

tests at the various Proving Grounds. The DD project was highly classified, and

therefore much of the documentation was not preserved. However, we did come

across the shipping report reproduced above. The prototype is listed towards

the bottom of the page as USA 3070327. It was ordered from Lima Tank Depot on

December 16, 1943, and shipped to Firestone for DD conversion 2 days later. The

prototype used DD parts that the British had provided, and due to some

US/British thread incompatibility issues, developed problems and sank in

shallow water during testing at Ft. Story, Virginia. The Registration Numbers

of the first 23 M4A1s shipped from LTD to Firestone for DD conversion are

listed. Note that all but the prototype have RNs in the 30704XX (December large

hatch production) range. This appears to have been a case of "last in,

first out." There is at least one typo in the document - 3080448 was most

likely 3070448, one of the two pilots shipped to Ft. Story for trials. Along

with 3070441, this was later placed in secure storage at the Lima Tank Depot

"for possible future development or production work." If we assume

that Mr. Small's DD is actually Serial Number 37830, its corresponding

Registration Number, USA 3070427, is listed in the document.

Mr. Small's DD now stands as a

memorial in Torcross to the servicemen who were lost during Exercise Tiger, an

amphibious training operation conducted off the coast of Devonshire. On the

morning of April 28, 1944, negligence on the part of the naval screening force

left a convoy of LSTs open to attack by German E-Boats. Two LSTs were sunk and

another badly damaged. Nearly 700 US soldiers and sailors lost their lives in

this tragedy.

The photos above highlight

some of the features of the large hatch M4A1(75). It is thought that all of the

US DD conversions would have had late E8543 differential housings. Both the

early version with cast in steps, as well as the later with welded on steps

have been seen. Note the fittings for the Barber-Colman type exhaust deflector

(circled). This was reported to have been factory installed by PSC starting

December 1, 1943, and, if accurate, would have applied to the last 175 M4A1s

accepted, including all of the large hatch units. The example on the right is

said to have been a DD of the 741st Tank Battalion. The disastrous decision to

launch the Battalion's 32 DDs in extremely rough seas nearly 3 miles off Omaha

Beach resulted in the loss of 27 by sinking. Miraculously, 2 of the 741st's DDs

managed to swim in, and 3 were deposited on shore by their LCT when their

canvas screens were torn by shrapnel prior to the decision to launch. This

Sherman, along with a small hatch DD, and the turret from another were recovered

by M. Claude Lemonchois, and are on display at the D-Day Wrecks Museum in

Port-en-Bessin, France. Left side photo courtesy of Alf Adams.

The casting information on the

high bustle turret of the Torcross DD is of interest because it is a General

Steel, not Union Steel turret. The turret Serial Number is 5939 and it has the

later D78461 part number. We can document one other General Steel D78461 turret

installed on a DD, but can't publicize it at present, except to note that the

serial number is about 100 units lower than the one on the Torcross. From this

we can merely conclude that General Steel provided some of the high bustle

turrets used by Pressed Steel in the last months of production. The majority of

the General Steel D78461 turrets were used on the Second Generation M4A3(75)Wet

Shermans made by Fisher Body. Turret Serial Numbers recorded on those run from

6020 through 7679. As a point of Sherman minutia,

we would note that the secondary antenna brackets on the turrets used by Fisher

are seen fabricated from several pieces, as shown in the inset on the right,

whereas the ones on the two General Steel DD turrets appear to be one piece

forgings.

It is thought that the 3 DD

turrets at Port-en-Bessin were cast by Pressed Steel's primary supplier, Union

Steel. The single low bustle turret is Serial Number 4452. Other Union Steel

low bustle, loader's hatch turrets that have been recorded are 4444 and 4471.

The D50878 casting marks on both low and high bustle Union Steel turrets are

seen on the left front (inset), and the Serial Number is repeated on the

turret's left side. We don't find evidence that a padlock fitting (inset) was

factory installed by PSC with the introduction of the loader's hatch. It may

have been installed on some of the late production M4A3(75)Wets, or retrofitted

later in the post war years. Curiously, this turret has the fitting for the sun

compass (circled in red) installed by the British, or added by US Tank Depots

on Commonwealth Lend Lease Shermans. We can only note that the compass fitting

is seen on some but not all of the US converted DDs.

It

was not possible to record the Serial Numbers of the 2 high bustle

D50878 turrets at Port-en-Bessin due to their condition. Examples that

have been noted are Serial Numbers 4548 (inset), 4564 and 4595. Above

shows a rear view of the large hatch DD. The overhead photo of the

November 1943 production "Aunt Jemima 2," USA 3070232 featured earlier

shows the recessed lifting handles on the rear engine deck plate in the

"usual" side by side orientation. Here we see that that the handles have

been reoriented front to back. This is also the case on the Museum's

small hatch DD. From this we might infer that PSC instituted this small

change in either November or December 1943. It was standard throughout

production of the M4A1(76). M. Lemonchois recovered a number of US AFVs

from the sea off Omaha Beach, including the M7 Priest seen in the

background. While he was not able to find the Ordnance Serial Numbers of

the DDs, he reported the M7's was 2537, and that the vehicle was lost

by the 58th Armored Field Artillery Battalion.

Update:

At some point in the last few years, a large section of marine growth

(inset) was removed or fell away from the turret of the large hatch DD

at Port-en-Bessin. This enables us to see that the turret serial number

is either 4732 or 4762. Either way, this would now be the highest Union

Steel 75mm turret serial number we have recorded. This "revelation"

changes the counting heads equation somewhat, since it suggests that

Union Steel may have produced over 200 high bustle, 75mm turrets. In

addition, it is reported that the US Government bought the museum's

small hatch DD and intends to display it at the National Museum of the

United States Army at Ft. Belvoir, Virginia. If that is accurate, we

hope we might be able to obtain the turret's serial number in the

future.

Nearly 300 DDs embarked from

the UK. Those that survived D-Day were converted to regular gun tanks when time

and circumstance permitted. Above shows a large hatch model photographed in July,

1944 by the 3rd Armored Division to show the "T2 Rhinoceros" device

developed as a mean to breech the hedgerows of Normandy. Hundreds of tanks were

installed with various types of these cutters before the start of Operation

Cobra in late July. Here one can see that the USA Registration Number was

painted on the turrets of DDs, since the skirting would have obscured it in the

usual position on the hull sides. This December production M4A1 can be seen to

be USA 3070459. The DD's headlamps (1) and guards were extended up in order for

the light beams to clear the screen when it was in the lowered position. A

section of the ventilator was removed (2) to accommodate part of the DD's

hydraulics. The differential housing of 3070459 does not show the telltale weld

scars of the "prow" of the DD conversion. We suspect that the

original differential was damaged, and that this tank was turned in for high

echelon repair by one of the three US Tank Battalions that employed Duplex

Drive Shermans on D-Day. It seems likely that the 3rd Armored Division drew it

from the 1st Army replacement pool.

This screen capture from a

Signal Corps movie shows another large hatch former DD of the 3rd Armored

Division in Cologne, Germany in March, 1945. The fitting (circled) for the

reinforcing strut on the high bustle turret provides the DD clue. The

Registration Number can be seen as USA 3070398. The corresponding Serial Number

of this tank would have been 37801. At present this is the first large hatch

M4A1(75) we can document. We would note that SN 37798, USA 3070395 and SN

37799, USA 3070396 were small hatch models, designated "M4A1E3," and

used in automatic torque converter tests at Aberdeen Proving Ground.

The British received 80 of the

US converted M4A1 DDs, all of which were allocated to the 8th Armoured Brigade

for the Invasion. Photos indicate that some of them were the large hatch

models. Above shows an example in action with the Sherwood Rangers, the junior

Regiment of the 8th AB. The unit was photographed on August 4, 1944 advancing

towards Ondefontaine, France on a farm lane in the hedgerow country typical of

Normandy. The "SCR 528" stenciled on the turret stands for

"Signal Corps Radio Model 528," the standard tank radio used by the

US at the time. For some reason, the British did not overpaint this along with

the USA Registration Number when they applied the circle tactical marking

indicative of C Squadron. Perhaps they used the SCR 528 in lieu of the British

#19 on the DDs received from the US? Because the M4A1 DDs transferred to the

British in the UK were not originally intended for Lend Lease, they did not

have British WD Numbers assigned beforehand. A May 24, 1944 Roster of the

Nottinghamshire Sherwood Rangers Yeomanry lists the USA Numbers of some of

their DDs, and several are in the large hatch range, such as USA 3070473,

3070488 and 3070492. Photo courtesy of the Imperial War Museum, IWM B8588.

It was the policy of the Army

to employ used tanks for conversion projects. In the Summer of 1943, Pressed

Steel Car was contracted to convert 936 M4s, M4A1s and M4A3s to M32 series tank

retrievers. Production commenced in December, 1943, but there had been some

difficulty in rounding up used Shermans. In order to get the program underway,

an exception was made, and it was agreed that 91 new M4A1s would be pulled from

the line at PSC. The new Shermans required only conversion, not remanufacture,

which was a much more extensive process involving the replacement of engines

and other internal systems with new or rebuilt components. The 91 new

conversions were done from December, 1943 through March, 1944, and were

assigned Serial Numbers 6 through 96, and USA Numbers 40149307 through

40149397. As some of the earliest M32 series conversions, a number of these

were shipped to Europe in time to take part in the D-Day Invasion and

subsequent build up in Normandy. Above shows front and rear views of Serial

Number 59, USA 40149360, completed in January, 1944, and photographed at APG in

February. The new M4A1s provided for conversion would have been from PSC's last

few months of production, more or less the same M4A1s available for the DD

program. One can see that Serial Number 59 has the thickened sides in the areas

of the sponson mounted ammunition bins. This unit features the early E8543

differential housing with the cast in steps. As mention previously, the

Barber-Colman exhaust deflector was reported to have been introduced on PSC

M4A1s on December 1, 1943. If this unit was accepted before then, it is likely

that the new deflector would have been added during the M32B1 conversion.

It was the policy of the Army

to employ used tanks for conversion projects. In the Summer of 1943, Pressed